Cable Pulling & Laying

Cable Drum Handling | Halogen Free Shipboard Cables Recommendations

July 15th, 2021Cable Drum Handling

Transport, Storage & Installation Recommendations for Halogen-free Shipboard Cables from Helkama

The purpose of this guide about Cable Drum Handling is to illustrate how cable damages can be avoided by correct handling and storage practices.

Handling Cable Drums

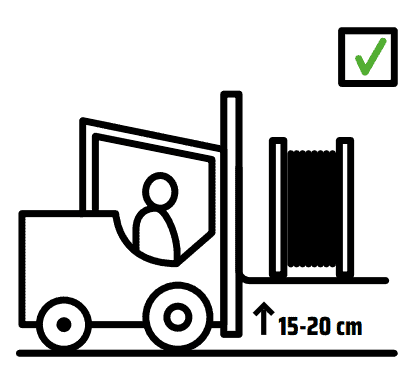

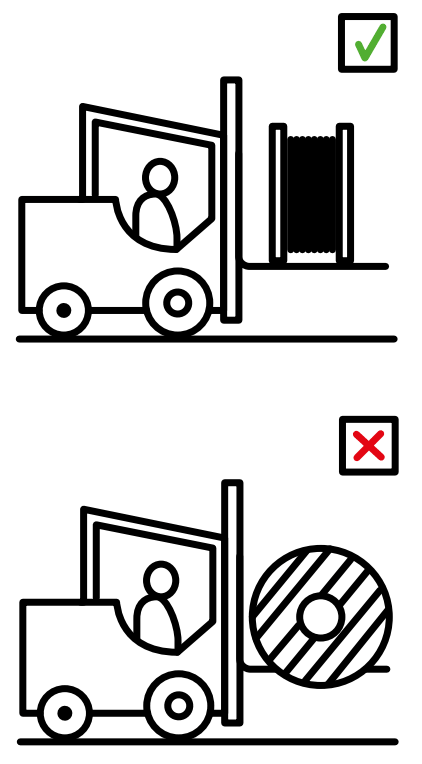

Drum flanges are marked to provide vital information to assist with the handling of the drums and the installation of the cable. This information includes drum weight, a mark on the flange indicating the end of the cable, and an arrow indicating the rotating direction of the drum for rolling or transportation. If the handling is done correctly, the drum will protect the cable from damages. The forks of the forklift must be longer than the width of the drum, so that the lagging is not damaged. Raise the forks of the forklift sufficiently (15-20 cm) above the ground.

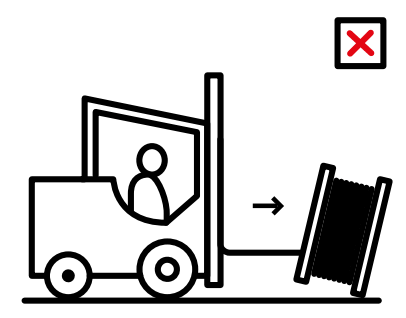

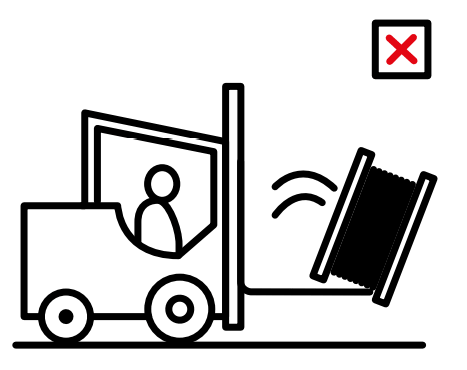

Insufficient cable drum lifting height may cause the drum to be dragged on the ground and eventually get damaged or dropped off the forks, especially if the ground surface is uneven. The drums may be placed and stacked on pallets to make it safer and easier to move them. Don’t push the drum with the forklift.

Storage of Cable Drums

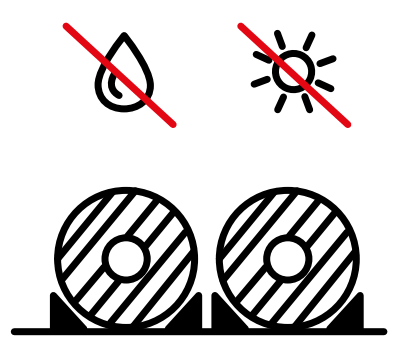

Cable drums shall be stored properly. Improper storage conditions can easily cause damage to cable drums or the actual cables. Cable ends shall be sealed with caps to prevent ingress of water. The caps must be protected to avoid any mechanical risk and exterior shocks. Always check drums before moving. Drums shall be stored on a level and firm surface (e.g. timber baulks, flange edges) standing upright and strapped/wedged securely to place. Do not store the drum with the flange flat on the ground.

Drums shall not be standing in water or be stored in continually damp conditions.

Failure to provide these conditions is likely to result in timber rot and weakening of the flange with potential breaking or collapse of the drum to the point where the cable will end up resting on the ground. Any of these outcomes will make later installation of the cable more problematic or impossible.

Cables with coloured outer sheaths shall not be stored in direct sunlight to prevent fading.

Cables shall be protected against direct sunlight with suitable protective packaging, such as plastic sheeting. If the cable is used progressively (partial lengths are cut and used), the exposed cable end must be immediately sealed with a new end cap. Heat shrinkable end caps are recommended.

Packing of Cables

Before shipping the cable drums shall be packed correctly for transportation. The packing consists of the following items:

- Plastic foil is wrapped over the cable layers and affixed with adhesive tape.

- The cladding boards are attached with a plastic or steel strap (optional). Do not tighten the strap too much to avoid damage to the cable.

If the cladding boards need to be attached to the flanges of the drum with nails, the nailing shall be done making sure the nails hit the middle of the flanges, and don’t damage the outer cable layers.

Transport of Cable Drums

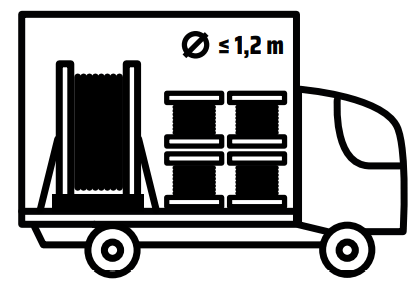

The bigger cable drums shall be loaded in the container or transportation vehicle in vertical position, i.e. standing up, so that they don’t move during transportation. For cable drums with diameter ≤ 1,2 m a horizontal position can also be used and the drums can be stacked.

Secure the drums firmly.

The round shaped cable drum rolls easily. Make sure that each drum is secured in place with stoppers/wedges to prevent rolling during transportation and storage.

During transportation, the drum shall be fastened with a combination of wedges and transportation straps to tie down the front and rear of the drum, to prevent movement of drums.

Lifting cable drums with a forklift is only allowed from the “flange side”. To avoid damage, never touch the cable or its protective cover with the fork.

Main dangers are the invisible damages that lead to unusable cables. Therefore some basic guidelines need to be followed. The cable itself must always be protected. Cable or drum, damaged by handling etc., must be checked before use.

The unloading and handling shall be done carefully using correct lifting equipment. When handling the drum with a forklift truck, place the drum vertically on the forks. Never let a drum fall during unloading.

Inspect the cables when they arrive on site. Check the condition of the end caps of the cables and the lagging (a break in the wooden lag could tear the outer sheath of the cable).

If the cable drums show signs of damage from handling and/or storage, any warranty obligation given for the cable drums and any subsequent problems resulting from it, are null and void.

INSPECTION

Drums, cables and delivery documents must be inspected when the products are first received at the storage area. The packing list and the product order have to match the received products. In case of document flaws it is necessary to contact the nearest Helkama representative to assess the situation and advise an appropriate solution.

The received drums should be carefully inspected to ensure that no damage occurred during transportation. If any damage is discovered on the drum, it is advisable to also check the cable for damages. It is essential to inform Helkama representative if any cable damage or severe drum damage is found. The damage shall be documented before moving the drum in order to demonstrate the situation properly.

LONG-TERM CABLE STORAGE

Always inspect the drum before moving it from long-term storage.

Transport vibrations and movement, weathering or environmental damage can cause changes in the drum and an assessment of the state of the drum is necessary. In changing dry and wet weather, or consistently dry and hot weather, the wooden sections of the drum can shrink and the whole drum could become unstable and cause damage to the cable when moving the drum. Therefore, the transverse bolts must be tightened with a torque wrench before the drums are moved, to prevent the drums from collapsing. To ensure the bolts stay tight they must also be re-tightened during cable installation.

Note that timbers of the drum flanges and barrels that have shrunk are also likely to have loose nails, but they are harder to fix than bolts. Apply caution and vigilance during the cable unwinding to identify loose nails and reduce possible damage to the cable.

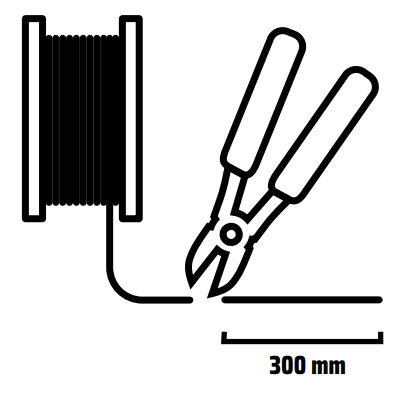

If the cable ends are accessible, it is recommendable to inspect the condition of the end caps. The end cap is designed to prevent the ingress of water. If the cap or seal has been absent for a long time (more than one month); or the cable end faces up toward the sky; or the end cap has been absent during periods of rain; or any form of cable end deterioration / ageing / swelling / or soiling is observed; it is recommended that the cable end be cut back 300 mm and re-examined for presence of moisture. If moisture is found, cut back further, and apply a new end cap to the cable end, ensuring a tight seal to the cable outer layer.

Installation Recommendations

for Halogen-Free Shipboard Cables

This document presents the guidelines for installing Helkama halogen-free shipboard cables. The guidelines are based on the standard IEC 60092-352 1) and on the experience from users.

Because the requirements of classification societies may differ, it is strongly recommended to get installation procedures approved by the classification society involved in each project.

CABLE SELECTION

Underground Cable Protection

Helkama halogen-free cables can be installed outside on open deck. If the cable will be exposed to heavy direct sunlight, it is recommended to use cable with black colour on outer sheath. Power and control cables with rated voltage 0,6/1 kV are black. Other cables are available in black on request. Another option is to paint the cables with water solvent paint.

CABLE PULLING

Only same size cables should be pulled at the same time. If different size cables (i.e. big difference in cable diameters) are pulled at the same time, the small cables may get damaged.

When pulling big cables, it is recommended to use cable rollers, especially if the cables are pulled with the help of cable pulling winches.

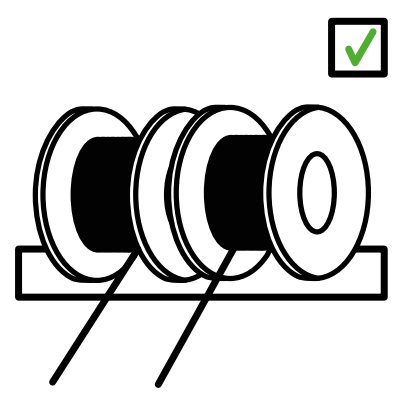

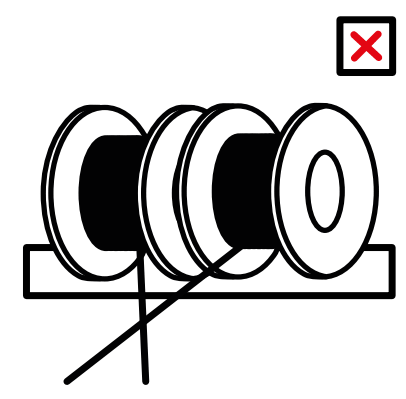

Cables should not be pulled crossing each other to avoid abrasion of the sheath at the crossing point. The number of cables to be pulled at the same time is determined by the installation conditions at site: distance to be pulled, open space available for looping the cable at intermediary drawing stations and the routing of cables (number of bends and number of corners).

The number of cables to be pulled at the same time is determined by the installation conditions at site: distance to be pulled, open space available for looping the cable at intermediary drawing stations and the routing of cables (number of bends and number of corners).

PROTECTION OF CABLES DURING BUILDING OR REPAIR

Against welding sparks:

- When welding close to cable drums or already installed cables:

- The drum and cable should be protected against the welding sparks e.g. with a fire blanket or with a protection plate. A fire blanket is found to be very practical and easy to use.

- Same methods can be used for the protection of installed cables.

Against abrasions on outer sheath:

- Temporary cables used at the site (e.g. for welding and lighting) should not be pulled crossing already installed cables to avoid abrasion of the sheath at the crossing point.

MINIMUM CABLE BENDING RADIUS

The minimum bending radius during installation and for fixed installation shall be according to the following table.

| Unarmoured & Unshielded Cable Types (LKM-HF AND LKMM-HF) | ||

| Diameter Range | During Installation | Fixed Installation |

| ≤ 25 mm | 6 x D | 4 x D |

| Unarmoured & Unshielded Cable Types (LKM-HF, LKMM-HF AND LKM-FRHF) | ||

| Diameter Range | During Installation | Fixed Installation |

| ≤ 25 mm | 9 x D | 6 x D |

| All Other Types | ||

| Diameter Range | During Installation | Fixed Installation |

| All sizes | 9 x D | 6 x D |

MINIMUM INSTALLATION AND OPERATION TEMPERATURE

MINIMUM INSTALLATION AND OPERATION TEMPERATURE

Minimum installation temperature for all cable types is –15 °C. Lowest operation temperature for all cable types is –40 °C.

CABLE FIXING

Cables shall be fixed by means of clips, saddles or straps of suitable material, which if ignited, will not contribute to any spread of flame along the cables or insulated wire. The material shall have a surface area sufficiently large and shaped so that the cables remain tight without their coverings being damaged. (IEC 60092-352 Clause 3.19)

As a guideline, the following recommendations can be given for straps (partly from Panduit web-site):

| Length of the Strap (mm) | Width of the Strap (mm) | Maximum Diameter of the cable bunch (mm) |

| 102 | 2.5 | 22 |

| 142 | 3.5 | 35 |

| 188 | 4.8 | 48 |

| 292 | 4.8 | 75 |

| 371 | 7.6 | 102 |

| 510 | 12.7 | 130 |

| 718 | 12.7 | 200 |

The distances between supports shall be chosen according to the type of cable and the probability of vibration. It shall not exceed 400 mm for a horizontal cable run where the cables are laid on cable supports in the form of tray plates, separate support brackets or hanger ladders. The spacing between the fixing points may be up to 900 mm, provided that there are supports with maximum spacing as specified above. This exemption shall not apply to cable runs along weather decks, when the cable run is arranged so that the cables can be subjected to forces by water washing over the deck. (IEC 60092-352 Clause 3.19)

When designing a cable support system for single core cables, consideration shall also be given to the effects of electrodynamic forces developing in the occurrence of a short circuit. The distances between cable supports given above are not necessarily adequate for these forces.

Cables with class 5 conductors may require additional support to prevent sagging. (IEC 60092-352 Clause 3.19) The requirement above can be fulfilled by fixing the cables to each step of the cable tray or at maximum 400 mm intervals.

Fixed installation must be used when the cable is protected with a heat shrinkable sleeve. If there is a possibility that the cable outside the heat shrinkable sleeve may vibrate or move, the heat shrinkable sleeve must be long enough to be fixed on both ends.

REPAIR INSTRUCTIONS FOR HELKAMA HALOGEN-FREE SHIPBOARD CABLE OUTER SHEATH

If the cable has a damaged outer sheath, screen and insulation:

- The whole cable has to be replaced.

If the cable has damages only (a hole or similar) on outer sheath, it can be repaired according to following instructions:

- Clean the damaged cable surface with a suitable cleaning agent.

- Grind the cable surface with sandpaper.

- Clean the grinded cable surface from sliver.

- Wind tape (Scotch 70) around the cable with a little extension. Ensure the winding has 20-50 % overlap.

- Set a shrink-on sleeve of flame retardant material over the taped length with 10 % overlap. Ensure that the diameter of the shrunk sleeve is correct.

- Heat up with a hot-air blower, not with a fire blower. Start heating from the middle and work towards the ends.

If the cable has a deformation but the outer sheath of the cable is undamaged:

- It may be difficult to determine if there is damage inside the cable.

- It is difficult to know if the screen wires have deformed the cable insulation. The screen wires may have damaged the cable insulation and the insulation wall thickness may have decreased.

- The characteristics will not be the same as for an undamaged cable.

If unsure, please contact the local representative of the classification society.

SPECIAL INSTRUCTIONS FOR LIGHT CABLES

Light cables include cable types LKM-HF L, LKSM-HF L, RFE-HF L, LKSM-FRHF L that are designed for applications where low weight and small size are required. Compared to standard cables, these cables are manufactured using smaller insulation and outer sheath wall thickness.

All the instructions in this document are also applicable to Light cables. In addition, using special caution is recommended in handling Light cables during cable pulling due to smaller outer wall thickness. IEC 60092-352 Ed.3.0 2009-9

Press Release | Thorne & Derrick Appointed Approved Stockist for UK Leading Cable Pulling Equipment Manufacturer

CABLE SOCKS & PULLING PRODUCTS LV MV HV

Complete range of LV, MV and HV cable pulling products for installation and enabling cable jointing in trench or ducts including LV, 11kV/33kV medium voltage (MV), 66kV/132kV high voltage (HV) and EHV transmission and distribution cables up to 400kV.

Further Reading | Cable Drum Handling & Laying Cables | A Guide from Nexans

Cable Rollers | Duct Rods | Cable Socks | Cable Lubricant | Duct Seals | Cable Duct | Cable Grips

HV Cable Jointing Preparation Using Cable Spiking Gun

July 8th, 2021

Spiking Cables

Spiking Cable

Pictured: One of Quartzelec’s cable jointers is applying a spiking gun to a cable on a recent substation installation project in Chester, UK in preparation for HV cable jointing. Cable spiking is the Quartzelec approved method of proving that any HV cables are not live before they are released for work.

Image Courtesy of: Quartzelec Limited

Quartzelec

Quartzelec Limited provide a unique range of contracting services to a diverse range of clients in the industrial, infrastructure and commercial and services sectors. They offer design, construction, commissioning, inspection and maintenance of distribution networks from 415V to 33kV.

Press Release | Thorne & Derrick Appointed Approved Stockist for UK Leading Cable Pulling Equipment Manufacturer

Further Reading

- Cable Drums | Recommended Transport & Storage

- How to Prepare Cables To Avoid Cable Damages & Faults

- Cable Pulling | Safe Pulling of Cables Using Motorised Pullers

- Cable Pulling | Safe Pulling of Cables Using Manual Laying

- Installation of Cable Sleeves | Jointing & Splicing Cables

- Installation of Rail Foot Cables

Cable Pulling Equipment

Thorne & Derrick distribute an extensive range of Cable Pulling & Laying Equipment to enable the safe installation of fibre and copper cables within the telecommunications industry. Safely installed cables reduces operational and maintenance requirements to the network and reduced service interruption to telecom cables, wires, ducts, cabinets and exchanges – products include cable spiking tools, conduit rods, cable lubricant, cable socks and rollers.

Jointers blog

Subscribe now to our POWER NEWSLETTER– a monthly email circulation packed with news, projects, videos, technical tips, training information, promotions, webinars, career opportunities and white papers.

Includes access to our popular JOINTERS BLOG with contributions from utility professionals, linesmen and cable jointers working on MV HV EHV cables and overhead lines typically at 11kV, 33kV, 66kV and up to 132kV.

Cable Grips | Supporting Inter-array, Export, Umbilical & Subsea Cable Installations

July 8th, 2021

Cable Grips

uploaded by Chris Dodds | Sales Marketing Manager at Thorne & Derrick International

Cable Grips

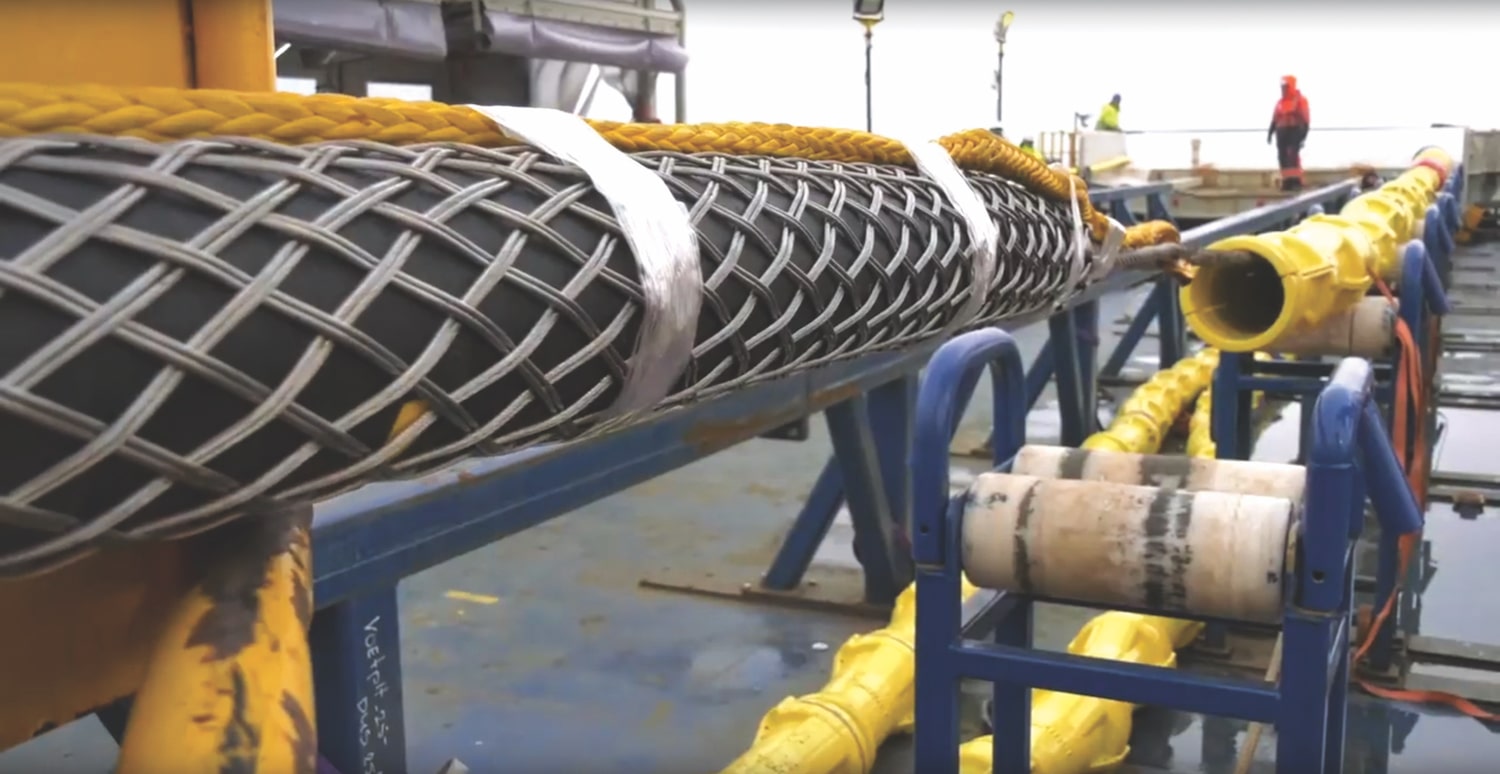

Pulling & Supporting Power & Subsea Cables in the Wind Sector

Slingco have developed a range of cable grips (commonly referred to as cable socks) specifically tailored to the needs of the renewable energy sector – working with Slingco we have produced engineered and customised solutions using cable grip innovation for Boskalis, NKT, Nexans, DEME and other major cable laying contractors for the connection of wind farm projects globally.

Thorne & Derrick have extensive ranges of marine cable grips and hose restraint grips – applications including LV MV HV EHV cable installation (onshore and offshore), support and gripping of cables inside wind turbines, pulling cables shore-to land, substation cable laying and general cable management. We have also developed a range of cable pulling grips for use in the installation and pulling of inter-array and export cables from offshore windfarm installations. We offer a complete range for cable diameters up to 350mm , 10Te to 90Te+ MBL in galvanised steel, stainless steel and aramid fibre.

Cable Grips | Standard Double Eye Cable Support Grips are available for low/medium/high voltage power cable pulls and support with approximate break loads up to 27,000kgs, stainless steel 316 grade option and outside cable diameter capacity of 250mm. Customer Application Cable Grips available on request.

Marine Grip Options

Option 1 – Limited Lay Down

Galvanised cable grips with aluminium ferrules are suitable for cable installation / loading and typically used for OSS pull in.

Option 2 – Limited Lay Down / Wet Storage

Galvanised grips with galvanised steel ferrules for installation / loading with limited wet storage that can be further extended for longer wet storage with the addition of an anode.

Option 3 – Lay Down / Wet Storage up to 1000 Hours

Stainless steel cable grips with stainless steel ferrules for laying and limited wet storage up to <1000 hours, subject to inspection after such time elapsed.

Option 4 – Lay Down / Wet Storage over 1000 Hours

Non-metallic grips in Aramid for used for cable laying and wet storage applications over >1000 hours, these would be the preference of the leading installation contractors based in the Netherlands and Europe, degradation was not seen other than some signs of salt on the surface. Non-metallic cable grips are specified to provide safe cable handling and are used for offshore saltwater environments when prolonged lay down durations are required.

Supplied by Thorne & Derrick

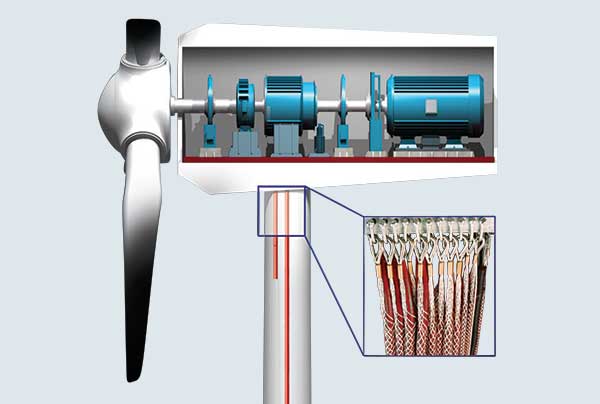

Wind Energy Cables

Pulling & Supporting Power & Subsea Cables in the Wind Sector | These cable socks manufactured from offshore/marine grade type 316 Stainless Steel are suitable for use in the renewable energy sector in applications such as cable installation (onshore and offshore), cable support inside wind turbines and cable management – used to pull, protect and support wind turbine cables. Pictured: June 2020 : the first of two export cables, each 37 kilometres in length, has been installed at the nearshore of Thorntonloch Beach as part of construction of the Neart na Gaoithe (NnG) Offshore Wind Farm.

Wind Turbine Support Grip

- Cable supports designed for minimal contact with the actual cable

- High working loads and cable support

- Manufactured from 316 stainless steel for corrosive atmospheres

- Rounded copper ferrules

- Bespoke cable grip design options available

For wind turbines, special features have been included to allow for minimal contact with the actual cable while still allowing impressive working loads and cable support. The range of cable support grips for wind turbines are woven from 316 stainless steel and feature rounded copper ferrules, offering reduced cable contact for high vibration environments. In addition to the standard range of catalogued cable grips and pulling socks we can offer a custom design service to suit your cable support requirements.

Cable Grips, Socks & Support products for the Renewable Industry

Single Eye | Double Eye | Lace-Up Grips for Marine Offshore Cable Support & Pulling | Extreme Heavy Duty for Underwater Application up to 550mm Cable Diameters

- Hose Restraint Cable Grips

Hose Restraint Grips | Heavy Duty Hose Restraint Grips | Hose Armour Grips for Hose Protection | 316 Stainless Steel U Type Hose Grips | Prevents Whipping From Detached Pressure Hoses

- Non-Metallic Cable Grips (Aramid)

- Wind Turbine Support Grips

- Extended Thimble Eye Heavy Duty Stainless Steel Cable Grips

Slingco has 40 years of experience manufacturing marine cable grips via their Distributor Network including Thorne & Derrick serving customers in over 70 countries worldwide – they are an award-winning supplier of high-quality cable grip, cable sock and wire rope products, having won the Queen’s Award for Export International Trade in both 2016 and 2020.

Large Cable Project Capacity & Delivery

Slingo and Thorne & Derrick are known for their excellent customer service, technical support and on-time order fulfilment – additionally we have the skills, experience and manufacturing capacity to deliver on the most challenging demands. From initial product design and manufacture to technical support and customer service, our aim is to become a partner you can trust for the safe installation, support and pulling of cable in the wind energy sector.

Client Confidence | Test Reports Certification

Quality matters in all industries, but none more so than those we serve. Every Slingco product is designed, manufactured and tested to exacting standards to ensure safe and reliable operation under the most challenging conditions – this level of customer service is backed-up with detailed test reports and relevant certification, all available on request.

Aramid | non-metallic / non-conductive marine grip manufactured from Aramid recommended for array / export cable installation were the cable needs to be laid down for a prolonged duration before installation.

fURTHER iNFORMATION

- Cable Pulling | 37km Offshore Cable to Connect NnG to Onshore Substation

- Slingco Take A Firm Grip on The Future With Cable Socks

- MV HV Cable Laying, Installation & Support Products | Offshore Windfarms

Image Courtesy | Max States Site Engineer at Balfour Beatty plc (Viking Link) – here the EHV 526kV cable is pictured being pulled from a 62 tonne cable drum (1240m circuit) into the cable trench via rollers in July 2021. Viking Link is a 1,400 MW HVDC submarine power cable under construction between the United Kingdom and Denmark.

Cable Pulling & Laying Equipment

Suppliers & Distributors

Thorne & Derrick distribute the most extensive range of Low & High Voltage Cable Installation & Electrical Distribution Equipment to the Power Transmission & Distribution industry in the onshore and offshore wind, solar, rail, oil/gas, data centre, battery storage and utility sectors – this includes the most extensive range of Cable Pulling & Cable Laying Equipment to enable the installation of low, medium and high voltage power cables into underground trench or duct.

We service UK and international clients working on underground cables, overhead lines, substations and electrical construction at LV, 11kV/33kV and up to EHV transmission and distribution voltages.

Key Products: MV-HV Cable Joints & Terminations, Cable Cleats, Duct Seals, Cable Transits, Underground Cable Protection, Copper Earth Tapes, Cable Jointing Tools, Feeder Pillars, Cable Ducting, Earthing & Lightning Protection, Electrical Safety, Cable Glands, Arc Flash Protection & Fusegear.

Distributors for: 3M Electrical, ABB, Alroc, Band-It, Cembre, Centriforce, CMP, Elastimold, Ellis Patents, Emtelle, Furse, Lucy Zodion, Nexans Euromold, Pfisterer, Polypipe, ProGARM, Prysmian, and Roxtec.

- Scope –single-source supply of extensive range of products

- Stock – a multi-million pound stock holding provides complete global supply solutions

- Staff – technical support from a trained, proactive and friendly team

- Delivery – UK stock turnaround with express logistics to all international destinations

Further Reading | Cable Drum Handling & Laying Cables | A Guide from Nexans

HV Cables | Underground Cable Tunnel Pull 400kV By ABB

July 6th, 2021

HV Cables | Underground Cable Tunnel Pull 400kV By ABB

Cable Pulling & Laying

ABB manufactured, installed and commissioned the 400kV cable for the National Grid’s largest ever tunnelling project, called ‘The London Connection’, a 20km long 400kV underground cable to supply central London which was energised in 2005 and which was at the time one of the longest 400kV underground cables in Europe.

The need

With electricity demand in North West London and the City increasing twice as fast as the national average and projections showing that this growth would be sustained for a decade, National Grid set out a project called The London Connection designed to create a three phase high voltage supply for North West London and the City.

Essential to National Grid’s future licence to operate, the connection linked Elstree to St John’s Wood through a new three metre diameter, 20km long tunnel to a new £60 million substation, also constructed by ABB.

Project details

ABB manufactured a total of 61km of high-voltage cable using cross-linked polyethylene (XLPE) insulation technology, which eliminates the need to use old-fashioned oil and high maintenance gas filled cables. A similar ABB 400 kV XPLE underground cable has been in service in Berlin since 1998.

The cable was manufactured at our own plant in Germany and underwent a one-year duration test at an independent test facility, where it was signed off as fit for purpose.

Three phase HV AC cable installed in the tunnel

ABB supplied 150mm diameter cable for three 20km lengths – one for each of the three phases of the supply. At a total weight of 2,440 tonnes, the act of pulling the cable along the length of the tunnel was an element of the project that threw up significant challenges.

ABB delivered the cable to site on 63 massive separate cable drums and pulled it through the tunnel in three sections at intermediate shafts along the length of the tunnel, with the longest cable pull being around 7.5 km. ABB used a special arrangement of cable pulling equipment for the safe and smooth installation through the tunnel. A post-pulling cable insulation test proved that the cable was ready for safe service as part of the grid.

As a full turnkey project, ABB’s successful installation of the cable and connection to the new St John’s Wood substation meant that the London Connection was ready for National Grid to operate in summer 2005 and it has been in operation providing energy to London consumers ever since.

Cable Pulling & Laying Equipment

Suppliers & Distributors

Thorne & Derrick distribute the most extensive range of Low & High Voltage Cable Installation & Electrical Distribution Equipment to the Power Transmission & Distribution industry in the onshore and offshore wind, solar, rail, oil/gas, data centre, battery storage and utility sectors – this includes the most extensive range of Cable Pulling & Cable Laying Equipment to enable the installation of low, medium and high voltage power cables into underground trench or duct.

We service UK and international clients working on underground cables, overhead lines, substations and electrical construction at LV, 11kV/33kV and up to EHV transmission and distribution voltages.

Key Products: MV-HV Cable Joints & Terminations, Cable Cleats, Duct Seals, Cable Transits, Underground Cable Protection, Copper Earth Tapes, Cable Jointing Tools, Feeder Pillars, Cable Ducting, Earthing & Lightning Protection, Electrical Safety, Cable Glands, Arc Flash Protection & Fusegear.

Distributors for: 3M Electrical, ABB, Alroc, Band-It, Cembre, Centriforce, CMP, Elastimold, Ellis Patents, Emtelle, Furse, Lucy Zodion, Nexans Euromold, Pfisterer, Polypipe, ProGARM, Prysmian, and Roxtec.

- Scope –single-source supply of extensive range of products

- Stock – a multi-million pound stock holding provides complete global supply solutions

- Staff – technical support from a trained, proactive and friendly team

- Delivery – UK stock turnaround with express logistics to all international destinations

Thorne & Derrick International, based in the UK, are delighted to announce they have entered into an Approved Stockist Agreement with SEB International, the market-leading Cable Laying Equipment manufacturer.

Cable Drum Handling & Laying Cables | A Guide from Nexans

July 5th, 2021

Handling Cable Drums

Extract from Instructions for Transportation, Handling, Storage of the Drums & Laying of the Cables | Sept 2014

Cable Drum Handling

Deformation of Cable Sheath Jacket

When Handling Cables

The following information provides advice on the handling of cable drums published by Nexans – always consult with your client or local electric utility to ascertain local preferences and procedures for the Laying, Pulling & Handling of Cable Drums (LV – EHV).

- The cable must not be pulled with a tension above the maximum pulling tension

- The cable must not be subjected to a bend smaller than the minimum bending radius (given as the “minimum bending radius during installation” and not to be confused with the “minimum bending radius after installation”)

- The cable must not be subjected to lateral pressure that exceeds the sidewall bearing pressure

A combination or action of any of the above three items, even without exceeding any of the manufacturers recommendations, can result in the elongation of outer layer of the cable and form a “rucking” or “corrugation” of the cable sheath during installation. Deformation of the sheath during installation is known to occur when the sheath material is softened by elevated temperatures, such as the range of PVC sheathing materials, particularly when the cable is installed in warmer ambient temperatures (near and above 30°C).

Note that actual cable surface temperature can be higher than ambient temperature. It is also known to occur when the outer layer is thinner than a full sheath, such as may occur when installing a Nylon covered cable, which is covered by a thin Sacrificial Sheath.

Such deformation should be monitored to avoid an escalation to very severe puckering, which could induce the tearing of the sheath. Rucking, corrugation, and puckering can be reduced by the use of lubricating substances which will reduce the friction experienced at turns or bends on fixed deflectors and on rollers and even on long straight sections.

Note that longer runs and heavier cables will experience this deformation more often.

Corrective action includes the pausing of the installation pull and the easing of tension and pulling the affected cable length past the bend or roller or friction point that is causing the effect. Once the affected area is moved along, there is often a re‐settling of the elongated sheath and the effect is reduced. Stopping and allowing the cable to cool, will tend to set the corrugations in place and they will not easily be removed. Where this deformation takes place, there is a small reduction of the thickness where the material is stretched, but such deformation as a whole is considered to be of minor consequence. Usually, no repair or corrective action is required on the cable itself. Repair is only necessary when there is a breaking or tearing of the sheath – should you have any technical or commercial enquiries on the subject of Cable Drum Handling please do not hesitate to contact us.

➡ Download the Document | Instructions for Transportation, Handling, Storage of the Drums & Laying of the Cables | Sept 2014

Thorne & Derrick are Official & Approved GMP4 Contracted Distributors for Nexans Power Accessories (UK) Ltd.

Press Release | Thorne & Derrick Appointed Approved Stockist for UK Leading Cable Pulling Equipment Manufacturer

Cable Pulling & Laying Equipment

Suppliers & Distributors

Thorne & Derrick distribute the most extensive range of Low & High Voltage Cable Installation & Electrical Distribution Equipment to the Power Transmission & Distribution industry in the onshore and offshore wind, solar, rail, oil/gas, data centre, battery storage and utility sectors – this includes the most extensive range of Cable Pulling & Cable Laying Equipment to enable the installation of low, medium and high voltage power cables into underground trench or duct.

We service UK and international clients working on underground cables, overhead lines, substations and electrical construction at LV, 11kV/33kV and up to EHV transmission and distribution voltages.

Key Products: MV-HV Cable Joints & Terminations, Cable Cleats, Duct Seals, Cable Transits, Underground Cable Protection, Copper Earth Tapes, Cable Jointing Tools, Feeder Pillars, Cable Ducting, Earthing & Lightning Protection, Electrical Safety, Cable Glands, Arc Flash Protection & Fusegear.

Distributors for: 3M Electrical, ABB, Alroc, Band-It, Cembre, Centriforce, CMP, Elastimold, Ellis Patents, Emtelle, Furse, Lucy Zodion, Nexans Euromold, Pfisterer, Polypipe, ProGARM, Prysmian, and Roxtec.

- Scope –single-source supply of extensive range of products

- Stock – a multi-million pound stock holding provides complete global supply solutions

- Staff – technical support from a trained, proactive and friendly team

- Delivery – UK stock turnaround with express logistics to all international destinations