Blog

Network Rail Full Acceptance for Nexans Tee Connectors & Bushings for 25kV Power Transformers

March 8th, 2022

PR by Chris Dodds Sales & Marketing Manager at Thorne & Derrick | 08.03.2022

Following extensive and successful field trial testing the Nexans Euromold range of Connectors & Bushings have now received Full Acceptance by Network Rail with Official PADS Approval – specifically this includes Nexans Tee Connector model QM909TB Interface F and associated equipment bushing QM909AR.

The product authorisation by Network Technical Head Power Distribution HV/LV on behalf of the Network Rail Acceptance Panel (NRAP) permits the installation of the Tee Connectors and Bushings to ground mounted oil filled transformers up to 52kV – this covers:

Nexans Euromold Tee Connector Model QM909TB | Interface F Nexans Part Number 7009193 | PADS Catalogue No 0086/099432

Nexans Euromold 52kV 1250A Bushing | Interface F including 6 hole KBCDS-400 Clamping Kit & Sealing Gasket | PADS Catalogue No 0086/099430

➡ See Certificate of Acceptance PA05/05422 | Network Rail Certification

Thorne & Derrick are currently supplying this range of transformer terminations to several UK rail projects – we are Approved Vendors to Network Rail, CP6 Framework Delivery Partners and several HS2 Joint Ventures working on rail transport projects.

➡ For further information on Interface F Cable Accessories including Tee Connectors, Slip-on Terminations, Joints & Bushings refer to the download.

Further Reading

- 25kV Live Line Voltage Indicators | Network Rail Approved

- Rail Cable Labels with Network Rail & London Underground (LUL) Approval

- Network Rail Approved Cable Trough Delivered to South Rail Systems Alliance

- 3M LO42 Cold Shrink Tube | Track Feeder Cable Joints | Network Rail Approved

25kV Switchgear Terminations

Nexans AFN36-6 42kV single core cable terminations are Network Rail PADS Approved for indoor 25kV air insulated switchgear applications.

The cold-applied Slip-on rail cable termination is approved for use with Siemens ASG25 – 25kV air insulated switchgear for AC traction power supply systems.

Nexans 42kV Order Code AFN36-6

Network Rail 054/214930

Network Rail Certificate of Acceptance PADS PA05/06215

AFN36 cable terminations are used to connect medium voltage feeder cables to supply three-phase AC electrical power to traction substations on electrified lines.

Contact Thorne & Derrick for further information, competitive quotations or assistance with the selection and specification of Medium Voltage Rail Cable Accessories.

Rail Cable Accessories, Electrification

& Installation Equipment

Thorne & Derrick supply an extensive range of 400V-33kV Rail Cable Accessories & Power Distribution Sytems including feeder pillars to contractors undertaking Low Voltage Power Distribution, HV Electrification & Substations, DC Traction & Networks, OLE and Track Feeder Cable Renewals – a complete range of Network Rail PADS approved track terminations, cable joints, cable repair and connection products up to 25kV AC.

Full range of Cable Pulling Equipment & Products to ensure safe and efficient of rail cables in to cable ducts and containment infrastructure including cable troughs.

Thorne & Derrick

Nexans Main UK Stockist & Distributor

Contact us for Competitive Prices & Fast Delivery from Stocks for Heat Shrink, Cold Shrink & EPDM Rubber Connectors, Joints & Terminations up to 66kV.

Go to our Price List and contact us with your enquiries.

Thorne & Derrick International are specialist distributors of LV, MV & HV Cable Accessories, Jointing, Substation & Electrical Equipment – servicing UK and global businesses involved in cable installations, jointing, substation, overhead line and electrical construction at LV, 11kV, 33kV, 66kV and EHV.

Stocking & Supplying | Duct Seals | Cable Cleats | Cable Glands | Electrical Safety | Arc Flash Protection | Jointing Tools | Cable Pulling Eqpt | Earthing & Lightning Protection | Feeder Pillars | Cable Joints LV | Joints & Terminations MV HV | Live Line Testers

Euromold MV HV | Cable Terminations, Connectors, Elbows & Joints

Nexans Supply Electrical Conductors To The Largest Onshore Wind Farm In America

March 7th, 2022

Madeco by Nexans will supply 840 km of cables that it will produce at the Nexans plants in Chile and Peru.

Nexans

Electrical Conductors

Madeco by Nexans continues to promote the development of renewable energies, by concluding a significant agreement with Sigdo Koppers Ingeniería y Construcción SA to provide cabling solutions to the Horizonte wind farm.

There will be 840 kilometres of electrical conductors, mainly aluminium medium voltage, which will be produced in collaboration with Nexans Indeco (Peru), one of the Nexans Group plants in the Andean region. Conductor design was optimized based on the requirements of the project, located in the municipality of Taltal, Antofagasta Region. The first deliveries are planned for May 2022.

Thorne & Derrick | Nexans Distributed from Stock | Approved Supplier | UK & Export Sales

Colbún’s Horizonte wind farm will have an installed capacity of 778 MW, equivalent to the consumption of more than 700 thousand homes per year. The project is the largest onshore wind farm under construction in Latin America and one of the world’s highest installed capacities.

“ We have worked with Sigdo Koppers and Colbún to find the best solutions, in terms of the of conductors, section and reel design, and thus generate relevant efficiencies that contribute to the success of the project. ” Miguel Fernandez, Commercial Manager Of Nexans In Chile.

“ We are very proud to be part of the largest wind farm under construction in Latin America, and one of the most significant worldwide. Participating and working with the various actors involved in the project reaffirms our commitment to developing renewable energies, both in Chile and in the region, as well as our commitment to supporting the carbon-neutral transition by 2030, thereby ensuring a safer, more sustainable, renewable energy future and, above all, accessible to all. ” Luis Ernesto Silva, Vice President Of Nexans For The Andean Region.

This newly awarded project is part of the Nexans’ strategy to promote energy transition, electrifying the future through innovative solutions, and fostering the development of renewable energy initiatives around the world.

Joints, Terminations & Connectors up to 66kV from UK Stock | Contact Thorne & Derrick

Horizonte Project

Horizonte is a wind farm that will have an installed capacity of 778 MW generating 2,400 GWh per year, equivalent to the consumption of more than 700 thousand homes in the country. It includes the installation of 140 wind turbines on 8 hectares, thereby reducing CO2 emissions by 1.2 million tons annually. Finally, the energy generated is to be released onto the National Electric System as of the fourth quarter of 2023.

For over a century, Nexans has played a crucial role in the electrification of the planet and is committed to electrify the future. With around 25,000 people in 42 countries, the Group is leading the charge to the new world of electrification: safe, sustainable, renewable, decarbonized and accessible to everyone.

Thorne & Derrick International are specialist distributors of LV, MV & HV Cable Accessories, Jointing, Substation & Electrical Equipment – servicing UK and global businesses involved in cable installations, jointing, substation, overhead line and electrical construction at LV, 11kV, 33kV, 66kV and EHV.

Stocking & Supplying | Duct Seals | Cable Cleats | Cable Glands | Electrical Safety | Arc Flash Protection | Jointing Tools | Cable Pulling Eqpt | Earthing & Lightning Protection | Feeder Pillars | Cable Joints LV | Joints & Terminations MV HV

MV HV High Voltage Cable Joints | Cable Terminations | Cable Connectors | Distributed from Stock | UK & Export Sales

Transformers | Is It Time To Upgrade?

March 7th, 2022

Transformer Replacement Projects Were A Great Success For Smith Brothers In 2021

-

Special thanks to Ben Whitaker Business Development & Sales Manager at Smith Brothers for the kind permission to republish

Transformers

Alongside some of the large connections we talk about often, our services and infrastructure division are always working away in the background – to ensure our customers remain online 24-7-365.

And, as technology progresses, transformers have become more efficient in performing their duty of increasing or decreasing voltage for electrical distribution. With that in mind, our Business Development & Sales Manager, Ben Whitaker, takes a look at why replacing your transformer with a modern alternative could result in a ‘greener’ site whilst reducing energy bills.

Transformer replacement projects were a resounding success for Smith Brothers in 2021, and saw us complete 19 in total as organisations continued to strive to reduce carbon emissions and operate their sites more efficiently.

Yet, rather than simply ‘fixing a problem’, investment in new technology which can help to counter rising energy tariffs across the UK has been a firm topic of conversation for our team. It’s nothing new, though. In fact, a study in 2018 suggested that lost energy in transformers contribute to 25% of the UK’s wasted energy.

What’s more, the European Union estimates that 2.9% of all electricity generated across the continent gets wasted in lost energy in transformers, this combined figure equates to 93.4TWh – enough to power Denmark for three years.

Over the past 12 months, Smith Brothers has contributed to the energy sector in the UK significantly through the construction and delivery of renewable energy projects – but also by replacing aged and inefficient transformers.

Transformer Regulation No. 548/2014

During their operation, transformers will lose heat, but legislation imposes in the EU the maximum level of losses for transformers placed on the market or put into service after 1st July 2015. And, while most pre-2014 transformers are manufactured to an undetermined efficiency level, we refer to these as ‘standard loss transformers’.

As of 2014, the minimum requirement for installed transformer assets adhered to Tier 1 level of efficiency. Further regulations were imposed in June 2021, introducing Tier 2, which determines an improved efficiency for newly manufactured transformers.

Tier 2 transformers have been readily available via manufacturers for some time – and have been included in any Smith Brothers tender proposals as a matter of default since 2018. Further energy savings can be achieved through the provision of a Wilson e3 amorphous core transformers, which is also something which we’re proud to be able to supply and install.

No Load Losses

No Load Losses arise within the magnetic core of a transformer and happen as a result of the energy consumed in hysteresis and eddy currents within the material as it is taken through its alternating cycles of magnetisation, in the UK 50 times per second i.e. 50Hz.

There are two ways of reducing no load losses in a transformer:

1) Reduce flux density by increasing the cross-sectional area of the magnetic core. 2) By using higher grades of core steel to reduce the watts/kg for a particular flux density.

The ‘no load losses’ of a transformer is a constant loss of energy and does not vary with increase/ decrease of load.

Load Losses

Load losses arise primarily because of the resistance of the transformer windings, that is the losses produced by the flow of current within the windings. Increasing the copper or aluminium cross-sectional area within a transformer winding has the effect of reducing the current density of the winding – this has the effect of reducing the losses. The load loss of a transformer varies to the square of the load.

Generally speaking – the larger kVA rating and the higher % load of this kVA rating, the more savings can be made by minimalising load/ no load losses.

Detailed below, is a comparison of the no load losses and full load losses of a 1000kVA ‘Standard Loss’ transformer, manufactured in 2013, prior to Tier 1’s introduction and a modern, 1000kVA Tier 2 transformer. We have also included the data for a Wilson e3 amorphous core transformer for comparative purposes. The monetary savings shown are subject to the transformer being run at 80% load 24 hours a day, 365 days a year at an energy tariff average of 12p per KWH.

| “Standard Loss” 100kVA | Tier 2 1000kVA Transformer | Wilson e3 Amorphous 10000kVA |

| No load losses: 1,350 Watts per hour | No loaded losses: 693 Watts per hour (647 Watts per hour saving) | No loaded losses: 450 Watts per hour (900 Watts per hour saving) |

| Full load losses: 12,500 Watts per hour | Full load losses: 7,600 Watts per hour (4,900 Watts per hour saving) | Full loaded losses: 6,630 Watts per hour (5870 Watts per hour saving) |

| Monetary savings: £3,987 per annum | Monetary savings: £4,896 per annum |

How do I work out how much energy is being lost from my transformers?

Due to fluctuating loads pulled from individual transformers on operational sites, it’s important to find the right partner to carry out load monitoring and power quality surveyance in order to accurately determine the specific lost energy of sites’ existing transformers.

A good supplier should consider these specific elements:

- 7-day detailed power and power quality logging at nominated LV incomers. Current, voltage, kW, kVA, power factor, harmonics (I& V), flicker, frequency, harmonic loss factor and unbalance

- Load analysis and dentification of voltage dependent equipment

- Determination of PFC requirement and specification

- Detailed analysis of all logging data including harmonic analysis against ENA G5/4-1 at each LV supply (400V)

- Determine true loading of transformers using harmonic derating

- Calculation of existing transformer losses and energy savings associated with selected replacement/s

- Compilation of the technical report including savings & outline recommendations, where applicable

Smith Brothers Ltd is a large, turnkey electrical contractor with over 20 years’ experience. Since their inception in 1999, they have worked on a vast portfolio of projects throughout the UK and overseas, both as an ICP and EPC contractor on schemes up to 132kV.

Offering a range of services and can cater for everything from the delivery of a turnkey project – including design, the supply and commissioning of equipment and cabling installations from LV up to 132,000 volts (220,000V in ROI).

With over 10 years’ experience in the power industry — Ben has specialised in many power distribution projects, as well as maintenance and HV/EHV connections throughout his career. He is responsible for new sales and quotation conversion.

For further information, or an initial discussion regarding replacement transformer options, contact business development and sales manager, Ben Whitaker on: 07387 108 377 or email [email protected].

Stockists | 11kV 33kV 66kV Joints Terminations Connectors – 3M Pfisterer Nexans

THORNE & DERRICK

Thorne & Derrick are national distributors of LV, MV & HV Cable Installation, Jointing, Substation & Electrical Equipment – servicing businesses involved in cabling, jointing, substation, earthing, overhead line and electrical construction at LV, 11kV, 33kV, 66kV and EHV. Supplying a complete range of power cable accessories to support the installation and maintenance of low/medium and high voltage power systems:

- Slip-on Cable Terminations

- Cold-shrink Cable Terminations

- Heat-shrink Cable Terminations

- Cable Joints – Heat & Cold-shrink

- Separable Connectors (Euromold)

- Surge Arresters & Switchgear/Transformer Bushings

Key Product Categories: Duct Seals | Cable Cleats | Cable Glands | Electrical Safety | Arc Flash Protection | Cable Jointing Tools | Cable Pulling | Earthing | Feeder Pillars | Cable Joints LV | Joints & Terminations MV HV

February 2022 VOLTS!

February 28th, 2022Welcome to our industry bulletin – VOLTS.

So what is VOLTS?

VOLTS is our monthly round-up of industry news, projects, videos, technical tips, training information, promotions, webinars and career opportunities from Thorne & Derrick. Take a moment to Follow Us on LinkedIn to receive future VOLTS.

Press Release

This month, Thorne & Derrick are delighted to have concluded a Preferred Distribution Agreement with P&B Weir Electrical Ltd.

The agreement is the culmination of discussions and strategy planning for the launch of our partnership – this arrangement is purposed to raise levels of operational and personal safety in the substation, distribution and transmission sectors of the electrical industry.

“I am personally pleased to have secured this valuable partnership and we are excited about introducing their combination of innovative and heritage engineered Electrical Safety Equipment up to 400kV to our clients. If you work on underground cables or overhead lines we look forward to discussing and supporting your project or personal safety requirements.”

“Down the trench or up the pylon, together we can protect workers against the daily hazards of working with electricity. We now look forward with ambition and commitment to implementing our business plan to achieve our shared business goals for 2022,” comments Chris Dodds, Thorne & Derrick. Read complete Press Release here.

pROJECTS & NEWS

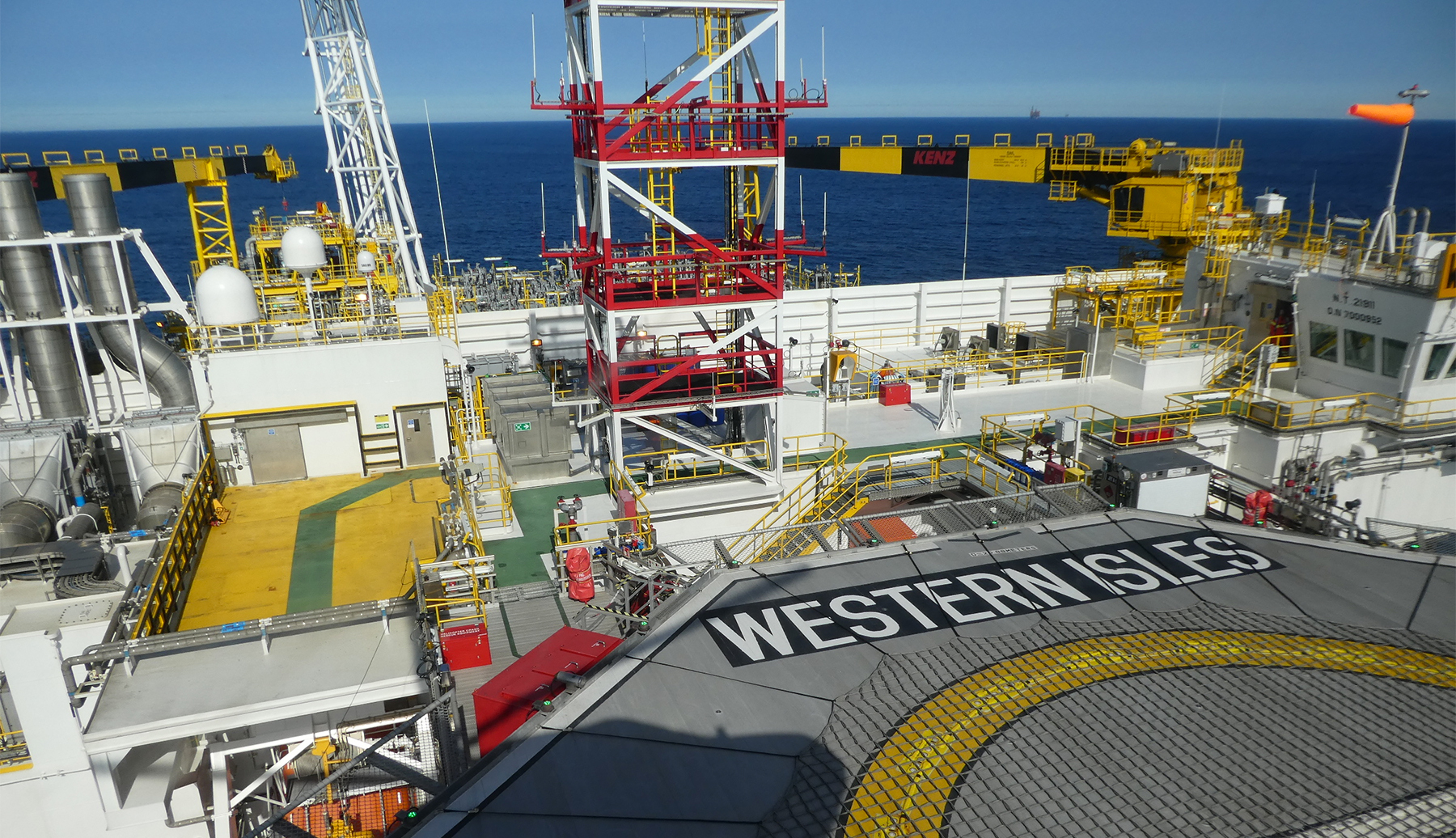

Floating production storage and offloading Unit

This month we have been working on a project to supply electrical safety equipment to switchrooms on a floating production, storage and offloading platform (FPSO) located in the North Sea – a floating production storage and offloading (FPSO) unit is a floating vessel used by the offshore oil and gas industry for the production and processing of hydrocarbons, and for the storage of oil. Ship-shaped FPSOs are by far the most widely used type of floating production unit, accounting for over 100 deployments globally.

The customer required a replacement for their current insulating matting to be installed in their LV and HV switchrooms on board the FPSO. The replacement was required due to the age of the existing matting; showing typical wear and tear and no longer providing the correct level of safety or insulating protection to offshore workers.

The switchrooms on the vessel ranged from 1kV to 17.5kV, and required matting to meet the correct voltages. After careful project specification, Thorne & Derrick supplied the client with Class 2 insulating matting for the HV switchroom, plus Class 0 matting for the LV switchroom according to IEC6111. Each versatile roll was supplied at 10 x 1m wide, with the end user intending to cut the rolls to suit the individual requirements.

Thorne & Derrick supplied the materials in 3-4 days from stock – see also storage, use and care of insulating matting for further information.

➡ See our range of Electrical Insulating Matting for the protection of workers involved in electrical installations for voltages of 1,000 volts – 33kV.

Image Credit: Dana Petroleum | Western Isles FPSO – the Dana-operated Western Isles is producing from two oil fields called Harris and Barra in the Northern North Sea, 160km east of the Shetlands and 12km west of Tern field. It involves a subsea development of production and water injection wells tied back to a floating production, storage and offloading vessel (FPSO) with oil export using shuttle tankers.

improving access

A pair of new lifts has been installed at Meols station to improve accessibility for those travelling on the Merseyrail network.

The £2.2 million project was funded through the Department for Transport’s (DfT) Access for All programme and forms part of a wider project funded by both the DfT and Liverpool City Region Combined Authority.

The Access for All programme was introduced to make travelling more convenient for disabled passengers travelling by train across the country, and previous projects on the Merseyrail network include lift installations at Formby, Birkenhead North and Orrell Park.

To read more about the project click here.

Thorne & Derrick have supported this project by supplying GRP ground-fixed trough and fixings to their client Amco Giffen and manufactured by Wibe MITA – we are Approved Vendors to most of the Network Rail Principal Contractors and electrification framework providers and support troughing system scheme design, specification and supply.

PADS approved cable trough ensures protection of trackside power and S&T cables on the UK rail infrastructure – this includes LV copper and aluminium dc traction power and medium/high voltage (MV-HV) power cables supplying 11kV, 25kV and 33kV electricity distribution. We are proud to have worked with the Access for All program to protect infrastructure against accidental damage or vandalism whilst remaining easy to access if maintenance or a future electrification upgrade is required.

Thorne & Derrick | Approved Vendors to Network Rail

Rail News |Network Rail Full Acceptance for Nexans Tee Connectors & Bushings for 25kV Power Transformers

- Joints & Terminations for Network Rail 25kV Power Projects | PADS Approved

- Convex Cable Hangers | Supporting Rail Cables & Tunnel Wall Applications

- Jointers & Splicers Tents For Irish Rail | Protecting Cables Against Water & Weather

Protection of Rail Cables & Power Infrastructure Using Cable Troughing Systems | GRP

Pillar Power

Since 2010, we have been working with Lucy Zodion and their highly skilled and experienced in-house electrical design and engineering teams to provide high-quality power distribution solutions – contact us to discuss your requirements.

Thorne & Derrick continue to specify and supply the Fortress range of feeder pillars manufactured from the highest quality galvanised steel with optional internal electrical wiring to client specification – the Lucy Zodion’s wide selection of steel pillar shells come in a number of sizes, finishes and treatments to ensure they meet your power distribution requirements; single-door, single-door, triple-door and other variants available.

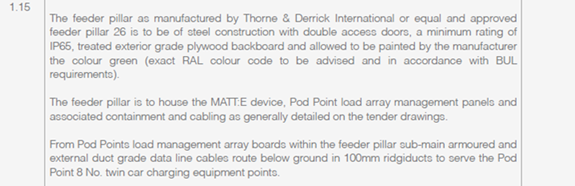

February projects included: C11 Cyber Security and Digital Innovation Centre, Network Rail Brookmans Park Station plus several electric-vehicle (EV) charging stations and mobile telephone sites throughout the UK for SSE. Here is an extract from our Scope of Work Specification for the EV Charging Points at Brunel University, London.

Pictured | The Walk-in WR2 | this is our double-door walk-in GRP Electric Enclosures handmade to the highest standard with stainless- steel hinges, secure lockable doors, IP55 dust and water protection and a UV stabilised gel coat finish. See the Specification.

From the largest UK stocks Thorne & Derrick distribute the most extensive range of feeder pillars for LV Power Distribution.

Building Scotland’s largest offshore wind farm

This month, Thorne & Derrick achieved Approved Vendor status with SSE Renewables, the renewable energy subsidiary of SSE plc which develops and operates onshore and offshore wind farms and hydro electric generation in the United Kingdom and Ireland. We are now working with their Project Managers & SAP’s to improve electrical site safety and outage response capabilities throughout their asset portfolio through the specification and supply of Joints, Terminations & Connectors for 33kV networks.

Supporting Seagreen

Seagreen Offshore Wind Farm project is located 27km off the coast of Angus in the North Sea. A joint venture between TotalEnergies (51%) and SSE Renewables (49%), Seagreen will be Scotland’s largest and the world’s deepest offshore wind farm when complete.

The Seagreen offshore wind farm was consented with permission granted to install 150 offshore wind turbines. 114 offshore wind turbines are currently under construction with an installed capacity of 1,075MW and will be fully operational by early 2023.

Seagreen is an offshore wind farm development owned by SSE Renewables (49%) and TotalEnergies (51%).

SSE Renewables is leading the development and construction of the joint venture project, supported by TotalEnergies, and will operate Seagreen on completion.

Substation | Seagreen is building a new substation at Tealing which will receive the electricity generated by the wind farm for conversion up to 400kV for onward transmission on the national electricity transmission system.

Thorne & Derrick distribute the most extensive range of MV HV Medium & High Voltage Cable Joints, Terminations & Connectors from manufacturers including 3M, Prysmian, Nexans Euromold, Elastimold, and Pfisterer CONNEX.

Let’s Meet

Throughout February, Thorne & Derrick continued to welcome their supply chain to our offices and we also conducted online meetings to ensure staff are up-to-date with product developments, discuss sales-marketing campaigns and strategy plan for 2022 with our team.

Last week, Thorne & Derrick welcomed Ian Joynson & Chris Thompson from CSD Sealing Systems to their offices for training and a live product demonstration of their market-leading NORFIRNO product – the NOFIRNO system is Type Approved for the harshest ratings for A, H and Jet Fire Class, and is also approved for watertight, gas-tight, blast and shock applications.

Thorne & Derrick are Approved Distributors for CSD Sealing Systems – we have specified and distributed their products across numerous onshore and offshore substation projects.

The half-day agenda covered developments and approvals within the UK DNO Utility sector, product conformance to ATEX Directive for hazardous areas and explosive atmosphere installations plus a round-up of our sales pipeline and current projects.

OFFSHORE NETWORKING & THE RENEWABLE REVOLUTION

Thorne & Derrick continue to support the Test & Termination requirements of High Voltage Engineering Services providers for cable tooling and installation materials – this includes Cold Shrink Caps & Mastic Tapes for sealing power and FO cable cores on inter-array cables, 33kV Jointers Tool Sets and Cable Heaters for the straightening of high voltage power cables prior to termination.

We stock 3M Cold Shrink terminations up to 66kV – this includes the 3M 96-EP720-2 for the Test & Termination of 66kV single core cables with XLPE insulation (120sqmm-1000sqmm).

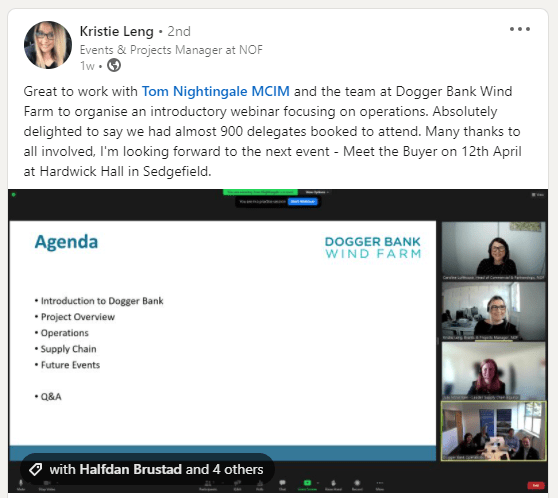

Webinar – An Introduction to Dogger Bank Wind Farm

Our Key Account Sales Engineer, Jonathan Hewitt, enjoyed attending the webinar hosted by NOF this month – the well supported online event provided an introduction to the operations phase of this extensive offshore renewables project. Over 900 delegates joined the w ebinar to learn and understand more about the North East based wind farm, the Tier 1 Contactors involved in the project and the opportunities for the supply chain. The presentation provided oversight of the supply-chain requirements from Wind Turbine to National Grid substation.

ebinar to learn and understand more about the North East based wind farm, the Tier 1 Contactors involved in the project and the opportunities for the supply chain. The presentation provided oversight of the supply-chain requirements from Wind Turbine to National Grid substation.

Dogger Bank Wind Farm is located more than 130km off the North-East coast of England and is being delivered by joint venture partners SSE Renewables, Equinor and Eni – in total the wind farm is expected to generate enough renewable electricity to supply 5% of the UK’s demand, equivalent to powering six million homes.

Thorne & Derrick look forward to working with our supply chain and clients to deliver support to the Dogger Bank development including Cable Termination, Jointing, Pull-in & Electrical Equipment up to 66kV.

Special thanks to Caroline Lofthouse (NOF Cluster Manager) for providing the Welcome and to Tom Nightingale (North East Stakeholder Manager) for a highly insightful and informative project overview. Following the event Thorne & Derrick have calendared further meetings with both DEME and GE Renewable Energy.

Building the world’s largest offshore wind farm | Located more than 130km off the North East coast of England, Dogger Bank Wind Farm will be capable of powering 6 million British homes – find out more.

Technical Tip

Watch Video | How to Remove Bonded Screens from MV Cables by Thibaut Rouyere (Marketing & Sales Director at Alroc)

Featured Jointer

Sector Spotlight | rail

Thorne & Derrick supply an extensive range of 400V-33kV Rail Cable Accessories & Power Distribution Sytems including feeder pillars to contractors undertaking Low Voltage Power Distribution, HV Electrification & Substations, DC Traction & Networks, OLE and Track Feeder Cable Renewals – a complete range of Network Rail PADS approved track terminations, cable joints, cable repair and connection products up to 25kV, including 3M Cold Shrink, Pfisterer CONNEX and Nexans Euromold products.

Full range of Cable Pulling Equipment & Products to ensure safe and efficient of rail cables in to cable ducts and containment infrastructure including cable troughs.

Transport for London Project

February Rail Project | Working with Ellis Patents we completed the specification and have now moved into manufacturing for our largest contract to date to supply TfL (London Underground) approved cable hangers across several depot modernisation projects.

Thorne & Derrick in consultation with the Asset Manager at Transport for London and their appointed Telecoms & Power contractor secured formal Authorisation & Approval for the Pegasus range of non-metallic cable support hangers. The product will provide safe cable management of the cable route within the Bridges & Structures category – over 1000 hangers with proven lifecycle performance and utilising the standard J-type design for support of multiple cable runs including single, 3-way and 5-way configurations are now scheduled for delivery.

Thorne & Derrick are Approved Vendors to both Network Rail and Transport for London.

Industry event

Energy Network Events exists to safely promote and further the interests of everyone working in and supplying the electricity industry. The management team have years of experience working in industry, organising and promoting events and use their experience and contacts to win the support of Legislators, Regulators, Senior Managers, World Class Suppliers and Inspirational Figures.

Visit

ENERGYx2022 Visitor Delegate FREE Tickets

Exhibit

ENERGYx2022 South Exhibitor Booking Form

ENERGYx2022 is the industry-leading Exhibition & Conference for anyone working within the Electricity Industry.

Jobs

HV Cable Jointer

ICS Cymru – Division of Instrument & Control Services Ltd based in Caerphilly, South Wales, are an Electrical Contractor specialising in Electrical Transmission, Distribution and Generation systems.

You will be responsible for carrying out and overseeing the cable jointing and termination works involved within our projects, for voltages ranging from LV up to 33kV …see more.

VOLTS! By,

Thorne & Derrick distribute the most extensive range of Low & High Voltage Cable Installation & Electrical Distribution Equipment to the Power Transmission & Distribution industry in the onshore and offshore wind, solar, rail, oil/gas, data centre, battery storage and utility sectors – this includes Joints, Terminations & Connectors to enable the installation of low, medium and high voltage power cables into underground trench or duct.

Key Product Categories: Connectors, Joints & Terminations MV HV | Cable Preparation & Jointing Tools | Duct Seals | Cable Transits | Cable Cleats | Cable Glands | Electrical Safety | Arc Flash Clothing & Protection | Cable Pulling | Earthing & Lightning Protection | Feeder Pillars

Main UK Stockists for: 3M Electrical, PFISTERER Connex, Nexans Power Cable Accessories (Euromold), Alroc, Ellis Patents, ABB, Roxtec, Cembre & CATU Electrical.

Volts! Archive

Jointing & Connecting MV Cables In The Energy Industry

February 27th, 2022

Jointing & Connecting MV Cables In The Energy Industry

-

uploaded by Chris Dodds - Thorne & Derrick Sales Marketing Manager

Shearbolt Cable Lugs & Connectors

Jointing & Connecting MV Cables

Nexans manufacture an extensive range of slip-on, cold-shrinkable and heat-shrinkable cable terminations, joints and connectors for 11kV-33kV-66kV power systems – to complement and ensure their reliable performance a complete range of Cable Lugs & Connectors utilising shearbolt technology are available from Nexans.

The GPH range of electrical connectors from Nexans are compatible with their medium voltage ranges of joints (JTS) and terminations (MONO).

GPH medium voltage mechanical cable connectors and cable lugs provide excellent electrical contact and are suitable for aluminium and copper conductor ranges 1.5-1200sqmm up to 52kV (EN 60228 Classes 1 & 2).

M-Series mechanical connectors are assembled with multiple shear-off-head bolts and are therefore a reliable and economical way of connecting identical or different conductor cross-sections and conductor materials – they allow the safe connection of copper and aluminium conductors with cross-sections of #16 AWG up to 2,000 kcmil (up to 1200sqmm).

Nexans have launched a new mechanical power connector as part of their range of GPH cable connectors and cable lugs available for medium voltage cables. All connectors are available with either Allen shear bolts or outer hexagon shear bolts.

The new Nexans GPH mechanical connector M-Series is specified for connecting, jointing and branching large conductor cross-sections on medium voltage power cables up to 52kV.

Typical applications for the Nexans GPH Connector are connections of large scale wind farms and offshore wind farms to the MV power grid. The patented Nexans GPH shear-off head bolt clamps the conductor into the connector at the optimum contact force.

Connects, Joints & Terminates all Types of Copper & Aluminium Cables

Installation is simple and quick and the GPH mechanical connectors have been electrically tested according to IEC 61238-1-A.

As with all medium voltage cable lugs from Nexans GPH, the M-Series has been successfully tested according to IEC 61238-1, class A and ANSI 119.4

Nexans support international onshore and offshore renewable energy projects with an extensive range of 52kV medium voltage electrical distribution equipment including cable joints, terminations and Euromold screened separable connectors.

M-Series Mechanical Connectors

Benefits

- Allows the safe connection of copper and aluminium conductors of all designs and cross-sections of 1.5sqmm up to 1,200sqmm

- Connects all common, compressed and compacted copper and aluminium conductors

- Fewer connector types cover the most common cross-sections

- Shear bolt connectors compensate conductor tolerances

- Provides the highest contact force for a maximum lifetime of the application

- Quick and simple installation with standard tools, no crimping tools required

- Prevents installation mistakes

- Tested acc. to ANSI 119.4, IEC 61238-1 class A

- Wide application range

- Customised solutions, special types and dedicated designs available on request

Mechanical Connectors M-Series

Product Range

The GPH connector body is manufactured from high quality aluminium alloy supplied with brass bolts (tin-plated):

| Mechanical Connector Part Number | AL in sqmm | CU in sqmm | Number of bolts |

Dimensions mm | Tool/ outer and inner hexagon | ||||||

| rm(v) round stranded |

re round solid |

sm sector stranded |

rm(v) round stranded |

sm sector stranded |

L | d1 | D | b | |||

| M16-95 | 16-95 | 10-95 | 25-70 | 16-95 | 25-70 | 2 | 70 | 12,5 | 24 | 32 | SW10 & SW6 |

| M25-150 | 25-150 | 25-150 | 35-120 | 25-120 | 35-120 | 2 | 85 | 15,5 | 30 | 35 | SW10 & SW6 |

| M70-240 | 70-240 | 70-240 | 70-240 | 70-240 | 70-240 | 4 | 120 | 221) | 35 | 56 | SW13 & SW6 |

| M95-240 | 95-240 | 95-240 | 95-185 | 95-240 | 95-185 | 4 | 120 | 20 | 33 | 56 | SW13 & SW6 |

| M95-300 | 95-300 | 95-300 | 95-240 | 70-300 | 70-240 | 4 | 142 | 231) | 36 | 67 | SW13 & SW8 |

| M120-300 | 120-300 | 120-300 | 120-240 | 120-300 | 120-240 | 4 | 142 | 25 | 38 | 67 | SW19 & SW6 |

| M185-400 | 185-400 | 185-400 | 185-300 | 185-400 | 185-300 | 6 | 170 | 26 | 42 | 82 | SW19 & SW6 |

| M300-500 | 300-500 | 300-500 | 300-400 | 300-500 | 300-400 | 6 | 200 | 34 | 52 | 94 | SW19 & SW8 |

| M400-630 | 400-630 | 400-630 | 400-500 | 400-630 | 400-500 | 6 | 200 | 34 | 52 | 94 | SW19 & SW8 |

| M630-1000 | 630-1000 | 630-1000 | 630-1000 | 8 | 220 | 41 | 65 | 105 | SW19 & SW8 | ||

| M800 | 800 | 800 | 800 | 8 | 220 | 37 | 60 | 105 | SW19 | ||

| M1000 | 1000 | 1000 | 8 | 220 | 41 | 60 | 105 | SW19 | |||

| M800-1200 | 800-1200 | 630-1200 | 630-1000 | 8 | 220 | 45 | 72 | 105 | SW22 & SW8 | ||

- 1) Dimension d2 = 26 mm

- 2) Centric conductor positioning by centre inserts

The below video shows how GPH range-taking mechanical connectors and bolted cable lugs with shear-off-head bolts connect power cables with copper and aluminium conductors up to 1,200 square millimetres in power transmission and distribution networks.

Thorne & Derrick

Thorne & Derrick are national distributors of LV, MV & HV Cable Installation, Jointing, Substation & Electrical Equipment – servicing businesses involved in cabling, jointing, substation, earthing, overhead line and electrical construction at LV, 11kV, 33kV, 66kV and EHV. Supplying a complete range of power cable accessories to support the installation and maintenance of low/medium and high voltage voltage power systems:

- Slip-on Cable Terminations

- Cold-shrink Cable Terminations

- Heat-shrink Cable Terminations

- Cable Joints – Heat & Cold-shrink

- Separable Connectors (Euromold)

- Surge Arresters & Switchgear/Transformer Bushings

Key Product Categories: Duct Seals | Cable Cleats | Cable Glands | Electrical Safety | Arc Flash Protection | Cable Jointing Tools | Cable Pulling | Earthing | Feeder Pillars | Cable Joints LV | Joints & Terminations MV