Blog

Overcoming Cable Corrosion On Steel Wire Armoured & Braided Cables

April 24th, 2023

Cable Corrosion Solutions & Products

-

uploaded by Chris Dodds - Thorne & Derrick Sales & Marketing Manager

Solutions To Cable Corrosion

3M Electrical Products provide an extensive range of cable repair solutions to prevent and overcome cable corrosion for the utilities, renewable energy, solar, construction, rail, mining, offshore, oil, gas and petrochemical industries – cable corrosion tapes and protection products are available to suit both direct burial (underground) and cables located onto containment in both indoor and outdoor installations.

Cable repair solutions are available for low and medium voltage cables suffering advanced cable damage caused by atmospheric steel corrosion – both onshore and offshore galvanised steel wire armoured and wire braided cables are especially vulnerable.

The Problem

Formation of Rust

The overall chemical equation for the formation of rust is:

Iron + Water + Oxygen → Rust

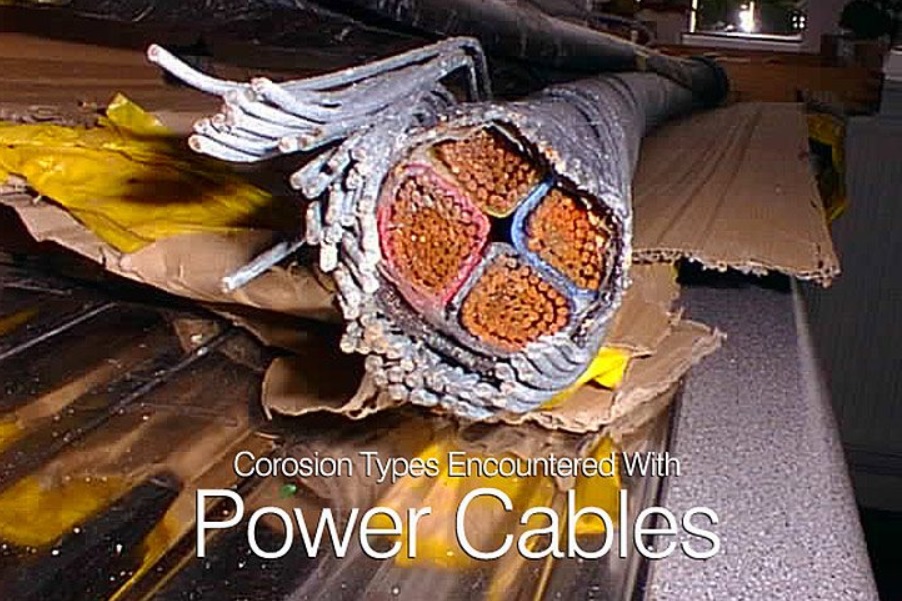

Advanced Cable Corrosion & Degradation

The pictured low voltage cables evidently have serious damage caused by long-term cable corrosion effects. The cable sheathing has been aggressively damaged and stripped back down to the galvanised steel wire armours. Steel typically corrodes or rusts rapidly in moist or humid conditions and the rate of corrosion accelerates with exposure to salt water, for instance in the marine and offshore industry.

The cable sheath should provide both waterproof and corrosion protection to the steel wire armours and copper conductors – in this case there is an urgent demand to prevent further cable corrosion damage to both the accessible and inaccessible cables strapped and cable cleated to the cable tray.

The complexity of the cable repair is compounded two-fold : the area is a “no-heat” zone designated a hazardous area location Zone 2 according to the ATEX Directive therefore traditional heat shrink cable repair kits are precluded from consideration due to the presence of a potentially explosive atmosphere. Furthermore due to the brittleness of the cables, resultant from significant corrosion damage, it was not an option to man-handle and subject the cables to further physical movement and mechanical strain.

Chemical Corrosion of Cables In Industrial

& Hazardous Area Locations

Hydrocarbons in the onshore and offshore oil/gas exploration and production sector seriously impact upon the integrity and ability of cables and cable accessories to provide uninterrupted service – standard polyurethane cable repair and jointing products would overtime degrade to destruction in the presence of aggressive chemicals.

Consequently, 3M Electrical have developed a chemical resistant cable joint utilising their 1402FR resin for harsh and hazardous cable installation environments where hydrocarbon exposure is expected under normal conditions – the Scotchcast resin cable joints have been adopted as specification standard by international oil and gas companies including Exxon Mobil, Chevron, Total and Royal Dutch Shell.

➡ Read our Blog for further information about the selection and specification of cable joints according to the ATEX Directive.

Cable Corrosion – 3M Solution

2 solutions to suppress future cable corrosion using 3M Electrical cable repair products :

- Accessible Cables – 3M Scotchrap 50 Tape provides advanced corrosion protection to cables exhibiting excellent resistance to abrasion, moisture, corrosive salt water, soil acids, alkalis and salts.

3M Scotchrap tapes are UV resistant and also resist impact punctures and tears with a very high weather and corrosion proofing performance for use on underground cables.

3M Scotchfil Electrical Putty can also be used to build-up irregular surfaces to provide a smooth, waterproof taping surface around cables where there is localised pitting type corrosion.

Scotchfil putty provides a versatile corrosion resistance solution to general cable and electrical equipment applications, the Scotchfil putty can be wrapped, stretched or moulded to conform to both standard and irregular surfaces.

3M Scotchfil Electrical Putty when over wrapped with either Super 33+ or Super 88 Vinyl Electrical Tape. Scotchfil™ electrical putty can also be used to build up cable joints and fill out major irregularities and voids.

- Inaccessible Cables – where cable access is limited 3M 1603 Insulation Spray can be used to protect cables and surfaces (including galvanised steel cable tray) against weather, moisture, corrosion, oil, alkalies and acids. 3M 1603 sprays provide easy access to hard-to-reach spots. eabling versatile on-site cable repairs without specialist tooling or requirement to disconnect or isolate cable circuits. 3M insulating spray sealers to spray over insulation on wire and cable splices, as a general-purpose sealer, or for touch-up insulation on motor windings and frames. Precautionary and first aid information for this product may be found in its Material Safety Data Sheet and on the product container.

Another type of cable failure is evidenced by visual indication of burning or arcing on the surface of the semiconductive layer of medium voltage cables. If the burning or arcing becomes extensive, the MV cable can fail from the outside in (pictured below).

The MV cable failure cause was determined to be a damaged cable sheath or jacket, which created a flowpath for corrosive ground water to penetrate the cable and cause severe corrosion to the metallic shield.

Scotch 70 silicone rubber electrical tape is a high temperature arc-and track-resistant tape composed of self-fusing, inorganic silicone rubber and easy-tear and easy-strip liner – the Scotch 70 tape is used as an over-wrap for protection of high voltage terminations and cables against arcing and tracking.

Some Further Reading : Corrosion Types Encountered With Power Cables : Underground Cables and Anodic Corrosion (Stray DC Currents), Cathodic Corrosion, Galvanic Corrosion, Chemical Corrosion, AC Corrosion, Local Cell Corrosion. By Edvard Csanyi (Electrical Engineering Portal EEP).

Whatever the cable condition or type of installation, 3M can provide innovative cable corrosion protection solutions based on Scotch electrical tapes, Scotchcast resin, heat shrink, cold shrink or spray based technology.

LV Cable Joints (Low Voltage Cables)

Thorne & Derrick stock and distribute LV Joints in Cold Shrink, Heat Shrink or Resin Cast technologies – multicore and multi-pair cable joints are available for immediate backfill and energisation of Low Voltage power, control and instrumentation cables 600V/1000V 3.3kV.

Complete range of LV Cable Accessories ➡

Cable Breakouts | Cable Caps | Cable Lugs | Cable Cleats | Cable Trough | Cable Duct | Feeder Pillars | for 11kV/33kV/66kV networks see MV HV Joints & Terminations

Pfisterer | Nexans Euromold | Prysmian | Cable Joints & Terminations MV HV

Cold Shrink by 3M | Joints | Abandonment | Terminations | Low Voltage LV Cables

Solar Farms | Insulate, Connect & Protect LV HV Electrical Cables & Equipment

April 17th, 2023

Photovoltaic Solar Farms

Reliable 3M Electrical Solutions That Help Keep Your Power On

Since 1985, Thorne & Derrick have been Authorised Distributors for the 3M Electrical range of Low & Medium Voltage Cable Accessories for the insulation, connection, repair and provision of reliable electrical power up to 33kV utilising Cold Shrink, heat shrink, Scotch Tape and Scotchcast Resin technologies.

For more than 30 years, 3M Electrical has been a trusted supplier of advanced materials for the solar industry. From engineered films to modular assembly solutions, 3M products are engineered to enhance performance, help improve reliability, and help drive down the critical cost per watt.

As one of the world’s leading suppliers of advanced films, tapes, coatings and adhesives, 3M have the ability to supply products and provide technical support around the world.

11kV | 33kV | 66kV Connections & Energisation

Thorne & Derrick distribute the most extensive range of MV HV Medium & High Voltage Cable Joints, Terminations & Connectors – this includes heat shrink, cold shrink, push-on and slip-over cable accessories enable the jointing, terminating and connection of 11kV-33kV and 66kV-132kV cables to oil, air or gas insulated switchgear, transformers, motors and overhead lines distributing electricity at medium/high voltages.

3M Electrical Products — the right protection for less downtime, fewer interruptions

Insulate, Connect, Protect & Energise

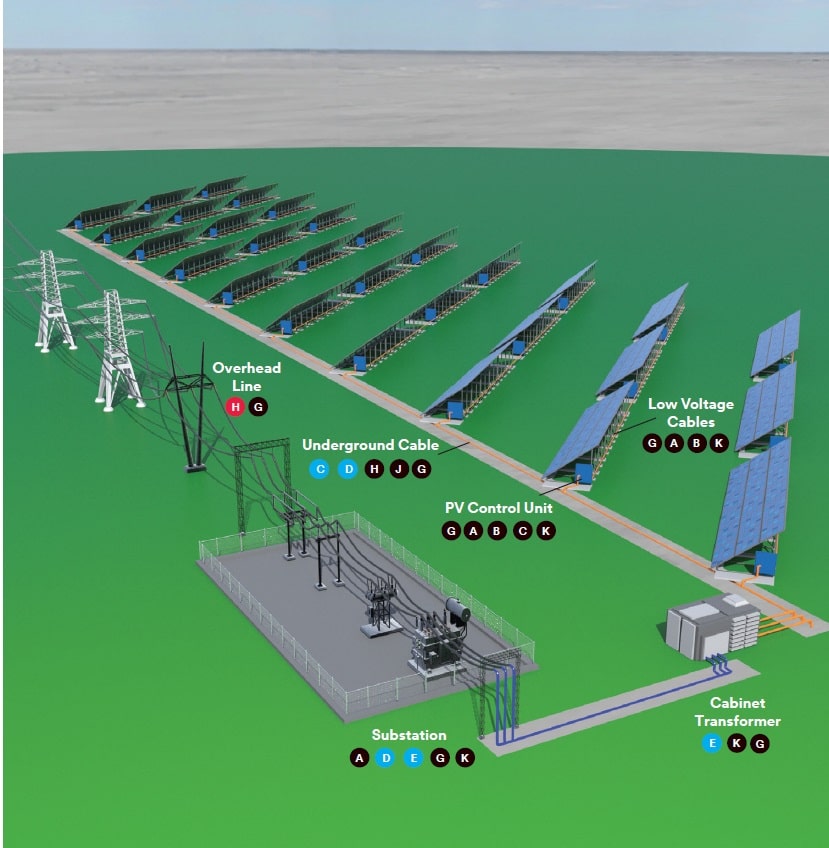

Each letter below represents an electrical construction or maintenance application.

Match all letters that apply to the facility illustration to see all the places where 3M Electrical Products help you deliver efficient, reliable, and sustainable energy solutions.

Cable Applications

A |

Insulate Wires and Cables • Repair and re-insulate LV cables and busbar • Repair or replace busbar insulation • Insulate and seal in harsh conditions |

| Connect Wires and Cables • Conductor to conductor (pigtail and inline) • Conductor to flat pad or pin-connection |

|

|

Splice Cables • Splice underground buried and submerged • Splice in cable tray or ductwork • Shearbolt and compression connectors |

| Rejacket and Protect Medium Voltage Cables • Rejacket buried and submerged cable • Provide mechanical and abrasion protection |

|

E |

Terminate Cables • Terminate in switchgear • Terminate live-front busbar connections • Terminate with dead-front separable equipment connection • Terminate in outdoor pole top and substation connection |

| Motor and Equipment Maintenance • Insulate motor lead connections • Repair busbar insulation • Repair metal housing for motors and pumps |

|

|

Be Safe on the Job • Equipment outlet line insulation • Personal protection |

| Protect Cables from Fire, Water or Corrosion • Resist water, oil and chemicals • Resist abrasion, puncture and cut-through • Resist pipe corrosion |

|

|

Fire Protection • Protective wraps • Caulks, putties, foams and large opening solutions • Sprays, sealants and tapes |

| Locate & Mark • Map path and depth of underground assets |

|

|

Maintain & More • Cable identification and cable management • Metal lubrication and rust resistance |

Photovoltaic Solar Farms

Voltage Rating of 3M Product Applications

Indicates high voltage application (69KV-145KV)

Indicates medium voltage application (5KV- 46KV)

⚫ Indicates low voltage application (<1000V)

3M Electrical Product Application Guide

| Application | 3M Solution | Faster installation | Outdoor/UV resistance | Low temps performance< 0°C | High temperatures > 105°C | Moisture/humidity | Chemical/corrosion protection | Small or tight spaces | Irregular shapes or sharp edges | No access to cable end | Mechanical protection |

| Connect | Spring Connectors | • | • | • | • | ||||||

| IDC Connectors | • | • | • | • | • | • | |||||

| Direct Bury Kits | • | • | • | • | • | ||||||

| Butt Connectors | • | • | • | • | • | ||||||

| Insulate & Protect |

Vinyl Tapes | • | • | • | • | • | • | • | |||

| Rubber Tapes | • | • | • | • | • | • | |||||

| Mastic Tapes | • | • | • | • | • | ||||||

| Specialty Tapes* | S,C | S,G,V | C,S | C,S | • | • | G,V | ||||

| Motor Lead Kits | • | • | • | • | • | • | |||||

| Heat Shrink | • | • | • | • | • | • | |||||

| Splice & Terminate |

Resins | • | • | • | • | • | • | • | • | ||

| Cold Shrink Splices | • | • | • | • | • | • | |||||

| Compression Lugs & Connectors | • | • | • | • | |||||||

| Terminations | • | • | • | • | • | • | |||||

| Separables | • | • | • | ||||||||

| Locate & Mark |

Locators | • | • | • | • | • | • | • | • | ||

| Markers | • | • | • | • | • | • | • | • | |||

| Maintain & More |

Wire Terminals | • | • | • | • | ||||||

| Lubricants | • | • | |||||||||

| Wire ID | • | ||||||||||

| Cable Ties | • | • | • |

NOTE: Products vary within each category. Not all products will be suitable for all the application requirements listed.

*Speciality Tapes coding: S=silicone, C=corrosion protection, G=glass cloth, V=varnished cambric

Thorne & Derrick are Specialist Distributors to Solar EPC’s & High Voltage Jointing Contractors working on the design, construction and maintenance of UK, European and international projects supplying an extensive range of LV HV Solar Cables, Jointing, Substation & Electrical Eqpt.

Based in the UK, we are highly customer responsive and absolutely committed to providing a world-class service.

We stock LV HV Solar Cables, Accessories & Electrical Equipment to enable the construction, maintenance and operation of utility-scale PV installations – our products connect 600V/1500V solar cables into combiner boxes, inverters, transformers and energise switchgear up to 33kV/132kV for high voltage grid connections.

Since 1985, we have provided expert technical support and express delivery from extensive UK stocks to world-wide destinations.

Further Reading

- Jointing, Grounding & Terminating DC Solar Cables

- Solar Farms Replace Nylon Cable Ties With Metal Cable Ties

- Video : Solution to Terminating & Connecting Photovoltaic Solar Aluminium Cables

- Seaward Solar Utility Pro | Solar Cable & PV Installation Tester

- Bi-Metallic Cable Lugs | Compression Crimp Terminations for Aluminium Cables

- Nexans Euromold Connectors : EPDM Rubber Screened Separable Connectors For Medium Voltage Cables

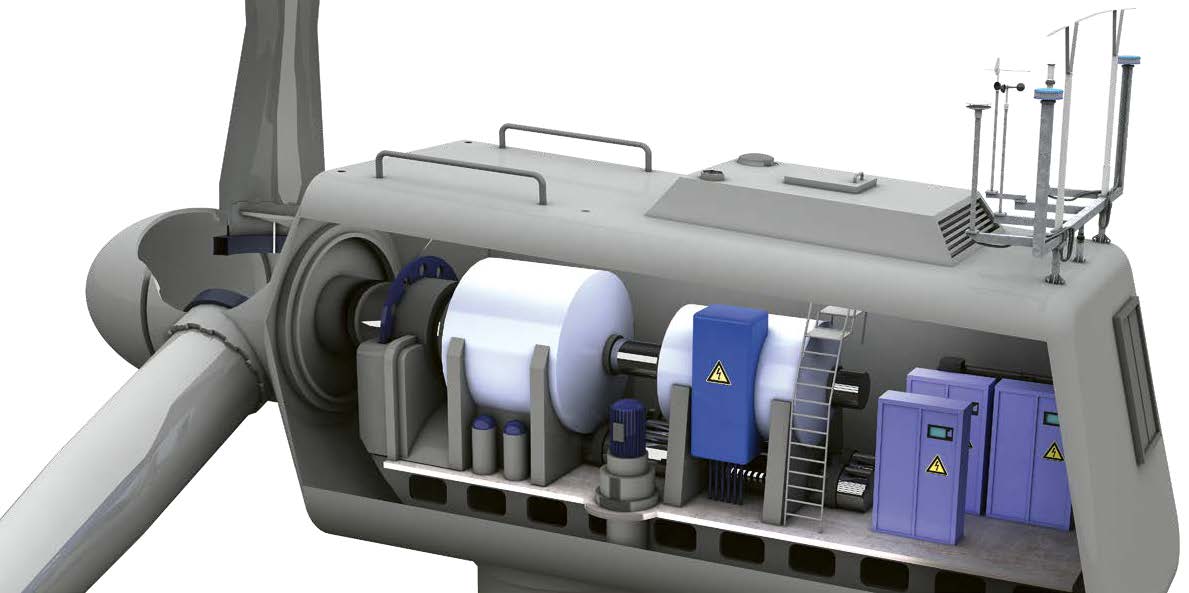

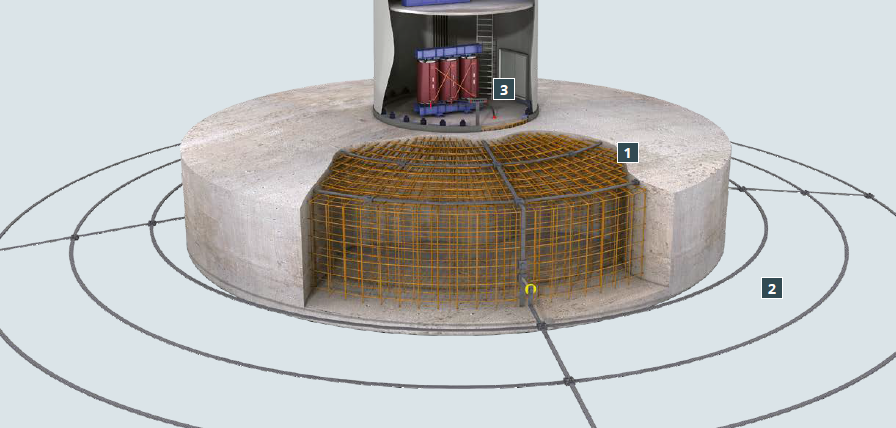

See How DEHN Provides Electrical Protection for Wind Turbines

March 29th, 2023

Electrical Protection For Wind Turbines

Electrical Protection for Wind Turbines

Lightning & Surge Protection by DEHN

Ensure smooth operation and protect investments with lightning and surge protection safety equipment from DEHN.

Committed to the protection of workers and material assets, Thorne & Derrick together with DEHN can offer electrical protection specifically for wind turbines with a range of innovative products.

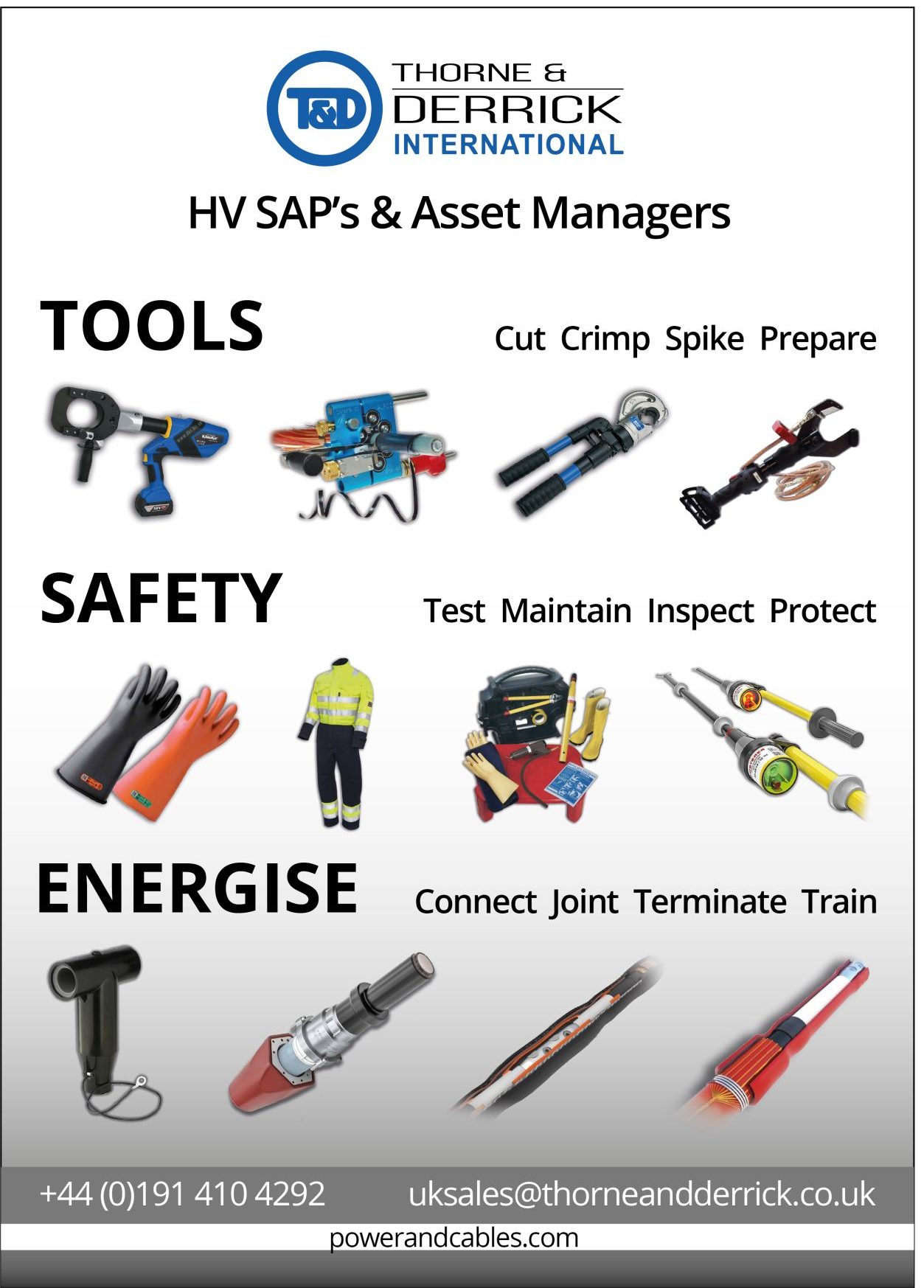

Thorne & Derrick provide an extensive range of electrical safety equipment including insulating gloves, voltage detectors, insulating matting and portable earthing to ensure worker safety when carrying out maintenance on LV-HV switchgear, substations, cables and electrical equipment.

Electrical Safety Products for LV MV HV Cables, Conductors, Substations & Earthing

Secure profit on your investment

The feed-in remuneration for renewables is sinking worldwide and putting the wind branch under increasing pressure. To ensure that investments in new wind turbines pay off in future, too, the top priority is to optimise the availability of the turbines. This prevents loss of revenue due to downtime and high service and repair costs.

Their height makes wind turbines particularly susceptible to destructive lightning events. If insufficient protective measures are taken, the risk of damage and downtime due to lightning is correspondingly high. An integrated lightning protection system is therefore a must.

It consists of external and internal lightning protection, earthing and equipotential bonding.

Take the safe option and entrust the globally recognised specialist DEHN with your lightning and surge protection. Our high-quality and durable products protect turbines on all continents, from the foundations to the rotor blades. Take advantage of our services and make quicker and verifiable progress. We can assist you by, for example, conducting risk analyses, creating bespoke protection concepts and product solutions, or conducting system tests in our accredited test centre.

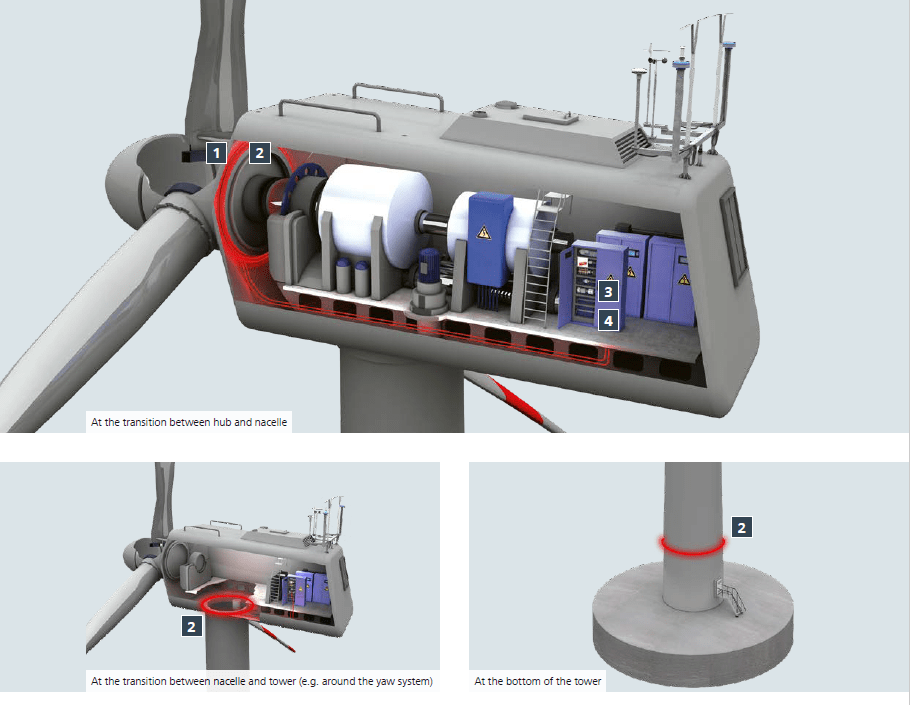

Developing lightning protection zone concepts with expertise

To secure the availability of wind turbines, the lightning protection zone concept aims to prevent lightning damage to mechanical and electric components. This is achieved by discharging lightning current and controlling surges.

The lightning protection zone concept for wind turbines described in IEC 61400-24 deals with the topic of lightning protection for wind turbines including detailed information on the selection of lightning and surge protection measures 1).

As the basis for creating a protection concept, a wind turbine is subdivided into lightning protection zones. One distinguishes here between external zones (LPZ 0A und 0B) and internal zones (LPZ 1, LPZ 2…n) 2). The external zones of a wind turbine – except the rotor blade – are determined by way of the rolling sphere method. The subdivision of the internal zones very much depends on the construction of the individual wind turbine and should be conducted accordingly.

Having laid down the relevant lighting protection zones, one can then define the necessary protective measures. It is advisable to create a lightning protection concept at the initial planning stage of a wind turbine to avoid later cost-intensive repairs and retrofitting. Long experience in the field of lightning and surge protection and the numerous system tests conducted for the wind industry have given DEHN the know-how to develop effective lightning protection systems for wind turbines. We will assist you in developing a lightning protection concept for your turbine consisting of external lightning protection, internal lightning protection, equipotential bonding and earthing.

1) IEC 61400-24 Lightning Protection of Wind Turbines

2) LPZ: Lightning Protection Zone

Always reliably informed with DEHNdetect

Lightning Current Measuring System Prevents Subsequent Damage

Damage resulting from a lightning strike does not necessarily lead to the immediate failure of the turbine. This means that lightning events often remain undetected, especially in the case of upward flashes where the initial long stroke current flowing is only a few 100 A and can be the main cause of damage, e.g., to the rotor blades.

Continued operation of the turbine can lead to serious subsequent damage. Lightning current measuring systems are often employed to detect lightning events and prevent subsequent damage. However, dangerous upward flashes are not always fully detected due to the low current flow of the measuring system. As well as impulse currents, DEHNdetect also reliably registers these dangerous long stroke currents, thus preventing expensive maintenance work and long downtimes. DEHNdetect identifies the following parameters:

- Impulse current [kA]

- Long stroke current [A]

- Load [C]

- Specific energy [MJ/Ω]

- Rise time [kA/μs]

Benefits:

- Prevention of subsequent damage

- Reduction of maintenance / repair costs

- Reduction of downtime

The system can be integrated in the IT infrastructure of the wind turbine via existing interfaces. The data can then simply be read out and managed using the available SCADA systems. If direct integration is not possible, the data can be transmitted to a cloud and evaluated via a web application. This makes it possible to monitor several turbines or even entire wind parks.

Invest in availability to secure the power supply of your turbine, today and tomorrow.

| DEHNdetect Components | ||

| 1 |  |

DEHNdetect BDU Detector for the wireless detection of lightning current in the rotor. |

| 2 |  |

DEHNdetect ICC IMP Measuring coil long stroke current and impulse current. Measuring range 60 A to 250 kA. |

| 3 |  |

DEHNdetect DL Data logger with different interfaces for integration in IT systems. |

| 4 |  |

DEHNdetect integrator Processing of the measuring signals and transmission to the data logger. |

Lightning & surge protection

in the Wind Turbine nacelle

All lightning and surge protective devices by DEHN for application in wind turbines are vibration- and shock-tested in compliance with IEC 60068-2.

Power Supply Systems

By implementing coordinated surge protection measures for power supply systems, the risk of system downtime due to lightning currents and surges can be avoided. This increases the availability of the wind turbine in the long term.

Information Technology Systems

A consistent protection concept prevents damage to information and data systems. Condition monitoring is indispensable for operational safety and plant availablity. The monitoring unit for the condition-oriented monitoring of up to 50 BLITZDUCTORconnect arresters fulfils this task. Remote monitoring is also possible.

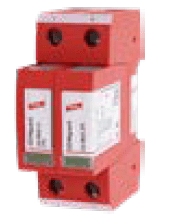

| Application | Type | ||

| Power Supply Systems | |||

| 1 |  |

DEHNsolid | Rotor blade heating Coordinated type 1 SPD, with 200 kA discharge capacity and low voltage protection level (Up ≤ 2.5 kV). |

| 2 |  |

DEHNguard M TN CI | Pitch system, aircraft warning light Type 2 SPD, especially space- and cost-saving due to integrated backup fuse. |

| 3 |  |

DEHNguard SE H 1000 VA FM + earthing clip |

Generator Type 2 SPD, further development of the “Neptune circuit” – Advantages: small dimensions save space and costs, improved protection level. |

| 4 |  |

DEHNguard M TNC | Voltage supply

Type 2 SPD |

|

Information Technology Systems |

|||

| 5 |

|

BLITZDUCTORconnect |

Protects signal, bus or control lines |

|

|

DEHNpatch Class E |

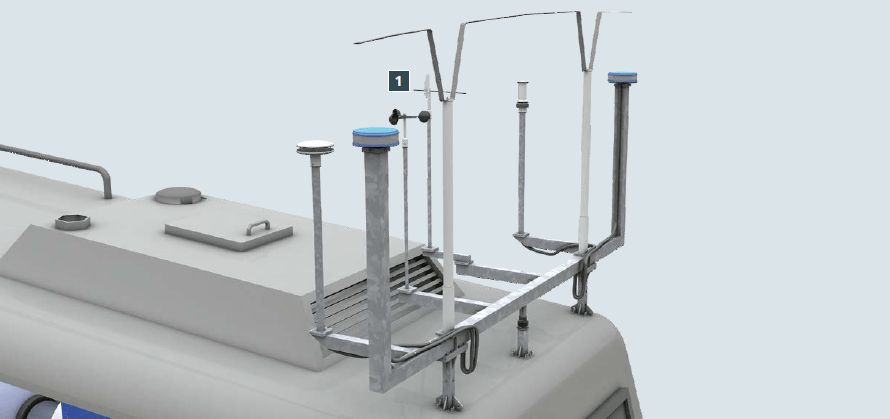

Universal type 2 SPD for Ethernet and structured cabling up to 250 MHz. |

|

|

|

BLITZDUCTOR VT |

Weather station |

|

|

|

DEHNrecord IRCM |

Condition monitoring unit for up to 50 BLITZDUCTORconnect arresters. With LED status indication and floating remote signalling contact. |

|

Safely discharging lightning current

External Lightning Protection

Safe interception and discharge of direct lightning strikes is paramount for the availability of a wind turbine. DEHN ensures that this is the case by testing components like the HVI power Conductor with a lightning current of 200 kA (10/350 μs) as stipulated in IEC 62561. The stainless steel design of the air-termination rods and connection elements fulfils stringent corrosion resistance requirements.

Earthing & Equipotential Bonding

Safe operation of electrical equipment and systems and a well-functioning lightning protection system require an earth-termination system designed according to IEC 61400- 24 1). Connection elements which are capable of carrying short-circuit current ensure the safe contact of the earth-termination system with metal parts of the foundations and the main earthing busbar. A high level of product quality safeguards long-term mechanical strength and corrosion resistance.

| Application | Type | ||

| External Lightning Protection | |||

| 1 |  |

HVI power Conductor (in supporting tube with air-termination rod)) |

Class of LPS 1 – 200 kA (10/350 μs) – High-voltage-resistant, insulated down conductor for maintaining the separation distance. |

|

HVI power long Conductor (cut to length) |

Individual lengths, on request we can assemble your conductors with the appropriate connection elements. |

|

|

UNI disconnection clamp 200 kA | 200 kA lightning current carrying capability according to IEC 62561- 1 2), stainless steel V2A. |

|

|

KS connector 200 kA | 200 kA lightning current carrying capability according to IEC 62561- 1 2), stainless steel V2A. |

|

|

MV clamp 200 kA |

200 kA lightning current carrying capability according to IEC 62561- 1 2), stainless steel V2A. Lightning current carrying connection of the air-termination system and down conductor. |

|

|

Tubular air-termination rod |

Safe interception of the flash charge in permanently corrosionresistant, stainless steel design. |

|

|

Air-termination rod StSt |

Safe interception of the flash charge in permanently corrosionresistant, stainless steel design |

|

| Application | Type | ||

| Foundation Earthing | |||

| 1 |  |

Connecting clamps | Clamps for connecting round and flat conductors in concrete foundations and reinforcements with round and flat conductors with tested short circuit current carrying capacity (50 Hz). |

|

Round wire 10 mm St/tZn | Round wire tested to IEC 62561-2 for use in lightning protection and earth-termination systems 3). | |

|

Strip 30 x 3.5 St/tZn | Strip tested to IEC 62561-2 for use in lightning protection and earth-termination systems 3). | |

|

Fixed earthing terminal type M V4A |

Corrosion-resistant connection of the ring earthing with the foundation earthing at the base of the tower. | |

| Ring Earth Electrode | |||

| 2 |

|

Connection clamp with threaded bolt StSt (V4A) |

For connection of round and flat V4A conductors to fixed earthing terminal |

|

Cross unit StSt V4A | Corrosion-resistant connection of the individual ring conductors in V4A. | |

|

Stainless steel strip V4A | Corrosion-resistant ring conductor in V4A. | |

| Equipotential Bonding | |||

| 3 |  |

Equipotential bonding in the tower base/equipotential busbar StSt |

Suitable for equipotential bonding and protective/functional equipotential bonding. |

Safe service and maintenance work

DEHN safety equipment

Safe Right Down The Line

Work on electrical systems is becoming more and more demanding. Make sure you use safe and reliable equipment. DEHN offers tested products and reliable services which protect your employees from injury caused by arc faults and secure the availability of your systems. This gives you, as the employer, legal certainty.

Safe At Work

- Personal protective equipment and arc flash clothing

- Voltage detectors

- EaS devices

- Fixed ball points

- Arc fault protection systems

| Application | |

| External Lightning Protection | |

|

Safe when it matters most Reliable protection against arc faults in electrical installations: DEHNcare personal protective equipment keeps you safe from the thermal effects of an arc fault. DEHNcare equipment is also comfortable to wear thanks to the unique material combination of leather and neoprene. The protective equipment is tested to international standards and consists of a hood, safety helmet for electricians, face shield, protective gloves, jacket and trousers or coat. |

| Voltage Detectors | |

|

Safe right down the line Make sure that no voltage is present with a capacitive voltage detector from 1kV to 420kV. Choose from a wide range of voltage detectors – you are bound to find your voltage and frequency! |

| EaS devices and fixed ball points | |

|

Safe earthing and short-circuiting (EaS) Configuring your individual EaS device for your system is simple and flexible. Fixed ball points |

|

Arc fault protection system |

|

|

Safe – fast – flexible DEHNshort quenches arc faults in your low-voltage switchgear installations in milliseconds. Your employees are safe when carrying out maintenance and repairs. Profit from optimised system availability: your system runs and runs, downtime due to an arc fault is significantly reduced. |

ELECTRICAL SAFETY PROVIDERS

We protect substation engineers, asset managers, SAPS, cable jointers, overhead linesmen and utility workers with PPE and safety equipment: this includes insulating gloves, arc flash clothing, voltage detectors, insulating matting and portable earthing to ensure worker safety when carrying out repair and maintenance on LV-HV switchgear, transformers, substations and turbines.

All of our Cable Connection & Energisation Accessories including Medium & High Voltage joints, terminations, connectors and cleats are tested to the latest international standards and supporting ranges of professional installation tools are stocked to reduce incident, accident and downtime to plant and people.

High Voltage Inspections | Wireless Inspection Camera for Systems up to 33kV/123kV

March 27th, 2023

DEHN High Voltage Inspections Camera

High Voltage Inspections Camera

Brings the invisible to light

DEHN are committed to the protection of workers and material assets with their developments and innovative products in the field of lightning protection, surge protection and safety equipment. DEHN ensure that your buildings and installations are protected during operation, maintenance and repair. Their focus is particularly on wind energy, photovoltaic, process industry, traffic and communication solutions.

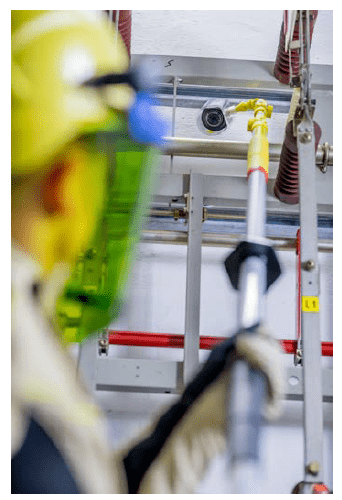

The Wireless Inspection Camera has been introduced for use with systems up to 123kV – allowing for easy and quick inspections on high voltage switchgear installations, even on difficult to access parts.

Facilitates work

The inspection camera makes regular inspections on medium-voltage and low-voltage installations easier: difficult to access parts can be easily reached with the flexible operating head.

Saves time

The installation does not have to be disconnected during inspection. The state of the installation can be evaluated with the help of photos and films and measures can be discussed.

Increases safety

Photos of the installation are transmitted live from the inspection camera to a smartphone or tablet computer via radio link. This ensures that the electrician does not have to enter the live working zone.

Brings the invisible to light

The inspection camera allows the state of the installation to be monitored without great effort. Tools forgotten during maintenance work can be found with the help of photos and films.

Brings light into the dark

Flexible working at any time, day or night, even in poorly illuminated environment. With the additional optional lighting you are independent of the lighting conditions.

Wireless Inspection Camera for High Voltages up to 123kV

Reliable inspection and easy operation via radio link to a smartphone or tablet

The 123kV wireless inspection camera is supplied as a complete set in a case. It consists of a camera with battery, USB cable, smartphone attachment, housing, adapter with gear coupling and transport case.

- For visual inspection of electrical installations with nominal voltages up to 123 kV / 15 to 60 Hz (without special training)

- Installation does not have to be disconnected

- For documentation of the state of the installation

- Wireless operation of the camera via smartphone or tablet computer (System requirements: Android version 4.0 – 5.1 or iOS version 7.0 – 12.0)

| SET DIGIK | Part No. 766 390 |

| Standard | Based on EN 50508 |

| Camera | 18.2 megapixels Wide-angle lens with 10x optical zoom Optical image stabiliser Autofocus PlayMemories Home App Wi-Fi integrated Micro-USB 2.0 connection HD video recordings in MP4 format Temperature range: 0 °C … +40 °C Material: Plastic |

| Dimensions of the case | 395 x 290 x 105 mm |

| HG ZK 230 | Part No. 766 393 |

| Handle*) with gear coupling up to 1000 V / 15 to 60 Hz and 1500 V / d.c. |

ELECTRICAL SAFETY PROVIDERS

We protect substation engineers, asset managers, SAPS, cable jointers, overhead linesmen and utility workers with PPE and safety equipment: this includes insulating gloves, arc flash clothing, voltage detectors, insulating matting and portable earthing to ensure worker safety when carrying out repair and maintenance on LV-HV switchgear, transformers, substations and turbines.

All of our Cable Connection & Energisation Accessories including Medium & High Voltage joints, terminations, connectors and cleats are tested to the latest international standards and supporting ranges of professional installation tools are stocked to reduce incident, accident and downtime to plant and people.

Protection Against Arc Flash, Faults & Electric Shock | 5 Safety Rules

March 24th, 2023Protect employees from electric shock and arc faults

In industries working around high and low voltage electricity, the importance of Electrical PPE and arc flash protection is widely recognised, and the latest electrical safety requirements are understood by managers and operatives alike.

It is imperative that the 5 safety rules are complied with to prevent accidents when working on electrical systems. By using insulating tools and equipment, electric arcs are prevented from forming and the working distance is made bigger.

DEHN are committed to the protection of workers and material assets. The energy and the spirit of innovation of more than 1,400 employees are reflected in their developments and innovative products in the field of lightning protection, surge protection and safety equipment.

DEHN protection at a glance:

Effective – The probability of an arc fault occurring is reduced and the PPE protection level increased.

Protective – The employee is further removed from the system, increasing his/her safety during work.

Competent – DEHN offers the right products for complying with the 5 safety rules.

Foresighted – A large range of services ensures that electrical equipment is kept safe permanently.

ARC FLASH Protection | Five safety rules

| 1. Disconnect completely |  |

Operating poles are used for safe hot stick working when switching and insulating live equipment. | ||

| 2. Secure against reconnection | Locking devices secure the work location against re-powering. | |||

| 3. Verify that the installation is dead | Voltage detectors are available for verifying a dead condition on all poles at the work location. | |||

| 4. Earthing and short-circuiting | Earthing and short-circuiting devices for earthing and short-circuiting electrical systems. | |||

| 5. Provide protection against adjacent live parts | Insulating protective shutters for protecting against accidental contact with live parts of an installation. |

reducing Arc Flash risk

The use of tested insulating tools and operating sticks reduces the probability of occurrence of an arc fault and thus also the risk involved. Furthermore, the individual is distanced further away from the system (working distance) due to the lengths of the insulating sticks, meaning the PPE protection level is increased.

Arc Flash Protection & Electrical Safety Products | Distributed By Thorne & Derrick

ELECTRICAL SAFETY PROVIDERS

We protect substation engineers, asset managers, SAPS, cable jointers, overhead linesmen and utility workers with PPE and safety equipment: this includes insulating gloves, arc flash clothing, voltage detectors, insulating matting and portable earthing to ensure worker safety when carrying out repair and maintenance on LV-HV switchgear, transformers, substations and turbines.

All of our Cable Connection & Energisation Accessories including Medium & High Voltage joints, terminations, connectors and cleats are tested to the latest international standards and supporting ranges of professional installation tools are stocked to reduce incident, accident and downtime to plant and people.

C

C