Blog

BAND-IT Cable Clamping Products – Training Day at Thorne & Derrick

March 2nd, 2023Band-It Products

Steve Franklin (Business Development Manager – Cable Management from BAND-IT) has supported and managed the Thorne & Derrick | LV HV Cable Jointing & Electrical Equipment Account for 25+ years. Today, Steve called into refresh and re-focus our Sales Team on the new business opportunities that the market-leading BAND-IT IDEX electrical range of Cable Support & Management Systems provide to both traditional (Oil & Gas), transitional (Renewable Energy) and emerging (Fuel Cell) markets.

Thanks for the project support, the cable tie and banding product demo’s and the frankly unrivalled service record you have provided to our business in our supply-chain history.

We’ve gained some wrinkles, lost some hair but together we have always kept faith and I am pleased we remain a key account to BAND-IT, as BAND-IT does to Thorne & Derrick.

BAND-IT Cable Ties, Band & Buckle Clamping Systems – Stainless Steel

66kV Jointing Tools | Alroc CAMF Tools Now in Stock

March 2nd, 202366kV Jointing Tools

WE LISTENED, SO INTO STOCK….. SHAVE, REMOVE, CHAMFER, & GROOVE

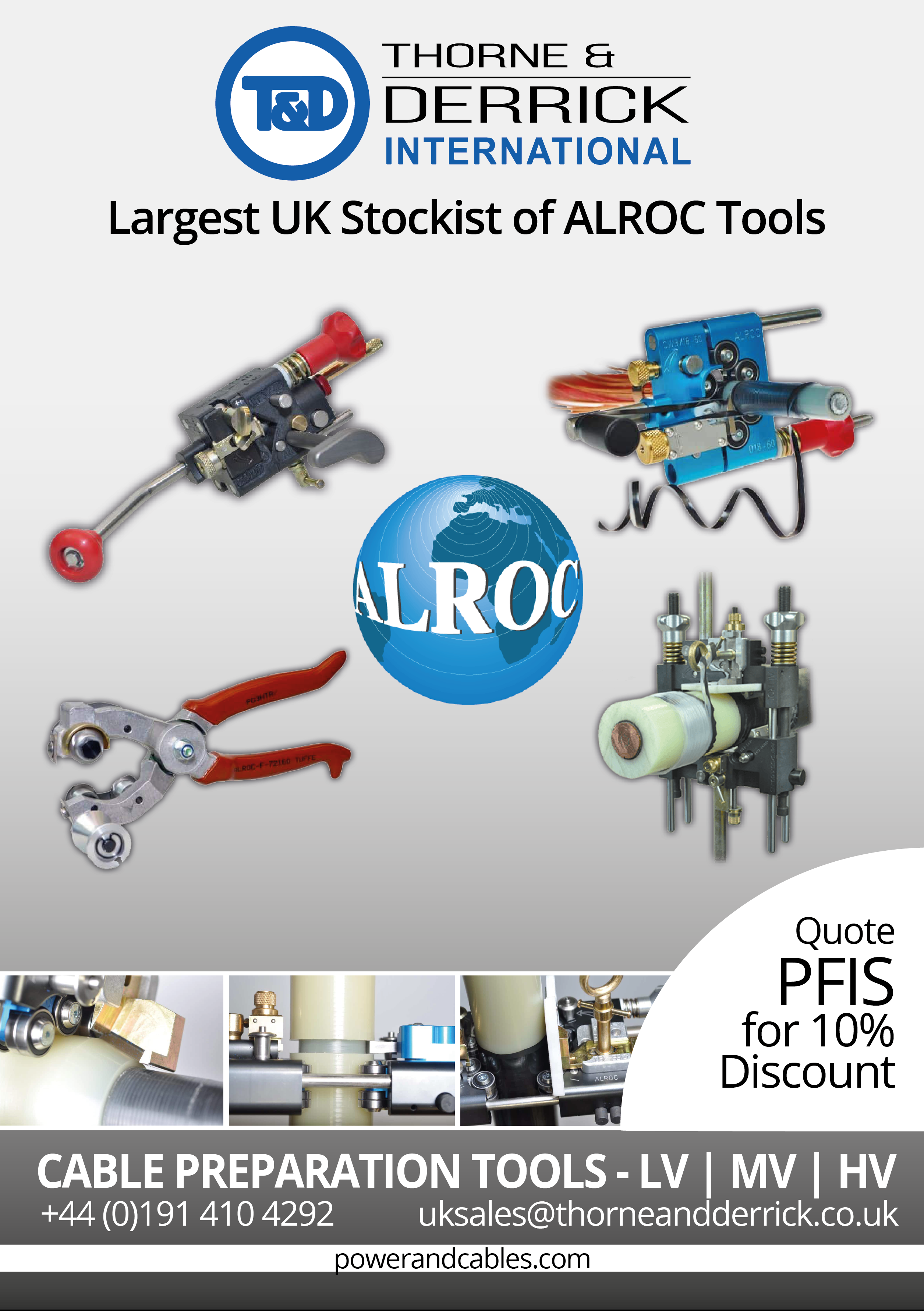

Thorne & Derrick have introduced the Alroc CAMF tools into stock to support customers in the UK & European offshore wind project marketplace. CAMFs are designed purposely for use with 66kV+ XLPE insulated IAC & power cables to provide balanced, consistent and precise cable preparation. CAMFs shave bonded semicon and remove insulation up to 90mm diameter without wobble, struggle or risk to HV cable integrity.

Manufactured by ALROC | NOW Stocked in UK by Thorne & Derrick | LV HV Cable Jointing & Electrical Equipment.

View the complete range of Cable Jointing Tools available from Thorne & Derrick International for stripping and preparing low, medium and high voltage power cables including 11kV, 33kV, 66kV and 132kV-400kV polymeric cables with XLPE or EPR insulation and bonded/peelable semi-conductive cable screens.

Suits MV HV EHV Cables 40-90mm Diameter | Stocked & Supplied by Thorne & Derrick

Thorne & Derrick | Distributed from Stock | Approved Supplier | UK & Export Sales

HV Cable Tools | Preparation & Termination & Testing & Jointing

Cable Lugs | How To Correctly Crimp & Connect Aluminium & Copper Conductors

March 1st, 2023

Cable Lugs

How To Correctly Combine Aluminium & Copper Cable Lugs

Are you installing, maintaining and connecting Aluminium power cables?

Here’s a useful article by Klauke to explain why you should use bi-metal cable lugs when transitioning to copper bus-bars or jointing Copper to Aluminium cables.

Thorne & Derrick can make recommendations to overcome the potential problems encountered when cable jointing aluminium to copper cables and provide guidance on best practice to avoid potential corrosion problems within resin cable joints up to 3.3kV/33kV.

Combining aluminium and copper can be problematic.

High-quality Al/Cu compression cable lugs are perfect for coupling and connecting aluminium conductors with copper elements. A compound in the aluminium connecting material improves the contact properties. Aluminium-copper connectors are necessary for the skilled connection of aluminium and copper conductors.

We want to focus on the not-so-simple task of connecting aluminium and copper.

As previously mentioned, aluminium is used quite often, but not always on its own. As copper has been the material of choice for decades, and continues to be used, there are problems in safely connecting both materials. In practice, electrical engineers are faced with this challenge more and more often.

Connecting aluminium and copper is required more often than you might think.

For example, it is necessary if an aluminium ring conductor is located in an industrial area, but the adjacent plants are supplied via copper conductors. Even in transformer stations, aluminium conductors need to be connected to copper bars.

Electrical engineers are confronted with the problem that aluminium and copper are not easily connected. For a durable and secure connection, special Al/Cu cable lugs and connectors should be used.

Aluminium/copper: a special Cable connection

Aluminium has proven itself to be corrosion-resistant in practical situations.

However, aluminium is generally an extremely reactive material that oxidises quickly. The durability of the material is down to a resistant oxide layer that is formed on its surface when atmospheric oxygen is applied – a process also known as self passivation.

If an electrically conductive liquid, such as condensation, comes into contact with an aluminium and copper connection, this results in an electrochemical reaction and the subsequent formation of contact elements.

The difference in potential by means of the electrochemical series plays a key role in this process. The contact element is formed by the copper electrode (anode), the electrolyte (water) and the aluminium electrode (cathode).

The voltage generated as a result is shorted by the contact between copper and aluminium. The aluminium is deposited and/or corroded in line with the current flow that is generated.

This process is visible as a vibrant oxidation mark and is applied to even the very smallest copper particles on the aluminium – with this being a permanent reaction as the copper does not therefore corrode. If there is an electrical connection, the consequence is an increase in the contact resistance, which can result in a temperature rise and, in the worst case scenario, a fire.

When combining copper and aluminium, it is therefore essential than you aim to prevent moisture from getting into the junction between both materials under any circumstances. In spaces where condensation builds up, you will therefore need to protect the contact point between copper and aluminium by way of special processing methods.

Use of aluminium/copper cable lugs and connectors is the most important step here. These items do not have any so-called creepage distances in which conductive liquid that is ultimately responsible for kicking off the oxidation process can accumulate.

As a result, aluminium/copper compression cable lugs and connectors are also particularly suitable for use in offshore wind turbines. There is also the option to use tin plated aluminium cable lugs. This solution should only be used in spaces that are kept constantly dry, as even small amounts of damage to the tin layer are enough to start the contact corrosion process.

Al/Cu compression cable lugs

Compression cable lugs which are developed for the special connection of aluminium conductors and copper bars are made of electrolytic aluminium (E-Al). They feature an attached copper mounting bracket according to EN 13600.

Aluminium conductors at a glance

Pursuant to DIN 60228, four different types of aluminium conductors are available – some of which require special processing methods. The following conductor types are available:

- single-stranded round conductors, class 1 (re)

- single-stranded sector shaped conductors, class 1 (se)

- multi-stranded round shaped conductors, class 2 (rm)

- multi-stranded sector shaped conductors, class 2 (sm)

The abbreviations and other information can be found among the markings on the Al/Cu compression cable lugs. This will help you to determine which cable lug is best for which aluminium connector.

The markings »8 KL16 50 rm 70 se« mean

- 8: Metric bolt dimensions of the connecting bolt bore (in this case M8 bolt)

- KL: Manufacturer code (Klauke in this particular instance)

- 16: Tool code

- 50 rm/sm: Nominal cross-section of the conductor in mm², when using a round or sector shaped multi-stranded conductor

- 70 re/se: Nominal cross-section of the conductor in mm², when using a round or sector shaped single-stranded conductor

For crimping Al/Cu compression cable lugs, we recommend using a hexagonal crimping die, according to DIN 48083 Part 4, or EKM60ID. Incidentally, Klauke aluminium inserts are silver, whereas copper inserts are gold/yellow. It is therefore very easy to tell them apart.

Al/Cu connectors: securely jointed Cables

Klauke offers reduction connectors to ensure that aluminium and copper are securely joined. Reduction connectors are often used in network repairs – more specifically in the production of non-tension connections for aluminium conductors in accordance with DIN EN 60228, and copper conductors in accordance with DIN EN 60228.

The connectors are made of two components: aluminium parts (E-Al) and copper parts (pursuant to EN 13600). The aluminium side generally has a larger diameter, because the lower conductivity is compensated by a correspondingly higher nominal cross-section.

As with compression cable lugs, the aluminium side of the connector also contains a compound, which is prevented from running out and drying out by a protective cap.

To ensure safe results when processing the Al/Cu compression joints, follow the relevant copper and aluminium processing specifications.

When using compression connectors underground, make sure that the joints are protected from moisture. It is best if you use a cast resin joint. The joint permanently protects the connections from moisture, dust and the penetration of foreign bodies.

Lastly, an important note on aluminium and copper cable lugs and compression joints. Do not expose these products to bending stress, otherwise there is a risk of breakage at the contact point between the two materials. Use in the overhead line sector is therefore not possible.

Crimping Cables, Lugs & Tools

Thorne & Derrick distribute Cable Lugs & Cable Connectors to terminate, splice and joint LV MV HV cables – this includes copper, aluminium and bi-metallic connectors and a range of crimping tools for specific use on all Low, Medium & High Voltage cable types.

Further Reading

- Solving 33kV Solar Cable Operational Issues Relating to Water Immersion

- Jointing, Grounding & Terminating DC Solar Cables

- Earthing Armoured Cables To Safely Protect LV AC Cables In The Solar Industry

Thorne & Derrick are Specialist Distributors to Solar EPC’s & High Voltage Jointing Contractors working on the design, construction and maintenance of UK, European and international projects supplying an extensive range of LV HV Solar Cables, Jointing, Substation & Electrical Eqpt. Based in the UK, we are highly customer responsive and absolutely committed to providing a world-class service.

We stock LV HV Solar Cables, Accessories & Electrical Equipment to enable the construction, maintenance and operation of utility-scale PV installations – our products connect 600V/1500V solar cables into combiner boxes, inverters, transformers and energise switchgear up to 33kV/132kV for high voltage grid connections.

Since 1985, we have provided expert technical support and express delivery from extensive UK stocks to world-wide destinations.

View our Solar Capability LV HV

Cable Lugs | How To Choose The Right One?

February 28th, 2023

Thorne & Derrick | Distributed from Stock | Approved Supplier | UK & Export Sales

Klauke Cable lugs

The choice of cable lugs available for all kinds of applications in the electrical sector is huge.

Making the right choice can be harder than you might think. However, choosing the right lug is essential to ensuring a clean and secure crimping result.

This overview provides a more detailed insight into the most common lugs for copper conductors, helping explain to you what you need to look out for when making your choice so that your connection will indeed be secure and long-lasting.

Cable lugs for copper conductors, connected to the conductor by way of so-called cold forming, are some of the most common connectors in electrical engineering.

They can be roughly divided into three groups:

- Compression cable lugs according to DIN 46235

- Tubular cable lugs as commercially available standard types

- Solderless terminals according to DIN 46234

Cable & cable lug: the perfect pair

Choosing the right cable lug also depends on the conductor class to be processed. As an example, the following cable lug types are available for cables according to DIN EN 60228:

- Class 1, 2, 5 and 6 conductors: compression cable lugs according to DIN 46235

- Class 2 conductors: standard type tubular cable lugs

- Class 2, 5 and 6 conductors: solderless terminals according to DIN 46234

To ensure safe crimping of conductors using DIN compression cable lugs, crimping tools with coded dies according to DIN 48083-4 are recommended in the standard. The requirements of the respective manufacturer must be observed for tubular cable lugs.

Solderless terminals according to DIN 46234 are processing using indent crimping.

Quality and resistance: on the test bench

Standards also apply to the electrical and mechanical properties of cable lugs. The international standard IEC 61238-1 part 1 applies in this particular instance. It specifies the tests that an electrical connection needs to fulfil in order to ensure long-term safe operation for its intended use.

The electrical connections must undergo different tests for this purpose. This involves an electrical durability test alongside a mechanical tension test. A test cycle simulates a practical application in this test.

Electricity is used to heat up the connection 1000 times to approx. 120 °C in order to bring about artificial ageing. The contact resistance is reviewed at regular intervals in between the tests.

Six high current tests are also carried out where the conductor is heated up to approx. 250°C in one second thanks to a short circuit. This high current test is required if the connector is due to be tested to check it is short-circuit protected.

The Klauke connecting material has also passed this test. The crimping connection passes the test if the contact resistance remained constant throughout.

Manufacturers are responsible for being able to guarantee the safety of their connections. With these additional tests that are carried out, you can rest assured that our connecting material satisfies the highest demands.

In addition, a significant amount of our materials are UL-tested and certified. This is particularly useful when control cabinets are to be supplied to North America, for example.

Electrical and mechanical properties of cable lugs

However, we also place additional requirements on the quality of our products that go beyond these standard requirements. Cable lugs made by Klauke are annealed as part of an additional manufacturing stage. This means we can reduce any hardening and tension in the material, as well as reduce the risk of breaking during crimping.

The quality of our cable lugs is already evident from their visual characteristics. Burr-free production and a consistently flat palm are signs of a high-quality product – likewise clean final machining of the tube section.

Contact our Sales Team for prices, technical support or to place an order for cable lugs or installation tooling for cutting and crimping cables manufactured by market-leader Klauke.

Klauke cable lugs and crimping tools are used by Jointers, Linemen, Panel Builders and Electrical Engineers to install underground cables and overhead line conductors on power, transmission and distribution networks including LV MV & HV systems, 11kV-33kV.

Crimping Cables, Lugs & Tools

Thorne & Derrick distribute Cable Lugs & Cable Connectors to terminate, splice and joint LV MV HV cables – this includes copper, aluminium and bi-metallic connectors and a range of crimping tools for specific use on all Low, Medium & High Voltage cable types.

➡ Associated Brands & Products | Klauke | Cembre | Pfisterer Sicon | Cable Crimping & Cable Cutting Tools

Should you require technical assistance to select the correct cable crimping or cable cutting tools please contact us.

Thorne & Derrick are Specialist Distributors of cable tools to enable the preparation of all LV MV HV cables prior to the installation of Joints, Terminations & Connectors – this includes Klauke, Cembre, Alroc and Boddingtons cable jointing tools for removal of cable sheath, screen and insulation on 11/33kV (MV) and 66kV/132kV (HV) power cables.

View the complete range of Cable Crimping & Cable Cutting Tools

Telecoms Cable Winch Supplied to Full Fibre, Gigabit-capable Network Infrastructure

February 28th, 2023

-

uploaded by Chris Dodds | Sales & Marketing Manager at Thorne & Derrick

Customised Cable Winch

Working with client NGE, Thorne & Derrick have supplied a custom engineered Telecoms Cable Winch for the pulling and installation of fibre optic cables to the Liverpool Backhaul project – the cable winch will support the high-speed fiber infrastructure project which will connect all 6 local authority areas in the Liverpool Region, by delivering Gigabit internet connectivity to a diversity of key economic activities.

Thorne & Derrick have supplied the AW1000 is an extremely robust piece of engineered plant, designed specifically to cope with Fibre Optic and light cable pulls, which are becoming a mainstay in today’s economic environment, especially as Fibre Optic is being laid to cope with the increasing demand for broadband internet. The Winch is designed and manufactured by SEB International in the UK, to be simplistic in operation, and consequently the client installation team will find the winch is also straightforward to maintain and service.

The result is a product, which is cost effective, and will provide many years of service. The AW1000 will be an excellent investment and addition to the plant fleet of construction companies responsible for the installation and maintenance of fibre optical cabling systems.

Custom Cable Winch for Offshore Cable Pulling Project

Pictured : More information Customised & Refurbished 5 Tonne Cable Pulling Winch

This refurbished and customised 5 tonne cable winch was customised to enable the pull and installation of medium/high voltage power cables – the winch was delivered within 2 weeks from receipt of client order. The cable winch enabled the installation of cable runs up to 120 metres from the variable frequency drive (VFD) to the compressor junction box which goes from underground cable trench to above ground and onto the cable containment ladder racking system.

The cable winch modification was based on the standard SEB TW5000 version with additional cable tension dynamometer – the dynamometer continuously checks the cable pulling tension to ensure the forces do not exceed the recommended guidelines.

Cable Pulling Equipment

Thorne & Derrick distribute an extensive range of Cable Pulling & Laying Equipment to enable the safe installation of fibre and copper cables within the telecommunications industry. Safely installed cables reduces operational and maintenance requirements to the network and reduced service interruption to telecom cables, wires, ducts, cabinets and exchanges – products include cable spiking tools, conduit rods, cable lubricant, cable socks and rollers.