Blog

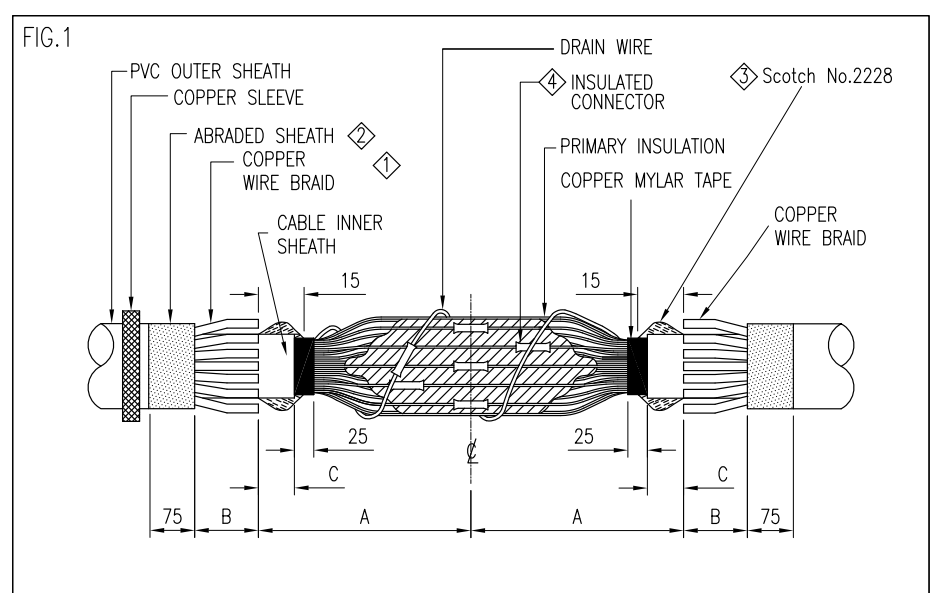

Jointing Instrumentation Cables with Mylar Screen

August 6th, 2020Thorne & Derrick supply 3M, Prysmian, Filoform and SPS low voltage cable joints suitable for connecting and jointing single and multi-core/pair power, control and instrumentation cables up to 600/1000V (3.3kV) in industrial and hazardous area locations – specialist applications include fire resistant, low smoke zero halogen, hydrocarbon resistant and utility cable joints.

Cable joints are available from stock in several technologies to suit the low voltage (LV) installation application and cable type to be repaired or jointed; this includes i) Cold Shrink ii) Heat Shrink and iii) Resin.

This includes Jointing Instrumentation Cables with Mylar Screen.

For the connection and jointing of the instrumentation cable conductors we can recommend Scotchlok 314 type Insulation Displacement Connector.

Jointing Instrumentation Cables with Mylar Screen

Cable Joints LV Low Voltage | Cold Shrink | Heat Shrink | Resin | 600/1000V 3.3kV

THORNE & DERRICK

SPECIALIST ELECTRICAL DISTRIBUTOR

Thorne & Derrick distribute the most extensive range of Cable Installation & Electrical Distribution Equipment to the Power Transmission & Distribution industry in the onshore and offshore wind, solar, rail, oil/gas, data centre, battery storage and utility sectors.

We service UK and international clients working on underground cables, overhead lines, substations and electrical construction at 11kV and up to and EHV transmission and distribution voltages.

- Key Products: MV-HV Cable Joints & Terminations, Cable Cleats, Duct Seals, Cable Transits, Underground Cable Protection, Copper Earth Tapes, Cable Jointing Tools, Feeder Pillars, Cable Ducting, Earthing & Lightning Protection, Electrical Safety, Cable Glands, Arc Flash Protection & Fusegear.

- Distributors for: 3M Cold Shrink, ABB, Alroc, Band-It, Catu, Cembre, Centriforce, CMP, Elastimold, Ellis Patents, Emtelle, Furse, Lucy Zodion, Nexans Euromold, Pfisterer, Polypipe, Prysmian, Roxtec.

LV – Low Voltage Cable Joints, Glands, Cleats, Lugs & Accessories (1000 Volts)

MV HV – Medium & High Voltage Cable Joints, Terminations & Connectors (11kV 33kV EHV)

Ellis Patents Lead The Way With Cable Cleat Calculator Innovation

August 6th, 2020

Ellis Patents Cable Cleat Calculator

Ellis Patents Cable Cleat Calculator

by Thorne & Derrick | Ellis Patents UK Distributor

Tool To Help With Cable Cleat Selection

Ellis Patents has once again demonstrated why they stands alone as the cable cleat market’s leading innovator – having developed an online calculator that will provide users with completely accurate specification information for any project in a matter of seconds.

The cable cleat calculator provides correctly specified cleat spacings with respect to short circuit conditions; and recommends the ideal products for that specific project. This is achieved through a pre-programmed calculation that takes into consideration cable formation, cable size, short circuit current and the installation environment.

The questions asked in this calculator are designed to provide Ellis with the proper information to specify the correct cable cleat for your project. The questions consider cable formation, cable size, short circuit forces and the installation environment only.

It should be noted that issues such as cable weight for vertical cable runs, thermo-mechanical forces, extreme environmental conditions (e.g. extreme temperatures, industrial pollutants etc.) and any other non-standard cable installation factors have not been considered.

Thorne & Derrick distributors for Ellis Patents should be made aware of these issues should they be present for your project.

PEAK VS RMS CURRENT

The formula uses peak current, however this is often unavailable with a Root Mean Square (RMS) value given instead. To calculate the peak current from the RMS, IEC 61439-1 Low voltage switchgear and controlgear assemblies is commonly referred to, which uses the following multiples:

10kA < I ≤ 20kA Multiply by 2

20kA < I ≤ 50kA Multiply by 2.1

50kA < I Multiply by 2.2

INTERMEDIATE Cable STRAPS

The use of intermediate straps are not considered within the calculator.

The below table details the straps suitable for each cleat whereby the cleat to cable strap spacing is the same as the calculated cleat spacing.

FLEXI-STRAP (SD) and PROTECT: VULCAN+, VULCAN+ QUAD, TRIDENT, ALPHA, VARI-CLEAT

FLEXI-STRAP (HD): EMPEROR, COLOSSUS

FIXED INTERVAL SPACING

For fixed interval spacing applications such as cable ladder, the calculated cleat spacing should be rounded down to the closest possible interval. In the example of standard cable ladder which provides a cleat mounting surface every 300mm, should the calculated spacing be 0.8m the spacing to suit cable ladder should be rounded down to 0.6m.

CALCULATION ASSUMPTIONS

- Multiplication factor of 2.2 used to convert RMS to peak (based on IEC 61439-1).

- Spacings given may only be suitable for a category 1 short circuit for certain products. Refer to Ellis to confirm whether category 2 criteria can be applied to the product spacing calculation provided.

- Spacings for No Bolts Cleat assume a worst case scenario of a stacked formation. Larger spacings can be achieved if the cleat is fastened separately, refer to Ellis for more details.

- Spacings for the 2F+ clamp assume the strength throughout the range is consistent. In reality it changes considerably and larger spacings may be achievable for larger cleats as the lowest strength has been assumed in this calculator.

- Ellis have strived to ensure that the results generated by the calculator are accurate and correct at the time of use, it is however recommended to contact Ellis to confirm the calculated spacing is suitable prior to order placement. All calculated spacings are based on the results of short circuit testing to IEC 61914.

Stephen Walton, Technical Director of Ellis Patents, said: “Correctly specifying cable cleats and the spacing that the cleats need to be installed at is vital in ensuring they function properly when called onto cable management systems. Until now, specifiers and planners needed to make the calculation using a complex formula, and then interpret these results into product type, quantity and exact spacing.”

“Our cable cleat calculator removes this complicated mathematical element from the specification process; and replaces it with a fool proof option that provides the correct cleat specification quickly and easily.”

Ellis Patents designs and manufactures all of its cable cleats in North Yorkshire, and has a global reputation for both its products, and its proven ability to solve problems through innovative thinking. This has seen the company create new products in live project situations for the likes of Balfour Beatty and Siemens; and cure a major health and safety installation headache for Network Rail.

“Our innovative approach to product and service development has served us well over the years; opening many doors that would have remained firmly shut to more traditional manufacturers,” continued Stephen.

“With the cable cleat calculator I’m confident this single online tool will have the biggest impact of any of our innovations to date; as it really does have the potential to be adopted as an industry essential across the globe.”

Ellis Patents Cable Cleats | UK Manufactured Cable Restraint & Support Products

FURTHER READING

- IEC 61914 – Cable Cleats & Short Circuit Protection Calculations

- Fire Resistance & Cable Cleats – Surviving Fire, Flame & Extreme Heat

- Triplex Cleats – Selection Guide for Cleating 11kV BS7870 Part 4.10 Cables

- Stainless Steel Cable Cleats – Preventing Galvanic Corrosion Of Cable Fixings

- Ellis Patents Cable Cleats & Cable Basket Tray for Securing High Fault Level Cables

- Stainless Steel Cable Cleats v Ties – The Myths Debunked By Ellis Patents

- Cable Cleats from Ellis Patents | Better By Design

Thorne & Derrick | Ellis Patents UK Distributors

Thorne & Derrick

T&D are Specialist Distributors to UK Distribution Network Operators (DNO’s), NERS Registered Service Providers, ICP’s and HV Jointing Contractors of an extensive range of LV, MV & HV Jointing, Earthing, Substation & Electrical Eqpt – this includes 11kV/33kV/66kV joints, terminations and connectors for both DNO and private network applications.

Contact our UK Power Team for competitive quotations, fast delivery from stock and technical support or training on all LV-HV products.

Key Product Categories: Duct Seals | Cable Cleats | Cable Glands | Electrical Safety | Arc Flash Protection | Cable Jointing Tools | Cable Pulling | Earthing | Feeder Pillars | Cable Joints LV | Joints & Terminations MV HV

Synaptec Cable Fault Detection For Mixed Lines / Hybrid Circuits

August 5th, 2020

Cable Fault Detection

-

Thanks to Gordon Lindsay Account Director Transmission at Synaptec

The Synaptec Cable Fault Detection solution delivers high availability, not affected by temperature fluctuations, cost-effective and proven technology.

Cable fault detection in a cable or overhead powerline is challenging & expensive. Synaptec Refase™ provides time-synchronized current measurements from any transition point. Works where there is no access or power (under cities, remote or deserts). Enables auto-reclose on overhead faults while blocking auto-reclose for cable section faults.

- High availability

- Not affected by temperature fluctuations

- Cost-effective

- Proven solution

In hybrid circuits containing both overhead lines and underground cable sections, it is advantageous to determine in which section an electrical fault has occurred. This enables an operator to auto-reclose (AR) in the event of a transient OHL fault, or to block auto-reclose in the event of a permanent cable fault.

This is not typically possible if simple distance protection schemes are deployed, which will typically result in some ambiguity in identification of the faulted section, rendering auto-reclose prohibitively risky.

Ideally, the circuit would be instrumented at every transition point such that robust differential current algorithms may be used to immediately and definitively identify the faulted section in the event of a fault, and so permit or block auto-reclose accordingly.

Cable Fault Detection

However, to deploy conventional current measurements at remote transition points is typically very expensive, requiring significant local supporting infrastructure including power supplies, active digital telecoms, and GPS access to obtain reliable measurements. Optical NCITs have fundamental limits on range and environmental withstand and consume multiple fibres per instrumented location, fundamentally limiting their deployment at scale.

A single Refase™ system is uniquely capable of instrumenting multiple hybrid circuit sections with passive, highly-multiplexable current sensors over unprecedented range.

This system enables discrete, robust, and scalable differential current monitoring over long-range, with measurements maintaining consistent high accuracy over wide operating temperature ranges when compared to these prior technologies.

Discrete AR block signals are output on protection timescales (milliseconds), allowing an operator to cost-effectively manage hybrid circuits in the most efficient manner possible.

About Synaptec

Synaptec radically enhances power system protection, monitoring and asset management using innovative light-speed technology easily deployed on existing infrastructure. The leader in secure, scalable and data-rich, multiparameter, power instrumentation.

Providing immediate and long term analysis of asset health and operational performance. Implement best practices over wide areas and throughout complex networks.

Specialist Suppliers of High Voltage Electrical Equipment & Cable Accessories

Jointing, Earthing, Substation Electrical & Safety Equipment Distributors

Thorne & Derrick International are specialist distributors of LV, MV & HV Cable Installation, Jointing, Duct Sealing, Substation & Electrical Equipment – servicing UK and global businesses involved in cable installations, cable jointing, substation, overhead line and electrical construction at LV, 11kV, 33kV and EHV.

THORNE & DERRICK Product Categories: Duct Seals | Cable Cleats | Cable Glands | Electrical Safety | Arc Flash Protection | Cable Jointing Tools | Cable Pulling | Earthing | Feeder Pillars | Cable Joints LV | Joints & Terminations MV HV

Distributors for 3M Cold Shrink & Scotchcast | Nexans Euromold | Pfisterer Connex

How to Locate Sheath Faults on MV Cables

July 29th, 2020

Image courtesy of EE Publishers

Republished with the Kind Permission of Sam Soady |

Eccentricity Pty Ltd Director /HV Operator / Cable Jointer

How to Locate Sheath Faults on MV Cables

Maintaining healthy sheath insulation is extremely important for the safe operation and lifespan of an MV cable. If there are faults in the outer sheath, you can expect an ingress of moisture, debris, and the premature degradation of the cables structure.

In turn, it is difficult to pinpoint the location of the fault as it can occur anywhere along the run of the cable (which is usually buried underground). There are, however, methods to accurately determine the location of the fault, which apply a surge energy of around 500J that tests for breakdown and insulation resistance of the outer sheath.

When Eccentricity comes across a sheath fault, we are able to utilise specific test equipment which enables us to locate the fault very easily and accurately.

Once the location of the fault has been determined, the cable can be exposed by means of vacuum digging which prevents further damage. It is at this point you can physically see the damage to the outer sheath of the cable. Damage usually occurs due to poor cable laying methods or not enough care taken during installation.

Rectifying the damage can sometimes be as simple as installing some resin filled zip tube heat shrink, which re-seals the outer sheath and re-establishes the insulation resistance. In some circumstances, further damage to the under layers of the MV cable can occur and extra repairs such as rectifying termite protection or other protective layers within the cable must be completed.

Once the integrity of the cable has been re-established from the repairs, it is important to re-test the cable prior to backfill to prove the rectification works. Once verified, the cable can be backfilled and tested once again in its final resting position.

About Eccentricity

Eccentricity is a specialised Brisbane based company with a team of dual trade electricians and cable jointers. Our technicians are fully qualified to work on cables up to 66kV, including XLPE, PILC and EPR cables, backed by over a decade of industry experience.

With a modern and fully compliant fleet of industry vehicles, we are capable of accessing any high risk environment to perform works with a wide range of major MV HV cable jointing projects including, mining, oil, gas, renewable energy, and high voltage transmission networks.

Eccentricity has the capacity for small or large scale projects, providing reliability of power networks wherein client satisfaction is a top priority. We provide a high level of quality with all aspects of both installation and commissioning, ensuring we comply with all relevant regulations and legislative provisions.

Specialist Suppliers of High Voltage Electrical Equipment & Cable Accessories

Jointing, Earthing, Substation Electrical & Safety Equipment Distributors

Thorne & Derrick International are specialist distributors of LV, MV & HV Cable Installation, Jointing, Duct Sealing, Substation & Electrical Equipment – servicing UK and global businesses involved in cable installations, cable jointing, substation, overhead line and electrical construction at LV, 11kV, 33kV and EHV.

THORNE & DERRICK Product Categories: Duct Seals | Cable Cleats | Cable Glands | Electrical Safety | Arc Flash Protection | Cable Jointing Tools | Cable Pulling | Earthing | Feeder Pillars | Cable Joints LV | Joints & Terminations MV HV

Distributors for 3M Cold Shrink & Scotchcast | Nexans Euromold | Pfisterer Connex

Fire Rated Cable Cleats | CMP Solace, Themis & Helios

July 29th, 2020

Fire rated cable cleats

Themis, Solace & Helios

This range of fire rated cable cleats from CMP launches as the use of fire resistant power cable and control cable systems for life safety and fire-fighting applications has become more prevalent in everyday use.

This product range is not only suitable for fire safety applications, but also highly corrosive environments where high grade stainless steel products should be used, or applications where high axial / lateral loads are required, such as the vertical installation of large high voltage cables (Themis only). All CMP cable cleats hold LUL 1-085 approvals.

Accessories are available for the fire rated cable cleats such as C-clamps (for unslotted rungs) and separation pads (to isolate dissimilar metals) are available for all products excluding the intermediate restraint.

Tested to the Highest Industry Fire Safety Standards

Fire tested to EN50200, BS5839, BS8491, BS8434 and AS 3013, CMP’s fire-rated range has been specifically designed for use with fire performance cables to ensure the safe retention and securing of cables in the event of a wiring system being affected by fire.

BS 5839 ‘Fire detection and fire alarm systems for buildings.

Code of practice for design, installation, commissioning and maintenance of systems in non-domestic premises’ states that;

“Methods of cable support should be non-combustible and such that circuit integrity will not be reduced below that afforded by the cable used, and should withstand a similar temperature and duration to that of the cable, while maintaining adequate support.”

To adhere to this, BSI standard fire rated Cable Cleats must be used to support the cable in the event of a fire.

High Quality Material & Temperature Rating

Available in cast and fabricated 316L stainless steel, the one and two bolt range has been rigorously tested to withstand temperatures of over 1000°C, whilst providing the superior corrosion resistance that 316L stainless steel affords, making it suitable for not only indoor and outdoor applications but highly corrosive environments too.

Extreme Axial & Lateral Load Retention

As well as offering superior fire-resistance, both the Themis and Solace have been designed with a unique twin arc internal patent pending design profile, offering extreme axial and lateral load retention. Please visit the individual product pages for 3rd party test data.

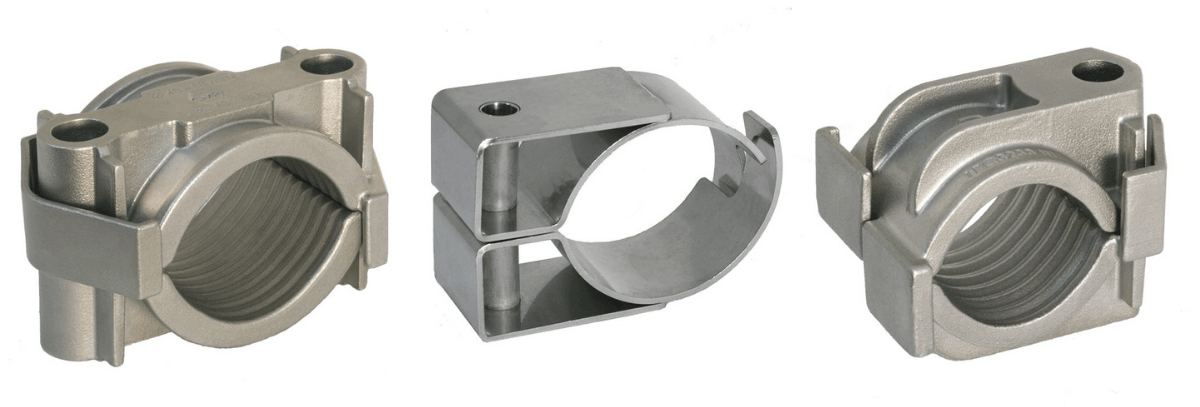

Solace

CMP Solace | Fire Rated Cable Cleats

The Solace heavy duty, one bolt, high temperature, stainless steel single cable cleat is a cast metallic fire rated cable cleat which has been designed, constructed, and tested in accordance with the International Standard ‘Cable Cleats for Electrical Installations’ (IEC 61914).

These fire rated cable cleats can be used with fire performance cables to ensure the safe retention and securing of single cables in the event of a wiring system being affected by fire. These fire resisting supports help to maintain the electrical system’s integrity for any critical circuits during an emergency situation to enable safe evacuation.

The cable cleat is manufactured from stainless steel 316L making it suitable for both indoor and outdoor applications. A unique twin arc internal patent pending design profile it exhibits excellent retention, limiting both the axial and lateral movement.

The Solace one bolt cable cleat is available in twelve sizes suitable for cable diameters of 10mm up to 71mm. It has an M10 clearance hole for securing it to a mounting surface.

Features

- 316L Stainless Steel

- Operating temperature -60°C to +250°C

- Surpasses requirements of Fire testing BS5839 / BS8491 / EN50200 / BS8434 / AS-NZS 3013 (1,200°C) (Fire, shock & water)

- 10 – 71mm cable range

- Single bolt fixing design

- Can be stacked

- Excellent axial & lateral load retention

- Corrosion resistant

Themis

CMP Themis | Fire Rated Cable Cleats

The Themis heavy duty, two bolt, high temperature fire rated stainless steel single cable cleat which has been designed, constructed, and tested in accordance with the International Standard ‘Cable Cleats for Electrical Installations’ (IEC 61914). It ensures the retention and securing of single cables, without damaging or deforming the cable.

These fire rated cable cleats can be used with fire performance cables to ensure the safe retention and securing of single cables in the event of a wiring system being affected by fire. These fire resisting supports help to maintain the electrical systems integrity for any critical circuits during an emergency situation to enable safe evacuation. The cable cleat is manufactured from stainless steel 316L making it suitable for both indoor and outdoor applications.

Due to its unique twin arc internal patent pending design profile it exhibits excellent retention, limiting both the axial and lateral movement. The Themis two bolt cable cleats have an excellent range take and are suitable for cable diameters of 38mm up to 97mm in only five sizes.

These cable cleats feature two M12 clearance holes for securing it to a mounting surface, which allows for either M10 or M12 fasteners to be used.

Features

- 316L Stainless Steel

- Operating temperature -60°C to +250°C

- Surpasses requirements of Fire testing BS5839 / BS8491 / EN50200 / BS8434 / AS-NZS 3013 (1,200°C) (Fire, shock & water)

- 38 – 97mm cable range take in 5 sizes

- Can be stacked

- Excellent axial & lateral load retention

- Corrosion resistant

Helios

CMP Helios | Fire Rated Cable Cleats

Helios standard duty, one bolt, high temperature fire rated single stainless steel cable cleat is a fabricated metallic cleat which has been designed, constructed, and tested in accordance with the International Standard ‘Cable Cleats for Electrical Installations’ (IEC 61914).

These fire rated cable cleats can be used with fire performance cables to ensure the safe retention and securing of single cables in the event of a wiring system being affected by fire. These fire resisting supports help to maintain the electrical systems integrity for any critical circuits during an emergency situation to enable safe evacuation. The cable cleat is fabricated from stainless steel 316L making it suitable for both indoor and outdoor applications.

The Helios high temperature stainless steel 316L cable cleat is available in eleven sizes suitable for cable diameters of 10mm up to 65mm. The cable cleat has an M10 clearance hole for securing it to a mounting surface.

Features

- Fabricated Stainless Steel 316L

- Operating temperature -60°C to +250°C

- Surpasses requirements of Fire testing BS5839 / BS8491 / EN50200 / BS8434 / AS-NZS 3013 (1,200°C) (Fire, shock & water)

- 10 – 65mm cable range take in 11 sizes

- Single bolt fixing design

- Can be stacked

- Corrosion resistant

Flameproof hazardous area cable glands with ATEX Certification for terminating armoured SWA cables in Zone 1 & Zone 2

LV, MV & HV Jointing, Earthing, Substation & Electrical Eqpt

Thorne & Derrick International are specialist distributors of LV, MV & HV Cable Installation, Jointing, Duct Sealing, Substation & Electrical Equipment – servicing UK and global businesses involved in cable installations, cable jointing, substation, overhead line and electrical construction at LV, 11kV, 33kV and EHV.

THORNE & DERRICK Product Categories: Duct Seals | Cable Cleats | Cable Glands | Electrical Safety | Arc Flash Protection | Cable Jointing Tools | Cable Pulling | Earthing | Feeder Pillars | Cable Joints LV | Joints & Terminations MV HV