Blog

Has Cable Jointing Just Moved On? Discuss.

August 31st, 2018

Leading ICP – Independent Connection Provider

With Guest Comment by Reece James MIET

Co-Owner and Operations Director at Rock Power Connections

-

uploaded by Chris Dodds - Thorne & Derrick Sales & Marketing ManagerLets put the Cable Jointing cat amongst the pigeons……..

Question: Has Triplex Killed The Jointer?

The universally respected BICC Generation of crème de la crème Cable Jointers experienced on jointing XLPE, fluid-filled and gas type cables might bemoan the modern industry trend, or nose-dive, towards polymeric power cable systems.

Recently nicknamed the Triplex Tripe Age on Linked-In by a former BICC’er.

Paper Lead is in vogue no more, Triplex is the new PILC and Plastic is here to stay.

Face facts, it’s unstoppable but as we hurtle headlong down BS7870 street does that mean we can all become Jointers overnight?

Yes, we know plastic is damaging the Planet and is bad for our environment but is it also messing with our Jointers? Or is plastic fantastic?

Polymeric cables have become increasingly simpler to strip, prepare and joint but surely Competency remains vital to safeguard industry standards?

What role have the Jointer Training Centres to play in this?

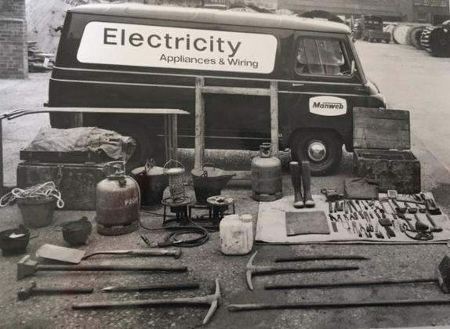

The days of metal pots, compound buckets, burners with heater, whackers for backfilling, picks and shovels is long gone. It’s 2018.

The drift away from paper insulated lead covered cables (PILC) started last century with the almost global adoption of modern polymeric type cables – this has heralded the introduction of precision engineered Jointers Tools to ensure efficient cable preparation of medium-high voltage cables.

Allegedly this has removed the skill, dexterity and Craft out of the Art of Jointing Cables?

For what it is worth here’s my two penn’orth.

The “roll-up roll-up”, pay your £2K and in 4 days time you can start your new career as a Cable Jointer message is frankly undermining confidence, reputation and the earning potential of the experienced Jointer.

experienced Jointer.

Familiarisation is not Competency.

But the issued Paperwork can dupe some Recruiters sometimes into booking “Jointers” onto projects they are not yet adequately qualified or trained to undertake.

Many have not invested in the tool-set never mind the skill-set. Believe me, on an average day I receive 10-15 LinkedIn Direct Messages from non-electricians aspiring to become Cable Jointers under the influence of often misleading social media messages.

There is no fast-track to achieve the workmanship and skills levels of most of the Jointers we meet here on LinkedIn – Great Jointers and Great Guys.

Check them out on our Jointers Blog.

Sorry but some Training Centres will take “all-comers” while others screen/vet potential Trainees via CV scrutiny – that’s an important distinction.

Another more important stand-out for me is peer attitude – some will nurture, care passionately and graft daylong to maintain Jointing industry standards through the sharing of their extensive skills and experience with their staff. Supporting their career paths and fuelling their ambition while getting them to knuckle under and earn their spurs.

People like Reece James.

So to answer the question Has Cable Jointing Moved On?

Read Reece James thoughts:

“Ok I’m going to be controversial here but Cable Jointing has moved on.

11kV Cable End Termination

As an apprentice trained DNO Cable Jointer who can work on old and new HV and LV lead cables, compound end boxes, do sweated cable joints and lead plumbing yes it did take years to learn the trade properly. However with new plastic Triplex cables, shearbolt connectors etc an experienced electrician can go on a short duration jointing course and learn how to joint / terminate cables to an excellent standard. I’ve shadowed a few of my staff before authorising them, giving them a few extra tips but the standard of there work is top notch. No, they are not fully rounded cable jointers like in the old days but on the cables they have been trained on and with on job experience there is no issue with the quality of there cable jointing work. It’s all down to the person and if they take pride in their work.

I remember the odd DNO trained jointer who did not care and turned out rough cable joints because they were in a rush. I just think it is unfair to tarnish all new (short training course) cable jointers with the same brush. I do however think there needs to be a minimum level of competence for someone doing these cable jointer training courses and in my experience a trained electrician is a good starting point!”

Meet Reece James MIET

♦ Bio

I am a highly motivated and experienced professional who is passionate about the electricity distribution industry and developing people. I have over 30 years experience in the electrical power industry, with the last 5 years as Operations Director of Rock Power Connections, which I Co-founded in 2012.

I have worked on various projects from LV connections to new EHV primary substation builds up to 400kV and have acted as Consultant Project Manager for many large developers, introducing competition, increased value and risk management for all their utility connections / requirements. I pride my self on my excellent customer service and relentless drive to deliver and exceed the customer’s expectations and my down to earth approach to business.

Developing my team and watching them succeed is one of my biggest motivations.

Who Are Rock Power Connections?

Rock Power Connections are power connection experts, specialising in independent electrical connections up to 33kV and DNO services up to 132kV – Lloyds accredited as part of the National Electricity Registration Scheme (NERS) and CHAS accredited.

Rock Power provides solutions from initial enquiry through design of electrical networks, construction (cable laying, jointing, substation installation), commissioning and final adoption of assets to DNO or Independent Distribution Network Operator (IDNO).

Working on behalf of a broad range of commercial developers to install new connections and repair / replace old equipment across sectors from retailers to residential, factories to farms – building and maintaining low, medium and high voltage cables and networks.

Thorne & Derrick – Stickists & Suppliers of MV HV Joints, Terminations & Connectors

Hover over our Interactive Electricity Grid to learn more about our product ranges – T&D are Specialist Distributors to DNO’s, ICP’s and NERS Registered Providers of LV, MV & HV Jointing, Earthing, Substation & Electrical Eqpt.

LV 600/1000V ◊ MV 11kV 33kV ◊ HV 66kV 132kV

T&D - CABLES ♦ JOINTS ♦ TERMINATIONS ♦ CONNECTORS ♦ GLANDS ♦ CLEATS ♦ CRIMPS & LUGS ♦ DUCT ♦ SEALS ♦ ARC FLASH PPE

EARTHING ♦ FEEDER PILLARS ♦ JOINTERS TOOLS ♦ CABLE CUTTING & CRIMPING TOOLS ♦ COLD SHRINK ♦ HEAT SHRINK ♦ FUSES

PRICE LIST | 11kV Triplex Cable Joints & Terminations

August 31st, 2018

Competitive Quotations | Large Stocks | Technical Support

Thorne & Derrick have an International Distribution Agreement with Nexans Power Accessories UK and are their main stockists and suppliers for their range of Heat Shrink Joints & Terminations up to 33kV, including 11kV Triplex cables.

Due to the following Key Points the Nexans brand of Triplex Joints & Terminations are increasingly preferred and adopted by NERS Accredited Independent Connection Providers (ICPs) working on 11kV DNO and private networks including Northern PowerGrid, WPD, UKPN and SSE.

Key Points:

- Manufactured by Nexans – “Global Expert in Cables & Cable Systems”

- Tested – International Standard IEC60502-4

- High Quality Heat Shrink Tubes & Components

- No Jointer Retraining Required – Clear Jointing Instructions

- Distributed By T&D – Technical Support, Fast Quote & Next-Day Delivery

The Nexans Training centre provides jointer training courses that are specifically tailored to enable upskilling of cable jointers from LV to MV 11kV, 33kV and 66kV.

The Jointer Training courses cover various cable constructions, cable preparation plus the installation of heat shrink / cold shrink push on cable terminations, separable connectors and cable joints.

Tripex Cable Termination & Joint Kits

Selection Tables

Heat Shrink Joints & Terminations Type Tested To CENELEC HD629.1 S2 & IEC 60502-4

| JOINT / TERMINATION DESCRIPTION | NEXANS ORDER CODE | |

| 95sqmm Joint 11kV | 17JTS1.95W | |

| 185sqmm Joint 11kV | 17JTS1.240W | |

| 300sqmm Joint 11kV | 17JTS1.400W | |

| 95sqmm Termination 11kV | 3x12MONIi1.95 | |

| 185sqmm Termination 11kV | 3x12MONIi1.240 | |

| 300sqmm Termination 11kV | 3x12MONi1.400 |

- All joints are heat shrink type, single phase and include mechanical shearbolt connector

- All terminations are heat shrink type, 3 phase and include universal cold-applied boots (FB1), “top-hat” Triplex gland (HSGK2), brass wire screen earth lugs and mechanical shearbolt connectors

- Also available – Cold Applied Slip On Joints & Terminations | Euromold Connectors (Screened Separable Connectors)

Cable Terminations & Joints

Nexans MONOi heat shrink cable terminations are a one-piece co-extruded anti-track (red) and stress control tube for connection and terminating 11kV BS7870-4-10 Triplex Cables 95-300sqmm into medium voltage electrical equipment.

Easy, quick to install without requirement to retrain Jointers.

Specification & Installation Instructions For Jointers

➡ TERMINATIONS TRIPLEX Jointing Instruction

➡ JOINTS TRIPLEX JTS1 W Jointing Instruction

♦ Joints & Termination Suit Cable Specification: 11KV Triplex Cable – available in sizes 95sqmm – 300sqmm. Stranded/solid aluminium conductor, XLPE insulation, copper wire screen (35sqmm). MDPE outer sheath. Colour Red. 6350/11000 volts grade to BS7870-4.10. The cable consists of 3 single core high voltage cables in Triplex formation.

33kV Cable Joint Kits

- All 33kV joints are heat shrink type, single phase and include mechanical shearbolt connector. Refer to Jointing Instruction.

| 33kV JOINT DESCRIPTION | NEXANS ORDER CODE | 2021 PRICE + VAT |

| 50-95sqmm Single Core Straight Joints XLPE CWS | 36GTS1.95w | |

| 95-240sqmm Single Core Straight Joints XLPE CWS | 36GTS1.240w | |

| 185-400sqmm Single Core Straight Joints XLPE CWS | 36GTS1.400W | |

| 400-630sqmm Single Core Straight Joints XLPE CWS | 36GTS1.630W | |

| 800-1200sqm Single Core Straight Joints XLPE CWS | 36GTS1.1200W |

Cold Shrink Splices & Cable Jointer Training

August 29th, 2018

-

Image Kind Courtesy : John Perez - Quanta Underground Power Services / A Quanta Company Words : Chris Dodds - Thorne & Derrick Sales & Marketing Manager

Cold Shrink

The dependability of any proprietary brand of Joint or Termination is dependent upon the skill and competence of the Splicer and ultimately the standard of the Splicer Training provided to that Splicer. Bad pun klaxon……this is a simple fact of Splice.

Since their introduction in the 1970’s, 3M Cold Shrink products, including cable splices and terminations, document exceptional field service history – BUT this failure rate is only as exceptional as those Splicers installing them.

Splicers specialising in the jointing and terminating of MV HV cables require initial work experience, on-the-job mentoring, training and often formal vocational education – training continues throughout the lifetime of the career of a Splicer as new methods and working practices evolve against the backdrop of changes to the types of cable being used.

Our dynamic Splicers with their nerves of steel and the concentration powers of a chess Grandmaster must maintain a steady hand and focussed mind when working their cables – whether strong-arming a PILC cross in a muddy hole knee deep in brown squelch or performing a high-wire terminator act out the back end of a Bucket Truck.

Anyway, here goes those jaw-drop 3M stats 🙂 :

- Low failure rates*

– 0.067% for Cold Shrink Cable Splices

– 0.022% for Cold Shrink Cable Terminations

*Data based upon U.S. failure data of U.S. manufactured 3M Cold Shrink Medium Voltage Cable Accessories between 2009 and 2012.

Cable Splices

Here, the trainee Splicers are shown the installation procedure for cable splicing of medium voltage PILC (Paper Insulated Lead Covered) cables – the Cold Shrink cable splice body is positioned on the cable following the preparation of the cable using appropriate jointing tools and prior to the installation of the mechanical shearbolt connectors.

Cable Type: MV Medium Voltage PILC 3 Core 15kV Manufactured by CME Wire & Cable.

QS4 Splices & QTIII Terminations

Listen, before the phone calls start these Videos are NOT for Training purposes – so to all the “You Tube Jointers“ watching out there, get real and get trained.

Better still become Competent. Then train some more. Stay Competent. Achieve Manufacturers Certifications – go get trained by Nexans Euromold, Pfisterer and 3M.

Choose your UK Jointer Training Centre with care, especially Live Cable Jointers Courses.

Let’s protect and preserve the reputation of the beautiful Craft of Splicing – like Andy O’ Malley says “build it like you own it.”

Take Pride but above all Take Care. Enjoy the Movies!

This Video demonstrates the installation of their 3M Cold Shrink Cable Termination QT III for terminating MV-HV Cables with tape shields.

3M pioneered and innovated Cold Shrink tubing and technology in the 1970’s and since then their products have secured global utility approvals: https://www.powerandcables.com/cold-s… 3M Cold Shrink Cable Joint QS4 – MV HV JCN CablesThorne & Derrick International, based in the UK, are Main Distributors for 3M Electrical products – further info: https://www.powerandcables.com/manufa…

This Video demonstrates the installation of their 3M Cold Shrink Cable Joint QS4 for jointing MV-HV JCN Cables.

Info Cold Shrink Tubes https://www.powerandcables.com/cold-shrink-tubes/

bitrate 628 kb/sheight 360duration 00:03:34.58fps 29.97width 640originaldate 2018-05-02T14:47:42.000000Z3M Cold Shrink Cable Termination QTIII – MV-HV Tape Shielded CablesThorne & Derrick International, based in the UK, are Main Distributors for 3M Electrical products – further info: https://www.powerandcables.com/manufa…

This Video demonstrates the installation of their 3M Cold Shrink Cable Joint QS4 for jointing MV-HV JCN Cables.

Info Cold Shrink Tubes https://www.powerandcables.com/cold-shrink-tubes/

bitrate 429 kb/sheight 360duration 00:02:16.02fps 29.97width 640originaldate 2018-05-02T14:46:17.000000Z

THORNE & DERRICK SPECIALIST ELECTRICAL DISTRIBUTOR

LV ♦ MV ♦ HV

T&D distribute the most extensive range of LV, MV & HV Cable Jointing, Terminating, Cable Pulling & Installation Equipment – we service UK and international clients working on underground cables, overhead lines, substations and electrical construction at LV, 11kV, 33kV and EHV transmission and distribution voltages.

- Key Products: MV-HV Cable Joints & Terminations, Cable Cleats, Duct Seals, Cable Transits, Underground Cable Protection, Cable Jointing Tools, Feeder Pillars, Cable Ducting, Earthing & Lightning Protection, Electrical Safety, Cable Glands, Arc Flash Clothing & Fusegear.

- Distributors for: 3M, ABB, Alroc, Band-It, Catu, Cembre, Centriforce, CMP, Elastimold, Ellis Patents, Emtelle, Furse, Lucy Zodion, Nexans Euromold, Pfisterer, Polypipe, Prysmian, Roxtec.

T&D, CATU Electrical Safety & Arc Flash Protection Specialists for SAP’s, Linesmen, Jointers & Electrical Engineers – Largest UK Stockist

Cable Lugs – Crimping Applications & Standards

August 29th, 2018

Cable Lugs – Crimping Applications & Standards

-

uploaded by Chris Dodds - Thorne & Derrick Sales & Marketing Manager

Thorne & Derrick International, based in the UK, are leading suppliers of cable crimp lugs and associated crimping tools for Low, Medium & High Voltage Cables and Power Systems – this series of articles by Klauke discusses the theory and practise of installing compression type cable lugs and connectors.

Klauke cable lugs and crimping tools are used by Jointers, Linesmen, Panel Builders and Electrical Engineers to install underground cables and overhead line conductors on power, transmission and distribution networks including LV MV & HV systems, 11kV-33kV.

➡ Download 2018 Klauke Cable Lugs catalogue and see the complete range of tools for cutting and crimping cables.

In this Article we cover the following:

- Compression cable lugs according to DIN 46235 for crimping solid, stranded, fine stranded and finest stranded copper conductors

- Copper tube cable lugs “standard design” made from electrolytic copper (EN 13600)

- Compression cable lugs DIN 46235 terminals not for solid conductors

- Selection of the correct lug very much depends on the cable type

- International Standard IEC 1238 Part 1 – electrical and mechanical properties of cable lugs

Although cable connections are relatively low cost in comparison to price-per-metre of cable and often a project afterthought the importance of specifying and installing the correct type of lug is critical to safe and reliable performance of LV MV HV Power Systems – a poor cable connection can result in an increased joint resistance and even in fire. Worse still, fatality.

Incorrect tools and cable crimps cause increased temperatures and fire.

In this blog T&D will show you the correct cable crimping procedure. There are hundreds of different versions of cable lugs available.

For the electrical engineer and cable jointer it is very difficult to choose from this broad range the correct lug for each specific application.

The following article gives an overview of the different types of lugs for copper conductors and details the facts which will guarantee a safe and permanent electrical connection.

In principle we differentiate between 3 types of cable lugs:

- Compression lugs according to DIN 46235

- Standard tubular lugs

- Sheet metal solderless terminals according to DIN 46234

Compression cable lugs according to DIN 46235

DIN Standard 46235 defines the application, dimensions and marking of cable lugs – this standard allows use of these lugs for compression of solid, stranded, fine stranded and finest stranded copper conductors and cables.

3 types of lugs: DIN cable lugs, standard tubular cable lugs and sheet metal terminals (from left to right)

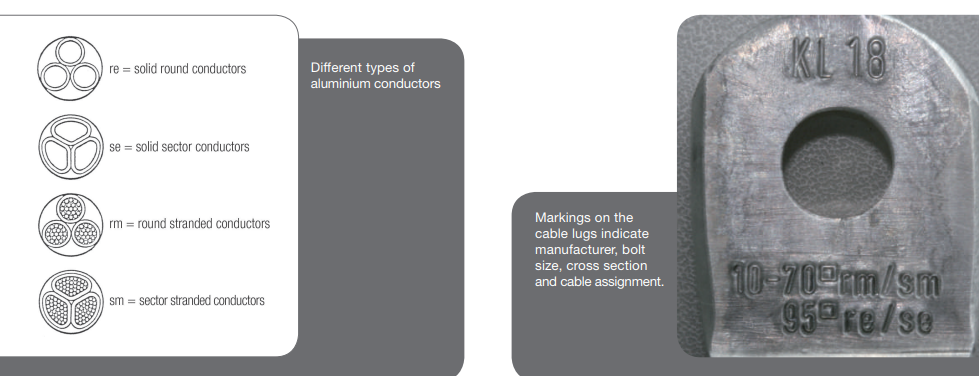

Markings on the product provide the installer with information relating to the origin and application of the DIN 46235 cable lugs, which also applies for standard tubular cable lugs.

DIN crimp cable lugs show the required number of crimps stipulated by the manufacturer: Marking “KL 22 12 – 150”

- KL: indicates manufacturer (in this case Klauke)

- 22: Die set code (only for compression lugs DIN 46235)

- 12: Metric bolt size for connecting bolt: size M12 (12mm hole diameter)

- 150: Cross section of conductor in sqmm

In addition, these lugs indicate the number of required crimps. For installing, the DIN standard recommends crimping dies according to DIN 48083, Part 1, 3 and 4 for solid, stranded and fine stranded conductors.

For braided ropes the standard refers to the information of the manufacturer.

Klauke generally recommends the use of hexagon crimping dies according to DIN 48083, Part 4 for installing of compression lugs DIN 46235 – the range of cable conductor cross sections is from 6sqmm up to 1000sqmm, bolt sizes range from 5mm up to 20mm.

Electrolytic copper according to EN 13600 is mandatory.

For corrosion protection the compression cable lugs – also standard tubular cable lugs and terminals – are tin plated to protect against oxidisation.

Copper tube cable lugs “standard design”

Apart from DIN cable lugs, many manufacturers also offer standard tubular cable lugs, also made from electrolytic copper according to EN 13600. As far as sizes are concerned, standard tubular lugs are mostly shorter than DIN lugs and also differ in tube dimensions.

- DIN EN 13600 Copper & Copper Alloys – Seamless Copper Tubes For Electrical Purposes; German version EN 13600:2013

DIN compression cable lugs are longer than standard tubular cable lugs

However, since these lugs are also subject to test standard IEC 1238 Part 1 the durability of electrical and mechanical connection is not affected.

All lugs – irrespective of type – can only be crimped properly when a suitable cable crimping tool is used. Incorrect tools or an unprofessional crimp can result in increased joint resistance, increased temperatures and even fire.

Standard tubular cable lugs (left) have different tube dimensions to DIN crimp cable lugs (right)

To eliminate this risk Klauke recommends the crimping of their lugs with their tools – this is a matched crimping systems avoid a mixture of brands which are potentially incompatible.

Sheet metal terminals according to DIN 46234

Solderless Terminals

Also for the sheet metal terminals certain DIN standards apply regarding application, dimensions and marking.

Other than compression cable lugs DIN 46235 terminals are designed only for crimping of stranded, fine and very fine stranded conductors – not for solid conductors.

Incorrect Crimping |

Incorrect Crimping |

Correct Crimping |

| Incorrect and correct crimps in comparison: An incorrect crimp (crimping,middle: low force crimping, and usage of incorrect crimping tools can result in an increase in joint resistance and may jeopardise the installation) | ||

Which cable lug suits which application?

Cross section ranges from 0.5sqmm up to 240sqmm, bolt sizes from 2mm to 16mm.

Among others terminals they can be found in electrical control cabinets and vehicles of public transportation services, such as rail carriages and rolling stock.

Sheet metal terminals are also made from electrolytic copper according to EN 13600. But there is a difference in the basic material – compression standard tubular lugs are produced from copper tubes while solderless terminals are made from copper sheets.

Terminals show a soldered seam as the DIN standard prescribes a closed tube.

The DIN standard does not specify crimping tools – Klauke recommends their self-designed indent crimping tools.

Useful Information

The selection of the correct cable lug very much depends on the cable type. For cables according to DIN 57295 the following lugs can be used:

- Cables Class 1, 2, 5 and 6: Compression lugs DIN 46235

- Cables Class 2: Standard tubular lugs

- Cables Class 2, 5 and 6: Terminals

In practice it can happen that flexible class 5 and 6 cable conductors do not fit into the appropriate cable lug. For such cases, Klauke recommends the so called F-cable lugs which have a larger inner diameter and feature a flared entry. Indent crimping is recommended.

For installing the DIN lugs, crimping tools with die codes according to DIN 48083 Part 4 have to be used.

Electrical & mechanical properties

The International Standard IEC 1238 Part 1 applies to electrical and mechanical properties of cable lugs. The requirements for a permanent and safe electrical connection for the intended application are detailed in this standard.

Both a mechanical pull-out test and an electrical durability test are defined.

A test cycle simulates the application in practice: the connection is being heated 1000 times up to 120°C to imitate the morning voltage peak in-rush in the public power supply system.

Also high current tests are being carried out on the cable lugs at temperatures of 250°C.

The responsibility of adherence to these safety rules lies with every manufacturer of cable lugs. For this reason the manufacturers specify the appropriate cable type to be used with their lugs. Apart from normative standards, renowned manufacturers stipulate additional quality requirements.

F-Cable lugs with flared entry represent an option when cables of class 5 and 6 will not fit into normal cable lugs.

Klauke cable lugs are subject to an “annealing” process to condition the material from tension and hardness and to reduce the risk of fracture. F-Cable lugs with flared entry represent an option when cables of class 5 and 6 will not fit into normal lugs.

This process increases the durability and provides greater protection for the lug against vibration. This is another reason why Klauke recommend use of high-quality cable lugs from well known manufacturers.

The longer tube of Klauke cable lugs (above) guarantees a high quality connection.

The quality of lugs can often be recognised by visual characteristics: burr free cable lugs with flat palm and a cleanly machined end are signs of a high quality electrical connector.

High Quality Klauke Cable Lugs

Further Reading

Review other Blogs in this series of articles about Cable Lugs, Crimping Cables & Tools:

Copper Cable Lugs For Special Applications

Indent Crimping Of Cables – Benefits & Limitations

Cable Lugs & Crimps – Hexagonal v Indent Methods of Crimping

Cable Lugs & Crimping Using The Hexagonal Crimp Method

DIN Standard – Crimping & Compressing Aluminium Cable Lugs & Connectors

Copper & Aluminium – Crimping CU-AL Cables

Electrically Driven Crimping Tools For High Volume Applications

LV MV HV Cable Accessories & Substation Electrical Equipment

Thorne & Derrick are Specialist Distributors of leading manufacturers of Cable Accessories, Jointing & Installation Equipment.

LV MV HV cable accessories used to joint, terminate, connect, cleat and gland power cables to air and gas insulated substations, transformers, switchgear and overhead line networks.

Hover over our Interactive Electricity Grid to learn more about our product ranges.

LV 600/1000V ◊ MV 11kV 33kV ◊ HV 66kV 132kV

|

|

|

|

|

|

|

|

|

|

Substation & Overhead Line Electrical Safety Equipment

Manufactured by CATU Electrical to enable the safe construction, maintenance and repair of underground cables and overhead lines network up to EHV (400kV).

T&D - CABLES ♦ JOINTS ♦ TERMINATIONS ♦ CONNECTORS ♦ GLANDS ♦ CLEATS ♦ CRIMPS & LUGS ♦ DUCT ♦ SEALS ♦ ARC FLASH PPE

EARTHING ♦ FEEDER PILLARS ♦ JOINTERS TOOLS ♦ CABLE CUTTING & CRIMPING TOOLS ♦ COLD SHRINK ♦ HEAT SHRINK ♦ FUSES

DIN 48083 – The Standard for Cable Lugs & Crimping Tools

August 29th, 2018

-

uploaded by Chris Dodds - Thorne & Derrick Sales & Marketing Manager

DIN 48083

The following information is provided courtesy of Nexans Euromold to ensure the safe and reliable termination of LV MV HV cables using cable crimping lugs prior to installing any proprietary brands of cable termination – the information is relevant to Cold Shrink, heat shrink, slip-on and EPDM rubber screened separable connectors.

brands of cable termination – the information is relevant to Cold Shrink, heat shrink, slip-on and EPDM rubber screened separable connectors.

The standardised hexagonal crimp allows cable lugs and electrical connectors according to DIN 46235 to be crimped with certified crimping die sets and tools according to DIN 48083 Part 4.

Crimping Cables & Cable Lugs

Crimp lugs, compression connections and tubular cable lugs manufactured from copper or aluminium require precise matching of crimp cable lugs, conductor type and crimping tool size.

DIN standard crimping requires adherence of conductor, selected crimp cable lugs and compression die sets to provide optimum results when terminating cable lugs to DIN standards at LV MV HV.

The hexagon crimp or compression is designed for a cable conductor temperature up to 90°C, according to IEC.

DIN Standard 48083

DIN Standard 48083 is a hexagonal crimping profile and to conform to DIN standard where the correctly designated die sets must be used to compression/crimp the lugs or connectors.

All crimp cable lugs are stamped with cross section specification, manufacturer’s logo as well as die set code number, corresponding roughly to the outer diameter of the sleeve.

Select the crimp tool die corresponding to this code.

The hexagon crimps or compressions are carried out by means of mechanical,hydraulic or battery operated crimping tools according to the standard DIN 48083. “Cu” (Copper) marked dies have to be used for copper or steel compression cable lugs.

Designated “Al” (Aluminium) dies are used for aluminium or aluminium alloy compression cable lugs. In the case of hydraulic tools differentiation regarding the conductor materials is not necessary – if in doubt call Thorne & Derrick in connection with any of your cable crimping, lug or tool queries and requirements.

Installing Cable Lugs

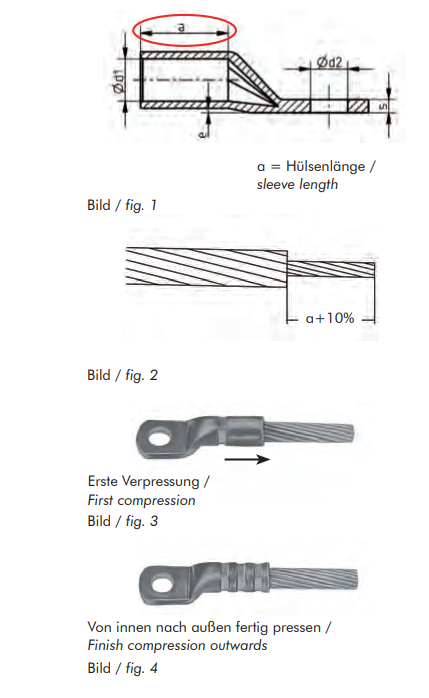

1. Strip cable conductor to sleeve length a+10% (fig. 1, 2)

2. Remove all tapes/yarn or similar conductor filling materials before mounting the cable lug

3. Remove dirt and oxide layers from the cable conductor using a metal brush

4. Insert conductor into compression sleeve up to the stop/inspection hole of the cable lug

5. Before compression verify the die code with the crimp mark number on the cable lug

6. Start crimping using correct tool from the palm side to the barrel end (fig. 3, 4)

7. The number and position of the compression points is indicated by marking lines. Attention: All markings must be compressed by the crimping tool

8. Final Check: The extension length of the sleeve is about 5 % by correct compression with correct conductor – cable lug – die – combination

9. Remove excess grease using cable cleaning wipes

Thorne & Derrick distribute for Cembre and recommend the use of their hydraulic and battery operated crimping tools in order to crimp cables in accordance with DIN Standard 48083 – contact us for technical support, quotations and delivery from stock.

More Reading ➡

Crimping Tools & Die Sets For Aluminium Crimp Connectors – DIN Standard

Cable Lugs & Crimping Tools

THORNE & DERRICK SPECIALIST ELECTRICAL DISTRIBUTOR

LV ♦ MV ♦ HV

T&D distribute the most extensive range of LV, MV & HV Cable Jointing, Terminating, Cable Pulling & Installation Equipment – we service UK and international clients working on underground cables, overhead lines, substations and electrical construction at LV, 11kV, 33kV and EHV transmission and distribution voltages.

- Key Products: MV-HV Cable Joints & Terminations, Cable Cleats, Duct Seals, Cable Transits, Underground Cable Protection, Cable Jointing Tools, Feeder Pillars, Cable Ducting, Earthing & Lightning Protection, Electrical Safety, Cable Glands, Arc Flash Clothing & Fusegear.

- Distributors for: 3M, ABB, Alroc, Band-It, Catu, Cembre, Centriforce, CMP, Elastimold, Ellis Patents, Emtelle, Furse, Lucy Zodion, Nexans Euromold, Pfisterer, Polypipe, Prysmian, Roxtec.

T&D, CATU Electrical Safety & Arc Flash Protection Specialists for SAP’s, Linesmen, Jointers & Electrical Engineers – Largest UK Stockist