Blog

Battery Crimping Tools – Cable Crimping Tools Battery Operated

June 5th, 2018

Battery Crimping Tools

➡ Thorne & Derrick International, based in the UK, are the largest stockist and distributor for the Cembre range of battery operated tools for crimping all types of LV MV HV power cables – battery operated type tooling is increasingly replacing conventional hydraulic type tooling for the maintenance and installation of underground power cables and overhead conductor lines.

Browse below to view the complete range of Battery Crimping Tools – should you require any technical advice, recommendations or product demonstrations please do not hesitate to contact us.

Battery Crimping Tools

Contact our Sales Team for competitive quotations and fast delivery from extensive stocks for the complete range of Cembre tools.

Battery Crimping Tools Manufactured by Cembre

Battery Crimping & Cutting Tools | Cable Cutters & Crimpers

June 5th, 2018

➡ Thorne & Derrick International, based in the UK, are the largest stockist and distributor for the Cembre range of battery operated tools for crimping and cutting all types of LV MV HV power cables – battery operated type tooling is increasingly replacing conventional hydraulic type tooling for the maintenance and installation of underground power cables and overhead conductor lines.

The battery crimping tools deliver a compression force of up to 132kN for installation of connectors up to 400sqmm (LV & HV) – the cordless hydraulic cutting tools utilising new 18V Li-Ion type battery power have the capability to cut 95mm diameter.

Browse below to view the complete range of Battery Crimping & Cutting Tools – should you require any technical advice, recommendations or product demonstrations please do not hesitate to contact us.

Crimping & Cutting Tools

Contact our Sales Team for competitive quotations and fast delivery from extensive stocks for the complete range of Cembre tools.

Battery Crimping & Cutting Tools Manufactured by Cembre

Earth Tape – The Manufacture of Copper Earthing Tapes

May 31st, 2018

-

uploaded by Chris Dodds - Thorne & Derrick Sales & Marketing Manager

Thorne & Derrick, are UK distributors, stockists and suppliers for AN Wallis Copper Earthing & Lightning Protection Systems – we were recently invited to visit their UK based location in Nottingham to understand and learn more about the manufacturing processes for copper earth tapes.

In this post we provide a selection of photographs taken during the AN Wallis factory tour – all copper earthing products are manufactured according to BSI ISO 9001:2008 and BSI OHSAS 18001:2007.

Since 1946 AN Wallis earthing products including earth tapes, earth rods, earth bars and earth mats manufactured from high conductivity copper have provided Earthing & Lightning Protection to LV MV HV Network Assets including primary/secondary substations, overhead line towers and power cable systems from 11kV/33kV up to 400kV.

Copper is a chemical element with symbol Cu (from Latin: cuprum) and atomic number 29 – a soft, malleable, and ductile metal with very high thermal and electrical conductivity. A freshly exposed surface of pure copper has a reddish-orange colour.

Earth Tape

A panoramic photograph of the AN Wallis production facility and factory where the earth tapes are manufactured from raw material into finished product – earthing tapes in bare copper form or with optional PVC covering and coloured are manufactured in a range of tape thicknesses and widths to achieve the required cross sectional area.

AN Wallis extensive copper feed stocks enable fast turnaround of major earthing project requirements for the global electrical power and utility industry – the 17,000 square feet manufacturing facility and extensive raw material copper holding ensures short lead times with “off the shelf” deliveries or quick turnaround manufacturing of all earth tapes.

1 Earth Tape Manufacturing

2 Raw Material Copper Feed Stocks

The raw material is supplied in solid copper conductor form – note the circular form of the feed stock which must be processed via the manufacturing machinery into the flat tape copper configuration. The Conform machine processes the copper into flat tape form and can be pre-set to optional dimensions. Weekly maintenance checks of the Conform machine include a general clean down, gearbox oil level check, hub cooling oil check, hub cooling water check and ensuring no water or hydraulic pipes are leaking.

3 Copper Earth Tapes

The circular copper conductor is fed from coil into the Conform machine – the conductor is conformed from circular to flat configuration producing a range of flat copper earth tapes from 12.5mm to 50mm widths. Computer software, such as CDEGS, can be used to calculate the power system earthing and grounding. Asset managers must calculate the level of site protection required depending on the cross section area of conductor required to provide effective earthing and lightning protection.

Methods to improve high voltage substation earthing and grounding with supporting measurements of earth resistance and computational models to simulate the possible Ground Potential Rise (GPR) due to injected current surges are a key consideration in providing effective lightning and earthing protection.

4 Processing Circular Form Copper Into Flat Earth Tape

Here the circular copper conductor is shown entering the Conform machine – in the “On” mode the motors and pumps feed the copper conductor into the Conformer via the machine wheel. Adjustable settings enable the manufacture of an extensive range of widths and thicknesses of copper tape.

5 Copper Earth Tapes

From this angle the photograph shows the complete AN Wallis manufacturing process for copper earth tape. The finished copper earth tape has now been conformed by machine to a flat tape design from the circular copper feed stock – this production run is manufacturing 50mm wide x 6mm thick copper earth tape, a UK utility standard for medium/high voltage substation earthing. The copper earth tape is annealed and produced with radiused edges for safe site handling by installers.

Wallis copper tapes are marked “Wallis U.K.- BS EN 13601”.

BS EN 13601 2013 is the current British standard covering Copper, Copper Alloys, Copper Rod, Bar & Wire for electrical purposes. The copper tapes are available embossed or inscribed with the client owners name as a copper theft deterrence measure.

6 Aluminium Earth Tapes

AN Wallis manufacture aluminium earth tape also at their Nottingham factory – lower cost than copper but with reduced conductivity the range of aluminium earth tapes are also available from stock.

7 Large UK Stocks Of Copper Earth Tapes

AN Wallis manufacture and hold the largest UK stocks of copper earth tapes – T&D, the UK’s largest supplier of AN Wallis products provide internationally competitive prices, delivery and technical support. A complete supporting range of copper clamps are available to secure and install the earth tapes to building infrastructures.

Full range of Earth Tapes

About AN Wallis

AN Wallis & Co Ltd has over 70 years experience in the design and manufacture of Lightning Protection, Earthing & Low Voltage Electronic Surge Protection products – a broad range of technical and earthing design services are provided including full design of structural lightning protection systems, design of substation earthing systems, soil resistivity tests, commissioning and project consultation.

AN Wallis has grown steadily and is a recognised world leader in the manufacture of quality Earthing, Lightning Protection, LV Surge Protection and Exothermic Welding products.

The Earthing Product range includes copper tape conductors, earth bars, copper earth plates, DC fixings clips, earth rods produced from solid copper, copper bond and stainless steel. Air terminals, earth rod clamps, inspection pits concrete and heavy duty polymer, earth rod seals, low resistance soil conditioning agents and also CU-NNECT exothermic welding products.

Thorne & Derrick distribute the complete range of Copper Earthing Products manufactured by AN Wallis to UK and overseas projects and competitive prices from extensive stocks – this includes earthing products for MV HV EHV substation projects including:

- Neasdon Depot Substation London Underground / Enterprise Rail

- Sleaford 132kV Substation EON / Enterprise

- Iver 132kV Substation/Windfarm SSE Scottish & Southern / Enterprise

- Swansea 400kV Substation National Grid / Electricity Alliance West

- Cardiff East 400kV Substation National Grid / Electricity Alliance West

- Sundon 400kV Substation National Grid / Electricity Alliance West

The products also provide Earthing & Lightning Protection for railway traction substations, distribution substations, overhead line towers, solar farms, STOR sites, data centres, hospitals and hazardous area sites.

-

Further Reading

Underground Cable Photo Album 1890-1940 – Western Power Distribution (WPD)

Copper Earthing Tape & Rods Protecting 33kV Substation & Transformer Bund

Portable Earthing – Short Circuiting Kits For HV Substations & Overhead Lines

Thorne & Derrick

THORNE & DERRICK are national distributors of LV, MV & HV Cable Installation, Jointing, Duct Sealing, Earthing & Electrical Equipment – we service UK and global businesses involved in cable installations, cable jointing, substation, overhead line and electrical construction at LV, 11kV, 33kV and EHV.

Contact us for 3M Electrical, ABB, Alroc, AN Wallis, CATU Electrical, Cembre, Centriforce, CMP, CSD, Elastimold, Ellis Patents, Emtelle, Euromold, Filoform , Furse, Lucy Electric & Zodion, Nexans, Pfisterer, Polypipe, Prysmian, Roxtec, Sicame, WT Henley.

Some Thoughts On MV HV Heat Shrink Cable Joints & Cable Terminations

May 30th, 2018

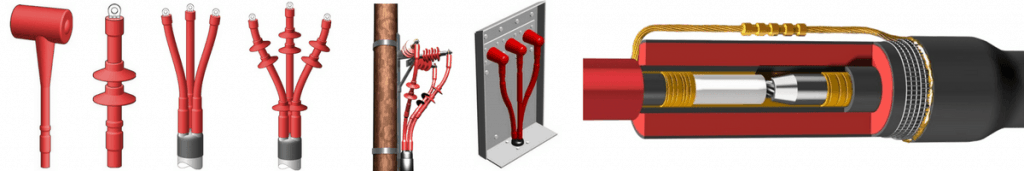

Heat Shrink Cable Joints & Cable Terminations | Manufacturers & Assemblers

uploaded by Chris Dodds - Thorne & Derrick Sales & Marketing Manager

Although modern cable manufacturing technologies evolve and develop the essential factors to consider when installing heat shrink type joints or terminations on medium/high voltage power cable systems remain essentially unchanged. Materials quality allied with installation by competent trained Jointers is the fundamental basis to ensure reliability, safety and operational service of MV HV cables, joints and terminations.

Here, from the archive we reproduce an important Technical Article by Norman Poulter – Norman was the Managing Director of Shrink Polymer Systems, the UK’s leading specialist manufacturer and assembler of MV HV cable joints and terminations for standard and non-standard cable applications up to 33kV.

Today, SPS’s Managing Director Richard Poulter continues to support the UK and overseas market with the competitive supply of MV HV heat shrink cable accessories for all cable voltages including 11kV/33kV and types such as XLPE, EPR, PILC and Triplex cables.

Medium & High Voltage Cable Accessories

author Norman Poulter

Power cable installation throughout Europe and the UK until the early 1960s exclusively used impregnated paper for the primary insulation of the conductors for both single- and three-core MV-HV cables.

The UK adopted both aluminium and lead-sheathed cables with and without steel wire armouring (SWA); these are still in use today. In the very early days of paper-insulated cable terminations, dry-type systems were employed along with compound-filled end box designs and cast-iron boxes with hot pour bitumen for cable joints.

PILC SWA Paper-insulated Lead Covered & Steel Wire Armoured Cable

- Circular stranded copper phase conductors

- Conductive paper screen

- MIND paper insulation

- Metallised paper insulation screen

- Circularising fillers

- Lead sheath

- Bitumenised hessian bedding

- Galvanised steel wire armour

- Bitumenised hessian serving with whitewash coating

11kV PILC Cable

Cold shrink products such as push-on, pre-stretched tube and grease applied slip-on types also became popular in the 1960s and are still specified by specific electric authorities and utilities for terminating and jointing MV-HV cables.

In the early 1970s polymeric (XLPE) cable types began to emerge in Europe and the UK, mainly on three-core cables, while the USA employed the single-core cable concept at 10kV, 20kV and 35kV medium voltages.

The heat shrink concept began to be employed at this period by the utility companies and has now spread internationally as the preferred method of cable terminating and jointing.

There are many advantages of using heat shrink cable accessories and techniques, such as:

- Wide shrink ratio – one joint/termination kit assembly to cover numerous cable ranges

- Heat concept dries out moisture from the MV HV cables

- Mastic seals are activated by heat so sealants are usually visible at sleeve ends

- They are not size sensitive and can be used on sector-shaped conductors

Figure 1 – Cable Box Air Insulated Termination

Cable Joint & Termination Kit Instructions

Shrink Polymer Systems also realised the importance of good cable jointing and terminating instructions. By using pictorial drawings with a minimum of text, non-English speaking countries can identify the important highlighted areas in an easily identified format.

Cable Terminations 11kV 33kV – Instruction Excerpt

Failures are nearly always attributed to poor cable preparation by the jointer and failure to observe the correct jointing procedures in the areas where the electric cable stresses are prudent, such as the semicon screen cut back.

Although the USA shares a language with the UK, there are many differences in the selection of words to describe various things. Below is a list of some UK terminology and the common equivalent used in the United States.

- Core – Conductor

- Screen – Shield

- Joints Jointing – Splice Splicing

- Cable Jointers – Cable Splicers

- Earth Earthing – Ground Grounding

- Armour Support – Reinforcing

- Metal Sheaths – Armour

- Self-Amalgamating – Self-Fusing

Heat Shrink Cable Joints

& Cable Terminations

Terminations

Terminations | Indoor or Outdoor

The major MV HV switchgear and transformer manufacturers have, for many years, designed dry-air filled cable boxes, resulting in a much greater demand for heat shrink-on terminations.

All heat shrink cable terminations and joints have to be tested to various international standards, and while cables prepared by experts in perfect laboratory conditions will undoubtedly meet these requirements under test, field experience shows that failures still occur at working voltage due to a variety of reasons.

Typical List Of Weakness Resulting In Failures

Of Heat Shrink Terminations

- Compression lugs, or crimp lugs, fitted to outdoor terminations of the compression tube type with inspection holes allowing moisture to penetrate the conductor cores.

- Failure to eliminate air pockets on paper-insulated, lead covered (PILC) three-core “belted” cables in the crotch area.

- Core crossing resulting in discharge if cores are too close to each other in an unscreened area at the core cross point. This results in the air “breaking down” electrically at approximately 4kV on an 11kV cable, 6kV on a 24kV cable and 9kV on 36kV cable. The anti-track heat shrink material then begins to erode due to the ionisation of the air, which over time will inevitably cause failure of the cable termination.

- Poor cable preparation, in particular on extruded dielectric types where insufficient care is taken on semiconductive screen removal at the crucial area of the screen cut-off. Cable jointers are generally reluctant to purchase engineered screen removal tools and rely on knives, blades and homemade tools for removal. This can result in cutting through the screen and into the primary insulation, leaving voids which result in the discharge phenomena described in the third item above. Even well-prepared screen removal at the cut-off point can result in a possible void, as the stress control tube may not follow the semi-conductive edge profile. (See figure 2.)

- Moisture penetration due to poor heat shrink and mastic sealing techniques.

- Inadequate phase-to-phase and phase-to-earth clearance.

- Tracking.

- Poor cable jointing instructions.

Figure 2

There are solutions and remedies to these weaknesses relating to MV HV cable accessories which will be described later in the article.

Joints

Many of the points discussed regarding cable terminations are also relevant to joints.

The object of the cable jointing exercise is to replace all the materials that were removed to joint the conductors and replace them in such a way as to replicate the cable as closely as possible to its original state.

There are many techniques used in conductor jointing from “sweating” the weak-back ferrule (normally associated with the original cast iron paper joints) to compression and the present popular “shear bolt” designs.

Connector jointing is a complex subject due to the variety of designs for copper and aluminium conductors in circular-solid, circular-stranded, and sector-shaped styles.

There is also the consideration of copper being jointed to aluminium, cables of unequal cross sectional area being jointed to themselves, and transition jointing where paper is being jointed to polymeric at medium or high voltages.

Figure 3 An 11kV 3 Core Heat Shrink Cable Joint

Let’s look at some of these designs.

Compression Connections – Crimps

There are a substantial number of manufacturers, such as Cembre, who specify suitability of their electrical connector design for voltages up to 33kV/36kV. Caution is needed if the body of the barrel is not smooth and does not have tapered ends.

Also, responsible MV HV connector manufacturers will be able to manufacture appropriate crimping tooling for their designs or confirm the compatibility of other cable tooling and die combination for their connectors. There are three types of crimping configurations currently in use: hexagonal, oval, and indent.

For instance, the Cembre HT131-C is the industry standard hydraulic crimping tool used by LV HV cable jointers to install copper type lugs and splices onto stranded cable conductors.

Oval and hexagonal crimping can leave sharp “ears” if incompatible tooling is used.

These “ears” must be filed smooth to avoid a highly stressed area which will be subjected to electrical discharge. Indent crimping will leave void holes which must be filled with high permittivity, stress relief tape.

Mechanical Connections – Shearbolts

Mechanical split type connectors are now very popular in the UK, as this design comes in two halves which are easy to apply to three-core cables at 11kV or 33kV where the cable conductors do not have to be bent. The heads shear-off at a given torque; therefore, no compression tooling or die combinations are necessary.

As this connector is “blocked,” it is also suitable for transition cable jointing for paper to plastic to stop the migration of the paper oils. There are several disadvantages of this type of connector, however. The ends of connector are non-tapered, resulting in high “step downs”, and the conductor insertion is non-centralised. (See figure 4.)

Figure 4 Mechanical Shearbolt Connector

These two conditions result in areas of high electrical stresses leading to probable discharge.

Shrink Polymer systems have now standardised on a shearbolt connector design where these critical areas of high stresses are removed by tapering the ends and centralising the conductor. (See figure 5.)

Figure 5 Mechanical Shearbolt Connector (Tapered)

Stress-Relieving Tapes

This type of stress relief tape generally has permittivity values between 7 and 13 (test method IEC 250). (See figure 6.) This does not necessarily mean that a value of 13 will perform better than a value of 7, as void filling characteristics are equally as important.

Figure 6 MV HV Connectors & Stree Relief Tape

Shrink Polymer Systems have a yellow stress control tape, reference number TS 31785Y, which possesses high tack, high stretch, and low viscosity void-filling qualities with a permittivity value of minimum 9. Whichever type of cable connector is selected, stress-relieving tape must be used in conjunction with heat shrinkable installations.

This is applied in a half width overlap with stretch by the cable jointer and must also be applied to any indents left by the tooling.

Gaps between end of primary insulation and connector must also be filled in.

Push-on molded components are also widely used, eliminating the need to fill voids and use stress tapes.

They rely on the Faraday Cage principle, in which conductive rubber-ribbed moldings are in contact with the connector. As the potential difference across the air is very low, discharge should not occur. Push- on molded components, joints and terminations have several disadvantages however.

On three-core cables the molded components prove to be very bulky and have no design features to eliminate moisture penetration unless used in conjunction with large diameter shells and resins. On large aluminium conductor sizes the ferrule could possibly be longer than the moulded component. The positioning over the ferrule is critical.

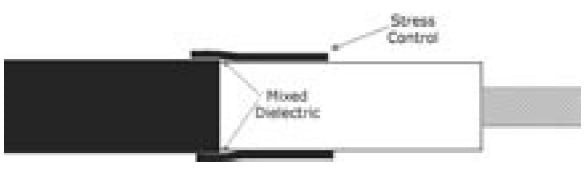

Stress Control Heat Shrink Tubing

Shrink Polymer Systems employ the heat shrinkable, high permittivity, and low resistivity stress control tubing which is shrunk onto the stress relief tape using heat applied by a jointers gas torch previously applied.

This has the effect of achieving a more uniform distribution of the field lines. This heat shrink tube extends over the ferrule or connector and onto the prepared screen cut-off points of the medium/high voltage power cable (See figure 2.)

Insulation Thickness

When designing cable jointing systems, the thickness of the insulation over the bare conductor (i.e. ferrule) should have a safety factor in excess of 15% of the original cable.

Shrink Polymer Systems employ a one-piece, combined dual wall (insulation / semiconductive) heat shrink tube of appropriate diameter to match this insulation at voltages to 11/12kV.

At 17.5kV, 24kV and 36kV additional heat shrink insulation tubes are added to meet these cable specifications.

The cable jointer must remember to shrink this material all around the heat shrink tube to avoid inconsistent wall thicknesses on full recovery.

Typical List of Weaknesses Resulting in Failures

- Incorrect crimping of connector.

- Air trapped in connector (if indent crimps not filled).

- Air trapped between end of insulation and end of connector.

- Discharge at screen ends caused by poor stress taping / cuts to primary insulation.

- Moisture ingress entering cable sheathing through poor sealing.

- Inadequate insulation levels over connector.

- Poor cable termination or cable joint kit instructions.

The solutions and remedies to these weaknesses are described below.

Earthing Cable Terminations

Earthing must be provided to carry any circulating currents to core screens, metal sheaths and armour wires. It must also have the ability to carry fault current. On indoor MV HV cable terminations the use of tin plated copper, solder-blocked braids, metal canisters, armour support, clamps and a complete corrosion protection system should be employed.

Figure 7 Low Voltage Heat Shrink Cable Joint For Multicore Cables

Earthing Cable Joints

Connecting the earthing components across a heat shrink cable joint requires correctly choosing and fitting the components to take care of both circulating currents and the short circuit requirements.

The outer semiconducting layer of the core/connector insulation should be wrapped in a tin copper mesh bandage and connected to the cable earth at each end.

There are a great many variations and earthing complexities and such a wide variety of cable types to consider.

Once a cable type, size, and voltage are specified it should be left to the manufacturer to supply the correct type of earthing system to meet both the national and local standards.

Remedies & Solutions To Overcome Cable Termination Failures

- Always use one-piece solid lugs for outdoor termination, not squashed tube type.

- Wrap butyl self-amalgamating tape around crotch and under lead cut on three-core belted cables to eliminate air. Check clearance dimensions on three-core cables.

- Care must be taken in semicon screen removal not to nick the primary insulation at the screen cut-off point.

- Ensure all mastic seals are in place on bushing boots, rain sheds and core tubes.

Remedies & Solutions To Overcome Cable Joint Failures

- Ensure cable connector is free from “burrs,” sharp points, not squashed tube type.

- Fill in all gaps with stress tapes before applying stress control tubing.

- Ensure correct application of stress tape at screen cut-off points. (See figure 2.)

- Fit all seals as supplied, in particular at crotch area, under armour beddings and end of connector insulations.

Cable Jointing & Terminating Instructions

It is the responsibility of cable accessory manufacturers to supply easy-to-read, simplified, pictorial jointing instructions and to avoid heavy reading of text manuals.

This point cannot be overstated, as, in the writer’s opinion, far too many jointing instructions are not read or understood, resulting in the installer compromising on the areas of importance previously mentioned. This all too often results in that first failure.

How Can We Help?

Since 1985 Thorne & Derrick have been servicing the UK and Export market with Joints, Terminations & Connectors for LV MV HV cables and power systems – call us to discuss your requirements including specialist LV cable joints for high performance applications including hazardous areas, marine and offshore cables, fire resistance cables and low smoke zero halogen cables.

Thorne & Derrick

Key Product Categories: Duct Seals | Cable Cleats | Cable Glands | Electrical Safety | Arc Flash Protection | Cable Jointing Tools | Cable Pulling | Earthing | Feeder Pillars | Cable Joints LV | Joints & Terminations MV HV

HV Cable Joints & Cable Terminations | Heat Shrink | 6.6kV 11kV 33kV Cables

3M Scotchcast Cable Joints – Your Cable Circuit Is Only As Strong As Its Weakest Link

May 25th, 2018

3M Scotchcast Resins – Powerful Cable Joints

uploaded by Chris Dodds - Thorne & Derrick Sales & Marketing Manager

Selection Factors, Specification Considerations & Application Notes

Why Gamble With Your Power Supply By Installing Underspecified Cable Joints?

A Failed Cable Joint

Since 1985, Thorne & Derrick International, have stocked and distributed 3M Scotchcast cable joints renowned for their field service record and dependability for the connection and repair of existing damaged cables or the extension or diversion of new cable installations.

Whether XLPE, EPR, PILC or other cable type, Scotchcast joints are the preferred option for LV power, instrumentation or control cables.

The primary purpose of any LV cable joint is to remove a damaged or faulted section of cable and re-instate the electrical performance of the jointed cable as closely as possible to the original manufactured condition.

The specification, selection and installation of Low Voltage Resin Cable Joints varies according to industry. So, without a universal methodology the selection factors are usually specific to the cable and industry. Several key factors include : cable function, cable reliability, installation application and consequential loss due to outage or downtime.

Standard resin cable joints are often inadvertently installed forming weak links in many industrial cable networks.

Scotchcast Joints

Whether by Land, Air or Sea

3M Scotchcast resin cable joints provide reliable and safe performance in the construction, rail, renewable, airfield lighting, port authority, offshore, marine, mining, utilities and hazardous area (oil, gas and petrochem) industries.

“Scotchcast” has now become a byword for cable joints.

Scotchcast resins are synonymous with reliability, quality and dependability when jointing cables, whether above or below ground – a comprehensive range of jointing resins have been developed by 3M with fire resistance, flame retardant, low smoke zero halogen and hydrocarbon resistant performance.

Deep Underground

3M Scotchcast 82-F cable joints are specified for the straight and branch jointing of flexible mining and trailing cables. Utilising flame retardant and flexible 3M Scotchcast 2131 resin with Mine Safety and Health Administration (MSHA) Acceptance 07-KA060002-MSHA.

3M 82-F flexible cable joints do not impair the bend radius of frequently coiled cables – the submersible cable joints are also seawater resistant for connecting cables by divers to ROV (Remotely Operated Underwater Vehicles).

♦ Further Reading : Top 10 Deepest Mines In The World

Seeing Beyond The Surface – Worker & Site Safety With 3M Cable Joints

The World’s Biggest Coalmine : Peabody Energy’s operations in the Powder River Basin of Wyoming USA. 40% of America’s coal comes out of the North Antelope Rochelle Mine. Photograph: Mae Ryan for the Guardian

Offshore Cable Joints

3M Scotchcast resin cable joints are specified by the global oil and gas exploration companies for the low voltage jointing of power, instrumentation and control cables.

3M LVI3 resin cable joints suit offshore and marine power, instrumentation and control cable (BS6883, IEEE, UL, UK00A, NEK606 BFOU RFOU types) and instrumentation cable (pair, triple, quad types) – typically used to joint and connect cables in Zone 1 and Zone 2 hazardous areas to provide low voltage electricity distribution to power and lighting in potentially explosive atmospheres.

3M LVI3 joints are hydro-carbon resistant based on the specification performance of 3M Scotchcast 1402FR and resist degradation by drilling fluids (mud) – the ability of offshore topside and shipboard cable joints to withstand degradation by hydro-carbons and drilling MUD is vital avoid potential cable faults.

3M : Specified By Global Oil & Gas Industry

Repairing Damaged Cables

Cable damage is common offshore due to the extreme mechanical conditions caused by vibration, shock and movement on oil and gas platforms.

Overtime, EPR type rubber cable sheaths are degraded and complete cable change-out can be cost prohibitive or actually impossible.

3M LVI cable joints provide an excellent cable repair or full cable joint to damaged offshore cables preventing possible downtime caused by cable failure due to salt sea atmospheres reacting with cable braiding and conductors and causing a short circuit.

The wrap-around or snap-on 2 part type cable joint moulds permit mid-span cable repairing or jointing without requiring cable disconnection from the remote end – refer to our recent post about repairing damaged cables for further information and solutions including use of cold shrink tubes.

3M Cable Joints are installed on offshore oil and gas platforms, FPSO’s, FPS’s, oil tankers and carriers

With You In The Cable Trenches

Image : Lovink.

Bent double in a muddy hole in the ground wrestling with a post-war imperial PILC cable.

And if you’re cable jointing in the UK then it’s probably raining.

We know the score. Hence, 3M cable joints are designed by jointers for jointers.

Large shell 3M cable joints enable crimping tool access or mechanical shearbolt connector compatibility for simplified cable jointing in tight access cable trenches and cable containment.

Cross core and transition cable jointing of multi-core XLPE to PILC is enabled.

Strong impact resistant cable joints shells withstand trench backfill. Often sand backfill can be mixed with sharp stones, clay and organic detritus.

3M can cope.

Size Matters

The internal working space permitted by the cable joint shell design impacts upon the ability of the LV cable jointer to work comfortably and safely often in tough site conditions.

Ample work-room enables efficient and reliable armour bonding, cross-core jointing, transition jointing and conductor connecting.

Large cable jointing shells enable the use of mechanical shearbolt connectors, such as Pfisterer Sicon, ideal for imperial-metric-AWG connections and hydraulic crimp tool heads where close quarter working is needed.

Is The Cable Joint Shell Large Enough For The Crossing Of Phased Cores?

Whatever the Weather

Cable damage is common offshore due to the extreme mechanical conditions caused by vibration, shock and movement on oil and gas platforms. Challenging offshore weather conditions vary from brutal hurricanes in the Gulf of Mexico to violent Atlantic nor’easters.

Closer to home, the North Sea UK continental shelf regularly experiences violent Force 10 storms inflicting extreme wind and wave effects on offshore assets.

3M Scotchcast Standing Out From The Crowd

3M Scotchcast low voltage cable joints are designed to ensure the installation process is simpler, quicker and safer.

Some selection and specification considerations :

- Safety – 3M’s unique Advanced Delivery system provides integrated resin pour for the cable jointer eliminating vapour inhalation or direct skin contact

- Simplicity – one part, wraparound cable joint shell enables rapid installation. Reduced man-hours cuts installed cost and drives labour productivity gains often during tight time schedule shutdowns

- Reliability – eliminate or minimise cable faults

Specify and buy 3M Scotchcast cable joints for first class safety and service record without any hidden dangers.

3M Scotchcast Resin Advanced Delivery

Just How Do 3M Do It?

- Single Piece Cable Joint Mould Shell – simpler installation process for the cable jointer. No cutting or sawing cable mould to size. Range taking foam seals at the ends of the cable joint shells provide an excellent tight and reliable seal – this adaptable 3M cable sealing system eliminates the need for the cable jointer to cut and tape the joint shell to size. Folding cable mould meets at the top of cable joint, not along both sides reducing potential resin leakage paths. 3M cable joint moulds resist cracks or breaks even at low temperatures. Suitable for direct burial.

Why Don’t I Need To Cut 3M Cable Joint Shell To Fit The Cable?

- Earthing – 3M’s robust armour continuity earthing system suits both wire armoured (AWA single core and SWA multi-core), wire braided (copper and phosphur bronze) and lead sheathed cables. To avoid awkward manipulation of armour wires while trying to fit worm drive clips over the cable support rings, 3M have chosen to use constant force springs for earthing. Constant force springs offer significant advantages over “single wire type” earth continuity systems, which can fail if poorly positioned within wire armour cores that have “spread”. The flat soft copper earth braid ensures good electrical contact.

Safe & Sound With Constant Force Springs : Cable joints move and expand due to earth shift and heat from electrical current. Constant force springs react to this movement and maintain a sound electrical connection between the steel wire armouring and the earth continuity braid

- Mechanical Connectors – fast, simple and range-taking conductor jointing of copper and aluminium conductors, whether stranded, sectoral or solid. Suits jointing of metric, imperial and AWG conductors.

- Resins – high quality cable jointing resin with good moisture resistance and always enough in the joint kit for the application. No need for “topping-up”.

- Scotchcast 1402FR Resin, Halogen Free – for public areas where fire, smoke and toxic fumes potentially threated lives and equipment

- Scotchcast 1402FR Resin, Hydrocarbon Resistant – suit air exposed and contaminated ground installations

- Scotchcast 2131 Resin, Seawater Resistant – salt water solution resistant to ISO 175

Did You Know?

3M Scotchcast resin cable joints, typically used for 600/100 volts cables, can be up-rated for 3.3kV cable jointing.

3M Scothcast Premium Low Voltage Inline Resin Cable Joint

THORNE & DERRICK SPECIALIST ELECTRICAL DISTRIBUTOR

LV ♦ MV ♦ HV

T&D distribute the most extensive range of LV, MV & HV Cable Jointing, Terminating, Pulling & Installation Equipment – we service UK and international clients working on underground cables, overhead lines, substations, switchgear and electrical construction at LV, 11kV, 33kV and EHV transmission and distribution voltages.

- Key Products: MV-HV Cable Joints & Terminations, Cable Cleats, Duct Seals, Cable Transits, Underground Cable Protection, Cable Jointing Tools, Feeder Pillars, Cable Ducting, Earthing & Lightning Protection, Electrical Safety, Cable Glands, Arc Flash Protection & Fusegear.

- Distributors for: 3M, ABB, Alroc, Band-It, Catu, Cembre, Centriforce, CMP, Elastimold, Ellis Patents, Emtelle, Furse, Lucy Zodion, Nexans Euromold, Pfisterer, Polypipe, Prysmian, Roxtec.

LV – Low Voltage Cable Joints, Glands, Cleats, Lugs & Accessories (1000 Volts)

MV HV – Medium & High Voltage Cable Joints, Terminations & Connectors (11kV 33kV EHV)

Cable Laying – Underground Cable Covers, Ducting, Seals & Cable Pulling Equipment

T&D, CATU Electrical Safety & Arc Flash Protection Specialists for SAP’s, Linesmen, Jointers & Electrical Engineers – Largest UK Stockist

INVITATION

Thorne & Derrick invite you to join LinkedIn’s largest LV-HV Electrical Discussion Group : Low & High Voltage Power, Cabling, Jointing & Electricals. Discussion subjects include cable installations, cable jointing, substation, overhead line and electrical construction at LV, 11kV, 33kV and EHV. Network, engage and promote your profile, company or products with over 10,000 influencers.