Blog

Caution Tapes | The 3M 7900 Electronic Marking System

November 1st, 2023

3M | Caution Tapes

Electronic Marking system

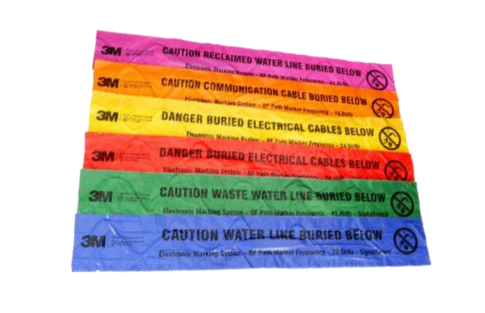

EMS (Electronic Marking System), manufactured by 3M Electrical, is a maintenance free product which is used for marking and locating the route of underground utilities – this includes the range of the following utilities: Wastewater 7904-XT (Green), Gas 7905-XT (Yellow), Recycled Water 7908-XT (Purple), Power 7902-XT (Red), Water 7903-XT (Blue) and Telecommunications 7901-XT (Orange).

Furthermore, the 3M EMS Tape is used to reliably overcome any associated problems and costs relating to the tracer wire and test stations.

Caution marker Tape

The 3M 7900 Marking Tape Series is available in 6 variations for any utility types which can be suitable for open trench applications, including direct buried electrical cables and utility pipework.

The 3M 7900 Caution Marker Tape works independently so if any part of the tape were to be cut or removed, the other markers consistently provide an accurate location whilst not requiring an external power source.

Electronic Caution Cable Tape | 3M

Key Benefits of 3m 7900 ems marker system

- 3M 7900 EMS does not require an external power source or connection to a transmitter

- The EMS System is easy to install and locate using the 3M Dynatel 7000 compatible locator

- Core materials inside allow for early warning for excavators digging nearby

- Work independently

Further Reading

- 3M Scotchcast™ Resins – EU Regulation 2020/1149 Amending REACH Restrictions

- 3M 92 NBA GS Scotchcast Resin Cable Joints (4GS Resin) – Unarmoured Cables

- 3M Dynatel | 1420 Marker Locators for Underground Cables & Utilities

3m scotch electrical tape

Thorne & Derrick distribute the complete range of 3M Scotch Electrical Tapes for the insulation, repair, identification, jointing and terminating of LV, MV & HV cables – specialist fire resistant tapes, arc resistant, semi-conductive and rubber splicing tapes up to 69kV enable the protection of LV-HV cables including 11kV-33kV medium voltages, against abrasion, moisture, alkalis and acids.

3M Scotch Tapes include vinyl electrical insulation, high temperature glass cloth, sealing mastics, rubber self-amalgamating and high voltage tapes to provide track resistance, semi-conductive and sheath repairs to LV, MV & HV cables.

Additionally, 3M Scotch tapes are suitable for end sealing high voltage cables and are highly conformable for irregularly shaped objects. Scotch tapes are stable and durable for years of maintenance-free service.

Thorne & Derrick provide competitive prices and fast delivery from stock for the complete range of 3M Scotchcast and Cold Shrink cable joints, terminations, resins and Scotch electrical tapes – we stock high voltage cable joints and terminations manufactured by 3M using Cold Shrink for 11kV, 33kV and 66kV cables.

Specialist Distributors to the UK and international industries to provide safe and reliable LV HV Electrical Cable & Power Distribution Systems up to 66kV – we are highly customer responsive and absolutely committed to providing a world-class service. Contact our UK Power Team for competitive quotations, fast delivery from stock and technical support or training on all LV-HV products.

Since 1985, T&D have established an international reputation based on SERVICE | INTEGRITY | TRUST.

Contact us for 3M Electrical, ABB, Alroc, AN Wallis, CATU Electrical, Cembre, Centriforce, CMP, CSD, Elastimold, Ellis Patents, Emtelle, Euromold, Filoform , Furse, Lucy Electric & Zodion, Nexans, Pfisterer, Polypipe, Prysmian, Roxtec, Sicame, WT Henley.

Stockists & Suppliers | UK & International Projects

Cable Cleats | Importance of Short Circuit Testing by Ellis Patents

October 31st, 2023

Cable Cleats | Importance of Short Circuit Testing

Ellis Patents Short Circuit Testing

Short-Circuit Testing is critical to the performance, reliability and safety of cable cleats and management systems- Ellis Patents, a global leader in the manufacture and innovation of cable cleats ensure that all their cable support products are tested to the latest version of the IEC 61914 International Standard.

Conducting a short-circuit test is a reliable solution to prove that a cable cleat can be capable of withstanding a specific set of fault conditions.

During a Short Circuit Test specifiers, consultants and engineers should also request, as standard, a complete Test Report. The Short Circuit test Report should include before and after photographs, and a table of results demonstrating the Short Circuit Test conclusions.

Live Cables and Health & Safety Improvements

The initial problem encountered by Network Rail was that live cables were having to be removed from cable cleats, work carried on around them, and then somehow placed back between tightly spaced upright studs at regular intervals along an entire cable run. Ellis Patents addressed the issue by designing a brand new cable cleat that could be stacked and fixed with nothing more complicated than a quarter turn fixing lock.

This means additional cable runs can be added quickly and easily, without any need to tamper with existing cable installations. The rapid-fit nature of the Ellis No Bolts cleat is further enhanced by the replacement of fixing nuts with a push-fit locking mechanism that securely fastens the lower and top section of the clamp together. In addition to its PADS approval, the Ellis No Bolts cleat also meets the London Underground 1-085 approved material standard, and conforms with international cable cleat standard IEC 61914.

Cable Cleats & Short Circuit Testing

pURPOSE OF sHORT ciRCUIT tESTING

Ellis Patents conducts Short Circuit Testing as a reliable way of proving that their cable cleats are capable of withstanding any specific set of fault conditions.

Conducting a Short-Circuit Test is the industry trusted procedure to demonstrate a cable cleat is capable of withstanding a specific set of electrical fault conditions.

Ellis Patents insist that any claims of cable cleat strength and performance should be supported by a short-circuit test carried out in an independent and accredited laboratory and appropriately certified.

This methodology is becoming commonplace, but prior to the publication of the international standard IEC 61914 many cable cleats were not tested, and those that were had no standardised testing method by which to gauge success or failure. As a result, test results were open to a wide range of differing interpretations.

IEC 61914 has provided a standardised method for conducting a short-circuit test and a definition of the criteria for a pass. It does though allow for a significant degree of latitude and so caution must be employed when interpreting results. Note should also be taken of the full report as opposed to just its headline page.

In the below video the team from Ellis Patents are showing witnessing testing of their cable cleat products at a independent laboratory in the Netherlands- this ensures the safety and reliability of LV MV & HV power systems.

Cable Cleats

Fix, Clamp & Support Cables

Cable cleats are used to provide effective short circuit protection, support and retention to LV, MV and HV power cable systems. When installed at intervals to circuits cable cleats and hangers are used to secure and retain power cables from 600V to 132kV.

Cable cleats or cable clamps manufactured from nylon, aluminium or stainless steel are installed to retain cables in the event of a short circuit – custom designed and engineered single and trefoil cable cleats are available.

These specific correct cable cleats will withstand forces corresponding to the values of the peak prospective short circuit current.

Specialist application cable cleats are available from stock for high performance cable applications including fire resistant, low smoke zero halogen/LSF, flame retardant and with specific end-user UK DNO utility approvals for medium/high voltage power cable cleating applications such as Triplex cables.

Key Benefits of Short Circuit Testing

- Provides short circuit protection up to 235kA

- Custom designed trefoil cable cleats to retain cables in event of a short circuit.

- Identifies capability of withstanding a specific set of fault conditions.

Further Reading

- Polymer Cable Cleats | Holding Power with Ellis Patents

- Cable Cleats | Importance, How To Specify & International Standards

- Important Factors You Need To Consider When Working With Cable Cleats

More Case Studies

- Ellis Emperor Cable Cleats | Sunrise Wind Offshore Wind Farm Case Study

- Phoenix Cable Cleats | Canary Wharf Tower

- Emperor Cable Cleats | Gwynt y Mor Offshore Wind Farm

Specialist Distributors to the UK and international Offshore Wind & Renewable industry to provide safe and reliable LV HV Electrical Cable & Power Distribution Systems up to 66kV – we are highly customer responsive and absolutely committed to providing a world-class service. Contact our UK Power Team for competitive quotations, fast delivery from stock and technical support or training on all LV-HV products.

Since 1985, T&D have established an international reputation based on SERVICE | INTEGRITY | TRUST.

Contact us for 3M Electrical, ABB, Alroc, AN Wallis, CATU Electrical, Cembre, Centriforce, CMP, CSD, Elastimold, Ellis Patents, Emtelle, Euromold, Filoform , Furse, Lucy Electric & Zodion, Nexans, Pfisterer, Polypipe, Prysmian, Roxtec, Sicame, WT Henley.

Stockists & Suppliers | UK & International Projects

Emtelle Fibrecast Microcable | Redefining Connectivity, Revolutionising Networks

October 31st, 2023

Emtelle | Fibrecast Microcables

Fibrecast Microcables

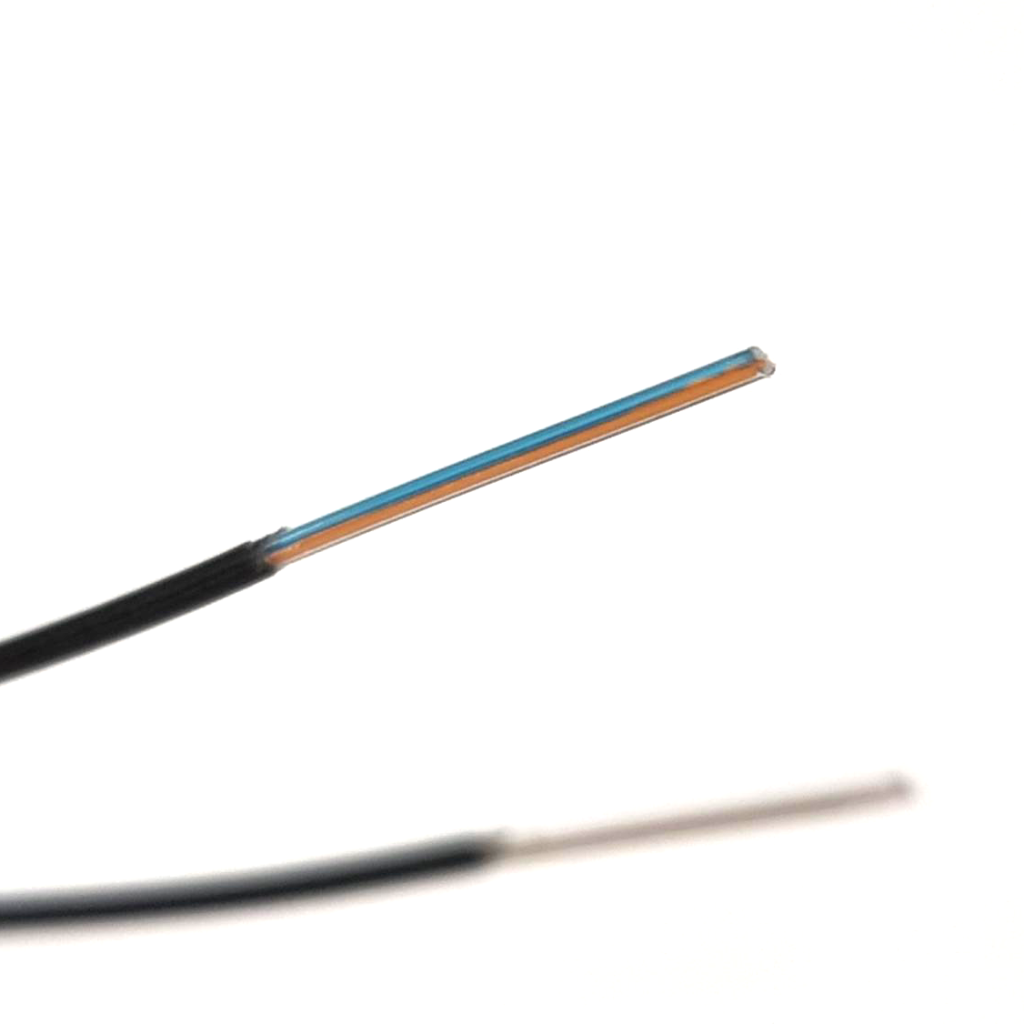

Fibre Unit (FU) with fibres set in an encapsulating layer providing excellent dimensional and thermal stability. An outer thermoplastic layer provides a high level of protection and excellent installation properties.

The FU is manufactured by Emtelle as a fibre element for installation into FibreFlow products. The fibres are dry, not coated with gel, thus permitting fast and contamination –free connections.

Fibrefast Microcable | Emtelle

Microcabling

An outer layer provides a high level of protection and excellent installation properties. The Microcable is designed for installation into FibreFlowTM duct products.

Emtelle’s microcable contains ‘low water peak’ single mode fibres meeting the ITU-T (International Telecommunications Union) recommendation G.657A2, G.657.A1 fibre is also available.

Outcome of using Microcables

FibreFastTM boasts an impressive 8% improvement in friction coefficient over our FibreFlow microcable. Rigorously tested on Emtelle’s test track, the innovative FibreFastTM results in superior blowing performance. With over 25 years of experience in manufacturing fibre cable solutions.

FibreFastTM microcable now features improved tensile performance making this product ideal for our pre-terminated blowable fibre cable solutions.

Fibrefast Microcable | FTTx | Emtelle

Fibrecast Microcable

Emtelle have developed the FibreFast microcable to improve the overall installation experience by reducing installation time (Ultra Low Friction Sheath) and equipment specification (lower installation pressure required) depending on the infrastructure quality.

FibreFast microcable now features improved tensile performance making this product ideal for our pre-terminated blowable fibre cable solutions and this is distributed by Thorne and Derrick.

The microcable is well suited to the FTTx market, where it excels as a blowable terminated solution. It has applications in 5G/FTTA (antenna)/IoT, distributions network infrastructure and FTTH (home) as a blowable customer connection cable.

Deployed in 2.1mm – 5.0mm internal diameter microduct infrastructure.

Also it has these key features:

- Perfect blowable customer connection cable when paired with Emtelle QWK connect

- Small is size meaning even better storage

- Assembles the LCv ferrule in under 30secs – Intuitive build compared to others on the market

Key Benefits from Alroc

- Superior blowing performance at low blowing pressure

- Improved durability – strong and lightweight cable.

- Tested in accordance with IEC 60794-5-20

Further Reading

- Sealing Cables | Decarbonisation & Storage Depot Case Study

- Sealing HV Cables | A Battery Energy Storage Systems (BESS) Case Study

- Sealing Cables | 400kV Substation Cable Sealing using CSD Systems]

Power Systems Earthing | An Introduction to Substation and Electrical Equipment Protection

October 31st, 2023

Power Systems Earthing | Electrode System

Power Earthing Systems

An earth electrode system, professionally designed by competent engineers, is essential to ensure the safety of personnel and protection of equipment from dangerous voltages in and around medium and high voltage (MV & HV) substations.

Earth Electrode Systems are a critical part of any electrical system and they are often seen as inert which may sometimes be dismissed as cost-saving or forgotten about until a later stage of the project – should these systems fail due to incompetent design or the use of cheap substandard components, the resulting events may be catastrophic or even lethal.

For instance this will carried out by competent and highly experienced electrical engineers and technicians. A.N Wallis are able to offer earth electrode system designs and associated testing services using the most up to date Earthing & Lightning Protection Equipment and design software CDEGS.

CDEGS (Copper Earth Electrode Design) is now recognised as the industry standard earthing design analysis software in the UK and in many other parts of the world.

Power Earthing System products, manufactured by A.N Wallis and distributed by Thorne and Derrick from high conductivity copper to BS EN 13601 is installed to protect buildings, overhead lines and medium/high voltage substations (MV-HV) against potentially catastrophic damage that can be caused by a lightning strike resulting in short circuiting.

Power Earthing System | A.N Wallis

CDEGS

CDEGS (Current Distribution, Electromagnetic Fields, Grounding and Soil Structure Analysis) is a grounding (earthing) and electromagnetic analysis software package. It is dedicated to accurately analyse problems involving grounding, electromagnetic fields, electromagnetic interference including AC/DC .

This software allows to stress test designs and systems to evaluate performance under given conditions making the electrode systems safe.

using Substation Electrode Systems

A.N Wallis offer high specification test equipment to carry out soil resistivity testing. This helps it gain data from tried and tested methods. It is then analysed using CDEGS software to then produce a representative electrical equivalent soil resistivity model which can be used in the earthing design process.

As a result if this were to fail due to a incompetent design they would be running multiple tests to keep the workplace safe.

The Importance of Earth Bars For Power Earthing Systems

Substation earthing bars (LV HV) are used to marshall earth connections, connect copper earth rods or earth cable conductors using crimp lugs for terminations in substations, cable pits, feeder pillars and switchgear.

Earthing bars can be tinned and bases power coated to improve corrosion resistance. Bars are pre-drilled with cable connection holes with optional threads for installation ease. Manufactured from highest conductivity and quality copper to British Standards.

Full range of standard, single and twin link types for LV, MV & HV switchroom/substations. Customised to suit the earthing requirements of your project on short lead times.

Electrode Systems

To outline, the three main areas to analyse with any Earth Electrode system are:

– Touch, Step and Rise of Earth Potentials (RoEP). (These are also known as Earth Potential Rise (EPR or Ground Potential Rise (GPR).

Thorne & Derrick working with A.N Wallis will liaise with the DNO (Distribution Network Operator) or Electricity Supply Company on your behalf to gain all the required ‘Point of Connection’ data for your new electrical connection. Using the Soil Resistivity data, A.N Wallis produce a conceptual earth electrode system layout based on the existing plant layout drawings and analyse the associated voltage contours using either the MALT or MALZ module of the CDEGS software. Graphical plots are produced using the CDEGS software that visually identifies any ‘hot’ spots around the site that may need further design time.

MALT (CDEGS) assumes that the entire earth mat is at the same voltage, which is very dangerous to consider, particularly on more significant sites with low soil resistivity.

MALZ (CDEGS) does allow for voltage drops along conductors but does not account for inductive or capacitive effects between conductors.

These Touch, Step and Rise of Earth Potential levels are assessed, and only when they are within safe limits will A.N Wallis pass this design for construction.

Further calculations will be carried out to determine whether the site may influence other electrical installations under fault conditions and from that we can determine the site ITU (International Telecommunications Union) classification as either HOT or COLD.

Only once we have confidence that the design parameters are met, a full ‘for construction’ style drawing will be produced.

Key Benefits of Power Earthing Systems

- Provides safety for LV MV HV electrical sites

- Provides protection against dangerous voltage in and around substations

- Helps identify and document loss in Power Earthing Systems

Further Reading

- Earth Bars | Wallis Earth Bar Software (WEBS)

- Correct Termination Of A Cable Lug Onto An Earth Bar | AN Wallis Guide

- AN Wallis Earthing & Lightning Protection | ECA Consultant & Specifier Associate

Earth Rods | Earth Tapes | Copper Earth Plates | Copper Earth Mats

THORNE & DERRICK are national distributors of LV, MV & HV Cable Installation, Jointing, Duct Sealing, Earthing & Electrical Equipment – we service UK and global businesses involved in cable installations, substation, overhead line and the installation of medium/high voltage cable joints and terminations at LV, 11kV, 33kV and HV.

Contact us for 3M Electrical, ABB, Alroc, AN Wallis, CATU Electrical, Cembre, Centriforce, CMP, CSD, Elastimold, Ellis Patents, Emtelle, Euromold, Filoform, Lucy Electric & Zodion, Nexans, Pfisterer, Polypipe, Prysmian, Roxtec, Sicame, WT Henley.

Utility Troughs | Anderton Concrete Cable Troughs

October 30th, 2023

Anderton | Utility Cable Troughs

Concrete Utility Cable Troughs

Anderton’s range of straight, tee, cornered and angled cable trough allow you to easily adapt to the environment you are working in. Whether that is requiring the ability to change direction or take off to another part of the construction site.

Anderton’s optimised Utility Troughs and Lids deliver outstanding protection for your large power and communications services. Not only that, but they are also manufactured here in the UK.

Utility Cable Troughs | Anderton

Utility Troughs and Lids

Anderton’s precast reinforced concrete Utility Troughs and Lids are used for a variety of purposes, from housing and protecting power and communications cables through to pipes carrying gas, water and chemicals. They safeguard against malicious or accidental damage and are easily accessible for maintenance and repair work. They can deliver up to 60% less embodied carbon than traditional concrete mixes.

cABLE tROUGHS

Anderton concrete cable troughs provide long term cable protection and easy access for cable repair, jointing and cable additions or diversions.

Cable troughing is an affordable sustainable solution to rail, highways and power industries for the protection and troughing of power, fibre optic, signal and rail cables including low and high voltages.

Concrete cable troughs are available in a variety of shapes and sizes ensuring cable protection solutions are possible for all routes of LV, MV & HV cables – rail cable trough provides trackside protection of power and S&T (Signal & Telecoms).

They are available for Pedestrian (LD) Occasional (LD) and Highways (HD) .

This is specified for cable containment in power, industrial, highways and nuclear projects.

Key Benefits of Concrete Cable Troughs

- Provides 60% less embodied carbon compared to traditional concrete mixes

- Safeguarding against accidental damage

- Easy to install

- Easy manual handling

- Anti-slip surface

Further Reading

- Anderton Concrete Cable Troughs

- LV Cable Joints & Terminations – Cold Shrink, Heat Shrink & Resin LV Cable Joints & Terminations

- GRC Cable Trough

Cable Sealing & Protection Case Studies

- Sealing Cables | Decarbonisation & Storage Depot Case Study

- Sealing HV Cables | A Battery Energy Storage Systems (BESS) Case Study

- Sealing Cables | 400kV Substation Cable Sealing using CSD Systems]

Specialist Distributors to the UK and international Offshore Wind & Renewable industry to provide safe and reliable LV HV Electrical Cable & Power Distribution Systems up to 66kV – we are highly customer responsive and absolutely committed to providing a world-class service. Contact our UK Power Team for competitive quotations, fast delivery from stock and technical support or training on all LV-HV products.

Since 1985, T&D have established an international reputation based on SERVICE | INTEGRITY | TRUST.

Contact us for 3M Electrical, ABB, Alroc, AN Wallis, CATU Electrical, Cembre, Centriforce, CMP, CSD, Elastimold, Ellis Patents, Emtelle, Euromold, Filoform , Furse, Lucy Electric & Zodion, Nexans, Pfisterer, Polypipe, Prysmian, Roxtec, Sicame, WT Henley.

Stockists & Suppliers | UK & International Projects