Blog

Cable Pulling | 37km Offshore Cable to Connect NnG to Onshore Substation

July 2nd, 2021

Pictured | Singco Cable Grips – we produce cable socks for Boskalis, NKT, Nexans, DEME and other major cable laying contractors for the connection of wind farm projects globally.

-

Thank you to NnG Offshore Wind for their kind permission to republish this article

Offshore to Onshore

Cable Pulling

The first of two export cables, each 37 kilometres in length, has been installed at the nearshore of Thorntonloch Beach as part of construction of the Neart na Gaoithe (NnG) Offshore Wind Farm.

These electricity transmission cables will connect NnG’s two offshore platforms to its onshore substation located in the Lammermuir Hills.

The offshore cable was transported to the nearshore area of Thorntonloch Beach by Prysmian Group’s cable-laying vessel, the 124 metre long Cable Enterprise.

➡ Go to cable grips to learn about how Thorne & Derrick provide safe installation, support and pulling of cable in the wind energy sector.

Cable Enterprise is Prysmian Group DP2 cable laying vessel that has been designed with almost 8 MW of power, allowing her to autonomously maintain position in harsh weather conditions. The vessel has the capability to undertake simultaneous lay and burial operations with any type of plough, including HD3 ploughs with up to 180 tons tensions. The vessel maintains her ability to ground out and to operate in very shallow waters with 7-point independent mooring system allowing her to meet stringent operational requirements. Wärtsilä NOx reducing system fitted to all 4 Wärtsilä engines to achieve 75% NOx reduction from base levels.

The onshore winch cable was pulled through a 650m long horizontal directional drill duct and connected to the offshore cable situated on the deck of the vessel, 1km from shore. The offshore cable was then directed back through the cable duct towards onshore where it will be connected to the onshore cables behind Thorntonloch Beach.

The Cable Enterprise will lay the offshore cable from the nearshore of Thorntonloch Beach to the site of NnG. The cables will be buried to protect them from damage. Prysmian, one of NnG’s tier one contractors, expect the second offshore cable to be installed in July.

NnG Offshore Wind

NnG, jointly owned by EDF Renewables and ESB, will supply enough low carbon electricity for around 375,000 homes and has a capacity of c. 450MW of low carbon energy and will offset over 400,000 tonnes of Co2 emissions each year.

Matthias Haag, NnG Project Director, said: “The installation of the first of our two offshore cables is a significant milestone in the construction of NnG.

“These two 37km cables will play a pivotal role in connecting our two offshore platforms to the onshore substation over in the Lammermuir Hills.

“We’re grateful to all our neighbours in and around the Throntonloch area for their patience as we carry out these vital construction works nearshore.”

Massimo Galletta, Project Director (NnG) at Prysmian Group, said: “We are proud of being selected for such a strategic project, proving our state-of-the-art cable technology, know-how and project execution expertise to support the growing renewable energy industry.”

Further reading

- How Do Cable Socks React To Salt Water?

- Cable Winch | Customised & Refurbished 5 Tonne Cable Pulling Winch

- Cable Socks – Technical Guide for Safe Cable Pulling Using Cable Socks

Press Release | Thorne & Derrick Appointed Approved Stockist for UK Leading Cable Pulling Equipment Manufacturer

CABLE SOCKS & PULLING PRODUCTS LV MV HV

Complete range of LV, MV and HV cable pulling products for installation and enabling cable jointing in trench or ducts including LV, 11kV/33kV medium voltage (MV), 66kV/132kV high voltage (HV) and EHV transmission and distribution cables up to 400kV.

➡ See Also Cable Laying, Installation & Support Products | MV HV Windfarm

Cable Rollers | Duct Rods | Cable Socks | Cable Lubricant | Duct Seals | Cable Duct

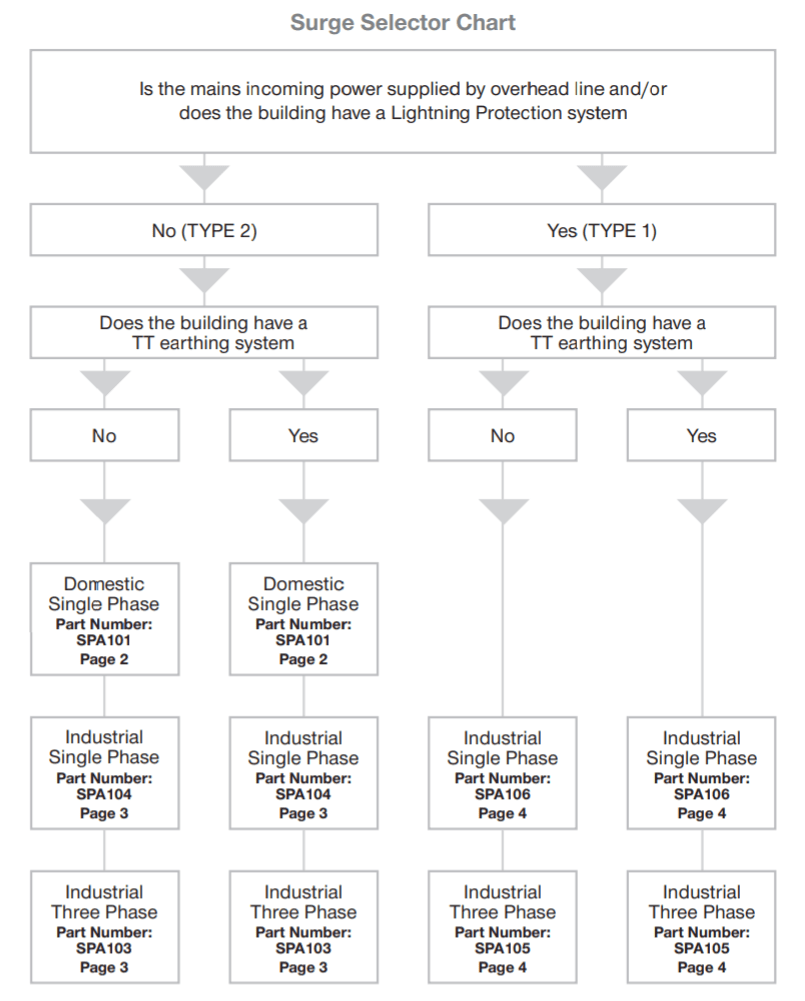

Surge Protection Devices | A Guide & Product Overview of Surge Protection Devices (SPD’s) with PADS Approval for Network Rail

June 30th, 2021

Surge Protection | with Network Rail PADS Approved Products

Surge Protection Introduction

Surges or Transients are short duration increases in voltage, measured between two or more conductors. These potentially harmful voltages can be induced into a building from various sources, from the direct and or secondary effects of lighting, to switching actions and equipment faults.

These events can generate thousands of volts across equipment leading to direct failure, undetected degradation and insulation faults leasing to premature failure.

An effective Surge Protective Device (SPD) should have a low let-through voltage, as this is the value of voltage that the protected equipment will be subjected to.

The lower the voltage the better the protection. the greater the voltage the higher the risk of distribution, degradation, damage to the equipment and the electrical network. As technology moves on, components within electronic equipment continue to become smaller and therefore more sensitive to these types of influences.

Surge Protection Device Definitions

Impulsive Discharge Current (for Type 1; Test Class I):

The maximum current of specified energy that a Type 1; Test Class 1 device must service during the type test.

Maximum Discharge Current; Imax:

The maximum current that a Type 2; Test Class II protective device will withstand.

Nominal Discharge Current (for Type 2; Test Class II):

In a measure of the longevity of a Surge Protective Device. It is determined by injecting multiple discharges into the SPD during its type test procedures. It is often specifies to be half of the maximum discharge current (Imax)

Voltage Protection Level / Let Through Voltage:

Is the maximum voltage across the Surge Protective Device terminals as a result of a specific discharge current. It is the maximum voltage that the equipment will see if it were positioned directly at the terminals.

Maximum Continuous Operating Voltage:

Is the maximum voltage that can be, safely, continuously applied to the terminals of the Surge Protective Device.

Surge Protective Device Types explained

Type 1 Surge Protection Devices (SPD’s)

A Type 1 SPD will deal with direct and proximity lightning strikes and have the highest energy discharge capacity. They are designed to survive in high stress environments, especially those at the incoming power supply. It is a requirement that they are installed where an External Lightning Protection System (Faraday cage) is fitted or the mains is fed from an Overhead Power Cable. The Type 1 should be accompanied by downstream Type 2 Surge Protective Devices.

Type 2 Surge Protection Devices (SPD’s)

A Type 2 SPD will deal with indirect Lightning strikes and the effects of surges locally generated from the numerous switching events within an installation. They are designed for the use in distribution boards located downstream of type 1 Surge Protective Devices or in the incoming power supply panel / consumer unit where an External Lightning Protection System is not fitted and the mains is fed by an underground cable.

Type 3 Surge Protection Devices (SPD’s)

A Type 3 SPD is designed to provide the lowest protection level to meet the voltage withstand of the equipment supplied from the final distribution panel. The SPD may also be of a design such that it can be placed or connected directly to the critical equipment.

PADS Approved Products

AN Wallis currently have a range of products with PADS approval for use in the rail industry, including products from the RTM series (Rail Track-Side Module), the SSI series (Solid State Interlocking) and the CRTM series:

- DSP1A/SSI/120

- DSP1A/SSI/140

- RTM150/650

- RTM12/110

- RTM12/140

- CRTM150/650

Thorne & Derrick distribute full range of AN Wallis Earthing Products | Bars | Rods | Tapes | Conductors | Clamps

RAIL CABLE ACCESSORIES, ELECTRIFICATION

& INSTALLATION EQUIPMENT

Thorne & Derrick stock and distribute an extensive range of 400V-33kV Rail Cable Accessories & Power Distribution Systems including feeder pillars to contractors undertaking Low Voltage Power Distribution, HV Electrification & Substations, DC Traction & Networks, OLE and Track Feeder Cable Renewals – complete range of Network Rail PADS approved track terminations, cable joints, cable repair and connection products up to 25kV, including 3M Cold Shrink, Pfisterer CONNEX and Nexans Euromold products.

Cable Joints, Terminations & Connections | Distributors & Stockists for 3M Cold Shrink | Nexans Euromold | Pfisterer CONNEX

RIS-3279-TOM Standard | Arc Flash & Protective Clothing & Standards

June 30th, 2021

RIS-3279-TOM Standard Arc Flash & Protective Clothing Standards

RIS-3279-TOM

Arc Flash & Protective Clothing Standards

RIS-3279-TOM (formerly GO-RT 3279) is a high visibility standard that only applies to the rail industry in the UK, as opposed to the EU-Wide nature of other EN standards. The aim is to ensure that rail workers on or near the trackside are sufficiently visible to trains approaching at speed or any other traffic.

Thorne & Derrick provide competitive prices and fast delivery for the complete range of arc flash clothing and accessories designed to protect people and save lives.

View further information about Arc Flash Clothing Standards.

RIS-3279-TOM | Standard Overview

Protective clothing. Electrostatic properties. Material performance and design requirements.

High visibility clothing is the fundamental principle behind the UK Rail Industry Standard. This is based on the European Norm EN 20471:2013, and garments must comply to Class 2 High Visibility, the middle of a three class range. The standard states the following: ‘high visibility clothing worn by people on the lineside or on or near the line should conform to a single standard for the colour and luminance of background material and that this standard will accord with the detail contained within BS EN 20471:2013 high visibility clothing – Test methods and requirements (ISO 20471:2013).’

Stated in the standard is that: ‘the colour specific requirements within this standard conform to the range specified within BS EN 20471 clause 5.1.2.’ In order to confine this to a specific orange colour, and to prevent the selection of a colour at the red end of the spectrum, the precise chromaticity co-ordinates for the colour are specified as: Fluorescent orange, X:0.588, Y:0.371. with a luminance factor of at least 0.4. The accepted tolerance in colour is as laid out in EN 20471. However, there is no tolerance for the luminance factor.

Also stipulated in RIS-3279-TOM is the need of retro-reflective materials, with photometric and physical performance aligned with EN 20471.

Mentioned in RIS-3279-TOM is the accepted use of a mini vest where the nature of the work being carried out will not obscure the high visibility clothing, and thus reduce the surface area’ that is visible. The same applies to company logos; these are permitted where they do not compromise the surface area of background colour, and compensation may have to be made for this.

➡ Standards | BS EN 1149-5 | IEC 61482-2 | BS EN ISO 11611 | BS EN ISO 20471| BS EN ISO 14116 | BS EN ISO 11612 | BS EN 13034 | BS EN 342 | BS EN 14404 | BS EN 343 | HSG47

Hi vis and Flame Resistant polo shirt in unique VXS+ blend of fibres developed to meet the requirements of RIS-3279-TOM for workers on or near the trackside.

Arc Flash Clothing With RIS-3279-TOM Approvals

The ProGARM® Hi-Vis Orange Collection features a range of 100% VXS+ inherent garments tested for minimal shrinkage, low colour washout and for long-standing protection against Arc Flash incidents. All garments are certified for use in Rail environments with the Rail Industry Standard, RIS-3279.

With a comprehensive range of arc workwear for both Men and Women, and with the ProGARM lifetime-seam guarantee, you can be confident of long-lasting protection.

Arc Clothing part number Cal Rating

| Lightweight Arc Waterproof Jacket | ProGARM 9422 | 25 Cal |

| Lightweight Arc Waterproof Trouser | ProGARM 9622 | 25 Cal |

| Ladies Arc Polo Shirt | ProGARM 5292 | 6 Cal |

| Ladies Arc Coverall | ProGARM 4692 | 8 Cal |

| Ladies Arc Flash Trouser | ProGARM 4614 | 8 Cal |

| Arc Flash Jacket | ProGARM 4608 | 10 Cal |

| Arc Coverall | ProGARM 4690 | 8 Cal |

| Arc Flash Trouser | ProGARM 4616 | 8 Cal |

| Waterproof Salopette | ProGARM 9660 | 47 Cal |

| Arc Waterproof Jacket | ProGARM 9440 | 47 Cal |

| Arc Polo Shirt | ProGARM 5290 | 6 Cal |

| Arc Sweatshirt | ProGARM 5648 | 21.6 Cal |

➡ Contact Thorne & Derrick for further information about the above arc flash garments with RIS-3279-TOM approvals.

Clothing & Garments

Protecting Workers Against the Dangers of Arc Flash

Thorne & Derrick stock and supply the most extensive range of Arc Flash PPE, Clothing & Protective Garments – should you require any further information, sample garments for field test and trial or a quotation please do not hesitate to contact us.

Thorne & Derrick International supply arc flash clothing and protection equipment including coveralls, gloves, helmets, face shields and general head-to-toe PPE is used to protect against flashover – complete range of insulating matting is also available for worker protection when exposed to energised electrical switchgear and transformers.

Typical applications include LV, HV & EHV cable jointing and terminating, fuse pulling, switchgear commissioning, racking circuit breakers, electrical switching and live working on medium and high voltage electricity networks.

T&D are national distributors LV, MV & HV Cable Installation, Jointing, Substation & Electrical Equipment – we service UK and global businesses involved in cable installations, cable cleating, cable jointing, substation, overhead line and electrical construction at LV, 11kV, 33kV and EHV.

Since 1985, T&D have established an international reputation based on SERVICE | INTEGRITY | TRUST.

Electrical Safety Equipment & Cable Accessories for the Maintenance of Low, Medium & High Voltage Power Systems

How Can I Connect To An Electricity Network? | UKPN Guide

June 30th, 2021

How can I connect to the electricity network?

An article from UKPN

As an Independent Connection Provider (ICP), we understand that your new electricity connection needs to be delivered in a safe, reliable and cost effective way. We have a long track record throughout the UK of successfully meeting clients’ power requirements through the design and build of electrical infrastructure, from the point of connection to the local distribution network to their onsite infrastructure.

Our Team of Experts

- Are National Electricity Registration Scheme (NERS) accredited as an independent connection provider for contestable works.

- Provide a nominated Project Manager for every connection so you know someone is always on hand for progress updates and to make sure any questions are dealt with in a timely manner.

- Work collaboratively with our clients to ensure delivery programmes are agreed, progress is regularly monitored and deadlines are met.

- Support customers to develop their requirements, taking account of current needs and future aspirations, supporting business objectives and sustainability goals.

- Apply industry best practice and integrate the latest in emerging technologies to develop connections solutions that encompass grid connection through to onsite infrastructure needs.

- Work closely with the local DNO to ensure seamless delivery of connections on time, every time.

How we can help

As an established ICP, we support our clients to ensure their new connection requirements are safely delivered to the highest standard, on time, in the most cost effective and innovative way.

Our extensive in-house capability, including designers, planners, authorised engineers and project managers are experienced in designing and building complex and essential electricity distribution networks.

In addition to the connection work, we can support you by taking a long term, holistic view of your energy infrastructure. Our range of solutions enable us to provide an end-to-end service to reduce your energy bills, decarbonise your assets and improve the resilience of your electricity network. Whatever your needs we will work with you to deliver a customised solution.

You can trust us. We have been delivering for some of the UK’s most critical electricity infrastructure for over 50 years, including High Speed 1, Network Rail, London Underground, Docklands Light Railway, and EDF (Hinkley Point C). We also deliver for leading UK airports, Heathrow, Gatwick, Luton, Stansted and London City.

UKPN deliver work associated with a connection to the distribution network, including:

- Cable laying (LV, 11kV, 33kV & 132kV)

- Diversion or reinforcement of LV, 11kV or 33kV circuits

- Diversion or reinforcement of substations

- Erection of new overhead lines

- Installation of substation plant

- Cable jointing and termination

FAQs

How can I arrange connection to the distribution network for a new development?

It’s straightforward, just let us know where your development is and what your requirements are and we will provide you with a proposal for the connection to the distribution network. We will make the necessary arrangements with the local DNO, or IDNO, and ensure any work they have to do is coordinated with our works.

How can I ensure my development capacity requirements are met?

We will work with you to understand your capacity requirements and design the optimum solution to meet those requirements. Our design engineers will work with the local DNO, where necessary, to identify the preferred point of connection to the distribution network to meet your expected demand. We also have experienced in-house consultants who can help you determine the most suitable technical and commercial solution for your entire development if required.

How can I be sure the connection will be energised in line with the site construction programme?

We understand the importance of meeting the delivery programme for connection to the distribution network for a new development. Our experienced designers, planners and engineers work closely with you, and your partners, from outline design through to construction on site to ensure your deadlines are achieved.

How can I reduce the cost of Connection to the distribution network?

By utilising our local in-house resources and an efficient and effective supply chain, our ICP Solution Offering is a competitive alternative to other providers. We ensure our proposal for the connection to the distribution network includes for the most cost effective design whilst also ensuring resilience and quality is maintained.

How can I be sure the electrical infrastructure is built to the optimum quality and in line with the correct standards?

Our knowledgeable design engineers understand electricity networks and make sure quality is at the forefront of all designs. We are experienced with Distribution Network Operator standards and, being closely affiliated with one of the UK’s largest DNOs, we take pride in operating to the highest quality and industry leading standards. Our experienced training resources, make sure we keep up to date with industry developments.

Further Reading

UKPN | Joints, Terminations & Separable Connectors 11kV 33kV

Pot Ending LV SWA PVC Sheathed Service Cables – Engineering Guide UKPN

11kV Triplex Cable Joint (UKPN)

LV MV HV Jointing, Earthing, Substation & Electrical Eqpt

Key Product Categories: Duct Seals | Cable Cleats | Cable Glands | Electrical Safety | Arc Flash Protection | Cable Jointing Tools | Cable Pulling | Earthing | Feeder Pillars | Cable Joints LV | Joints & Terminations MV

PFISTERER Sicon | Did You Know That PFISTERER Invented Hexagonal Pressing In The 1950s?

June 30th, 2021![]()

This article has been republished with the kind permission of Peter Samer – Key Account Manager at Pfisterer Ges.mbH Austria

PFISTERER Sicon Connectors

Did you know that PFISTERER invented hexagonal pressing in the 1950s?

The Pfisterer Sicon range offers reliable and durable connections for all conductors.

The security of supply of energy networks is based on reliable and lasting contacts.

They are the key to secure power transmission. At the same time, assembly should be as simple as possible and risks of error should be largely excluded. For contacting cable ends, there are two methods recognized in practice with pressing and screwdriving technology, which have proven themselves. Pfisterer as a contact technology specialist offers a complete program for both processes.

Press Connection – Proven & Known

With the invention of the six-edge pressing technology in the 1950s, Pfisterer set a standard that is still used today. There is a reason for this. The six-edge press connection is simple, fast and reliable. Prerequisites for assembly success are the exact assignment of sleeve, conductor and the right tool. In track construction and industrial series production, pressing technology impresses with its cost efficiency.

Pfisterer Sicon Connectors

Screw Connection – Universal & Simple

With the development of the SICON bolted connector, Pfisterer set new standards for easy handling and safety. Each connector covers a wide clamping range and is suitable for all types of socket. The patented ‘stepless’ shear bolt guarantees ideal contact for each specific conductor and helps the engineer to feel confident in the success of his installation.

SICON is always the right choice particularly suited to single connections, small series, and maintenance work.

Pfisterer also provides innovative solutions for connections and branches. Thanks to the 2DIREKT transformer terminal, you have a simple, universal, and space-saving way to connect distribution transformers. The patented tap-off ISICOMPACT terminal establishes all contacts for a 4-conductor cable branch using a single screw connection. And the PLUG system is a plug-in high-voltage connection for modern trains, wind power plants, industrial applications, and more.

A SICON Replaces 98 Press Connectors

Compared to the pressing technology, SICON connectors bring a significantly reduced variety of variants. The 1:1 assignment of conductor and sleeve is no longer necessary and with our eight standard variants, fitters on the construction site are equipped for all eventualities. This reduces warehousing and transport costs enormously. SICON connectors are mounted with a standard rattle with hexagonal bit – pressing tools are superfluous.

Pfisterer

The Pfisterer corporate group has been dealing with the interfaces in the flow of electricity ever since it was founded back in 1921.

As a specialist in energy transmission and distribution, Pfisterer offer our customers and business partners a range of sophisticated, future-ready products: For all voltage ranges and wherever reliable, long-lasting systems are needed for powerful energy grids.

As well as the energy sector, they are also active in transport technology and industrial solutions.

SICON SHEARBOLT CONNECTORS

The Right Connection for All LV MV HV Conductors – For years, bolted clamps, connectors, and cable lugs have been gaining ground – with good reason. Bolted connectors offer technical and practical advantages that compression technology cannot match.

Bolt type connectors offer not only technical, but also practical advantages over compression technology. All SICON Shearbolt Cable Connectors cover a wide conductor cross-section range so that you always have the right connectors on site for any application.

Main benefits of Sicon Connectors include:

- Reliable connection for all conductors

- Optimal contact force for all conductors

- No damage to individual strands

- Installation with standard tools

- Ideal for all type of joints or terminations

- Wide application range

LV MV HV Jointing, Earthing, Substation & Electrical Eqpt

Key Product Categories: Duct Seals | Cable Cleats | Cable Glands | Electrical Safety | Arc Flash Protection | Cable Jointing Tools | Cable Pulling | Earthing | Feeder Pillars | Cable Joints LV | Joints & Terminations MV