Blog

Arc Flash Calculation – Selecting Clothing & PPE To Protect Lives Against Arc Hazard

September 20th, 2017-

by Chris Dodds T&D - estimated reading time 8 minutes

“30,000 Arc Flash Incidents per year” Source: ISHN

We recently asked Hugh Hoagland (Managing Partner at ArcWear & e-Hazard.com) to recommend the 3 most effective and reliable software packages for Calculating Arc Flash Risk & Hazard in accordance with NFPA 70E and IEEE 1584.ƒ1

e-Hazard USA are the industry leader in electrical safety training based on the latest NFPA 70E Standard providing arc flash testing, electrical safety and arc flash training for companies across the globe.

Hugh recommended the following Arc Flash Hazard, Risk Assessment, Clothing & PPE software packages: SKM, Easy Power and Kinetrics – we overview them and provide further information links to all 3 including free demonstration packages.

Arc flash clothing and PPE requirements are often panic rather than planned purchases – most often contractors are over-spending on arc flash protective clothing only to arrive on site to carry out work tasks requiring manual dexterity in cumbersome arc flash suits of armour. Hampered, overheating and under pressure to work safely in high voltage substations.

Electrical engineers must wear appropriate level of arc flash protection when working on low, medium or high voltage electrical switchgear, panels and equipment.

Consequently, it is rare for a specific site risk assessment or arc flash hazard calculation to have been carried out. Contractors therefore default to a “worst case” scenario with decision making clouded by the online plethora of inconsistent product recommendations often motivated more by commercial intent rather than the provision of worker safety.

We hope this information will enable better forward planning by contractors to minimise arc flash hazards by selecting the most appropriate level of protective clothing and utilising an arc flash sofware calculator.

As leading UK distributors of arc flash clothing, we are committed to supporting the observance and implementation of electrical safety and managing arc flash risk in hazardous and high voltage working environments.

Arc Flash | Jackets | Coveralls | Trousers | Sweatshirts | Helmets | Gloves ProGARM

Arc flash can occur during live cable jointing, phasing in operations, racking in and out of switchgear, reclosing of electrical switchgear onto a fault, switchgear failure, excavating near live cables or accidental contact with live conductors during maintenance.

1. SKM Systems Analysis

Arc Flash Hazard Calculator

ArcCalc calculates the incident energy and arc flash boundary for any point in a power system be it low, medium or high voltage.

Minimum and maximum arcing short circuit currents are calculated using broad tolerances to provide conservative results with estimated system data.

ArcCalc saves time by automatically determining trip times from the protective device settings. Incident energy, arc flash boundaries and Arc Flash PPE clothing are calculated following the NFPA 70E and IEEE 1584 standards. More information.

SKM Arc Flash Tutorial & Arc Flash Assessment

2. Easy Power

Arc Flash Analysis Software

Easy Power arc flash software provides the most comprehensive productivity configuration for conducting arc flash analysis and ensuring full compliance with OSHA and NFPA 70E requirements.

Whether you’re designing electrical power systems, analyzing arc flash hazards, selecting suitable arc flash clothing or implementing an electrical safety program, this is software configuration can assist. More information – Download Free Demo.

EasyPower Arc Flash Analysis Intro : Automated Power System Design and Analysis

3. Kinetrics

ARCPRO™ Arc Hazard Assessment, Clothing & PPE Selection

ARCPRO™ has become the industry’s most widely-used application for computing arc hazards and selecting protective clothing for single arc situations, particularly for High Voltage Transmission and Distribution applications not addressed by other methods.

Kinectrics ARCPRO™ calculates the thermal parameters of electrical arcs and is designed to provide users with data regarding heat exposure, total heat flux and heat energy on a surface at various distances from an electric arc.

The software is used to predict the potential arc hazard in a particular work environment and provide basis for specifying the appropriate level of PPE and clothing to protect against arc flash hazards. More information.

Arc Flash Incident (Property of CATU Electrical)

ƒ1 IEEE Std 1584-2002 (Guide for Performing Arc-Flash Hazard Calculations) is a standard of the Institute of Electrical and Electronics Engineers that provides a method of calculating the incident energy of arc flash event – purchase copy of IEEE 1584.

Arc Flash PPE – The Last Line Of Defence

“PPE is the last item on the list when putting in place arc incident control measures. Your arc flash risk assessment should measure the severity of the hazard (incident energy levels) and then look how that incident energy can be minimised. You should then consider what activities you carry out that could expose you to any residual arc flash risk that may be controlled with PPE”, Paul Hopton (Principal Electrical Consultant at Electrical Safety UK Limited).

◊ Can Arc Flash Clothing Save Cable Jointers Lives?

Arc Flash Learning & Resources

Thorne and Derrick are proud to be distributors of ProGARM arc flash coveralls and protection.

We can help – should you require arc flash calculators or advice on the type of clothing and protection available please do not hesitate to contact us.

Electrical Safety UK

ESUK is a specialist company concerned with the safe management of risk associated with all LV & HV electrical work activities. Having pioneered the European approach to Arc Flash Hazard assessment and management, ESUK have a proven track record in ensuring that clients comply with their local law in the most cost effective way.

THORNE & DERRICK are national distributors of LV, MV & HV Cable Installation, Duct Sealing, Jointing & Substation Electrical Safety Equipment – we service UK and global businesses involved in cable installations, cable jointing, substation, overhead line and electrical construction at LV, 11kV, 33kV and EHV.

Since 1985, T&D have established an international reputation based on SERVICE | INTEGRITY | TRUST.

Invitation

Thorne & Derrick invite you to join LinkedIn’s largest LV-HV Electrical Discussion Group : Low & High Voltage Power, Cabling, Jointing & Electricals. Discussion subjects include cable installations, cable jointing, earthing and lightning protection, substation, overhead line and electrical construction at LV, 11kV, 33kV and EHV. Network, engage and promote your profile, company or products with over 10,000 influencers.

Northern Powergrid NPG – LV Cable Joints & Terminations

August 17th, 2017

Northern Powergrid – Cable Joints Cable Terminations LV Low Voltage

- UK DNO: Northern Powergrid NPG

- Product Category: LV Cable Joints and Cable Terminations

- Document Type: NPS/002/014

- Document Date: March 2015

Joints & Terminations LV

- Mains & Service Straight Joints

- Mains & Service Branch Joints

- Mains & Service Stop End joints

- Pole Top Mounted & LV Board Cable Terminations

- Note: Documents are prone to change – always check with T&D to ensure current and correct Joints & Terminations are selected.

➡ View our Northern Powergrid (NPG) complete product range for LV, MV & HV Cable Installation, Termination, Jointing, Substation & Electrical Equipment.

Northern Powergrid NPG Cable Joints

| NPG Commodity Code | Description |

| Heatshrink Cable Joints – Service | |

| 174505 | Straight Joint: Heatshrink: Single Phase CNE-CNE / SNE up to 35sqmm |

| 174506 | Straight Joint: Heatshrink: Single Phase SNE – SNE up to 35sqmm |

| 174507 | Straight Joint: Heatshrink: Three Phase CNE – CNE up to 35sqmm |

| 174508 | Straight Joint: Heatshrink: Single Phase up to 35sqmm CNE – PILC (up to 0.04in) |

| 174510 | Straight Joint: Heatshrink: Single Phase SNE – PILC up to 35sqmm |

| 174509 | Straight Joint: Heatshrink: Three Phase CNE up to 35sqmm – 4 Core PILC up to 0.04in |

| Resin Filled Service Straight Joints | |

| 086561 | Straight Joint: Single Phase CNE PVC (4sqmm) – Single Phase CNE up to 35sqmm |

| 174488 | Straight Joint: Single Phase PILC – Single Phase PILC (.0225 – 0.06) |

| 174489 | Straight Joint: Three Phase PILC – Three Phase PILC (.0225 – 0.06) |

| 174471 | Straight Joint: Three Phase 4 Core PILC – Three Phase SNE up to 35sqmm |

| Stop Ends Joints – (Service and Mains) | |

| 174361 | Stop End: Service: Heatshrink: Single Phase CNE/SNE up to 35sqmm |

| 174365 | Stop End: Service: Heatshrink: 3 Phase CNE up to 35sqmm |

| 174384 | Stop End: Service: Heatshrink: Single Phase PILC up to 0.06in |

| 174385 | Stop End: Service: Heatshrink: 3 Phase PILC up to 0.06in |

| 174698 | Stop End: Resin Filled: 70sqmm – 185sqmm 3 and 4 core Waveform |

| 174700 | Stop End: Resin Filled: 185sqmm 300sqmm 3 and 4 core Waveform |

| 174664 | Stop End: Mains: Resin Filled: 50sqmm – 95sqmm (0.06 – 0.15in) PILC |

| 174679 | Stop End: Mains: Resin Filled: 120sqmm – 300sqmm (0.2in – 0.5in) PILC |

| 174645 | Stop End: Mains: Resin Filled: 70sqmm – 300sqmm CONSAC |

| Branch Joints – Service | |

| 174511 | Branch Joint: Single Phase CNE Main – CNE Branch up to 35sqmm |

| 174490 | Branch Joint: Single Phase SNE – SNE cables up to 35sqmm |

| 174512 | Branch Joint: Three Phase CNE Main – Three Phase CNE Branch: up to 35sqmm |

| 174513 | Branch Joint: Single Phase: PILC Main – CNE Branch: up to 35sqmm |

| 174514 | Branch Joint: Three Phase PILC Main – 3 Phase CNE Branch: up to 35sqmm |

| Mains Straight Joints – 3 Core Waveform | |

| 166329 | Straight Joint: up to 95sqmm 3-core Waveform – 95sqmm 3-core Waveform |

| 166386 | Straight Joint: 95, 185sqmm 3-core Waveform – 185sqmm 3-core Waveform |

| 166441 | Straight Joint: 95, 185, 300sqmm – 3-core Waveform – 300sqmm 3-core Waveform |

| 166719 | Straight Joint: up to 95sqmm 3-core Waveform – 95sqmm PILC |

| 166831 | Straight Joint: 95, 185sqmm 3-core Waveform – up to 185sqmm PILC |

| 166901 | Straight Joint: 95, 185, 300sqmm 3-core Waveform – 300sqmm PILC |

| 166511 | Straight Joint: up to 95sqmm 3-core Waveform – 95sqmm Consac |

| 166583 | Straight Joint: up to 185sqmm 3-core Waveform – 185sqmm Consac |

| 166653 | Straight Joint: 300sqmm 3-core Waveform – up-to 300sqmm Consac |

| Mains Straight Joints (4-core Waveform) | |

| 165012 | Mains Straight Joint: 95sqmm 4-Core Waveform – 95sqmm 4-Core Waveform |

| 165013 | Mains Straight Joint: 185sqmm 4-Core Waveform – 185sqmm 4-Core Waveform |

| 165014 | Mains Straight Joint: 300sqmm 4-Core Waveform – 300sqmm 4-Core Waveform |

| Mains Straight Joints (4 – 3-core Waveform) | |

| 165015 | Mains Straight Joint: 95sqmm 4-Core Waveform – 95sqmm 3-Core Waveform |

| 165016 | Mains Straight Joint: 185sqmm 4-Core Waveform – 185sqmm 3-Core Waveform |

| 165017 | Mains Straight Joint: 300sqmm 4-Core Waveform – 300sqmm 3-Core Waveform |

| Main Straight Joint (4-Core Waveform – PILC) | |

| 165027 | Mains Straight Joint: 95sqmm 4-Core Waveform – 95sqmm 4-Core PILC |

| 165028 | Mains Straight Joint: 95sqmm – 185sqmm 4-Core Waveform – 0.3 PILC |

| 165029 | Mains Straight Joint: 185sqmm – 300sqmm 4-Core Waveform – up to 0.5 PILC |

| Mains Branch Joints – 3 Core | |

| 166973 | Branch Joint: up to 95sqmm 3-core Waveform – 95sqmm 3-core Waveform Main |

| 167035 | Branch Joint: 95,185 3-core Waveform – 185sqmm 3-core Waveform Main |

| 167105 | Branch Joint: 95,185 3-core Waveform – 300sqmm 3-core Waveform Main |

| 167637 | Branch Joint: 300mm 3-core Waveform – 300sqmm 3-core Waveform Main |

| 167707 | Branch Joint: up to 95sqmm 3-core Waveform – 95sqmm PILC Main |

| 167779 | Branch Joint: 95,185sqmm 3-core Waveform – 185sqmm PILC Main |

| 167849 | Branch Joint: up to 300sqmm 3-core Waveform – 300sqmm PILC Main |

| 168023 | Branch Joint: 95, 185sqmm 3-core Waveform – up to 185sqmm Consac Main |

| 168080 | Branch Joint: 300sqmm 3-core Waveform – up to 300sqmm Consac Main |

| Main Branch Joints – 4 Core | |

| 165018 | Mains Branch Joint: 95sqmm 4-Core Waveform – 95sqmm 4-Core Waveform |

| 165019 | Mains Branch Joint: 95-185sqmm 4-Core Waveform – 185sqmm 4-Core Waveform |

| 165020 | Mains Branch Joint: 95-300sqmm 4-Core Waveform – 300sqmm 4-Core Waveform |

| 165021 | Mains Branch Joint: 95sqmm 3-Core Waveform (Branch) – 95sqmm 4-Core Waveform (Main) |

| 165022 | Mains Branch Joint: 95-185sqmm 3-Core Waveform (Branch) – 185sqmm 4-Core Waveform (Main) |

| 165023 | Mains Branch Joint: 185-300sqmm 3-Core Waveform (Branch) – 300sqmm 4-Core Waveform (Main) |

| 165030 | Mains Branch Joint: 95sqmm 4-Core Waveform (Branch) – 95sqmm 4-Core PILC (Main) |

| 165031 | Mains Branch Joint: 95-185sqmm 4-Core Waveform (Branch) – 185sqmm 4-Core PILC (Main) |

| 165032 | Mains Branch Joint: 95-300sqmm 4-Core Waveform (Branch) – 300sqmm 4-Core PILC (Main) |

| Pole Cable Terminations | |

| 086652 | Pole Termination 25sqmm PILC |

| 086678 | Pole Termination 95sqmm PILC |

| 086637 | Pole Termination 185sqmm PILC |

| 164682 | Pole Termination 35sqmm 3-core Concentric CNE |

| 086645 | Pole Termination 120-185sqmm 3-core Waveform |

| 086660 | Pole Termination 300sqmm 3-core Waveform |

| 165000 | Pole Termination: 185sqmm 4-Core Waveform |

| 165001 | Pole Termination: 95sqmm 4-Core Waveform |

| 165002 | Pole Termination: 300sqmm 4-Core Waveform |

| Service Branch Joint 3 & 4-core Waveform – PILC & Consac | |

| 164998 | Service Branch: up to 185sqmm Waveform 2 x Single Phase Services up to 35sqmm (The 2 services from same phase) |

| 164997 | Service Branch: up to 185sqmm Waveform with up to 4 x Single Phase CNE Services |

| 165646 | Service Branch: 300sqmm Waveform with up to 4 x Single Phase CNE/SNE or 1 x 3-Phase CNE/SNE Services |

| 165970 | Service Branch: up to 95sqmm PILC with up to 4 x Single Phase Services |

| 166189 | Service Branch: up to 185sqmm PILC with 1-2 Single Phase Services |

| 166259 | Service Branch: up to 300sqmm PILC with 1 or 2 Single Phase CNE or 1 x 3-Phase CNE Services |

| 165788 | Service Branch: 70/120sqmm Consac with up to 4 x Single Phase Services |

| 165858 | Service Branch: 185/240sqmm Consac with up to 4 Services |

| Triple Concentric Cable Joints | |

| 168289 | Stop End: Paper Lead Triple Concentric up to 0.12Sq in |

| 168291 | Service Breeches Joint: Triple Concentric Paper Lead up to 0.12in with 3-Core CNE Branch up to 35sqmm |

| 168291 | Service Breeches Joint: Single Phase Concentric Paper Lead up to 0.15in with Single Phase CNE Branch up to 35sqmm |

| 168290 | Straight Joint: Transition; Triple Concentric up to 0.12Sqin to Waveform Cable up to 95sqmm ( with single phase service if required) |

Cable Pulling & Laying Equipment LV HV

T&D supply Utilities & Approved Contractors with cable pulling products including cable rollers, cable socks and drum lifting jacks to enable the installation of low voltage and high voltage cables intro trench or duct: this includes single core, 3 core and Triplex 11kV/33kV power cables and LV waveform, mains and service cables.

See our online UK DNO Register of Approved Joints, Terminations & Electrical Equipment

How To Abandon Cables Using 3M Cold Shrink Cable Abandonment Kits CSCAK

August 1st, 2017

A series of How-To videos for repairing, jointing and terminating cables using 3M Cold Shrink & Scotchcast products.

-

uploaded by Chris Dodds - Thorne & Derrick Sales & Marketing Manager

How To Abandon Cables

Low Voltage Polymeric Cables up to 3.3kV

This video by 3M Electrical shows how to abandon cables safely using 3M CSCAK Cable Abandonment Kits.

3M CSCAK cold shrink cable abandonment kits are used to temporarily or permanently seal power, control and instrumentation cables – especially the abandonment of redundant or decommissioned low voltage offshore, marine and shipwiring power, control and instrumentation cables.

3M CSCAK kits are complete with all components to provide temporary or permanent abandonment of cables – this ensures cables are safe even if re-energised using cold shrink end caps and pre-stretched tubes.

The 3M Electrical video explains how cables are effectively short circuited using 3M Scotch Electrical Tapes and earthing products, including Scotch 24 and constant force springs.

The 3M Electrical video also shows the “live memory” action of Cold Shrink providing reliable and durable cable end seals without need for “hot working” permits in potentially explosive atmospheres or hazardous area zones located onshore and offshore.

Cold Shrink – invented by 3M over 40 years ago and now the preferred technology for heat-free jointing, terminating, sealing and abandonment of LV HV cables

Watch Video ➡

We hope you find this video informative and educational, contact T&D for technical support, quotations and stock availability for 3M Cable Abandonment Kits.

Cable Abandonment Kit Selection Table

Should you require support about selecting the correct cable abandonment kit from the 3M Cold Shrink product range for use with low, medium or high voltage cables please contact us – a complete range of Cold Shrink cable joints and terminations is available for MV-HV cables, including 11kV/33kV.

Where additional mechanical protection for connecting underground power cables in cable trench is required we can recommend Scotchcast cable joints with resin encapsulation to resist impact damage during backfill or future excavation and digging works.

For jointing cables in hazardous area locations go to our Blog about ATEX cable joints utilising advanced specification Scotchcast resins to provide a hydro carbon resistant joint or repair to damaged or extended cable circuits.

➡ Cable Abandonment For HV Cables Including 11kV 33kV High Voltages

| 3M Part Number | Power Cables 600/1000V 3.3kV | Instrumentation Cables |

| Overall Cable Diameter | Number of Pairs | |

| 3M CSCAK/1 | 12 – 18mm | Up to 5 |

| 3M CSCAK/2 | 18 – 25mm | Up to 10 |

| 3M CSCAK/3 | 25 – 42mm | Up to 20 |

| 3M CSCAK/4 | 42 – 55mm | n/a |

| 3M CSCAK/5 | 56 – 81mm | n/a |

Cable Abandonment Using Cold Shrink

➡ Visit 3M Electrical for further information about 3M cable joints, terminations, tapes and insulation to seal, repair, splice and connect LV MV HV cables.

Cold Shrink | Joint | Terminate | Seal | Repair | Splice | LV MV HV Cables | 3M

- 3M Electrical Products Stocked By Thorne & Derrick International

Roxtec Cable Seals – Sealing Cable Ducts In Substations Under Running Water Conditions (VIDEO)

June 20th, 2017

Sealing Cables

-

uploaded by Chris Dodds | Thorne & Derrick Sales Marketing Manager Author | Gavin Cornall from Roxtec

Gavin Cornall (Roxtec)

Roxtec are the world leading manufacturer of cable and pipe sealing transits to protect against water ingress, gas migration and fire spread.

The following article by Gavin Cornall (Global Sub-Segment Manager T&D at Roxtec UK & Ireland) discusses cable sealing applications during running water or “flood” conditions.

Firstly, running water presents a major sealing issue for the installation of mastic type seals, curing and drying is almost impossible. This can place “stress and strain” on work programme completion times, especially approaching handover phase.

Secondly, this applies to any solution used to seal large power cables whether in a one cable, one duct format or passing in a trefoil formation through a larger duct. Such as 11kV and 33kV power power cables feeding MV substations.

The ability of the cable seal to provide reliable operation under high water pressure is essential – the flexibility of the cable seal to be installed during running water conditions is equally crucial.

Roxtec have inspected many seals where over time the cable has caused the sealant to rip or pull out of the substation wall.

Roxtec have also seen due to the weight and orientation of the cables, its almost impossible for the installer to space the cables to get sufficient coverage of compound around the cables to maintain a seal.

Roxtec Cable Transits provide effective protection to LV HV substation cables against flood damage and water penetration be it in dry or wet conditions.

In the Whitepaper we commissioned from EA Technology on Humidity Effects In Substations, I was pleased to see the emphasis on cable retention, both in normal and fault conditions.

It highlighted what I already thought, which is that without the ability to retain, the cable seal will fail over time.

The cable seal may fail on day 1 or year 1 but ultimately it will fail over time.

Cable Sealing – Key Considerations

I would ask the following questions when evaluating cable sealing technology options from either a design, specification or installation perspective.

1) Can it be installed in “running water conditions” – if yes, look a little deeper into what that actually means.

- Do you have to buy additional cable seals so you can install on both sides of the wall?

- Do you have to follow a special methodology which is more onerous than the normal installation?

- Is the installation sealed instantly or is there a drying or curing time? Is this still dependant on staying dry for an extended period?

2) Can the cable sealing solution cope with the weight and flex in operation?

- I would always ask what is the pull out force needed to pull out the cable from the cable seal or sealant?

- If that retention is based on unistrut or clamps on racking it won’t work as the cable will still move in operation at its point of seal.

Roxtec UG Cable Seal

Advanced Specification Sealing For MV Substation Cable Ducts

When Roxtec developed the UG range, we had a very specific set of tests in mind given our understanding of these 2 issues. We developed a cable seal that was even better than our blue rubber on constant pressure. We quickly realised it could be installed on running water just like its blue cousin, the Roxtec Multidiameter cable seal module.

But most importantly, Roxtec developed specific testing for cable retention and flex.

Roxtec UG Substation Cable Seals

We wanted to show Roxtec cable sealing solutions could maintain their seal, whilst the cables were pulled, bent and twisted, beyond the maximum bend radius of the cable.

All this whilst we cycled the temperature between +4ºC to +40ºC.

Needless to say it not only worked but it went beyond our expectations.

Our Roxtec H3 200 seal in fact had in excess of 3300nm put on it without failure, that’s over 336 kgs of pull out force!

So in conclusion, I would say if you only take one thing away from reading this article it is always consider: 1) Running Water Installation 2) Cable Retention Performance

THORNE & DERRICK SPECIALIST ELECTRICAL DISTRIBUTOR

LV ♦ MV ♦ HV

T&D distribute the most extensive range of LV, MV & HV Cable Jointing, Terminating, Pulling & Installation Equipment – we service UK and international clients working on underground cables, overhead lines, substations and electrical construction at LV, 11kV, 33kV and EHV transmission and distribution voltages.

- Key Products: MV-HV Cable Joints & Terminations, Cable Cleats, Duct Seals, Cable Transits, Underground Cable Protection, Cable Jointing Tools, Feeder Pillars, Cable Ducting, Earthing & Lightning Protection, Electrical Safety, Cable Glands, Arc Flash Protection & Fusegear.

- Distributors for: 3M, ABB, Alroc, Band-It, Catu, Cembre, Centriforce, CMP, Elastimold, Ellis Patents, Emtelle, Furse, Lucy Zodion, Nexans Euromold, Pfisterer, Polypipe, Prysmian, Roxtec.

LV – Low Voltage Cable Joints, Glands, Cleats, Lugs & Accessories (1000 Volts)

MV HV – Medium & High Voltage Cable Joints, Terminations & Connectors (11kV 33kV EHV)

Cable Laying – Underground Cable Covers, Ducting, Seals & Cable Pulling Equipment

T&D, CATU Electrical Safety & Arc Flash Protection Specialists for SAP’s, Linesmen, Jointers & Electrical Engineers – Largest UK Stockist

INVITATION

Thorne & Derrick invite you to join LinkedIn’s largest LV-HV Electrical Discussion Group : Low & High Voltage Power, Cabling, Jointing & Electricals. Discussion subjects include cable installations, cable jointing, substation, overhead line and electrical construction at LV, 11kV, 33kV and EHV. Network, engage and promote your profile, company or products with over 10,000 influencers.

132kV Surge Arresters

June 19th, 2017

Surge Arresters

-

uploaded by Chris Dodds - Thorne & Derrick Sales & Marketing Manager

This following Product Update is about 132kV surge arresters – the ABB PEXLIM surge arrester is manufactured and specified to provide overvoltage protection to high voltage 132kV electricity networks and gas insulated substations.

132kV

ABB PEXLIM is a 132kV surge arrester for protecting UK DNO electrical infrastructure including HV substations, transformers, switchgear, capacitor banks, motors, bushings and cables distributing high voltage power – usually the arrester is installed on overhead line to underground transitions on power networks.

The ABB design is safe, secure and effective.

💡 Did you know?

The ABB PEXLIM surge arrester is National Grid compliant and approved for 132kV electricity networks – contact us for technical specification support, competitive quotations and immediate delivery from UK stock for 132kV surge arresters.

- System Voltage 24-170kV

- Rated Voltage 18-144kV

- Nominal Discharge Current 10 kApeak

- Surge Arrester Classification IEC 60099-4 Ed 3.0 Station; SL

- Surge Arrester Classification IEEE Std. C62.11-2012 Station

- Up To Line Discharge Class 4

- Mechanical Strength (SSL) 1600Nm

T&D can supply an extensive range of Joints, Terminations & Connectors MV HV to support the installation and routine maintenance of 132kV polymeric type (XLPE) insulated cable systems – this includes copper earth tapes manufactured by ABB Furse to provide effective Earthing & Lightning Protection to high voltage substations up to 400kV.

This range of HV sure arresters complements our line of 132kV link boxes with UK DNO and National Grid Approval.

Lightning strikes the ground in Britain about 300,000 times a year – for the utility industry this is a risk factor that must be countered by the MV HV substation designer, EPC or power distribution contractor.

UK DNO’s take the uninterrupted supply of electricity to our homes and business seriously, very seriously.

Use our #powercutmap for regular updates or if you can’t see your #powercut you can report it with just a few clicks https://t.co/vFgjOxBIER pic.twitter.com/HITQfFS97V

— Northern Powergrid (@Northpowergrid) June 15, 2018

Surge Arresters

T&D working with ABB can provide surge arresters for electrical protection of all types of medium/high voltage MV HV assets – view the Buyers Guide or better still call us to discuss your particular requirements. Surge arresters can be supplied with compliance to all UK DNO specification requirements including WPD, Northern Powergrid, UKPN and Scottish & Southern Energy (SSE).

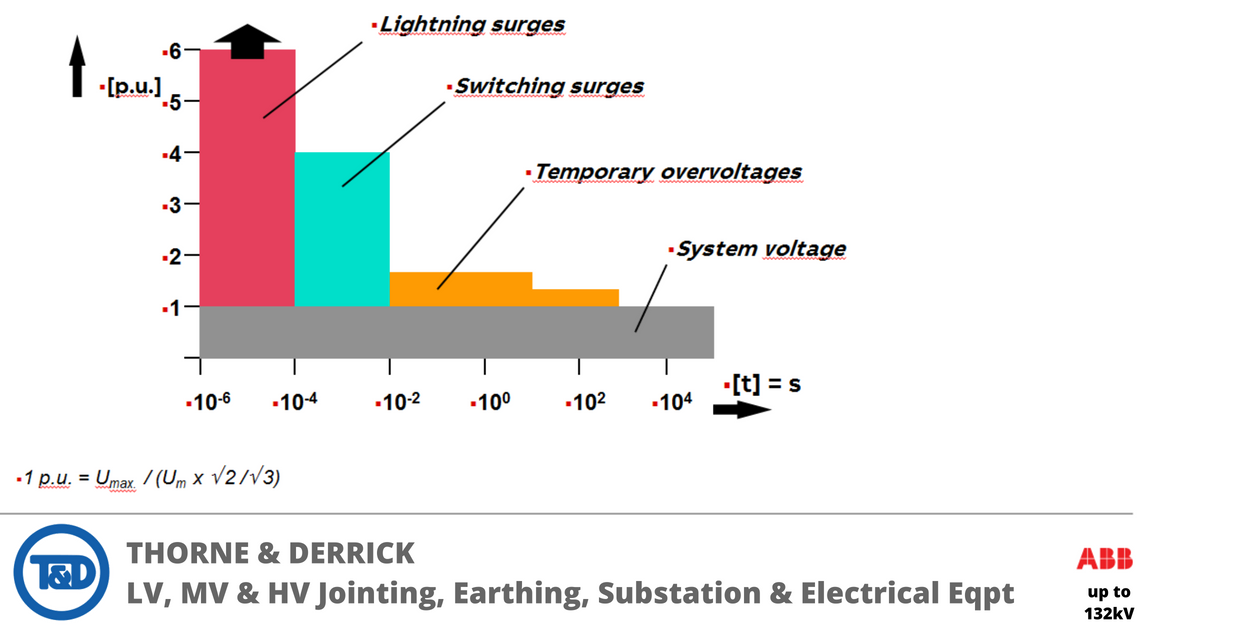

ABB surge arresters protect HV electrical power supply systems against the catastrophic effects of lightning and switching overvoltages.

See also Surge Diverters | Sheath Voltage Limiters

Causes Of Overvoltages In High Voltage Electricity Networks

To view further information about ➡ Medium Voltage 11kV – 33kV Surge Arresters

Thorne & Derrick Working With ABB

Since 1985 Thorne & Derrick based in the UK have been specialist distributors of LV, MV & HV Cable Installation, Jointing, Substation, Arc Flash Clothing & Electrical Equipment – customers include UK and worldwide contractors, specifiers, traders and end-users involved in cable installations, sealing cable ducts, cable jointing, substation earthing, overhead line and electrical construction at Low, Medium & High Voltages up to 132kV.

Should you require any technical support, specification guidance or would like us to visit you and discuss the range of ABB Surge Arrester products please do not hesitate to contact us – T&D are proud to distribute the ABB ranges of MV HV Electrical Equipment.

Chris Dodds (T&D) with Donald Thompson (ABB MV Surge Arrester Sales Manager) at Thorne & Derrick’s office in County Durham UK earlier today.

Suppliers of MV HV Joints, Terminations & Connectors | 3M | Prysmian | Nexans Euromold | Pfisterer | Elastimold | NKT