Cable Pulling & Laying

Cable Pulling & Installation | Advice for LV HV Cable Installations

September 24th, 2019

Cable Pulling & Installation | Advice for LV HV Cable Installations

Cable Delivery, Pulling and Installation

Top Do’s & Don’ts

-

Article Contribution Thanks to BASEC

BASEC is an independent accredited certification body for the cable industry worldwide.

BASEC’s name is synonymous with cable quality and safety.

Although present everywhere, cables seldom impact their users; they are usually hidden from view, and, if they are fulfilling their role correctly, require no attention. They should perform reliably for many decades if they have been correctly specified, conform to relevant standards and specifications, carry BASEC or another recognised approval, and have been carefully maintained. Protection from environmental and mechanical stress is also essential.

However, even cables that are sourced responsibly are at risk during initial delivery and installation. During this phase, they will be subjected to movements, stresses and strains – and if these exceed the cable design limits, damage becomes a strong possibility. Even simple issues like snagging on sharp edges can have serious consequences.

Installation damage during the cable pulling and laying process can lead to customer dissatisfaction, significant delays in project completion, extra resources being needed, and in particular, additional costs imposed on installers for removing and replacing damaged cables. These problems can be exacerbated if the effects of any damage do not become apparent, potentially affecting the supply of power, control or communications, until after the installation has gone into service.

Below are some top tips for a clean, trouble-free installation:

Cable delivery and cutting to length: Safe handling of cable starts with the supplier, often a distributor or wholesaler. Manufacturers will deliver cables on an appropriately sized drum or reel, loaded under controlled factory conditions. Cutting the cable to length, and redrumming onto an often-smaller delivery drum can result in over-bending if the drum belly diameter is too small; additionally, the cable may suffer external scuffing damage.

End caps: If suitable end caps are not fitted onto the cut length, water may penetrate the cable during storage or on site.

Bend radius – armoured cables: Bend radius is a key consideration, particularly for SWA cables and for higher voltages of 11kV or more. Minimum bend radius is generally defined by cable standards, or is advisory; it should be communicated by manufacturers and passed on by suppliers to the installers. Sometimes two figures are used; a dynamic radius for the pull, and a possibly smaller final static radius for when the cable is no longer under tension.

Maximum cable tension and sidewall pressure limits can both cause damage if exceeded when pulling cables. To prevent this, cable installation routing should be closely assessed, and several rollers or guides used at any bend points. A single cable roller or guide’s external radius is always likely to be much lower than the cable’s minimum bend radius. As a simple rule of thumb, for a four-core armoured cable larger than 40mm OD, a full-sized bicycle wheel should fit within the bend.

Bend radius – screened cables: With screened cables such as BS 7629-1- rated fire alarm types, the minimum bend radius must be maintained to ensure fire integrity. Kinks in the screening or over-tight entry into accessories may compromise fire performance. All such cables will have been fire tested at a specified bend radius, which the manufacturer should communicate to their suppliers and users.

Bend radius monitoring: Monitoring the bend radius on site is not straightforward. Many installers use simple go / no-go templates, but these can sometimes miss the tight parts of bends. Purpose-designed radius gauges can measure extremely accurately, providing reassurance that a cable installation has been completed correctly and safely.

Cable pulling: Problems can occur where cables are pulled in two directions from a common mid-point. Some cable is initially pulled in one direction, then the remaining cable is laid out from the drum before being pulled in another direction. This approach can cause significant damage to a cable that cannot twist freely during installation, or where loops of cable introduce twists. Damage to armour can result in bird-caging and sheath splits.

Workers pulling cable across pipes to supply energy to a neighbourhood

Avoiding cable torsion when pulling is important, and is largely addressed by using rotating pulling heads and a suitable cable pulling sock. Pulling the cable through a rope will restrict rotation and can create problems. Tension built up around each bend will propagate back down the cable, causing issues nearer the drum.

Conclusion

Competent and experienced cable installation teams, using the correct equipment including tension-monitored winches, pulling socks, and a generous quantity of rollers and guides, should experience fewer problems while ensuring a trouble-free installation.

Top 10 Articles | Thorne and Derrick & BASEC #CABLEQUALITY

With a shared passion and ambition to enhance electrical safety through the education and encouragement of industry stakeholders to specify and buy accredited, tested and certified Quality Cables & Cable Accessories.

#CableQuality is the hashtag – securing public safety through the specification and installation of BASEC approved and verified LV MV HV electrical cables by competent and qualified electricians is the objective.

Read on………

- Promoting Good Practices For Cable Products Following The Grenfell Tower Report

- End User Specification Of Approved Cable Products: Where Is The Value?

- Fire Testing Of Cables Is Important, But Not At The Expense Of Other Characteristics

- Top Dos And Don’ts – Cable Delivery, Pulling And Installation

- How To Write A Good Cable Specification

- New Testing and Certification Scheme Launched for YY, SY, CY Control Cables

- Specifying Quality Cable For Your Projects

- When Quality Matters: Early Indicators Of Error

- Tratos Supplies BASEC Approved Medium Voltage Cables Into WPD

- Electricians Guide to CPR

THORNE & DERRICK

Cable Pulling Equipment

Thorne & Derrick distribute an extensive range of Cable Pulling & Laying Equipment to enable the safe installation of fibre and copper cables within the telecommunications industry. Safely installed cables reduces operational and maintenance requirements to the network and reduced service interruption to telecom cables, wires, ducts, cabinets and exchanges – products include cable spiking tools, conduit rods, cable lubricant, cable socks and cable rollers.

Cable Replacement, Splicing & Terminating : A Video Tutorial

September 19th, 2019

Martha Davis

The following cable replacement tutorial has been republished with kind permission of Martha Davis (Senior Director of Content – T&D World and Utility Analytics Institute) from Transmission & Distribution World and their video sponsor Burns & McDonnell.

Burns & McDonnell is a full-service engineering, architecture, construction, environmental and consulting solutions firm, based in Kansas City, Missouri.

Participating Utility: Kansas City Power & Light (KCP&L).

Transmission & Distribution World’s mission is to provide utility executives, managers, engineers, supervisors, operators and linemen with must-read information on:

- Design

- Engineering

- Construction

- Operation

- Maintenance of the Electric Power-Delivery Systems

This includes an in-depth understanding of transmission, distribution, substations, automation and power flow control.

Want to learn how to perform tasks in the field?

T&D How videos are real-life and shot-on-site, showing transmission and distribution crews and cable splicers at work.

cable replacement project begins

Video: Kansas City Power & Light (KCP&L) crews begin a cable replacement project at the Meritex Caves in suburban Kansas City.

In Part 1, the crew installs new cable between an above-ground enclosure and a three-phase distribution pole. The linemen crew in the bucket truck prepare a copper cable feed from overhead to underground – a boom is used to enable a vertical cable lift by attachment to a wire mesh Kellem cable grip. The cable pull positions the cable onto the pole. An Altec cable pulling frame supports the cable pull into the underground cable duct.

Cable Replacement | termination

Video: In Part 2 we watch crews install a new di-electric switch in the caves below ground and pull cable from above ground, then create new splices into the switch.

See the engineers use “noisy sticks” to provide electrical safety check procedures for voltage detection and isolate the high voltage switching cubicles. The solid-dielectric-in-air fault interrupting switch is positioned for the cable splicer to commence cable termination.

The cable termination process starts with the “tamping down” of the neutrals prior to sliding on the cold shrink tube and separable tee-connector cable termination. Semi-conductor insulation is peeled back and cable insulation cut away with the aid of a heat shrink gas torch to soften the insulation layer. Compression style crimp lugs are terminated onto the cable using battery crimping tools as the cable is connected to the switch.

cable splicing

Video: In Part 3 a splicing crew installs new splices at the enclosure feeding power from the distribution pole to the caves underground.

See the cable splicer working 6 cables into the enclosures from the pole – peeling back the cable outer jacket on the concentric neutrals and installing protective water-sealing mastic and cold shrink. Clearances are measured and heat source used to expose cable imperfections, such as cuts, which can then be located and removed by sanding.

The medium voltage cable is terminated to the neutral busbar using separable elbow tee-connectors. Dummy caps are installed and used to test the ground wires.

3m scotch tape for electrical insulation

Video: In Part 4 crews go up on the distribution pole to create new splices and secure the grounding wire.

The distribution pole has been re-cabled and ready for connection as the cable phases are designated A, B and C by the linemen/splicers and prepared for termination.

The cable semi-con is stripped, cable lug depths measured, heat applied to the cable, insulation surfaces cleaned and sanded and cold shrink applied.

Watch the electrical taping techniques of the experienced cable jointer using 3M Scotch 33 tape to provide electrical insulation layers to the cable – neutral tails are taped up and switches opened up to begin the cable connection.

💡 Some 3M Scotch Electrical Tapes Tips & Skills….

closing the switches

Video: In Part 5 the crew adds jumpers and closes the switches to energise the line, bringing power from above ground to 80 feet under in the Meritex Caves, using new and larger cable to meet increased electrical demand.

Watch the linemen and cable splicers “running the tops”, use “pelicans” (hotline clamps) and wire brushes to clean thoroughly. Fault indicators are applied and “beat-on” wedge connectors installed by hammer. The “pelicans” are connected to the switch pins and a drop-out wire installed down from the arrester. Lastly, cable tags are used to provide identification to the medium voltage cables allowing energisation of the cable once switches are closed using switch sticks.

Press Release | Thorne & Derrick Appointed Approved Stockist for UK Leading Cable Pulling Equipment Manufacturer

Thorne & Derrick are national distributors of LV, MV & HV Cable Installation, Jointing, Substation & Electrical Equipment – servicing businesses involved in cabling, jointing, substation, earthing, overhead line and electrical construction at LV, 11kV, 33kV, 66kV and EHV. Supplying a complete range of power cable accessories to support the installation and maintenance of low/medium and high voltage power systems:

- Slip-on Cable Terminations

- Cold-shrink Cable Terminations

- Heat-shrink Cable Terminations

- Cable Joints – Heat & Cold-shrink

- Separable Connectors (Euromold)

- Surge Arresters & Switchgear/Transformer Bushings

Key Product Categories: Duct Seals | Cable Cleats | Cable Glands | Electrical Safety | Arc Flash Protection | Cable Jointing Tools | Cable Pulling | Earthing | Feeder Pillars | Cable Joints LV | Joints & Terminations MV HV

Cable Ploughing | Meet ATP The European Utility Ploughing Specialists

September 12th, 2019-

uploaded by Chris Dodds - Sales & Marketing Manager (Thorne & Derrick) with kind permission of Ben James - Operations Manager ATP Cable Plough

Cable Ploughing

Electricity, Gas, Water, Telecomms & Railways

ATP are the UK’s leading utility installation contractor to use cable ploughs to install LV MV HV Power & Fibre Cables into underground cable trenches – cable ploughing is a modern trenchless technology delivering fast and efficient laying of cables, pipes and fibre optics with minimal ground damage. The highly skilled and experienced workforce of ATP successfully operate specialist equipment to achieve safe installations of pipes and cables below ground.

This aspect of the Cable Plough’s operation is particularly significant when working in areas of outstanding natural beauty such as National Parks, SSSIs, or areas which are particularly sensitive to ecological and environmental issues. Consequently, it provides designers and specifies an opportunity to soften the impact of schemes when route planning.

Because Cable Plough causes minimal disruption to the ground’s geological structure, it offers a significant reduction in time, money and risk for the client and contractor – cable ploughing also operates very effectively on soft ground and marshland, has the ability to work on almost any terrain and manoeuvre around most obstacles.

Added to this, as it cuts, installs and back-fills the cable trench – all in one operation – the Cable Plough’s method eliminates any risk of trench-collapse and associated health and safety concerns. Ploughing cables provides a huge increase in productivity compared to conventional utility working methods.

Environmentally friendly cable ploughing offers a significant reduction in time, money and risk for the client and contractor. Contact ATP to discuss your requirements.

The Benefits of Ploughing Cables

Environment

The most significant advantage of the Cable Plough is its low-impact on the environment.

Whilst traditional methods of pipe and cable installation require a sizable trench to be dug and then refilled, the Cable Plough’s efficient way of cutting a narrow slit into the soil causes only minimum disturbance to the land.

For local authorities and planners, the laying of supply lines can pose huge problems, especially when installations pass through protected countryside or areas of outstanding natural beauty.

Initially, ATP will carry out a site survey and report back any issues to the client.

Then, with little or no preparatory work required – such as removing top-soil, extracting large stones or excavation; work can begin.

With only a narrow cut into the ground, there is little damage and therefore no structural changes to the geological formation of the earth. Then, with an almost automatic closure process, it does not take long for the area of land to return to it’s original and natural state.

Installation of 1x40mm² fibre cable over 2km in one tide. Cable depths installed were 1.5m. Very hard compacted sand ground on UK’s 2nd hottest day on record (24th July). Safe and well executed project with meticulous planning and attention to detail. Operators safety and machine performance with the highest quality standards of installation. The demarcation between plough operation and public safety was well marshalled and coordinated by GPC in their project planning with safety and exclusions well established.

Cable Plough Project | Southport Landfall Fibre Cable Installation by ATP

Flexible

Whether it is flat, hilly, or undulating terrain, the adaptability of the Cable Plough enables it to cope with almost any surface. It is also capable of operating in wet and adverse areas, such as across marshland, through ditches and even into rivers, provided the water is no more the 1m deep.

The all-round flexibility enables it to plough around or adjacent to a variety of obstacles, such as: rocks, trees, barriers, hedges and walls, by lifting or moving the jibs and positioning the wheels to one side, or around the object.

Because of its agility, the Cable Plough is ideal for carrying out roadside projects, as signs, fences and barriers can easily be negotiated and need not be moved. It can even follow curves in the road to a radius of 4m. Also, because of way the cable plough installs, reinstatement of the ground is easily carried out, so there is less likely-hood of having to hold up traffic, or the need to have staff working on the roadside for lengthy periods of time.

Installation of 20kV (3x630sqmm in trefoil and 1x Ø32 cable duct and cable warning tape over 28km. Depths installed at are 1.8m. Ground conditions were particularly hard in places with clay and sections of deep peat. Duct installation was completed ahead of the civil contractor completing the access roads for the windfarm construction. Reducing sub-contractor interface, pinch points and overall programme of works.

Efficient

As well as the cost to the environment, the conventional methods of laying pipes and cables can be extremely labour intensive and time consuming. As the Cable Plough cuts into the ground, installs and backfills in one operation, it can cover a far greater distance in a day. In fact, if conditions allow it can work at a speed of up to one kilometre per hour!

Because of the way the Cable Plough operates, it requires less manual input than traditional methods, especially when it comes to reinstatement. It is also capable of carrying three drums of cables or pipes at once – another factor which adds to its efficiency.

Cable Plough is also efficient in the way it makes installations.

The unique design of the combined blade and guidance system means that pipes and cables are laid exactly in accordance to regulations – whatever the speed of travel.

In fact, inspections have proved that pipe and cable installations carried out by the Cable Plough are of better and more uniform quality than that of open trench methods.

Installation of 1 x 11kV cable into trench and cable warning tapetile over 4km. Cable depths installed were 1.4m. Ground conditions were ideal for ploughing with some areas of flint in remote areas. Hedge crossings and ditches were passed in a number of locations on the route removing the need for HDD offering considerable cost savings to their client. All sites ploughed were reinstated within twenty-four hours to minimise the environmental impact. The project team manoeuvred plant and equipment around site and between sections safely with good coordination with Traffic Management on fast moving A Roads.

Effective

Each installation project starts with the power-winch being safely sited ahead of the Cable Plough in an area where it can secure itself by dropping its anchor into the ground. However, in the case of roadside installations, the cable winch is capable of gripping to the asphalt without the need of its anchor.

The Cable Plough is capable of installing everything from a small cable to a SDR11 620mm diameter pipe.

In one operation it can install several cables and/or pipes, plus lightning conductors and warning tapes – this includes high voltage cables, up to 220 kV in the prescribed triangular combination, or two systems with a lateral spacing of 120mm.

The cable laying depth is infinitely adjustable to a depth of 2 metres and, cable or underground pipe installations can be carried out in nearly all ground conditions, such as dry soil, marshland and even soft rock.

The Cable Plough’s operation means that its cutting blade is controlled in such a way that the insertion angle is adjusted to the curvature of the earth. This means that cables and pipes are carefully laid, with no strain or tension.

As the blade cuts through the earth is creates a channel that forms the installation bed.

As the Cable Plough continues forward, the aperture is firmly closed to approximately half its depth and the earth forms a bridge over the cable or pipe. Therefore, the lower part of the cut remains open and is gradually filled by the penetration of silt.

Installation of 3x20kV (630sqmm) cables in trefoil arrangement and 1x Ø40 cable duct (for fibre optics) and warning tape over 4.5km. Cable depths installed were 2.4m in three separate locations in wet winter months of 2018. Ground conditions were particular difficult with dewatering issues and ditch crossings overcome by our client. Safe and well executed project complete with mobilisation and demobilisation from the UK.

Cable Ploughing Applications

Telecomms

- Telecomms

- Fibre optic – Zero Tension

- Communication Ducts

- Copper Cables

- Roadside & Highways Communication Lines

Electricity

- High Voltage Cables up to 132kV

- Electrical Cable Ducts

- Lightning Protection & Warning Tape

- DC Cables & Ducting

- Sub Sea Cables

Gas

- HDPE Ducts (up to 620mm)

Water & Sewerage

- HDPE Ducts (up to 620mm)

Railways

- Multiple Cables, Ducts & Warning Tapes

Cable Plough | ATP providing cable ploughing technology to Spui Windpark, owned by Japanese renewables developer Eurus Energy Group, is located in the municipality of Hoeksche Waard in southern Holland. The wind farm consists of five Enercon E-126 EP4 wind turbines, each with a rated power of 4.2MW, hub heights of 135 metres and rotor diameters of 127 metres.

Get In Touch

Contact ATP

- Jason Thomas (+44) 07969 225476 (Managing Director)

- Ben James (+44) 07557 516273 (Operations Manager)

- Visit https://www.atpcableplough.com/

- Email [email protected]

THORNE & DERRICK

Thorne & Derrick are national distributors of LV, MV & HV Cable Installation, Jointing, Substation & Electrical Equipment – servicing businesses involved in cabling, jointing, substation, earthing, overhead line and electrical construction at LV, 11kV, 33kV, 66kV and EHV. Supplying a complete range of power cable accessories to support the installation and maintenance of low/medium and high voltage voltage power systems:

- Slip-on Cable Terminations

- Cold-shrink Cable Terminations

- Heat-shrink Cable Terminations

- Cable Joints – Heat & Cold-shrink

- Separable Connectors (Euromold)

- Surge Arresters & Switchgear/Transformer Bushings

Key Product Categories: Duct Seals | Cable Cleats | Cable Glands | Electrical Safety | Arc Flash Protection | Cable Jointing Tools | Cable Pulling | Earthing | Feeder Pillars | Cable Joints LV | Joints & Terminations MV HV

MULETAPE v Rope : Pulling Cables Into Cable Ducts To Avoid Duct Cutting

February 27th, 2019

Manufacturers of MULETAPE

-

uploaded by Chris Dodds - Thorne & Derrick Sales/Marketing Manager MULETAPE | Made in USA | Distributed in the UK & Europe by Thorne & Derrick

Burn Through

The Case for MULETAPE vs. Rope

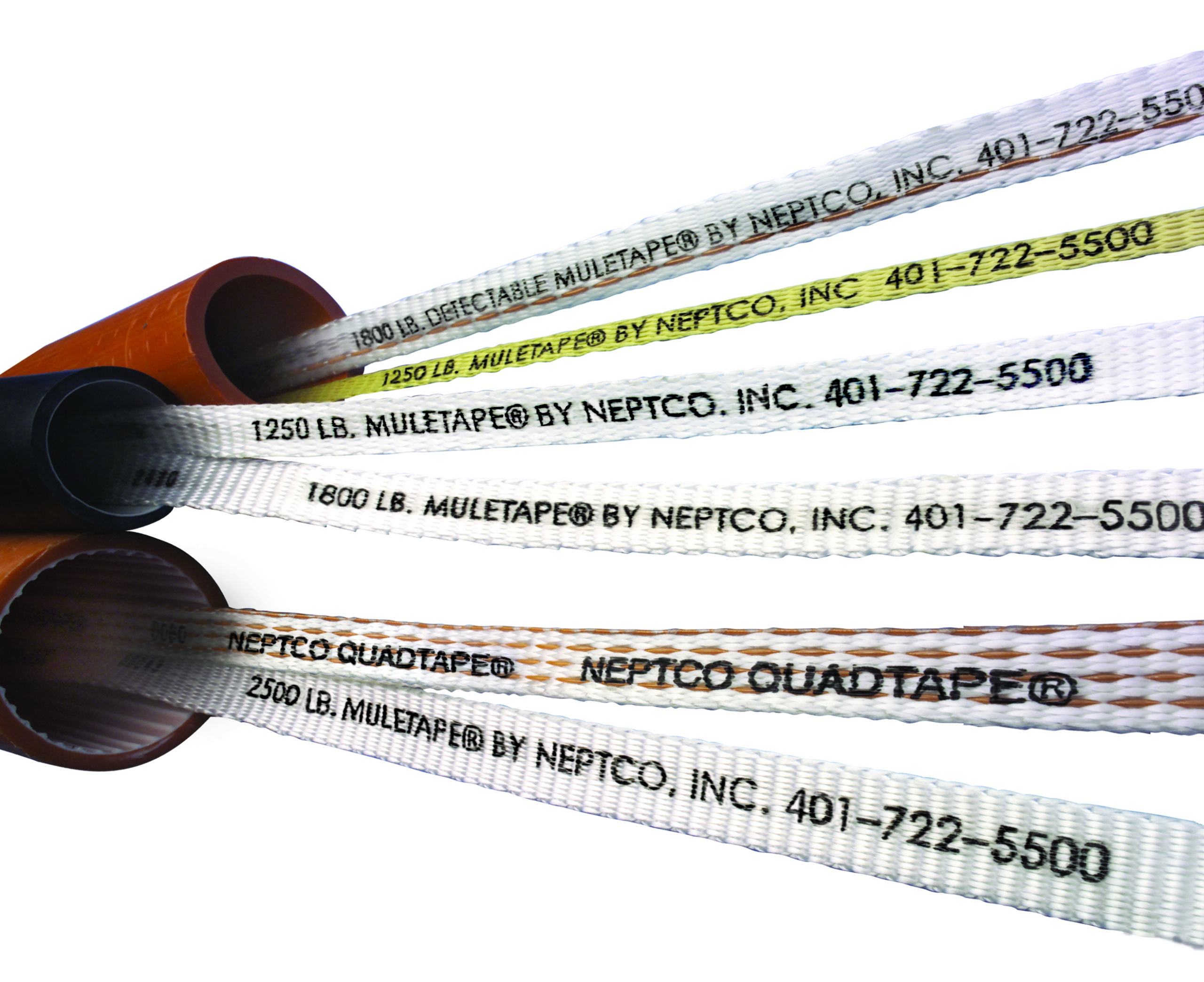

NEPTCO is a global leader in the manufacturing of materials used for the Detection & Pulling of Cables for a wide variety of commercial and industrial applications.

In this Blog, NEPTCO answer questions regarding their advanced specification MULETAPE which includes a comparison to using traditional cable pulling ropes.

NEPTCO’s range of measuring and pulling tapes substantially reduce cable installation labour, materials and stock holding costs by providing a threading line, a measuring tape and a winch line all in one product – this reduces damage to underground plants, improves efficiency and enhances worker safety.

NEPTCO’s range of measuring and pulling tapes substantially reduce cable installation labour, materials and stock holding costs by providing a threading line, a measuring tape and a winch line all in one product – this reduces damage to underground plants, improves efficiency and enhances worker safety.

Q: What is “burn through?”

A: When polypropylene rope is pulled through PVC or polyethylene duct, the friction generated by the rope rubbing against the conduit wall creates enough heat to actually “burn through” the cable ducting or conduit – this can occur with or without cable lubricant

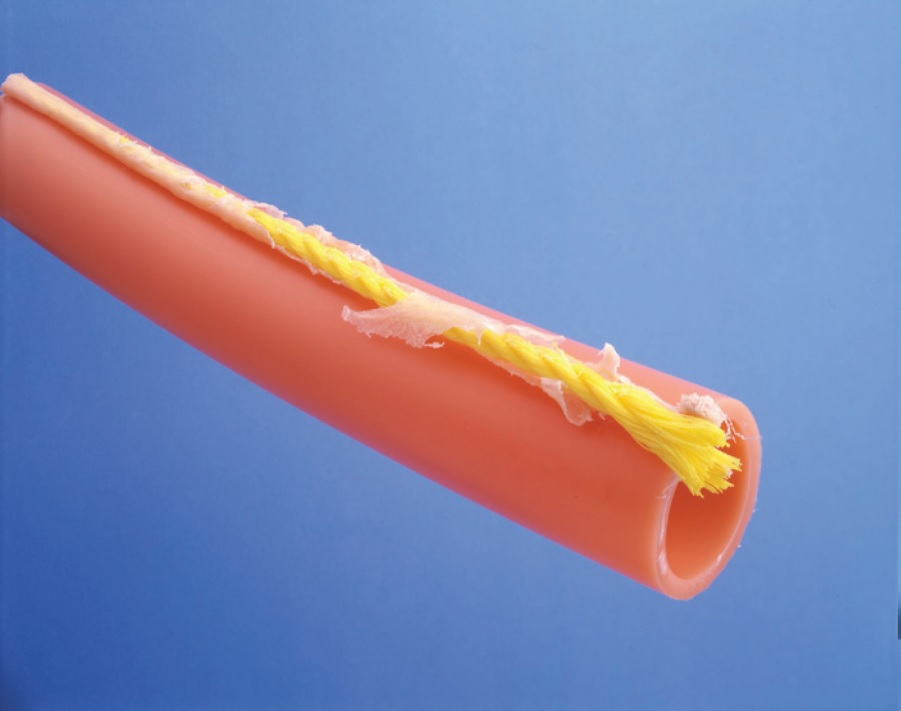

“Burn Through” caused by the friction from cable pulling rope.

Q: Why should this matter to me?

A: Aside from damaging the conduit or cable duct and creating opportunities, the jagged edges of the burned conduit pose a real threat to the cable installed by the contractor.

Cable surging through the damaged conduit or duct at an average rate of 100 ft. per minute will catch on the damaged areas of conduit, shredding the outer jacket. Fibre Optic cables are particularly vulnerable since the situation which can lead to excess tension and can cause micro-bending. As a result, the cable may fail prematurely, or simply not function at all.

A damaged cable as a result of using cable pulling rope.

Q: How does NEPTCO know these things happen? After all, you can’t see what’s happening underground!

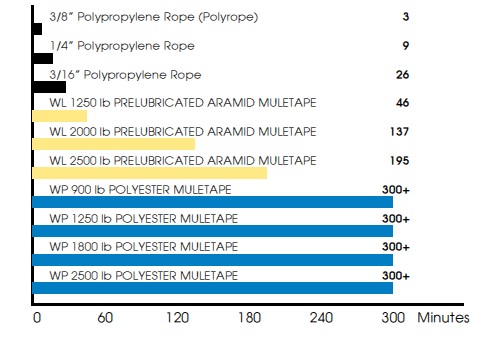

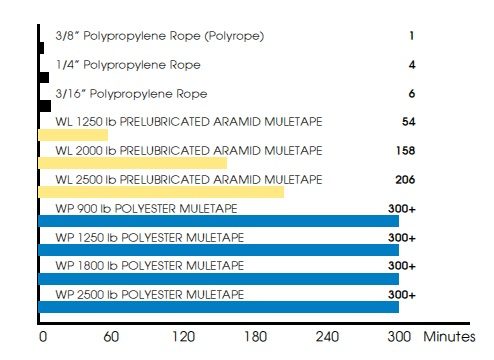

A: NEPTCO has gone to great lengths to test this theory by duplicating installation conditions in the lab and in the field. Their research engineers designed the Duct Cut Tester to evaluate the performance of various conduit materials and winch lines under typical installation conditions.

The results tabulated on the reverse side of this sheet are conclusive: pre-lubricated MULETAPE out-performs polypropylene rope in every installation scenario.

Q: Why does MULETAPE work so much better than cable pulling rope?

A: MULETAPE is pre-lubricated, which helps reduce friction and the heat it generates, but MULETAPE’s wide and flat profile is also important. A round rope will concentrate all heat and energy on the small area where the rope comes in contact with the innerduct. MULETAPE is flat, and therefore spreads this heat and energy across a wider area, reducing the chance of burn through.

|

|

| MULETAPE by NEPTCO | Cable Pulling

|

|

NEPTCO Duct Cut Tester

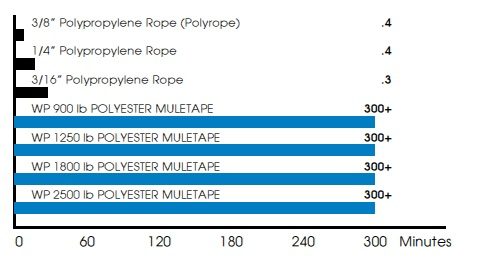

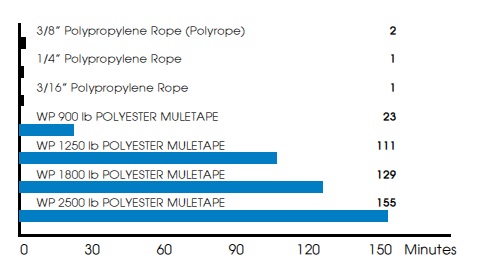

The charts below indicate the time elapsed before conduit experiences damage due to burn through:

Duct Cutting in Corrugated 1.5” ID HDPE Subduct |

Duct Cutting in Smooth Walled 1.5” ID HDPE Subduct |

Duct Cutting in Corrugated 1.5” ID PVC Subduct |

Duct Cutting in 2” Schedule 40 PVC 90° Subduct |

Q: Okay, I understand that burn through is a problem, but I’m still not convinced this is really happening in the field. Do you have any evidence that cable can actually be damaged in a real installation?

A: Absolutely. If you have ever experienced a rope breaking during a pull, it is caused by the cable getting snagged on a duct that has been burned through. The rope is usually narrower than the cable and pulling sock and is able to make its way back into the duct, however, because the cable and pulling sock are wider they may not be able to make their way back into the duct. When this happens, the tension rises, the pull becomes more difficult and the rope may break. This not only causes a health and safety hazard, the possibility that the cable is damaged is extremely high. In 1999, NEPTCO recreated a typical installation scenario in an above-ground test. The results were just as expected – the rope burned through the conduit in seconds, while the MULETAPE caused no damage.

To request a video of this experiment in CD or VHS format, please contact [email protected]

MULETAPE Features & Benefits

- Eliminates the potential for cable duct cutting

- Lower elongation reduces snap-back and enhances

- Worker safety reduces tension at the start of a cable pull

- Sequential footage or metric markings

- Reduces material, inventory and freight costs

- Cable pulling strength – 200 lbs. to 6000 lbs

- Patent pending

MULETAPE Ordering Information

| Item | MULETAPE Part Number | Strength (kg) | Typical Bowline Strength (kg) | Typical Muleknot Strength (kg) | Pail Quantity (km) | Approx Pail Weight (kg) | Pails Per Pallet |

| 41271 | WP400P | 182 | 86 | 136 | 1.4 | 6 | 27 |

| 41325 | WP1800P | 818 | 377 | 636 | 0.4 | 6.4 | 27 |

Request Your FREE MULETAPE Sample

Our products substantially reduce cable installation labour, materials, and inventory costs by providing a threading line, a measuring tape, and a winch line all in one product. Reduces damage to underground plants, improves efficiency, and enhances worker safety.

You can’t miss this opportunity if you are a Utility Company or a Contractor. Weather you are looking for pulling tapes, or a tracer wire, before you invest a large amount, we are giving you the option to see our products look and feel.

MULEGLIDE Cable Blowing & Cable Pulling Lubrication

NEPTCO‘s long-lasting silicone cable blowing/pulling lubricant called MULEGLIDE is an ideal LV, MV & HV cable lubricant, available as low-viscosity Underground Cable Blowing Lubricant or MV HV Underground Cable Pulling Lubricant, which allows for swift and safe underground cable installation.

Further Reading

- MULETAPE CALCULATOR | How To Select The Right Cable Pulling Tape For The Job

- Thorne & Derrick Appointed Approved Stockist for UK Leading Cable Pulling Equipment Manufacturer

Cable Pulling & Laying Equipment

Suppliers & Distributors

Thorne & Derrick distribute the most extensive range of Low & High Voltage Cable Installation & Electrical Distribution Equipment to the Power Transmission & Distribution industry in the onshore and offshore wind, solar, rail, oil/gas, data centre, battery storage and utility sectors – this includes the most extensive range of Cable Pulling & Cable Laying Equipment to enable the installation of low, medium and high voltage power cables into underground trench or duct.

We service UK and international clients working on underground cables, overhead lines, substations and electrical construction at LV, 11kV/33kV and up to EHV transmission and distribution voltages.

Key Products: MV-HV Cable Joints & Terminations, Cable Cleats, Duct Seals, Cable Transits, Underground Cable Protection, Copper Earth Tapes, Cable Jointing Tools, Feeder Pillars, Cable Ducting, Earthing & Lightning Protection, Electrical Safety, Cable Glands, Arc Flash Protection & Fusegear.

Distributors for: 3M Electrical, ABB, Alroc, Band-It, Cembre, Centriforce, CMP, Elastimold, Ellis Patents, Emtelle, Furse, Lucy Zodion, Nexans Euromold, Pfisterer, Polypipe, ProGARM, Prysmian, and Roxtec.

- Scope –single-source supply of extensive range of products

- Stock – a multi-million pound stock holding provides complete global supply solutions

- Staff – technical support from a trained, proactive and friendly team

- Delivery – UK stock turnaround with express logistics to all international destinations

How To Install Detectamesh – The Warning Tape For Buried Cables, Pipes & Underground Services

November 19th, 2018

The Warning Tape For Buried Cables, Pipes & Underground Services

-

uploaded by Chris Dodds - Thorne & Derrick Sales & Marketing Manager

Boddingtons Detectamesh detectable underground warning tapes are a coloured plastic detectable mesh netting for cable marking and detecting buried underground pipes, electricity cables and utility services.

The underground warning tapes for marking electricity cables and utility pipes (gas and water) are available in a range of different colours and different texts available in 200mm x 100m for the protection and visual identification of electric, water and gas utility services.

Detectamesh

The following Blog explains the installation process of the Detectamesh mesh netting:

Step 1

It is recommended that the detectable mesh be buried halfway between the buried service (cable or pipe) and the surface of the earth.

Step 2

Unroll the Detectamesh onto the backfill in the cable trench or utility trench ensuring that it is earthed at both ends.

Step 3

Join the wires of rolls or cut lengths using Boddingtons crimps.

Step 4

Backfill the trench further to the surface.

Step 5

The detectable mesh can easily be detected down to one metre.

Step 6

Please consult Thorne & Derrick for further details of the exact depth your equipment can locate to.

Detectamesh Detectable Mesh Installation

BODDINGTONS CRIMPS & CRIMPING TOOL

Ensuring a continuous signal along the Detectamesh is vital – it is recommended to use the Boddington wire crimps and crimping tool. This gives the join sufficient strength to cope with most back fills into the trench. If it is not installed correctly then the signal may not pass from join to join.

Step 1

Crimping Tool & Stainless Steel Wire Crimps

Peel back the top tape at one end to expose the wire

Step 2

Insert the crimp over the wire on one of the mesh rolls. Push the wire right through so that about 5mm protrudes from the end

Step 3

Insert the wire from the other mesh into the crimp

Step 4

Crimp the joint together using the crimping tool

Step 5

Check that you have a strong connection by pulling firmly on the two ends. If the wire comes out, make the connection again

Step 6

The Detectamesh can now be laid and the trench back filled

Boddingtons | Detectamesh | Utilitape Underground Warning Tapes | Cable & Pipeline Protection Mesh | Plastic Cable Protection Covers

Cable Pulling Equipment

Thorne & Derrick distribute an extensive range of Cable Pulling & Laying Equipment to enable the safe installation of fibre and copper cables within the telecommunications industry. Safely installed cables reduces operational and maintenance requirements to the network and reduced service interruption to telecom cables, wires, ducts, cabinets and exchanges – products include cable spiking tools, conduit rods, cable lubricant, cable socks and cable rollers.