Roxtec CF 8/32 BG Cable Transit Frame

Sealing Cables & Cable Ducts

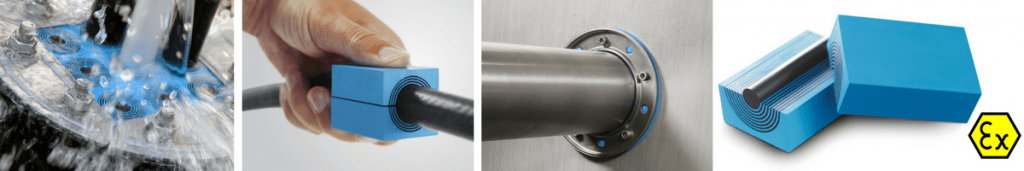

Roxtec CF 8/32 BG cable transit frames have a compact frame and are constructed from cast aluminium with nickel plating to ensure electrical conductivity – the Roxtec frame is suitable for installation also around existing multiple or single pre-terminated cables and pipes in one opening.

Roxtec rectangular cable transit frames are used to provide a reliable cable sealing ensuring safety, efficiency and long-term operational reliability – Roxtec cable seals protect against fire, gas, water, dusts, pests, blast load and electromagnetic interference.

➡ Visit Cable Transits to view the complete range of sealing systems for cable and pipe entries on cabinets, switchgear, electrical enclosures and substations (LV 11kV 33kV 66kV 132kV) – see Round Cable Seals for sealing round type cable ducts and pipe entries.

Roxtec CF 8/32 BG cable transit frames have an integrated compression unit within the frame and are supplied as ready made kits.

Installing Roxtec CF 8/32 BG Cable Transit Frames

Contact T&D should you require support on the installation of Roxtec CF 8/32 BG cable transit frames:

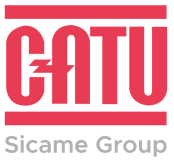

Frame Installation

- 1. Ensure good electrical conductivity between the counter frame and the structure. Clean the surface around the opening from inside the opening. Remove any paint if necessary. See installation preparations.

- 2. Insert the frame from the outside of the opening.

- 3. Insert the counter frame from the inside of the opening.

- 4a. Fasten the frame by tightening the nuts with an allen key. Fasten the ground lug with a spanner.

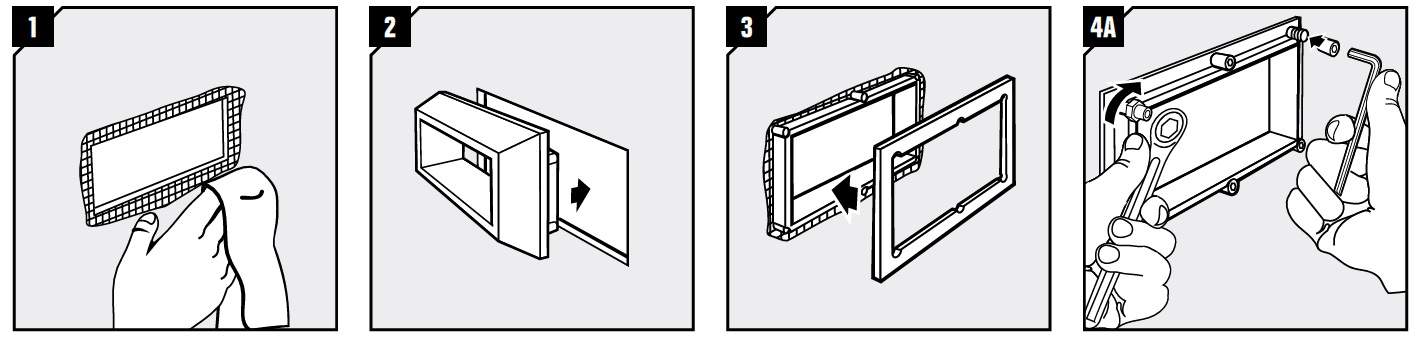

- 4b. If applicable, install an external ground conductor and secure with the hex nut.

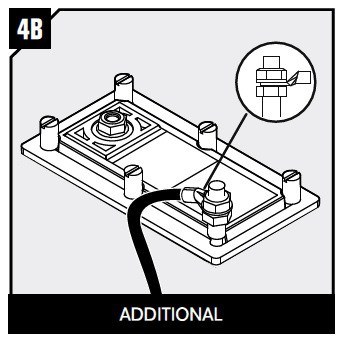

Module Installation

- 1. Clean the empty frame from paint, dirt etc. to secure good electrical conductivity.

- 2. Mark where the outer jacket is to be cut.

- 3a. Remove the outer jacket and armor/shield with a tool of your choice. Make sure not to damage the cable screen/armor. Remove any protection tape or plastic.

- 3b. When required for inner conduction protection, fit an anti-short bushing at the end cut of the cable screen / armor.

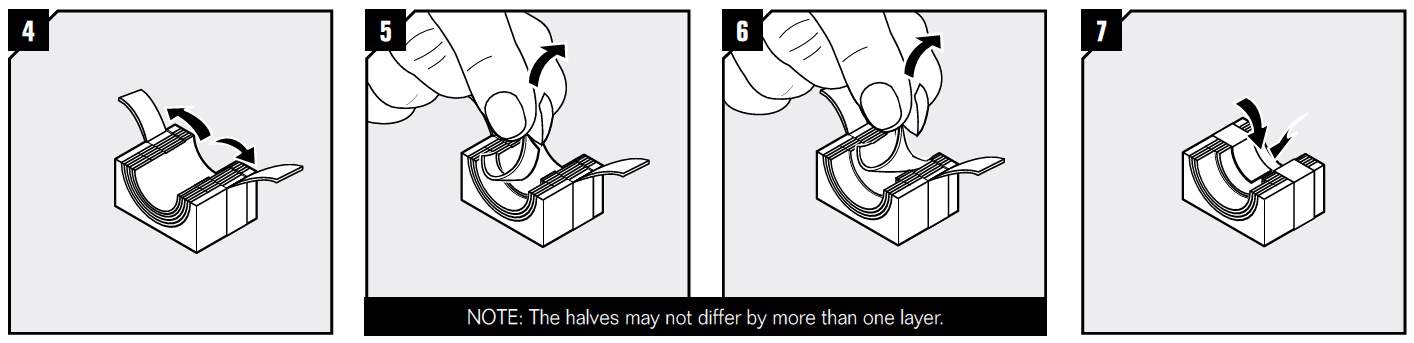

- 4. Remove the core and fold out the braid on modules that are to hold cables or pipes.

- 5. Adapt outer layers to cable/pipe on both module halves.

- 6. Adapt inner layers to cable screen / armor / pipe on both module halves.

- 7. Fold the braid tightly inside the module.

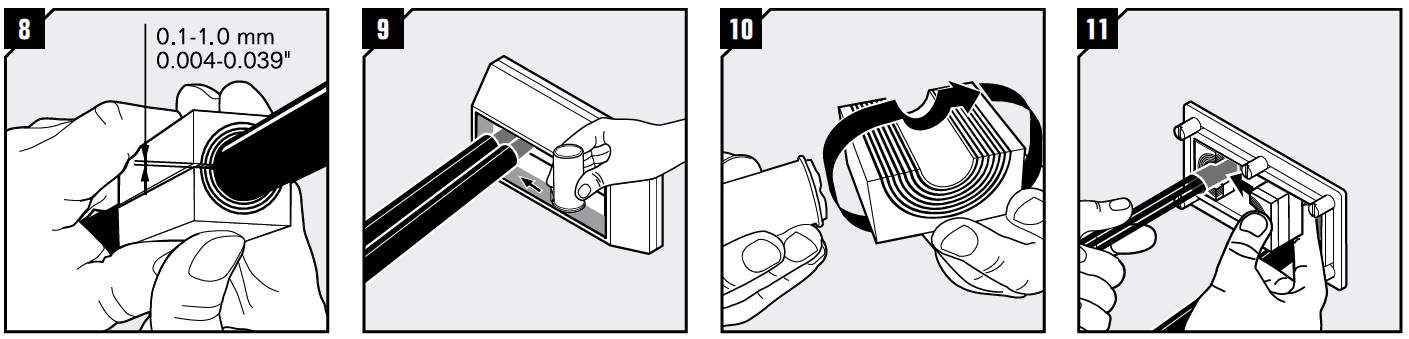

- 8. Achieve a 0.1-1.0 mm gap between the two halves when held against the cable or pipe.

- 9. Lubricate the frame on the areas that will be in contact with the rubber of the modules. Avoid excess lubricant on areas in contact with the braid.

- 10. Lubricate all modules for the frame thoroughly, both the inside and the outside surfaces. Avoid excess lubricant on the braid.

- 11. Insert the module halves around the cables from the inside of the cabinet. Make sure that the braid is in contact with the armor of the cable.

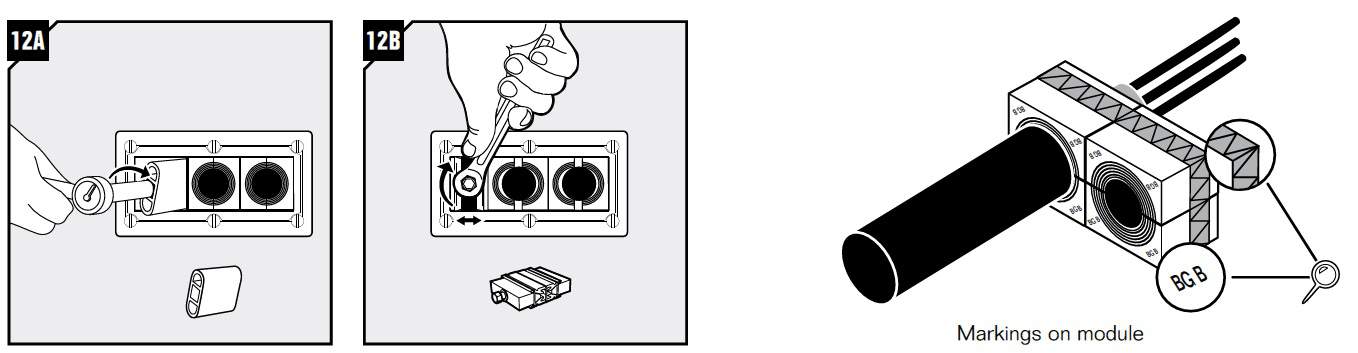

- 12a. You may use the CF compression tool to pre-compress the inserted modules and make room for the last modules.

- 12b. You can finalize pre-compression by using the Roxtec precompression wedge.

- All modules should be of the same type in each opening and turned in the same direction. Please note the markings on the face of the module.

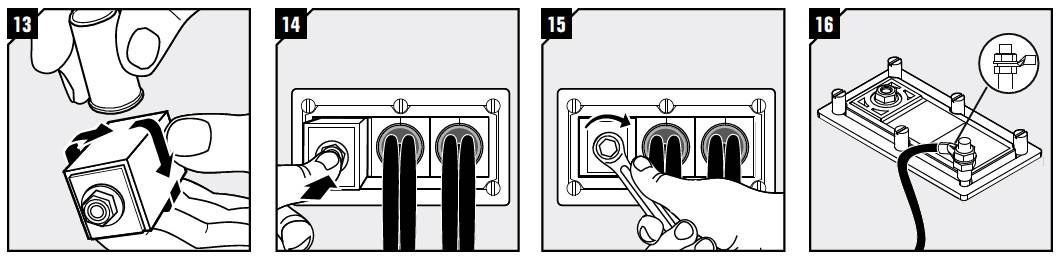

- 13. Lubricate the compression unit on all sides with Roxtec Lubricant.

- 14. Gently insert the compression unit from the inside of the cabinet until stop.

- 15. Tighten the compression unit to seal the frame. Recommended torque 8-12 Nm/5.9-8.8 lbf-ft.

- 16. If applicable, check that the ground lug is correctly installed.

Sealing Cable Ducts With Roxtec – cable sealing modules consist of two halves with removable layers and a centre core which is removed to permit cable or pipe installation in medium/high voltage substations, hazardous areas and electrical infrastructure

Cable & Duct Sealing Transit Frames – T&D Approved Roxtec Distributor