Blog

Installing Heavy Duty Safety Nets From Cable Safe

October 4th, 2023

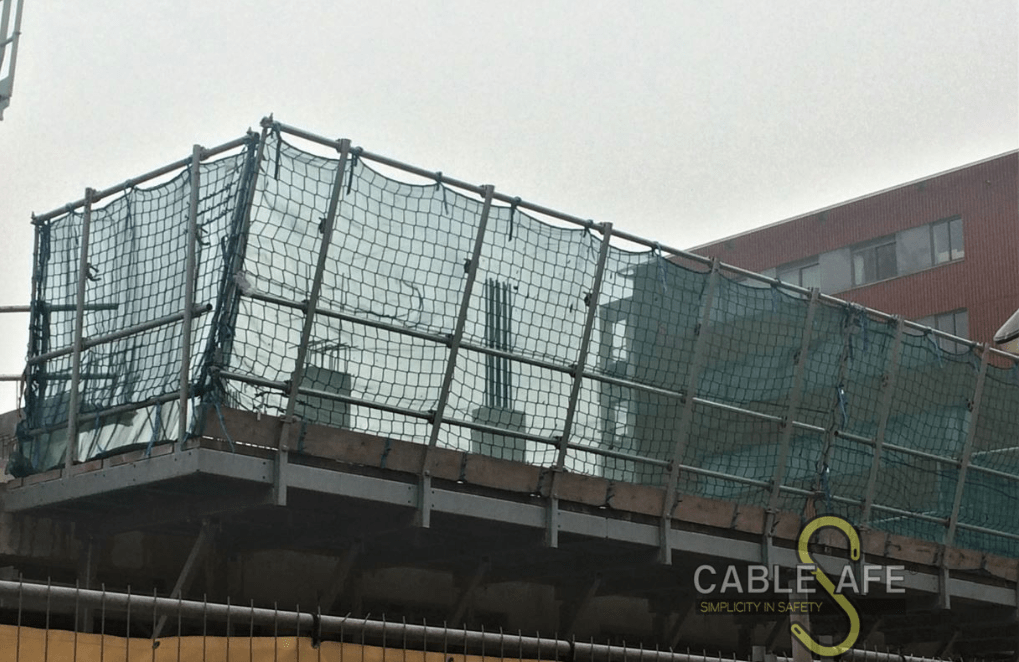

Heavy-Duty Safety Net From Cable Safe

Fall Protection Safety Net

Safety is paramount in the construction and industrial industry, and ensuring the well-being of workers and the protection of valuable equipment is a top priority.

Workplace safety refers to the measures put in place to prevent injuries, illnesses, accidents, and hazards in a work environment. These measures include equipment maintenance, employee training, safety protocols, emergency plans, and hazard identification and mitigation. Ensuring workplace safety is important for the well-being of employees, compliance with regulations and maintaining productivity. Employers have a legal and ethical obligation to provide a safe work environment for their employees and to take accountability for their well-being.

One essential component of workplace safety in these environments is the use of heavy-duty safety nets, particularly stainless steel secondary retention nets. In this blog we’ll explore types of safety nets, including rolls and fit-to-size solutions, and provide insights into their assembly along with industrial installation, safe use and the importance of a safety net for fall protection.

Stainless steel secondary retention safety nets are engineered to provide robust fall protection and containment, making them indispensable in industries where heavy machinery, tools, and materials are used. These nets are not only durable but also highly corrosion-resistant, making them ideal for long-term use in challenging environments.

➡ Thorne & Derrick supply the complete range of Safety Tools & Equipment from Cable Safe to enable safe working across all industries. This includes cable safety hooks, self-closing safety gates, confined space entry protection, guard nets and cable stands.

Assembly instructions

Correct assembly of fall protection nets is crucial for their effectiveness. Cable Safe provide detailed assembly instructions with all of their stainless steel safety nets to ensure that they are installed correctly. Following these instructions meticulously is essential to guarantee a secure fit and optimal protection.

Assembly involves precise measurements and installation techniques to create a reliable safety barrier. Stainless steel secondary retention safety nets can be custom-tailored to fit specific areas or come in standard roll formats. During assembly, it’s vital to account for factors like height, load-bearing capacity, and attachment points. Expertise in assembly ensures that the nets serve their intended purpose effectively.

Industrial Safety Net Installation

Personnel safety netting is designed to deflect and absorb the energy of a fall, to prevent injuries. As part of personnel safety and employee protection, safety net systems can be installed to high work areas to protect employees, nearby structures and pedestrians below

Installing industrial safety nets, especially in high-risk areas, demands skill and precision. To install the product correctly it involves inspecting anchor points, ensuring adequate tension, and verifying that the netting is securely fastened. When dealing with stainless steel secondary retention netting, which are known for their strength, the installation process requires high attention to detail. A construction safety net has to be as close under the surface on which employees are working, but never more than 30 feet below the surface.

Fall Protection Net Roll From Cable Safe

Ensuring the safe use of nets once installed is also vital. Workers should be trained in safety net protocols, including how to inspect the nets for damage, avoid overloading, and use proper personal protective equipment. Safety systems should be regularly inspected and maintained to identify and rectify any issues promptly.

Examples of Heavy Duty Safety Nets

- Safety Net Rolls: These versatile nets come in rolls, making them easy to transport and install. They are ideal for covering large areas quickly and effectively, offering reliable fall protection and containment.

- Safety Net Fit-to-size: custom-fit stainless steel nets are available in situations where precision is paramount. These nets are tailored to specific measurements, ensuring a perfect fit for any industrial setting. They provide maximum safety without compromising on aesthetics or functionality.

Stainless steel secondary retention nets play a crucial role in safeguarding workers and equipment in heavy-duty industries. Proper assembly, installation, and safe use are all important for full effectiveness. The addition of a safety catch net further enhances workplace safety.

CABLE SAFETY EQUIPMENT

CableSafe® Safety solutions are critical cable essentials and are well proven construction safety products. The CableSafe® range of cable hooks can be used during maintenance, turnaround, outages, shutdowns, construction work to suspend cables and hoses and other work gear and equipment from the working space.

Cable Safety Equipment | Cable Stand | Cable Bridge | Cable Rail | Cable Guard | Dropped Object Prevention Mats

PUSH PULL TOOLING

Thorne & Derrick stock and distribute a range of Safety Tools including Push Pull Tools from Hand Safety Tool Company designed to minimise hand injuries by keeping hands out of the line of fire.

Maximising Solar Assets in the UK: Repowering for Efficiency, Safety & Sustainability

October 2nd, 2023

Maximising Solar Assets in the UK

by Dathan Eldridge, CEO, Dynamic Energy Solutions

Solar power has emerged as a shining star in the global energy landscape, and the United Kingdom is no exception. Over the years, the UK has made significant strides in harnessing the power of the sun to meet its renewable energy goals.

As we continue our journey toward a sustainable future, it’s essential to explore every avenue to maximize the potential of our existing solar assets. One such avenue is repowering and revamping commercial and utility-scale solar assets.

In this Article, we will delve into the numerous benefits of this strategy and why it is crucial for the UK’s clean energy future.

Repowering and revamping commercial and utility-scale solar assets

- Boosting Efficiency: Repowering and revamping existing solar installations can significantly boost their efficiency. Innovations in solar panel technology, inverters, and tracking systems have made it possible to capture more energy from the sun. By upgrading older solar arrays with these advancements, we can extract more power from the same amount of sunlight, ultimately increasing energy production and reducing costs.

- Extending Lifespan: Solar panels are built to last, but over time, their performance may degrade due to factors like wear and tear, weather, and dirt accumulation. Repowering involves replacing or refurbishing components that have reached the end of their life cycle, effectively extending the overall lifespan of the solar asset. This not only preserves our initial investment but also reduces the need for additional resources and raw materials.

- Environmental Impact: The environmental benefits of repowering and revamping solar assets are substantial. By enhancing the efficiency of existing installations, we reduce the need to expand into new areas for solar development, helping preserve natural habitats and biodiversity. Moreover, the increased energy production from repowered assets means a decrease in greenhouse gas emissions, further contributing to the UK’s ambitious carbon reduction targets.

- Cost Savings: One of the most compelling reasons to consider repowering is the potential for significant cost savings. Upgrading solar assets can be more cost-effective than building new ones. The infrastructure and grid connections are already in place, reducing installation costs. Additionally, the improved efficiency leads to increased revenue generation, making the investment in repowering a financially sound decision.

- Grid Stability: As we transition to a more renewable energy-dependent grid, grid stability becomes a critical concern. Repowered solar assets can contribute to grid stability by providing a reliable and predictable source of energy. Advanced inverters and monitoring systems can help manage fluctuations in solar output, ensuring a steady supply of electricity.

- Job Creation: Repowering and revamping solar assets create opportunities for skilled jobs in the renewable energy sector. From installation and maintenance to research and development, the entire value chain benefits from these projects. This not only supports the growth of the clean energy industry but also contributes to local economies.

- Regulatory Support: The UK government has recognized the importance of repowering and has introduced supportive policies and incentives. These include streamlined planning processes and financial incentives for upgrading existing solar assets, making it easier and more financially attractive for stakeholders to embark on repowering projects.

Enhancing Electrical Safety and Mitigating Fire Hazards

- Rigorous Inspection and Assessment: Before commencing any repowering project, a comprehensive inspection and assessment of the existing electrical infrastructure must be carried out. This includes a thorough examination of wiring, connections, switchgear, and inverters. Any outdated or damaged components should be identified and replaced to prevent potential electrical faults.

- Compliance with Modern Standards: Electrical safety standards evolve over time to incorporate the latest safety measures and technologies. Repowering projects should aim to bring existing installations up to current industry standards. This includes complying with relevant codes and regulations, such as the IET Wiring Regulations (BS 7671) and electrical safety standards (e.g., IEC 62446 for PV systems). These standards provide guidance on safe design, installation, and maintenance.

- Upgraded Fire Detection and Suppression: Older solar installations may lack modern fire detection and suppression systems. Incorporating these technologies can be crucial in mitigating fire hazards. Install smoke detectors, heat sensors, and fire suppression systems as part of the repowering effort. Additionally, establish regular maintenance schedules to ensure these systems remain functional.

- Advanced Monitoring and Control Systems: Implement advanced monitoring and control systems that continuously assess the electrical health of the solar asset. These systems can detect anomalies, overheating, or electrical faults in real-time, allowing for immediate intervention before a hazard escalates.

- Employee Training and Safety Protocols: Invest in training programs for employees and contractors involved in repowering projects. Emphasize electrical safety procedures, hazard identification, and emergency response. Ensure that everyone on-site is well-equipped to handle electrical equipment safely.

- Proper Grounding and Bonding: A critical aspect of electrical safety is proper grounding and bonding. Ensure that all electrical equipment is adequately grounded to prevent electrical shocks and fires. This includes grounding the solar array, inverters, and any metallic components.

- Regular Maintenance and Testing: Implement a proactive maintenance schedule that includes routine inspections and electrical testing. This can help identify potential issues before they become safety hazards. Regular testing and maintenance also extend the lifespan of electrical components.

- Compliance Documentation: Maintain comprehensive documentation of electrical safety measures, inspections, and maintenance activities. Proper record-keeping is essential for accountability and regulatory compliance.

- Third-Party Audits: Consider conducting third-party safety audits to assess the electrical safety measures and fire hazard mitigation strategies in place. Independent audits can provide valuable insights and recommendations for improvement.

Conclusion

Repowering and revamping commercial and utility-scale solar assets in the UK is a strategic move that aligns with our clean energy goals, economic interests, and environmental responsibilities. By harnessing the latest technologies and innovations, we can maximise the potential of existing solar installations, increase efficiency, reduce costs, and contribute to a greener and more sustainable future.

Moreover, by prioritising rigorous electrical safety measures and robust fire hazard mitigation strategies, we ensure that these projects not only drive renewable energy but also safeguard lives, assets, and the environment. Together, we can make a significant difference in our energy landscape, paving the way for a cleaner, safer, and brighter future for the UK.

Who Are Dynamic Energy Solutions?

Dynamic Energy Solutions (DES) has been providing specialist, reliable renewable energy technologies to the commercial sector for many years. Our current and previous clients include councils, property developers, commercial landlords, multinational businesses, and plenty of independent local businesses.

Our services include (but are not limited to) rooftop solar, ground mounted solar, ac and dc electric vehicle charging, battery storage systems and specialist hv services. We have worked on projects all across the UK and have big plans for growth in the coming years as the renewables industry continues to develop.

DES are proud members of Solar Energy UK and are committed to providing high quality specialist services to all our clients and helping to shape the future of the renewables market in the UK. Our team regularly speak at industry events such as Solar and Storage and in the last few years have moderated several of the panels.

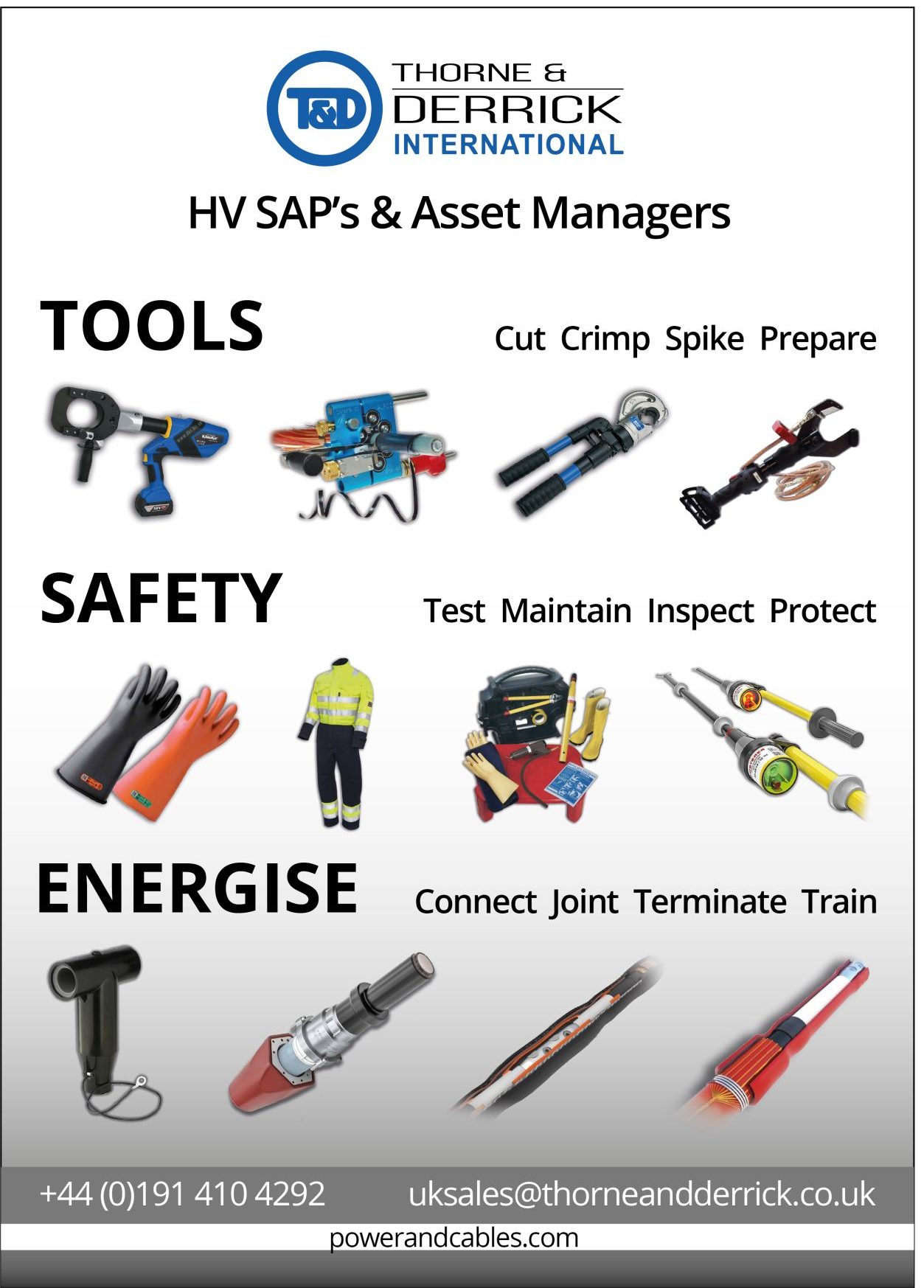

THORNE & DERRICK

SPECIALIST ELECTRICAL DISTRIBUTOR

Thorne & Derrick are Specialist Distributors to Solar EPC’s & High Voltage Jointing Contractors working on the design, construction and maintenance of UK, European and international projects supplying an extensive range of LV HV Solar Cables, Jointing, Substation & Electrical Eqpt. Based in the UK, we are highly customer responsive and absolutely committed to providing a world-class service.

We stock LV HV Solar Cables, Accessories & Electrical Equipment to enable the construction, maintenance and operation of utility-scale PV installations – our products connect 600V/1500V solar cables into combiner boxes, inverters, transformers and energise switchgear up to 33kV/132kV for high voltage grid connections.

Since 1985, we have provided expert technical support and express delivery from extensive UK stocks to world-wide destinations.

- Key Products: MV-HV Cable Joints & Terminations, Cable Cleats, Duct Seals, Cable Transits, Underground Cable Protection, Copper Earth Tapes, Cable Jointing Tools, Feeder Pillars, Cable Ducting, Earthing & Lightning Protection, Electrical Safety, Cable Glands, Arc Flash Protection & Fusegear.

- Distributors for: 3M Cold Shrink, ABB, Alroc, Band-It, Catu, Cembre, Centriforce, CMP, Elastimold, Ellis Patents, Emtelle, Furse, Lucy Zodion, Nexans Euromold, Pfisterer, Polypipe, Prysmian, Roxtec.

LV – Low Voltage Cable Joints, Glands, Cleats, Lugs & Accessories (1000 Volts)

MV HV – Medium & High Voltage Cable Joints, Terminations & Connectors (11kV 33kV EHV)

Further Reading

- Solar Farms | Insulate, Connect & Protect LV HV Electrical Cables & Equipment

- Electrical Safety Management | Solar Farms & Electrical Safety

- High Voltage Energisation of Solar Farms by HEIGHWAY Ltd

- Jointing, Grounding & Terminating DC Solar Cables

- PR: Solar Industry Relaxes Planning Laws For Large Scale Battery Storage

- UKPN 33kV Primary Substation Construction – Swanland Solar Farm

BAND-IT Ultra-Lok Free End Clamp System Supplied To Wessex Water

September 25th, 2023

Thorne & Derrick | Stockists & Key UK Distributor Since 1985

PR | Uploaded by Natalie Lundie | Supply Chain: Marketing Lead at Thorne & Derrick

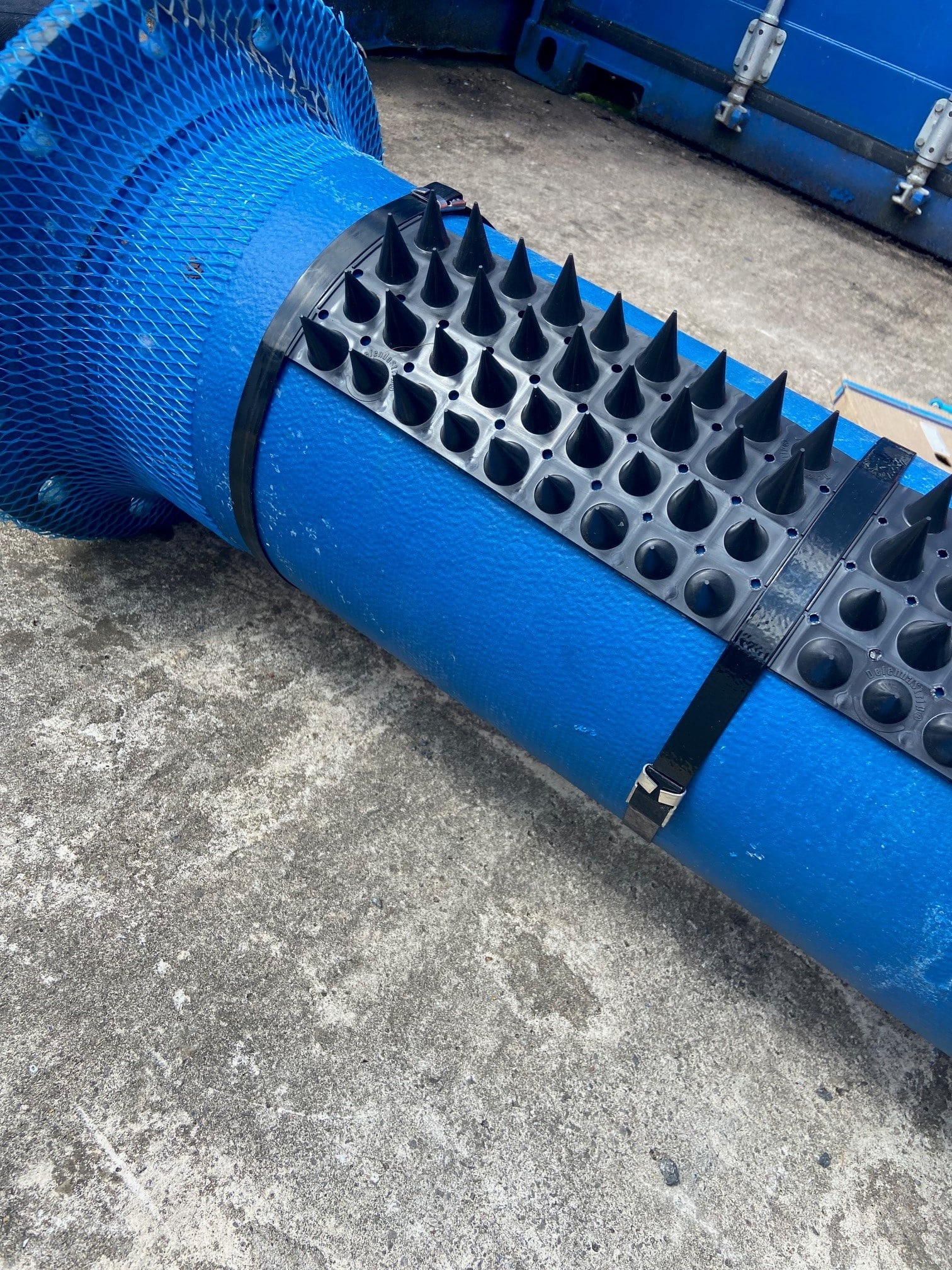

Thorne & Derrick, a UK Specialist Distributor for BAND-IT since 1985, have recently specified and supplied an engineered-solution to Wessex Water to improve workplace safety and site security across their pumping and sewerage treatment infrastructure in the UK – the Ultra-Lok Clamping System and PPA coated band system have been adopted by the water utility to protect both plant and people; reducing accidents and combating vandalism.

Application

The Water Industry Company contacted Thorne & Derrick requiring a solution to secure various products and signs to their pipe crossings to prevent people climbing on them – Wessex Water were looking for a fast, strong, and effective way to attach anti-climb spikes and signs to water pipes that cross rivers and roads.

Initially, Thorne & Derrick recommended using stainless steel banding and strapping systems, as this would guarantee a strong and secure solution resistant to corrosion and other environmental factors whilst deterring people from climbing on the pipes.

Thorne & Derrick contacted BAND-IT, The Clamping Experts to commence a consultation with the water utility to identify the optimum solution – an immediate customer site visit was organised with Steve Franklin (BAND-IT – Business Development Manager) and subsequent product demonstrations and testing was conducted for evaluation.

Stainless Steel Banding System | BAND-IT

Solution

At the very start it was agreed that a combination of different strappings would be required in various widths and lengths to suit the various products and signs.

It was determined that a PPA Coated Band Strapping System (installed with the C075 Bantam Tool) could be quickly and effectively used to attach the anti-climb spikes, whilst the “No Climbing” sign brackets required additional strengthened support to resist potential vandalism.

C075 Bantam Tool Compact & Lightweight

For this application the client selected the Ultra-Lok Free End Clamp System.

The Ultra-Lok rechargeable tool enables the high strength Free End Clamp to be installed quickly and at a consistent pre-set tension.

The result was a neat and secure solution that met the requirements of the utility Engineering Team and provided a reliable long-term solution.

Installation was quick and simple, with the banding easily folding around the products and signs and secured using the buckles by the site engineers.

Thorne & Derrick together with BAND-IT also provided guidance on the best practice for installation and maintenance of the banding and buckles to ensure maximum longevity and effectiveness of the solution.

Steve Franklin, Business Development Manager at BAND-IT commented, “this is another example of the great relationship between BAND-IT, our Distributor Thorne & Derrick, and the end-user enabling the customer to quickly specify and use an effective clamping solution that will withstand harsh and safety critical environments.”

PPA Coated Banding System

Ultra-lok Clamps & Tools

Ultra-Lok clamps and tools are effective in attaching safety critical equipment on to pipes to prevent people from climbing on them. These clamps can be installed quickly and easily, without the need for welding or drilling. They provide a secure grip on the pipe, reducing the risk of accidents or damage caused by people climbing on them. They are durable, easy to install, and require minimal maintenance, making them a cost-effective solution for keeping people safe.

The Ultra-Lok clamps are made from high-quality materials and are designed to withstand harsh conditions. They are a flexible option for a wide range of pipe shapes and sizes. In addition to the clamps, Ultra-Lok System is installed using a rechargeable electric tool that makes installation fast and consistent with predetermined tension and repeatability.

Anti climb spikes and signs attached to water pipes that cross river and roads

About Wessex Water

Wessex Water is a water supply and wastewater treatment company based in the south west of England. It operates in an area of about 10,000 square kilometres, providing water to over 2.8 million customers and treating sewage from over 1.6 million households.

The company is responsible for maintaining the quality of drinking water, supplying clean water to homes and businesses, treating wastewater, recycling water, and protecting the environment. In addition, Wessex Water has a strong commitment to reducing its carbon footprint and promoting sustainable practices, such as generating renewable energy from sewage sludge. The company was founded in 1973 and is headquartered in Bath, England.

Thorne & Derrick & BAND-IT

Together, Thorne & Derrick and BAND-IT offer a comprehensive range of Banding & Strapping products, including:

- Stainless Steel Banding: Used for bundling, clamping and securing a wide range of objects including cables, pipes and hoses

- Banding Tools: A range of tools for tensioning, cutting, and crimping stainless steel bands, making installation quick and easy

- Brackets & Mounts: A range of brackets and mounts for securing objects such as signposts, cables, and pipes to walls and floors

- Cable Ties: A range of cable ties for bundling and securing cables, wires, and hoses, in a variety of materials and sizes

- Identification Solutions: A range of markers, labels, and tags for identifying objects and cables easily

Other Past Project Wins & Applications

- 2023 | Secured project specification and purchase order for the supply off 285,000 stainless steel cable ties to provide permanent management of LV power cables at a major new battery plant currently in construction in the UK

- 2023 | Following successful site demonstrations of the BAND-IT Stainless Steel Ball-Lok Cable Tie system to project managers, T&D supplied nearly 100,000 cable ties to the Drax Power, Ecostore Project. The scheme was one of the largest biomass co-firing projects in the world, capable of producing 12.5% of Drax power generation from co-firing and represents a key element of their goal to reduce CO² emissions

- Ongoing | BAND-IT Easy Read is used to identify cables and pipes being used throughout the London Underground. T&D are Approved Vendors to Network Rail & TfL London Underground (LUL) and have supplied many of the easy read cable and pipe marking system to the rail industry as they are ideal for ID tagging in inaccessible areas, harsh environments and wherever visibility is low.

BAND-IT | Cable Ties, Band & Buckle Clamping Systems – Stainless Steel

Further Reading

- BAND-IT Stainless Steel Cable Ties Supplied to New Battery Plant Project

- Stainless Steel Cable Ties Replace Plastic Ties In Harsh Environments

- BAND-IT Cable Clamping Products – Training Day at Thorne & Derrick

Tie Lok | Ultra-Lok | Ball-Lok | Multi-Lok | Reusable | Band & Buckles | Stainless Steel

Staff & Support Training Day | Steve Franklin (Business Development Manager – Cable Management from BAND-IT) has supported and managed Thorne & Derrick for over 25 years – here Steve is pictured providing product refresher training to focus our Sales Team on the new business opportunities that the market-leading BAND-IT IDEX provides.

LV HV | Jointing, Earthing, Substation & Electrical Eqpt up to 66kV | Specialist Distributors

Safeguarding Multi-Core Cables: Ensuring Short Circuit Protection

September 18th, 2023

Short-circuit Test Showing Conductors Piercing Through Multicore Cable

Safeguarding Multi-Core Cables

Ensuring Short Circuit Protection

A question Ellis Patents and Thorne & Derrick still get asked on a regular basis is ‘Is it really necessary to use cable cleats for multi-core cables?’ The assumption is that the cable’s inherent strength, with fully encapsulated cores, is sufficient to withstand short circuit forces. The short answer is ‘YES’.

Essentially, the same guidance widely accepted for protecting single-core cables, both in trefoil and single formation, also applies to multi-core cables. Unrestrained or inadequately restrained cables can undergo violent movements, potentially causing damage to nearby circuits, and infrastructure, or even endangering people.

Cable cleats are vital – cable ties alone cannot contain certain short circuit faults.

If you’re still in doubt as to whether this applies to multi-core cables, then this short-circuit test should convince you of the importance of cable cleats on multi-core cables.

As with single-core cables, evaluating multi-core cables for short circuit force withstand requires a comprehensive assessment of three essential considerations:

1. Short-Circuit Current

2. Conductor Spacing, and

3. Cable Type

Short Circuit Cable Video Fault

The below video produced by Ellis Patents shows the catastrophic outcome when multi-core cables attached to cable ladder using cable ties only are subjected to short circuit cable fault. Depending on fault levels cable cleats should be used to secure LV MV HV cables and to provide short circuit protection against disastrous cable faults, this includes the cable cleating of multi-core power cables.

Read More Here – IEC 61914 – Cable Cleats & Short Circuit Protection Calculations

Together Ellis Patents & T&D, prioritise safety and strive to ensure the utmost protection for your electrical infrastructure. If you have any questions about protecting your cable installations from short-circuit faults, we’d love to hear from you.

Ellis Patents Vulcan | Alpha | Phoenix | Flexi-Strap | Triplex Cable Cleats | LV MV HV 11kV

Ellis Patents

Ellis Patents based in the UK are world leading manufacturers of cable cleats, hangers, hooks and cable clamps used to clamp and support LV-MV-HV cables – this includes cable support and management products to provide short circuit protection for 600V, 11kV-33kV-66kV and medium/high voltage power cables in single, trefoil or bundled formation up to 400kV.

Cable Safety Hooks from Cablesafe vs. Traditional Cable Management

September 8th, 2023Cable Safety Hooks

Safety Advantage on Construction Sites

Prioritise Safety Hook Placement for a Secure Workspace and Accident Prevention

Safety should be prioritised above all else in the high-paced construction industry, where productivity and efficiency are critical. With numerous workers, heavy equipment, and machinery on-site, creating a secure workspace is essential. This ensures the safety of employees while minimising the risk of accidents. One often overlooked yet critical aspect of construction site safety is cable management.

Loose cables lying around can pose significant risks, leading to tripping accidents and even potential injuries. However, with the innovative CableSafe Safety Hooks, a proactive approach can be taken to create a safer environment on construction sites.

The CableSafe Extreme hooks provide orderly support and suspension for temporary cables; creating a cable management system to ensure the safe and reliable delivery of electricity during construction, maintenance or Shutdown/TAR.

➡ Thorne & Derrick supply the complete range of Safety Tools & Equipment to enable safe working in sectors such as the construction, renewables, data centres, rail, manufacturing and oil, gas, petrochemical industries. We also offer a range of Push Pull Tools for the reduction in Hand Injuries in the workplace designed to improve safety at work.

Understanding the Importance of Cable Management

Proper cable management is crucial on construction sites to ensure safety, prevent accidents, and maintain efficient workflow. Construction sites are filled with various types of cables from power cords to communication lines, which are essential for the functioning of equipment and communication systems. However, when not properly managed, they can become a safety hazard. Efficient cable management reduces the time and costs associated with untangling cables or searching for misplaced wiring, ultimately saving time and money on construction projects.

Traditional cable management methods, such as laying cables on the ground or using adhesive tapes, may seem convenient, but they can lead to a host of issues. This is where cable safety hooks come into play, which are designed specifically to hoist cables. Organising CableSafe Safety Hooks on construction sites is a proactive step towards creating a secure workspace and preventing accidents caused by tripping on loose cables.

Safety Hook Extreme

The Safety Hook Extreme is an advanced specification and high performance version of the standard industrial cable hook manufactured with glass reinforced PBT and is UV stabilized, Flame Retardant (Class: 94V-0, Flame Class Rating 3) and Cold Weather rated.

The Safety Advantage of

CableSafe Safety Hooks

CableSafe Safety Hooks are designed to provide a secure and efficient cable management system. These hooks are made of high-quality materials, making them strong and durable enough to hold heavy cables and wires. They are easy to install and can be attached to walls, beams, and other structures around the construction site. This ensures that cables are elevated and out of harm’s way, reducing the risk of tripping accidents and promoting a cleaner and more organized workspace.

Another benefit of the CableSafe Safety Hooks is that they help to extend the life of cables and wires. When cables are left lying on the ground, they are more susceptible to damage from heavy machinery, equipment, and foot traffic. This can cause cable jackets to tear and expose wires, making them a potential fire hazard. Prioritising the placement of these safety hooks on construction sites offers several key safety advantages:

Preventing Tripping Accidents: The most immediate and apparent safety advantage of CableSafe Safety Hooks is the prevention of tripping accidents. By suspending cables overhead and away from foot traffic, the risk of workers or visitors tripping over loose cables is significantly reduced. This helps maintain a smooth and accident-free work environment.

Enhancing Construction Safety: Construction sites are prone to potential hazards, and every precaution must be taken to mitigate risks. CableSafe Safety Hooks contribute to enhancing overall construction safety by eliminating one of the common causes of accidents—tripping on cables.

Minimizing Downtime: Accidents on construction sites can lead to downtime, causing delays in project completion. By proactively organizing cables with safety hooks, the likelihood of accidents decreases, leading to increased productivity and efficiency.

Durability for Long-Term Use: CableSafe Safety Hooks are built to withstand the rugged conditions of construction sites. Their durable design ensures that they can be used repeatedly over time, providing lasting safety benefits.

Easy Installation and Flexibility: Installing CableSafe Safety Hooks is a straightforward process, saving valuable time during the setup. The hooks can be easily adjusted and moved as needed, offering flexibility for changing cable arrangements on-site.

Proactive Safety Measures

for Construction Sites

Construction site managers and workers can take proactive measures to enhance safety on-site. Prioritizing the use of CableSafe Safety Hooks for cable management is a simple yet highly effective step in this direction. By adopting safety hooks, construction sites can create a secure workspace that minimizes tripping hazards and ensures the well-being of everyone involved in the project.

CABLE SAFETY EQUIPMENT

CableSafe® Safety solutions are critical cable essentials and are well proven construction safety products. The CableSafe® range of cable hooks can be used during maintenance, turnaround, outages, shutdowns, construction work to suspend cables and hoses and other work gear and equipment from the working space.

Cable Safety Equipment | Cable Stand | Cable Bridge | Cable Rail | Cable Guard | Dropped Object Prevention Mats

PUSH PULL TOOLING

Thorne & Derrick stock and distribute a range of Safety Tools including Push Pull Tools from Hand Safety Tool Company designed to minimise hand injuries by keeping hands out of the line of fire.