Blog

How To Use 3M Cold Shrink Tubes – Silicone & Rubber Cold Shrink Tubings

December 11th, 2017

A series of How-To videos for repairing, jointing and terminating cables using 3M Cold Shrink & Scotchcast products.

-

uploaded by Chris Dodds - Thorne & Derrick Sales & Marketing Manager

Cold Shrink Tubes

Thorne & Derrick International, based in the UK, are the largest stockist and supplier of Cold Shrink Tubes manufactured by 3M Electrical – contact us for competitive prices, stock availability and delivery to UK and overseas destinations.

This video by 3M Electrical shows how to apply Cold Shrink Tubes safely and correctly.

3M Cold Shrink Tubes are a series of open-ended, tubular rubber sleeves, which are factory expanded and assembled onto a removable core. They are supplied for field installation in a pre-stretched condition and used by electrical engineers, installers and cable jointers to carry out electrical cable insulation, cable sheath repair and splice joints on cable containment or cable trench applications.

The 3M video shows how to install the cold shrink tubes by unwinding the removable core allowing the tube to shrink and form a tight waterproof seal to prevent water or humidity ingress into the cable. Quicker, easier and with enhanced installer safety benefits compared to heat shrink tube alternatives without a requirement for a heat source or tooling.

Cold Shrinking – the installer should use a gentle unwinding motion to release the expanded Cold Shrink tube from the core maintaining a consistent and even technique resisting temptation to snatch and pull as this will snag the plastic tail within the cold shrink tube. The outer core should remain relatively stationary while unwinding the inner core – the live memory action of the specially formulated 3M Cold Shrink material ensures a permanent, durable environmental seal and insulation. The tough, durable, EPDM rubber construction ensures 3M Cold Shrink tubes withstand operating temperatures of -40 to 194 degrees F (-40 to 90 degrees C).

- Black EPDM Cold Shrink Tubing Manufactured by 3M Electrical

Hazardous Areas

Consequently, cold shrink tubes have been adopted by the hazardous area industries (oil, gas and petrochem) for safe cable sealing and environmental protection in potentially explosive atmospheres and confined spaces where flammable gases or combustible vapours combined with “hot-working” could ignite the “Fire Triangle”.

Suitable for hazardous area cable repair, however where installation location is exposed hydro carbons a complete range of ATEX cable joints are available for jointing cables in hazardous areas, Zone 1 and Zone 2.

Safe Cable Protection & Jointing In Hazardous Areas & Potentially Explosive Atmospheres – cold shrink is safe to use where “hot-working” is precluded

The absence of a naked flame requirement eliminates fire risk and removes the danger of incurring heat, burn or scorch damage to cable sheath by over-heating with gas torches.

The core is removed manually by a simple clockwise unwinding of a tail piece of the inner former – after the cold applied tube has been positioned for installation over an inline connection, cable terminal lug or other similar application the cold shrink is collapsed to form an effective cable seal.

Faster to install for use on LV, MV or HV cables where working access is possible to an open cable end either by cable cutting or disconnecting from supply point.

Other possible applications include electrical installation, cable repair, mechanical protection and moisture sealing barrier – providing a constant radial seal and pressure even under thermal cyclical load.

No playing with fire when installing Cold Shrink by 3M

Selecting Cold Shrink Tubes

Cold shrink tubes are supplied in a range of sizes with specified minimum/maximum tolerances per tube – the selection of the correct 3M tube requires the outside diameter of the cable to ideally be midway between the recommended min/max range of the shrink tube. Once installed the tubes are immediately energisable and suitable for direct burial, overhead or submersed applications on 1000 volt cables located in indoor/outdoor locations in both safe (non-hazardous) and hazardous area cable locations.

Cold shrink tubes are available in EPDM and Silicone.

Cold Shrink – invented by 3M over 40 years ago and now the preferred technology for heat-free jointing, terminating, sealing and abandonment of LV HV cables

We hope you find this video informative and educational, contact T&D for technical support, quotations and stock availability for 3M Cold Shrink Tubes.

♦ More Cold Shrink | Cable Caps | Cable Abandonment | Cable Joints LV | Cable Joints Terminations HV 11kV 33kV

Silicone Cold Shrink – Fire resistant & Low Smoke Zero Halogen

Silicone cold shrink tubes are open ended, silicone rubber, tubular sleeves installed onto cables, pipes and umbilicals to provide a watertight seal with additional resistance for fire, acids, ultra violet light, moisture and flame – the cold shrink tube is inherently low smoke zero halogen (LSOH).

No heat source or naked flames are required to install cold shrink – specified for cable joint, repair or cable splice work in hazardous area locations or potentially explosive atmospheres.

The 3M 8440 series of silicone tubes are outlined in the below table to enable correct selection – call should you require any assistance.

The silicone cold shrink tubes manufactured by 3M Electrical provide primary electrical insulation on solid dielectric (rubber EPR and plastic XLPE) insulated low voltage LV cables up to 1000 volts.

| 3M Silicone Cold Shrink Tube | OD Min mm | OD Max mm | Length mm | Type |

| 3M 8443-2 | 6.86 | 14.0 | 44.0 | Silicone |

| 3M 8443-6.5 | 6.86 | 14.0 | 159.0 | Silicone |

| 3M 8445-2.5 | 8.89 | 18.0 | 57.0 | Silicone |

| 3M 8445-7.5 | 8.89 | 18.0 | 179.0 | Silicone |

| 3M 8447-3.2 | 12.19 | 24.0 | 76.0 | Silicone |

| 3M 8447-8 | 12.19 | 24.0 | 184.0 | Silicone |

Silicone Cold Shrink Manufactured By 3M

➡ Visit 3M Electrical for further information about 3M cable joints, terminations, tapes and insulation to seal, repair, splice and connect LV MV HV cables.

Cold Shrink | Joint | Terminate | Seal | Repair | Splice | LV MV HV Cables | 3M

- 3M Electrical Products Stocked By Thorne & Derrick International

132kV Cable Joint By Energi Cable Engineering Limited

December 11th, 2017

132kV Ericsson Transition Joint – 3 Core Cable Joint XLPE To Oil Filled Cable

Uploaded by Chris Dodds T&D

- Contractor: Energi Cable Services

- Contributed By: Dan Chessher

Energi Cable Engineering

Energi Cable Engineering have developed a strong and close relationship with two of the leading manufacturers of high voltage cable systems: NKT of Denmark and LS Cable & Systems of South Korea. Through these partnerships Energi Cable Engineering can design, specify, procure and deliver high voltage cable systems up to 500kV to provide solutions for XLPE, Oil Filled and Gas filled cable systems.

Energi Cable Engineering provides a complete range of cable accessories for XLPE, oil filled and gas filled cable systems. The highly experienced team of cable design engineers ensures that a fully engineered solution is provided to meet customer requirements, including all the ancillary equipment.

More from ECS

- 132kV Cable Sheath Testing With Pfisterer GIS Terminations

- 132kV HV Cable Testing Using Amprobe ISO 5000 Test Equipment

- Oil Cabinet Monitoring Oil Pressure On 132kV Circuit

- 132kV Outdoor Sealing Ends (ODSE) Manufactured By nkt Cables Installed By Energi Cable

- Degasifier Trailer – Oil Preparation For Extra High Voltage Cable Circuits

66kV Ericsson Transition Joint

See more: MV HV EHV Cable Jointing & Installation Photo Blogs.

Thorne & Derrick | Stockists & Distributors for 3M Electrical | Nexans Euromold | Pfisterer Connex | Joints Terminations Connectors up to 66kV from Stock

11kV Triplex Cables Terminated Onto Switchgear Bushings Using Heat Shrink Cable Terminations

December 8th, 2017

- Application: 11kV Triplex Cables Terminated Onto Switchgear Bushings

- Cable Type: 11kV Triplex Cables BS7870-4.10 – 3 Core Cable High Voltage (HV) Power

- Cable Jointer: Watkins and Jacomb Construction Power & Consultancy

- Featured Product: Heat Shrink Cable Terminations 11kV

Heat Shrink Terminations

In order to safely and professionally prepare medium/high voltage cables a complete set of cable jointing tools are required to enable the stripping and removal of the 11kV triplex cable sheath, insulation and screen – this includes Alroc tools used by jointers for MV/HV cable preparation and Cembre tools to cleanly cut and crimp cables.

The jointers have used cable cleaning wipes to carefully remove debris, dust or contaminants from the Triplex cables to ensure the overall reliability of the 11kV heat shrink cable terminations.

Lucy Switchgear

11kV cables are shown terminated using heat shrink terminations into Lucy VRN2a SF6 Ring Main Unit with a 200A Circuit Breaker to UKPN specification – the Sabre range of RMU’s manufactured by Lucy Switchgear are non extensible ring main units for outdoor high voltage substations. Along with low voltage distribution cabinets, these RMU’s can be easily coupled to the distribution transformer forming a compact outdoor package substation.

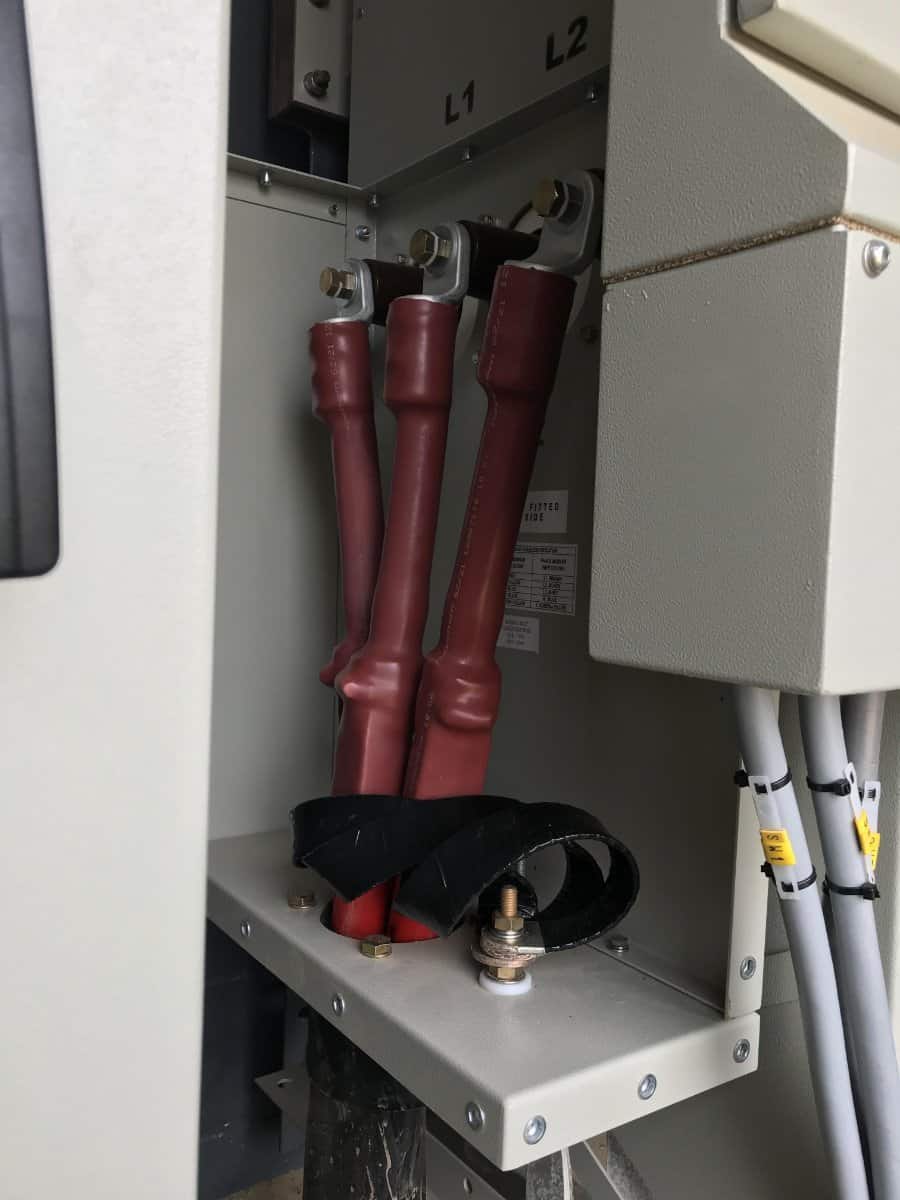

The 11kV heat shrink terminations are crimped using mechanical shearbolt cable lugs and bolted to the interface bushings of the air insulated cable box.

Terminating Triplex Using Cold Shrink

Here, the 11kV Triplex cables are shown terminated into a high voltage cable termination box using 3M Cold Shrink terminations – the concertina style bushing boot is cold-applied and suitable for both straight or right-angled 11kV switchgear connections, part code 3M 92EE717-1.

The bushing boots insulate the cable lug connection onto the bushing interface located on the electrical equipment. The Triplex copper wire screens are shown bonded to earth using brass mechanical shearbolt cable lugs.

The unarmoured Triplex cables are provided with mechanical cable retention and moisture ingress protection using heat shrink cable glands – the glands provide a watertight and fume-tight cable seal where the Triplex cables enter high voltage connection boxes, switchgear, bulkheads, or other enclosures.

The HV cables are cable ducted within the hot zone and a stand-off insulator is mounted in each HV cable box. The cable sheath is shown terminated to an earth bar mounted onto the stand-off insulator.

Image: NPG Northern Powergrid

Triplex Cable Sheath Earthing Arrangement 11kV

Should you require any assistance with the selection or specification of 11kV triplex cables or 11kV cable lugs please do not hesitate to contact us.

♦ Also 11kV : Nexans Connectors | Pfisterer Plugs | 3M Joints & Terminations | Ellis Cable Cleats | Duct Seals

Thorne & Derrick Specialist Electrical Distributor

LV ♦ MV ♦ HV

T&D distribute the most extensive range of LV, MV & HV Cable Jointing, Terminating, Installation & Cable Pulling Equipment – we service UK and international clients working on underground cables, overhead lines, substations and electrical construction at LV, 11kV, 33kV and EHV transmission and distribution voltages.

- Key Products: MV-HV Cable Joints & Terminations, Cable Cleats, Sealing Cable Ducts, Cable Transits, Underground Cable Protection, Cable Jointing Tools, Feeder Pillars, Cable Ducting, Earthing & Lightning Protection, Electrical Safety, Cable Glands, Arc Flash Protection & Fusegear.

- Distributors for: 3M, ABB, Alroc, Band-It, Catu, Cembre, Centriforce, CMP, Elastimold, Ellis Patents, Emtelle, Furse, Lucy Zodion, Nexans Euromold, Pfisterer, Polypipe, Prysmian, Roxtec.

LV – Low Voltage Cable Joints, Glands, Cleats, Lugs & Accessories (1000 Volts)

MV HV – Medium & High Voltage Cable Joints, Terminations & Connectors (11kV 33kV EHV)

Cable Laying – Underground Cable Covers, Ducting, Seals & Cable Pulling Equipment

More…

T&D’s Power Blog covers: LV MV HV & EHV Transmission & Distribution, Substations, Switchgear, Cable Jointing & Termination, Cable Fault & Repair, Underground Cables.

➡ Visit Power Blog.

11kV Cable Terminations – HV Switchgear Substation Installation & Commission

December 7th, 2017

- Project Scope: 11kV Cable Terminations, Switchgear, Transformers – LV HV Cables

- Featured Contractor: ISS Industrial Switchgear Services Ltd

- Cable Specification: 11kV 3 Core XLPE Cable BS6622 IEC60502-2

- Switchgear Type: Air Insulated 11kV High Voltage Switchgear Siemens NXAIR

- Credit: Peter McKenna (Operations Manager) & John Bower (Manager & 33kV SAP)

- All Images Courtesy: ISS Industrial Switchgear Services Ltd

11kV Terminations

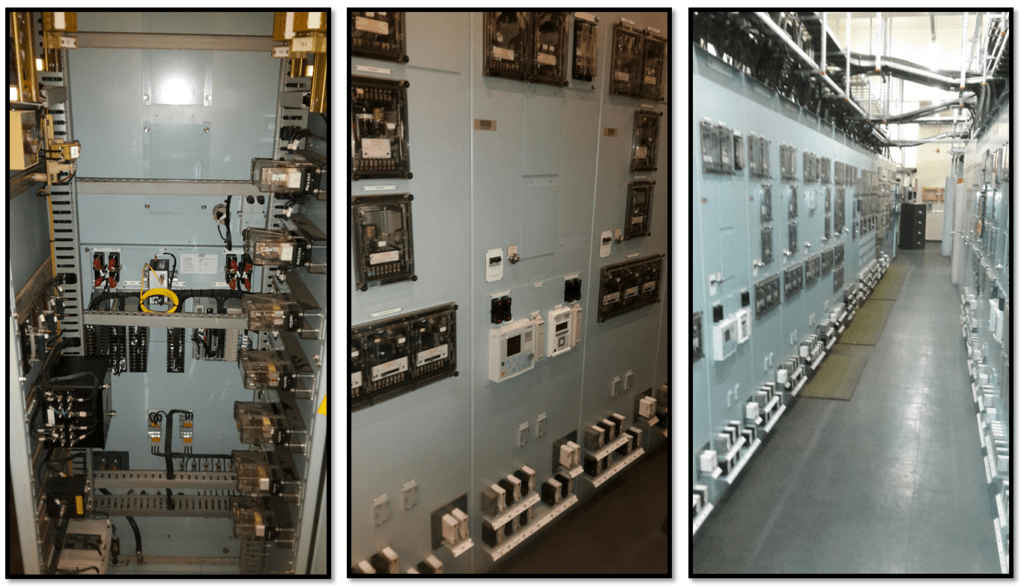

ISS were contracted to carry out the Design, Build & Installation of 10 new low voltage switchboards and a 24 panel 11kV high voltage switchboard, cabling and terminations installation.

The high voltage cables were connected using 11kV cable terminations into Siemens NX air insulated switchgear – the armoured 3 core 11kV cables with polymeric insulation (XLPE) were glanded using top-hat type cable glands and terminated into the switchgear using 11kV indoor heat shrink cable terminations.

Careful selection of the correct cable lugs are required – 11kV lugs tested to relevant international standards should be used with extended barrels for excellent connection and circuit conductivity.

The 11kV cable containment design and erection shown in the image below was carried out by ISS – 11kV cable spacings and cable cleat ratings were calculated and correctly specified by ISS to protect and restrain the high voltage cable circuits in the event of a short circuit.

ISS design engineers created and installed a bespoke A frame arrangement located on the ground floor to support the bottom cable entry of 11kV cables into the switchgear units located on the first floor.

A total of 22 new 11kV/415V high voltage transformers manufactured by Wilson Power Solutions were installed by ISS and all associated new low voltage (LV) power supply cables.

The LV cables were BS5467 type single core XLPE insulated power cables with aluminium wire armour and stranded copper conductors, 300-500sqmm.

High Voltage Cable Chamber – showing 11kV high voltage switchgear, terminations, cable cleats and containment

HV Switchgear – Siemens NXAIR Air Insulated Switchgear

Siemens NXAIR circuit-breaker switchgear is used in medium/high voltage transformer and switching substations up to 24kV for primary electricity distribution.

All HV switchgear from the Siemens NXAIR air-insulated range are approved with internal arc classification IAC A FLR, loss of service continuity category LSC 2B and partition class PM.

Some features of the high voltage switchgear include:

1 As an electrical insulating medium – air is always available

2 Type-tested HV switchgear according to IEC 62271-200 or VDE 0671-200

3 Use of standardised block-type current transformers

4 450,000+ air-insulated switchgear panels of Siemens in operation worldwide

5 Uses maintenance-free high voltage vacuum circuit-breakers or contactors

6 Testing of the vacuum circuit-breaker and make-proof earthing switch in switchgear panel

7 Pressure-resistant partitions

8 Flexibility regarding the low-voltage equipment (removable compartment, plug-in wires)

9 Quality assurance in accordance with DIN EN ISO 9001

11kV 24kV Air Insulated High Voltage Switchgear – Siemens NXAIR

Industrial Switchgear Services

ISS Ltd are a HV/LV Power Engineering company operating nationwide, undertaking Turnkey Electrical Distribution Projects and Site Service activities including installation, commissioning, pre-commissioning, final commissioning, HV/LV switching, maintenance, repairs, refurbishment of HV/LV AC & DC Switchgear, power transformers, SCADA systems, control panels, HV/LV cabling, cable terminations and associated ancillary equipment.

ISS Ltd manufacture low and high voltage switchgear, protection cubicles, LV generator changeover panels, marshalling cabinets and bespoke protection and control equipment.

- HV Switchgear & Cable Terminations 11kV 33kV

- LV Switchgear & Cable Gland Terminations

- Transformer & Rectifiers

- Substation Construction 11kV 33kV

- Protection & Control

22kV Rail Cable Installation

“ISS have completed further 22kV high voltage protection upgrades, upgrading 5 circuits at this particular site, all communicating back to a new 22kV switchboard installed a few miles away on the cable network. ISS removed the existing MBCI Translay, MCRI Overcurrent, MRTP Pilot Wire Supervision, KCEG Directional Overcurrent/Earth Fault MVTW Destabilising Relays. These have been replaced with a new Line Differential ABB RED615 Relay and Modem and Agile P14D Back Up Protection Relays.”

“New multicore cables have been installed from the switchboard back to the Marshalling cubicle, with ISS successfully proving the SCADA signals back to the RTU and control room. ISS commissioned the circuit into service, carrying out On Load Line Diff stability checks. A great team effort, from the design and manufacture of the protection fascia’s from our Manchester HQ, to the installation and commissioning of the circuits for a London based rail network. Great collaborative interfacing and planning between everyone involved to upgrade 22kV cable circuits on an operational railway” – Peter McKenna (ISS Operations Manager).

22kV Rail Cable Installation

More ISS project information:

Commissioning 25kV AIS Switchgear On Containerised Rail Traction HV High Voltage Substations

Flood Defence & Replacement Of Low & High Voltage

11kV Switchgear & Cables

The disaster recovery project involved the replacement of water damaged high voltage electrical equipment and cables – this included replacement of primary high voltage switchgear, cable terminations, associated power transformers and distribution cables.

Watch, listen and learn more about the project:

Should you require any further information about 11kV Cable Termination, Switchgear, Substation & High Voltage services provided by ISS please call 0161 344 1117.

Copper Earthing Tape & Rods Protecting 33kV Substation & Transformer Bund

December 6th, 2017- Application: Using Copper Earthing Tapes, Rods & CADWELD To Earth 33kV Substation, Switchgear & Transformer

- Contractor: Power Jointing Services Ltd (Hampshire UK)

- Image Courtesy: Robert Coleman LV HV Cable Jointer at Power Jointing Services Ltd

- Featured Product: Earthing & Lightning Protection MV HV

Copper Earthing Tapes & Earth Rods

33kV substation earthing is provided around the transformer bund and new building structure using copper earthing tapes, electrode rods and exothermic welding (CADWELDing) of the earth rods to tape – 50mm x 4mm earth tapes are installed as a ring and cross earthing design with 40mm x 4mm copper tape braised for additional stairs and walkway earthing.

The 33kV switchgear housing within the high voltage substation is earthed and bonded to a new transformer ring and Neutral Earth Resistors (NER). The copper tapes and earthing cables are shown connected to the 10 way earth bar. To achieve the required earth resistivity reading 3 x 1.2 metre length coupled copper earth rods were driven into the ground.

Driven earth rods are used to exploit lower resistivity ground conditions where present to reduce the earth potential rise (EPR) on substation earthing and lightning protection projects from 11kV/33kV up to 400kV.

Substation Earthing

Earthing of low, medium and high voltage electrical networks is critical to ensure safe and correct operation preventing and minimising against the consequences of a direct lightning strike to equipment and buswork within substations. UK DNO’s publish primary and secondary substation earthing designs for the application of earthing systems to HV and LV underground cables and overhead line networks, typically operating at 33kV, 20kV, 11kV, 6.6kV, 3kV and 2kV.

Similarly, the National Grid publish an Earthing Technical Specification for the lightning protection of transmission and distribution systems located in the busbar protection zone of the electricity grid operating at nominal voltages of 400kV, 275kV 132kV and 66kV. The general requirements of the substation earthing systems are compliance with technical standard EA TS 41-24 and British Standards BS EN 50522 and BS7430.

➡ Read our Blog about Substation Earthing

Earthing Standards

- Energy Network Association (ENA) Technical Standard (TS) 41-24 (Substation Earthing) – the standard provides guidelines for the design, installation, testing and maintenance of main earthing systems in substations

- BS EN 50522:2010 – the British Standard provides guidance for Earthing of Power Installations Exceeding 1kV a.c

- BS 7430:2011+A1:2015 – the British Standard is a code of practice for Protective Earthing of Electrical Installations

Copper Earth Tape – the earthing tape 40mm x 4mm shown bonding to the existing medium/high voltage substation earth bar

Copper Earth Tape Dropper – 50mm x 4mm earth tape is shown earthing switch 1 of 3 on the 33kV distribution board

Earth Tapes – the 50mm x 4mm copper tapes are routed back to the rebar earths on the earth bar

Transformer Earthing – using 40mm x 4mm copper earthing tape on the 33kV high voltage transformer

Power Jointing Services Ltd

Power Jointing Services Ltd established in 2007 specialising in 33kV-400V electrical network construction, establishing industrial and commercial supplies, installing residential service connections and street lighting connections. Also: High voltage service alterations, cable fault finding and replacement of assets including transformers, low voltage distribution boards and link boxes.

Copper Earthing Tapes & Products

T&D provide competitive prices and fast delivery from stock for Earthing & Lightning Protection products including copper tapes, rods, electrodes, earth bars and ancillary items for low, medium and high voltage substations.

♦ Visit Substation Earthing for further information.

Thorne & Derrick Specialist Electrical Distributor

LV ♦ MV ♦ HV

T&D distribute the most extensive range of LV, MV & HV Cable Jointing, Terminating, Installation & Cable Pulling Equipment – we service UK and international clients working on underground cables, overhead lines, substations and electrical construction at LV, 11kV, 33kV and EHV transmission and distribution voltages.

- Key Products: MV-HV Cable Joints & Terminations, Cable Cleats, Duct Seals, Cable Transits, Exothermic Welding, Underground Cable Protection, Cable Jointing Tools, Feeder Pillars, Cable Ducting, Earth Tapes, Electrical Safety, Cable Glands, Arc Flash Protection & Fusegear.

- Distributors for: 3M, ABB, Alroc, Band-It, Catu, Cembre, Centriforce, CMP, Elastimold, Ellis Patents, Emtelle, Furse, Lucy Zodion, Nexans Euromold, Pfisterer, Polypipe, Prysmian, Roxtec.

LV – Low Voltage Cable Joints, Glands, Cleats, Lugs & Accessories (1000 Volts)

MV HV – Medium & High Voltage Cable Joints, Terminations & Connectors (11kV 33kV EHV)

Cable Laying – Underground Cable Covers, Ducting, Seals & Cable Pulling Equipment

More…

T&D’s Power Blog covers: LV MV HV & EHV Transmission & Distribution, Substations, Switchgear, Cable Jointing & Termination, Cable Fault & Repair, Underground Cables.

➡ Visit Power Blog