Feeder Pillars

July 23rd, 2021

EV Charging Feeder Pillars

EV Feeder Pillars

EV Charging

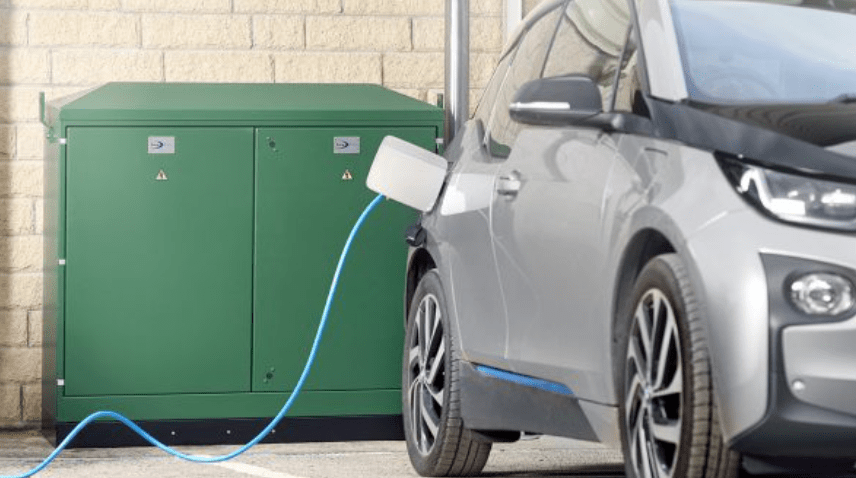

Lucy Zodion manufacture a wide range of products suitable to provide Low Voltage Electrical Power Distribution for EV charge points – from distribution network operator (DNO) accredited cut-outs and isolators for on-street chargers, to feeder pillars for electrical vehicle charging.

Meet the increasing demand for accessible EV charging points with power distribution solutions that connect DNO supply with charging outlets. Lucy Zodion’s adaptive and reliable supply solutions consider the charge speeds and times each EV charge point is capable of, from fast to super, to ensure you receive the most suitable and compatible option.

As one of the UK’s leading suppliers of pre-wired power distribution enclosures, Lucy Zodion have developed a standard range of pillars that will support EV charge point requirements that fall into the four categories of main current rating: 100 Amp, 200 Amp, 400 Amp and 630 Amp, providing a link between the DNO and EV charge points. The configuration of all EV feeder pillars in this range can be upgraded once installed to meet future demand requirements.

3-Phase AC Supply | 100 Amp Feeder Pillars

| EV Feeder Pillar Type |

Fortress Pillar Size 14 |

| Part Number |

EV1008007 |

EV1003022 |

EV1002043 |

EV1001050 |

| Rating |

7kW (40A SPN) |

22kW (40A TPN) |

43kW (63A TPN) |

50kW (80A TPN) |

| No. of charge points per feeder pillar |

8 |

3 |

2 |

1 |

| Dimensions H, W, D (mm) |

1300,1250,450 |

1300,1250,450 |

1300,1250,450 |

1300,1250,450 |

| Weight |

250kg |

250kg |

250kg |

250kg |

| Main incomer (MCCB) |

✓ |

✓ |

✓ |

✓ |

| Mild steel: Hop dip galv 3mm |

Wedgelocks |

Wedgelocks |

Wedgelocks |

Wedgelocks |

| Lock type |

✓ |

✓ |

✓ |

✓ |

| Anti-condensation heater |

✓ |

✓ |

✓ |

✓ |

100 Amp supply pillar is the smallest feeder pillar within the range and is available in four different configurations. These pillars cover 7kW supplies through to 50kW, with a differing number of connections on each solution.

100 Amp Supply Feeder Pillar

3-Phase AC Supply | 200 Amp Feeder Pillars

| EV Feeder Pillar Type |

Fortress Pillar Size 24 |

| Part Number |

EV1008007 |

EV1003022 |

EV1002043 |

EV1001050 |

| Rating |

7kW (40A SPN) |

22kW (40A TPN) |

43kW (63A TPN) |

50kW (80A TPN) |

| No. of charge points per feeder pillar |

16 |

6 |

4* |

3* |

| Dimensions H, W, D (mm) |

1600,1250,450 |

1600,1250,450 |

1600,1250,450 |

1600,1250,450 |

| Weight |

275kg |

275kg |

275kg |

275kg |

| Main incomer (MCCB) |

✓ |

✓ |

✓ |

✓ |

| Mild steel: Hop dip galv 3mm |

Wedgelocks |

Wedgelocks |

Wedgelocks |

Wedgelocks |

| Lock type |

✓ |

✓ |

✓ |

✓ |

| Anti-condensation heater |

✓ |

✓ |

✓ |

✓ |

* Use of load management on chargers required

200 Amp Supply Feeder Pillar

200 Amp supply pillar within our range is available in four different configurations.

These pillars cover 7kW supplies through to 50kW, with a differing number of connections on each solution.

3-Phase AC Supply | 400 Amp Feeder Pillars

| EV Feeder Pillar Type |

Fortress Pillar Size 40 |

| Part Number |

EV4001222 |

EV4008043 |

EV4005050 |

EV4002120 |

| Rating |

22kW (40A TPN) |

43kW (63A TPN) |

50kW (80A TPN) |

120kW (250A TPN) |

| No. of charge points per feeder pillar |

12 |

8* |

5* |

2* |

| Dimensions H, W, D (mm) |

2200/2850/600 |

2200/2850/600 |

2200/2850/600 |

2200/2850/600 |

| Weight |

400kg |

400kg |

400kg |

400kg |

| Main incomer (MCCB) |

✓ |

✓ |

✓ |

✓ |

| Mild steel: Hop dip galv 3mm |

Barlock (3 point) |

Barlock (3 point) |

Barlock (3 point) |

Barlock (3 point) |

| Lock type |

✓ |

✓ |

✓ |

✓ |

| Anti-condensation heater |

✓ |

✓ |

✓ |

✓ |

400 Amp supply pillar within our range is available in four different configurations.

These pillars cover 22kW supplies through to 120kW, with a differing number of connections on each solution.

3-Phase AC Supply | 600 Amp Feeder Pillars

| EV Feeder Pillar Type |

Fortress Pillar Size 40 |

| Part Number |

EV6301822 |

EV6301043 |

EV6307050 |

EV6303120 |

| Rating |

22kW (40A TPN) |

43kW (63A TPN) |

50kW (80A TPN) |

120kW (250A TPN) |

| No. of charge points per feeder pillar |

18 |

10 |

7 |

3 |

| Dimensions H, W, D (mm) |

2200/2850/600 |

2200/2850/600 |

2200/2850/600 |

2200/2850/600 |

| Weight |

400kg |

400kg |

400kg |

400kg |

| Main incomer (MCCB) |

✓ |

✓ |

✓ |

✓ |

| Mild steel: Hop dip galv 3mm |

Barlock (3 point) |

Barlock (3 point) |

Barlock (3 point) |

Barlock (3 point) |

| Lock type |

✓ |

✓ |

✓ |

✓ |

| Anti-condensation heater |

✓ |

✓ |

✓ |

✓ |

Further Reading

➡ More Lucy Zodion Blogs:

Galvanised & Stainless Steel | GRP | Pre-Wired | Underground Retractable Feeder Pilars

THORNE & DERRICK SPECIALIST ELECTRICAL DISTRIBUTOR

LV ♦ MV ♦ HV

T&D distribute the most extensive range of LV, MV & HV Cable Jointing, Terminating, Pulling & Installation Equipment – we service UK and international clients working on underground cables, overhead lines, substations and electrical construction at LV, 11kV, 33kV and EHV transmission and distribution voltages.

- Key Products: MV-HV Cable Joints & Terminations, Cable Cleats, Duct Seals, Cable Transits, Underground Cable Protection, Cable Jointing Tools, Feeder Pillars, Cable Ducting, Earthing & Lightning Protection, Electrical Safety, Cable Glands, Arc Flash Clothing & Fusegear.

- Distributors for: 3M, ABB, Alroc, Band-It, Catu, Cembre, Centriforce, CMP, Elastimold, Ellis Patents, Emtelle, Furse, Lucy Zodion, Nexans Euromold, Pfisterer, Polypipe, Prysmian, Roxtec.

LV – Low Voltage Cable Joints, Glands, Cleats, Lugs & Accessories (1000 Volts)

MV HV – Medium & High Voltage Cable Joints, Terminations & Connectors (11kV 33kV EHV)

Cable Laying – Underground Cable Covers, Ducting, Seals & Cable Pulling Equipment

June 10th, 2021

May 5th, 2021

Prevent your LV Switchboard from Overheating

LV Switchboards

The monitoring of the heat build-up, often carried out by thermography, allows early detection of anomalies that will lead to spurious tripping or even fire and the immobilisation of the installation for a long period. It is therefore a subject that deserves our full attention because it deals with the safety and availability of the installations and therefore the continuity of production.

Thermography is a solution that ensures that there is no abnormal heating of the switchboard during operation.

However, well before its operation, at the time of specification, purchase and installation of the switchboard, there are a few keys factors not to be overlooked.

In the field of high-power, withdrawable, low-voltage switchboards, it is possible to have a positive influence on the future of the installation from the moment of purchase. Similarly, the choice of equipping the switchboard with certain devices allowing easy and safe access to the components to be controlled will make its’ operation simpler and safer.

A good, original design, continuous monitoring and appropriate maintenance are key to the durability and reliability of the electrical panel over the years.

1. Design your LV switchboard according to the IEC 61439-2 standard

A well-designed electrical panel should be chosen, it should be validated in all respects according to IEC 61439-2. Indeed, this standard requires tests and checks to ensure that each component is implemented in accordance with the rules of the standard and that the temperature rise is perfectly controlled, within acceptable limits.

By carrying out these tests, the original manufacturer has the data at its disposal that enables it to produce suitable, reliable and long-lasting low-voltage assemblies, in line with their operating conditions.

Temperature rise tests on an LV switchboard

2. Maintain your LV switchboard regularly

During installation, care should be taken to ensure that the air vents are not obstructed or limited in their effect to ensure natural ventilation of the switchboard.

The cleanliness of the air vents but more generally of the electrical panel should be periodically checked to avoid any degradation of the intrinsic qualities of the assembly. In addition, the forms of internal separation will not be removed, they are the ones which ensure the protection of the personnel during the thermography and maintenance campaigns.

3.Monitor heat build-up by thermography

Thermography campaigns require going as close as possible to, and aiming at, live components. In doing so, the operator will take more risks than during the operation of his switchboard.

In addition to periodic inspections, certain safety features can facilitate or supplement the monitoring of overheating. Discover the safety elements that can be implemented at the time of the initial investment or modernisation of your existing installation.

Easy & Secure Access

Inspection of the cable terminations is a must. Easy access and the width of the cable sheath are criteria to be considered. The position and shape of the downstream power connections are elements that can bring a increased ease of this operation.

For feeders, the possibility of opening the front opening drawer allows all components and all clamping points of the drawer to be seen.

If this option was not chosen at the time of purchase, the starter may have been fitted with a sighting window, which will nevertheless allow some thermal readings to be taken, but in a much smaller sighting area.

Thermographic sighting

The main busbar, which is often placed in the upper position of the switchboard, can also be examined. The main purpose is to check the temperature at the busbar joints and connections. The fewer they are, the fewer points to be monitored.

The roof of the electrical panel must meet certain safety requirements:

- Easy removal of the sheet metal

- Equipment of removable sheets with captive bolts

- Presence of forms of protection

By its’ design, the assembly must facilitate this operation, which is often uncomfortable to carry out because it is high up and close to live elements.

When choosing the LV switchboard, it is therefore important to ensure that it offers a safe and easy access solution for this type of operation.

The power connections on the incoming circuit breaker(s) are also often difficult to access. This is particularly true for switchboards with cable connections from the front. In this case, permanently readable infrared sensors can be offered.

Points of Vigilance for Sighting Devices without Dismantling

For sighting devices without dismantling (arc-proof windows, large arc-proof windows, grids), the solution must allow measurements to be taken without opening the LV switchboard casing and guarantee the protection of the operator during the inspection, thus avoiding the need for reinforced individual protection to protect against the effects of a possible internal arc flash.

The electrical panel can be fitted with these devices on the incoming columns, to monitor the temperature at the main busbar sides or even on the fronts of some withdrawable drawers.

Focus On Viewing Solutions

Polycrystalline sightglasses are the best known solution; they are relatively expensive and offer a fairly narrow viewing surface but promise good internal arc resistance.

Larger sighting solutions of various shapes and sizes are also available. They consist of a honeycomb structure firmly attached to a plastic film. They allow a much better viewing angle and an increased inspection area. Their internal arc resistance is sufficient in many cases and their plastic film does not degrade over time, unlike polycrystals which lose their transparency over part of the spectrum as they age.

In the case of withdrawable drawers, cheaper solutions can be considered, such as the use of Plexiglas or removable metal sheets that allow partial inspection of the interior but with the appropriate individual protection. The use of front opening drawer is the solution allowing a complete inspection of the inside of the drawer but it leads to an increased risk for the operator during the measurement campaign.

Conclusion

In short, a well-designed, well maintained low-voltage switchboard and regular monitoring of its components enable you to prevent the risk of fire resulting from abnormal heating of your installation.

It should be remembered that each intervention requiring the opening of a door or front plate exposes the operator to a greater risk of internal arcing and contact with live parts.

In fact, tests on the behaviour of the electrical panel during an internal arc are always carried out with the enclosure closed and the effects of the arc on the operator are only evaluated outside the LV switchboard during internal arc conditions.

For thermography campaigns, it is necessary that the operator wears adequate individual protection and is trained to follow the appropriate methodology.

Original article can be found here

About Comeca

Our aim is to help your company to improve its performance.

COMECA is also a solid and innovative business partner, with strong knowledge of the major trends in the energy market such as energy efficiency, renewable energy sources and infrastructures for electric vehicles.

COMECA continues to support its established installed base all over the world, while bringing its know-how and expertise in new projects.

To support changes in energy distribution and meet customers’ needs, COMECA offers :

- A « Global Solution » approach that presents important elements of differentiation

- A complete and complementary range of products through its strategic core businesses, providing “package solutions”

- A customised proposal, based on free choice of electrical components brands

- The largest range of original manufacturer switchboards in the market

- A full range of services for your existing COMECA equipment as well as for your new equipment

Power Cable Accessories

To support the installation of Low Voltage Power Cable Systems, Thorne & Derrick stock and supply an extensive range of Cable Accessories to enable to support, jointing, glanding and termination of BS5467 Armoured Cables from leading manufacturers including CMP, Cembre, Ellis Patents and 3M Electrical.

May 4th, 2021

Electric Vehicles | Power Distribution By Lucy Zodion

Did you know that we will need over 29,000 charging points for Electric Vehicles across Great Britain by 2030? Over 85% of these need to be fast or rapid chargers.

Want to know more about the difference?

Electric Vehicles

Electric vehicles are a key technology to reduce air pollution in densely populated areas and a promising option to contribute to energy diversification and greenhouse gas emissions reduction objectives.

The growing demand for Electric Vehicles (EV) and the resulting strain charging infrastructure has on our electrical network, means a wide range of safe and compliant connection solutions are required. Global sales rose a dramatic 65% from 2017 to 2018, for a total of 2.1 million vehicles. However, the subsequent outbreak of the coronavirus pandemic has resulted in a 25% decline in EV purchases during the first quarter of 2020.

Despite these setbacks, Electric Vehicle demand is again expected to rise with improved batteries and a more readily available charging infrastructure.

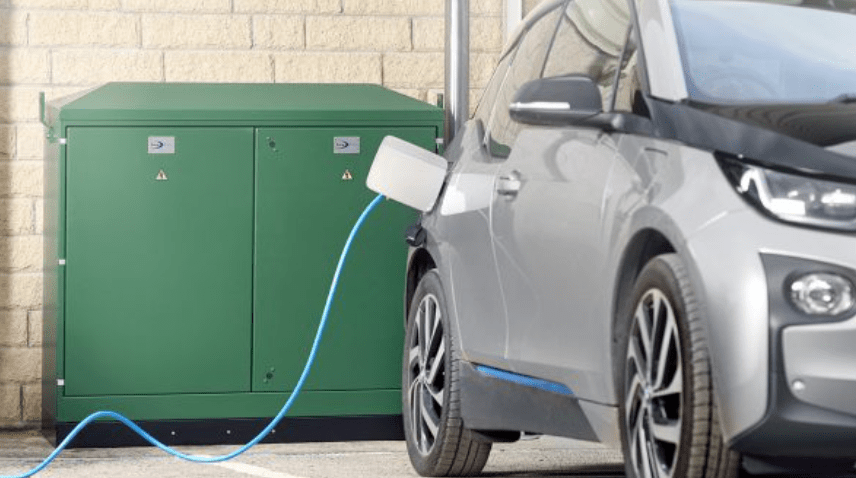

From DNO accredited cut-outs and isolators for on-street chargers, through to larger ‘heavy duty’ EV feeder pillars for fast, rapid and super chargers, Lucy Zodion’s products and design team can solve your connection requirements.

Empowering EV with pre-wired solutions

As one of the UK’s leading suppliers of pre-wired power distribution enclosures, we understand the importance of electrical safety and flexibility to meet the growing demands of power infrastructure. EV is becoming commonplace throughout the UK, with a number of initiatives in-place to drive-up use of electric vehicles in a bid to reduce emissions and increase efficiencies. As the demand for EV increases, there becomes a growing need for the implementation of accessible charge points, meaning a step-change in urban infrastructure is required, therefore the demand for power distribution solutions are on the up.

With this in mind Lucy Zodion is able to meet a number of EV power distribution requirements, to meet almost all specifications, configurations and styles. We have an in-house Design Centre dedicated to the design and manufacture of bespoke power distribution pillars and have extended our service to EV power distribution enclosures, developing solutions to meet growing demand. The benefits of our service include:

- Case-for-case approach to EV power distribution projects to ensure we meet your specification objectives

- In-house Design Centre to ensure approved drawings are closely followed and tested for functionality, fit and form, based on drawings

- IET and BS industry standards followed to ensure product suitability and conformity at application

Reaching the streets with on-street connection products

As plans for the ‘Road to Zero’ become clearer, transport has been identified as a key focus to ensure the nation is able to meet its net zero targets by 2050. As a result, a range of Governmental initiatives have been introduced to drive the uptake of electric vehicles (EV). One of these initiatives is to make on-street EV charging more accessible to residents without access to private charging facilities, with £2.5 million funding to be made available for the provision of over 1,000 on-street electric car charge points.

On-street charging can be provided by either street-side charge points, or via transforming existing street furniture into charging hubs; such as lampposts. As a specialist in the street lighting industry for over 50 years, we have a wealth of knowledge in the electrical infrastructure and equipment necessary to provide effective and safe illumination. This knowledge means that we can develop connected, adaptive and reliable solutions to meet the growing demand for on-street EV charging.e nation is able to meet its net zero targets by 2050. As a result, a range of Governmental initiatives have been introduced to drive the uptake of electric vehicles (EV). One of these initiatives is to make on-street EV charging more accessible to residents without access to private charging facilities, with £2.5 million funding to be made available for the provision of over 1,000 on-street electric car charge points.

Our on-street connection products enable EV charge point manufacturers to utilise existing street lighting infrastructure and transform it into an EV charging facility that is both safe and accessible. Benefits of the solutions we offer to support on-street charging are:

- Lucy Zodion has distribution network operator approval (DNO) throughout the UK, which means our fused products are compatible and compliant with most existing streetlight infrastructure.

- Lucy Zodion’s fused street lighting solutions undergo rigorous in-house and third party testing (KEMA) to ensure they meet industry and safety standards

- The on-street EV connection solutions we develop are in line with the IET Code of Practice for Electrical Vehicle Charging Equipment Installation (BS7671:2008+A3: 2015)

We collaborate to energise the final mile

In order to ensure towns and cities are able to cope with the increasing demands EV and charging infrastructure place on them, collaboration throughout the entire ecosystem is vital.

Our position within the Lucy Group affords us with the ability to collaborate with Lucy Electric, specialist in innovative secondary power distribution solutions for industrial and commercial networks. Working together, Lucy companies are able to offer a holistic solution that helps to decarbonise, decentralise and digitalise urban spaces with smart, adaptive technology that considers the entire EV ecosystem and power infrastructure.

This approach doesn’t stop at power management and distribution; we are passionate about collaborating with EV specialists to ensure power reaches the streets in a sustainable and environmentally conscious way. We have always viewed collaboration as central to evolution; stimulating innovation to help drive credible solutions to the market.

This means working with businesses throughout the supply chain to offer an end-to-end EV solution that energises the final mile. Find out how, via our case studies in the Innovation & News section at the bottom of this page.

FURTHER READING

More Lucy Zodion articles:

More Lucy Zodion articles:

THORNE & DERRICK SPECIALIST ELECTRICAL DISTRIBUTOR

T&D distribute the most extensive range of LV, MV & HV Cable Jointing, Terminating, Pulling & Installation Equipment – we service UK and international clients working on underground cables, overhead lines, substations and electrical construction at LV, 11kV, 33kV and EHV transmission and distribution voltages.

Key Products: MV-HV Cable Joints & Terminations, Cable Cleats, Duct Seals, Cable Transits, Underground Cable Protection, Cable Jointing Tools, Feeder Pillars, Cable Ducting, Earthing & Lightning Protection, Electrical Safety, Cable Glands, Arc Flash Clothing & Fusegear.

August 18th, 2020

By David Hall, Head of Sales at Lucy Zodion

EV Charging | Lucy Zodion Feeder Pillars

The government has the unenviable task of managing one of the world’s most significant, and important, transitions to occur in industry for a very long time. Perhaps the most important to happen in motoring, ever.

The government’s Road to Zero strategy aims to be net-zero by 2050. The sale of new conventional petrol and diesel cars will also be phased out by 2040 (and now brought forward to 2035) to support this ambitious goal.

The Department for Transport said its £400m public-private Charging Infrastructure Investment Fund will see thousands more charge points installed around the country. The UK currently has approximately 11,000 public charging locations providing 30,000 EV connectors. Whilst that is quite impressive, it is still a cause for concern.

One factor that impacts on our industry enormously is the lack of charging infrastructure available. While charge point numbers are increasing, the UK is still some way short of what it needs, and this feeds into consumer EV ‘range anxiety’, in turn dampening demand.

Home & Workplace Charging

It is claimed 90% of people who charge their electric car do so at home. The government has set out ambitions for all new homes in the UK to be built with the provision of EV charge points, a world first. But while charging at home is ideal for those who have access to a drive and a charge point, for those without, charging immediately becomes more challenging.

The BBC recently reported on this apparent gap in charging infrastructure, where it identifies real life cases of users struggling to charge thier new electric vehicle due to lack of off-road parking. Read the article here.

The article states: “A recent report from Capital Economics suggested that fleshing out the UK’s electric vehicles (EV) charging network will cost £45.9bn between now and 2050. There are even fears that the electricity grid won’t be able to cope as thousands more EVs get plugged in by their new owners.”

Nevertheless, as Lighting Journal highlighted in the autumn, on-street EV charging is gradually becoming more available, with a range of funding streams available for local authorities and others to tap into (‘Plug in and play?’, November/December 2019, vol 84, no 10). All this, in turn, puts street lighting and streetlamps firmly in the spotlight when it comes to EV charging.

Why Street Lighting? It is existing infrastructure, ubiquitous and common throughout most urban spaces. As streetlights are constantly powered, it makes sense to utilise existing street furniture, especially when adding further street clutter is not suitable or desired.

Nevertheless, as Lighting Journal highlighted in the autumn, on-street EV charging is gradually becoming more available, with a range of funding streams available for local authorities and others to tap into (‘Plug in and Play?’, November/December 2019, vol 84, no 10). All this, in turn, puts street lighting and streetlamps firmly in the spotlight when it comes to EV charging.

Retrofitting EV charging facilities into streetlights can often be cheaper than installing new on-street charge points, which often include expensive ‘new connection’ costs.

Saying that, existing streetlights have their own costs and complications, particularly around connections and earthing requirements. However, manufacturers such as ubitricity have made good headway in tackling this area.

As Allan Howard outlined in Lighting Journal in January (‘It’s not just a case of “here’s a vertical tube, let’s go and drill a hole in it”,’ vol 85 no 1), in order to make streetlights multi-purpose assets in this way, providing both illumination and charging facilities, the electrical infrastructure within the lighting column itself must be adapted, and done so by an approved electrician.

Although streetlights are already connected to a DNO electricity supply there are a number of considerations and requirements, particularly on earthing systems (conversion to a TT earthing system). The correct type of protection must be used and locality of nearby assets must be considered to reduce the potential of electric shock (touching distance).

At Lucy Zodion, we strongly recommend using the latest edition of the IET Code of Practice for Electrical Vehicle Charging Equipment Installation (BS7671+ A3) as your guide for installations. Work with your DNO and appoint an approved contractor to help ensure that your street lighting infrastructure is compatible and in line with industry standards.

In the event when a secondary isolator is not present, ensure you install a product such as (to use our own examples) a Trojan Midi (3-way) or Trojan Maxi (4-way), manufactured to current British and industry standards and tested to IEC/EN 60947-3 and the fuse carrier to IEC/ EN60269-1.

This will provide a reliable protection. Use any service department to help manage variations, gland plates, locking options and so on, where possible, giving individual protection for both the EV charging equipment, feeder pillars and the luminaire.

Public Realm Charging Points

One thing is certain, to implement a holistic EV charging infrastructure, a mix of charging types is required, not just slow (home) and fast (7kW on-street). Public realm charging points are becoming increasingly crucial as adoption rates for electric vehicles surge. People will need to charge their cars as they go about their daily lives. Whether at schools, shopping, train stations, or airports (and the list goes on), EV charging needs to be commonplace and readily accessible, not just when at work or home. The need for convenience is paramount.

These public realm chargers will need to have faster charging times – between four hours and 30 minutes – falling into the ‘rapid’ and ‘super charging’ category. With this, of course, comes a different set of requirements. These are associated with larger power capacity, the need for new connections, either from DNO supply or perhaps even a package sub station if a large installation.

And the requirements will vary in different areas of the country, as each DNO will have its own approved products and working practices. Luckily for us at Lucy Zodion our street lighting cut-outs are widely approved across all DNO networks. Additionally, our sister company Lucy Electric has been working with DNOs for decades, supplying heavy duty cut-outs, CTCOs and package sub stations.

Given all this, we recommend five things to consider when installing a new connection for an EV charge point.

1. Plan properly – Anticipate that the process will take longer than expected and, given the increasing demand for new connections, timescales will only get longer.

2. Follow the process – Check with your DNO when ordering a new connection that you are using the right process. Many have fallen foul by not checking first, resulting in an installation that will not get approved.

3. Install quality products –Installing high-quality products will reduce potential issues that may arise in the future. Ensure all your products comply to the appropriate regulations and are tested regularly.

4. Consider oversizing – Consider oversizing your supply and include some spare capacity in your EV connection and supply pillar. By making your system scalable, you can add to the number of charge points or upgrade the rating of your charge points in the future, when technology supersedes current equipment.

5. Maintain regularly – In order to keep your equipment in good working order test and inspect regularly. It is pointless having stranded assets that aren’t serving customers and/or earning revenues.

This article was originally published in the March 2020 edition of the Lighting Journal, available here.

Further Reading

➡ More Lucy Zodion blogs:

Cut Outs & Isolators – Lucy Zodion Explain The Differences

Feeder Pillars From Lucy Zodion – LV Electrical Power Distribution

Optional Extras For Use With Lucy Zodion Fortress Feeder Pillars

Waveform Cable Termination – 3 Core 300sqmm Cable Onto A 2 Ganged Metered Way In Lucy Cabinet

Galvanised & Stainless Steel | GRP | Pre-Wired | Underground Retractable Feeder Pilars

THORNE & DERRICK SPECIALIST ELECTRICAL DISTRIBUTOR

LV ♦ MV ♦ HV

T&D distribute the most extensive range of LV, MV & HV Cable Jointing, Terminating, Pulling & Installation Equipment – we service UK and international clients working on underground cables, overhead lines, substations and electrical construction at LV, 11kV, 33kV and EHV transmission and distribution voltages.

- Key Products: MV-HV Cable Joints & Terminations, Cable Cleats, Duct Seals, Cable Transits, Underground Cable Protection, Cable Jointing Tools, Feeder Pillars, Cable Ducting, Earthing & Lightning Protection, Electrical Safety, Cable Glands, Arc Flash Clothing & Fusegear.

- Distributors for: 3M, ABB, Alroc, Band-It, Catu, Cembre, Centriforce, CMP, Elastimold, Ellis Patents, Emtelle, Furse, Lucy Zodion, Nexans Euromold, Pfisterer, Polypipe, Prysmian, Roxtec.

LV – Low Voltage Cable Joints, Glands, Cleats, Lugs & Accessories (1000 Volts)

MV HV – Medium & High Voltage Cable Joints, Terminations & Connectors (11kV 33kV EHV)

Cable Laying – Underground Cable Covers, Ducting, Seals & Cable Pulling Equipment

More Lucy Zodion articles:

More Lucy Zodion articles: