Cable Cleats

Cable Hangers | Bespoke Cable Supports for Rail Tunnel Application

December 9th, 2022

Cable Cleats & Hangers

Thorne & Derrick | Distributors for Ellis Patents | Cleats | Supports | Hooks | Hangers

Cable Support Requirement

Ellis were approached by a customer to supply cable hangers and bespoke cable supports for a rail project. Cable hangers are standard products for Ellis Patents and we carry a wide range in stock. We can also offer bespoke solutions which are designed and fabricated entirely in the UK. On this occasion the requirement was a little different, the cable hangers were required to be affixed to a tunnel lining in a rail tunnel using a non-standard mounting. Usually, the team at Ellis would travel to site to size up the fitment details and ensure that they had fully understood the requirement, this would include hanger loadings, location, installation considerations etc. Due to restrictions in place because of Covid, this was not possible. The customer took photographs and provided measurements. Ellis then developed a bespoke cable supports product around this specification with consideration taken into account for the “unknown unknowns” to ensure a perfect fit on site and a product that was fit for purpose. FEA was used to check the strength of the hangers prior to production drawings being released.

Bespoke Cable Supports

Ellis Patents Solution

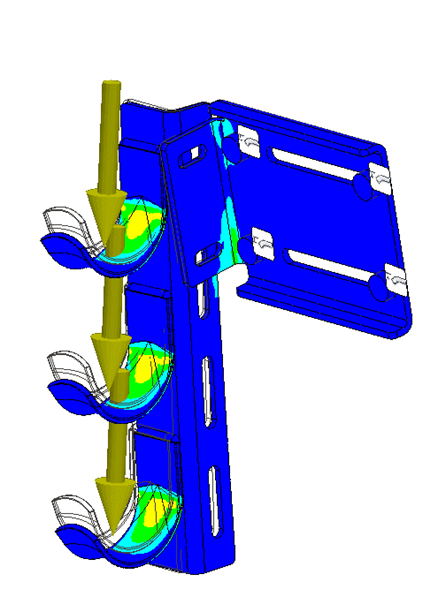

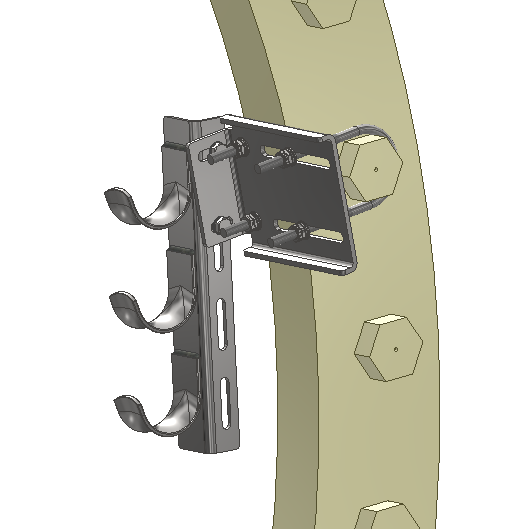

Ellis used their 3D CAD design capability to create a design. The strength of the product was then checked with FEA and hand calculations. Once this was complete manufacturing drawings were released to the production team at Ellis who then used their plasma cutter to create prototypes on a very short timescale. These were tested at Ellis on site test facility to validate the strength and the prototypes were supplied to the customer for a trial fitment. This went well and Ellis proceeded to manufacture the full quantity of hangers.

Hanger being load tested in Ellis test facility

FEA (Finite Element Analysis) of design with loads applied

3D CAD software used to design hanger and create virtual installation location

Completed hanger assembly complete with mounting fixings

Thorne & Derrick | Cable Cleats | Ellis Patents UK Distributors

Specialist Distributors of High Voltage Jointing & Electrical Safety Equipment

Thorne & Derrick International are Specialist Suppliers of products to provide safe and reliable LV HV Cable Termination, Jointing, Installation & Power Systems up to 66kV.

Key Product Categories: Connectors, Joints & Terminations MV HV | Cable Preparation & Jointing Tools | Duct Seals | Cable Transits | Cable Cleats | Cable Glands | Electrical Safety | Arc Flash Clothing & Protection | Cable Pulling | Earthing & Lightning Protection | Feeder Pillars

Thorne & Derrick distribute the most extensive range of MV HV Medium & High Voltage Cable Joints, Terminations & Connectors from manufacturers including 3M, Prysmian, Nexans Euromold, Elastimold, Pfisterer CONNEX & SEANEX.

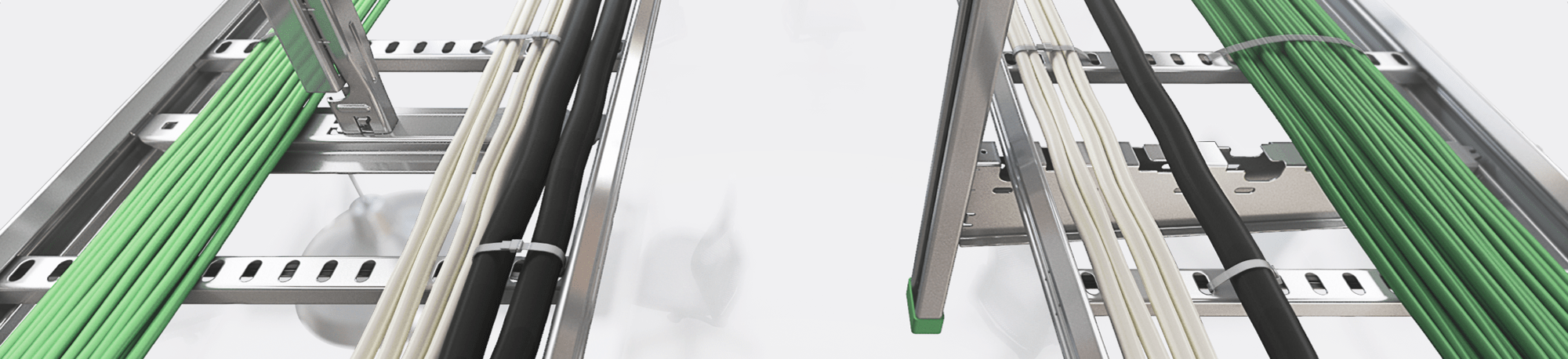

GRP Cable Support Systems | Features & Benefits

November 23rd, 2022

GRP Cable Support Systems

Thorne & Derrick together with Mita® can offer an extensive range of GRP cable support solutions that are suitable for any kind of application. As a leading manufacturer of corrosion resistant industrial cable support products, Mita® hereby presents all you need to carry and support each and every kind of electric cable, data, instrumentation, computer or power circuit without any doubt.

Their GRP offer includes a complete industrial cable support systems and trough range specifically designed for harsh and corrosive environments. Whether you are specifying a range of equipment for a major project or buying a selection of components for a simple maintenance installation, their range is unequalled.

What is GRP?

GRP is a composite material formed if glass rovings/shavings together with resin fillers and additives. GRP is the abbreviation of Glass Reinforced Polymer, meaning it is a man-made resin based material which makes it a polymer, reinforced with glass. There are also different acronyms used by different manufacturers, such as FRP and GFRP, however, they all refer to the same type of composite.

The mechanical properties of GRP can vary widely depending on the matrix fibre combination, fillers, veils, reinforcement design, and manufacturing methods.

These properties allow an initial comparison of different types of composites as well as providing a benchmark against which to measure the success of the specific recycling process in achieving acceptable material properties.

How is GRP Manufactured?

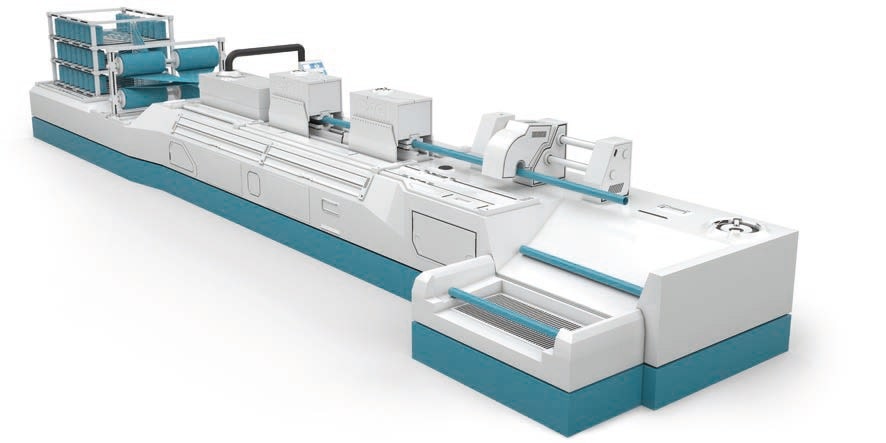

GRP is manufactured through a process called pultrusion.

Above you see the glass rovings going into the resin bath, then mats are placed on to these to create the profile first and goes into the die which shapes and cures it in the form of a ladder or tray, and at the end of the line it is cut to the required length.

Pultruded Technology is used whenever the benefits of whole life cost are appreciated and although the process was originally developed in the USA around 50 years ago, low levels of technology have traditionally meant high costs and therefore applications suited mainly to the extreme longevity of the material.

Pultruded Composites consist of four or five main elements:

1) Glass rovings (strands) and mats -approx. 50% by weight

2) Resin – usually Polyester

3) Filler – usually Calcium Carbonate

4) UV Veil and UV additives

5) Fire Retardants as required

Pultruded composites remain largely impervious to corrosion regardless of application. The GRP pultrusion process uses a combination of unidirectional and cross strand glass mat which is resin impregnated and pulled through a hot die to produce a very solid, structurally sound profile.

Pultrusion process gives outstanding structural strength when compared to other composite processing techniques.

GRP Cable Support systems

Production Methods

There are 2 common production methods for GRP cable support systems, which are moulding and lamination (though pultrusion) and do not produce the same results.

Compression Moulding:

Light / Medium Duty

1.Enough structural strength for light and medium duty applications (Low/medium load carrying )

2.Glass content is around 20-25%

3.High filler content

4.Orthothalic resin or Isopthalic resin which might end up having a low fire retardancy

5.Good for indoor applications, its manufacturing results in nice bends and better shape

Lamination through Pultrusion:

Heavy duty

1.High structural strength for heavy duty applications (high load carrying)2.Glass content is around 40-55%

3.Low filler content

4.Isopthalic polyester resin which has a good corrosion/fire performance, and Acrylic resin resulting in better corrosion, fire performance and low smoke/fumes

5.Good for indoor and outdoor applications thanks to the UV surface veil applied during the lamination

The main 2 methods that we come across in GRP cable support manufacturing is pultrusion and moulded manufacturing.

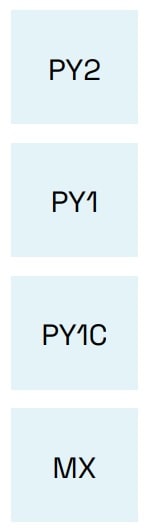

Cable Trough Resin Types

MITA offers 4 main resin types to accommodate the requirements of various industrial applications which can be in chemically aggressive, demanding heated environments.

|

POLYESTER Type 2 | Referencing Convention: Ending with PY2 This type of polyester is for general applications, is resistant to corrosion suitable in industries using heavy chemical and caustic materials, and resistant to UV light by nature. |

| POLYESTER Type 1 | Referencing Convention: Ending with PY1 This type of polyester has better fire retardance which makes it suitable for railway, trackside and any other application requiring UL94 compliance and 5VA classification. |

|

| POLYESTER Type 1 Carbon Loaded | Referencing Convention: Ending with PY1C This type of polyester has anti-static properties as it contains carbon powder. It, therefore, requires grounding. It is for on-shore and off-shore oil and gas applications which are classified as explosive environment. |

|

| MODIFIED ACRYLIC | Referencing Convention: Ending with MX This type of polyester has anti-static properties as it contains carbon powder. It, therefore, requires grounding. It is for on-shore and off-shore oil and gas applications which are classified as explosive environment. |

Cable Trough Approvals

| Materials | Standards |

| PY2 | BS 476 Part 7 |

| BS EN 60695-2-12:2001 | |

| PY1 | UL 94 – V0 |

| UL 94 – 5VA | |

| BS EN 60695-2-12:2001 | |

| PY1C | BS476 Part 7 |

| UL94 – V0 | |

| UL94 – 5VA | |

| NES713 | |

| BS60079-0 | |

| BS EN 60695-2-12:2001 | |

| MX | BS 476 Part 7 |

| BS 476 Part 6 | |

| NES 713 | |

| BS 6853 – D8.3 | |

| BS 6853 –D8.4 Cat 1B | |

| BS 6853 – Annex B2 | |

| BS EN ISO 4589-2 | |

| BS EN iSO 4589-3 | |

| UL 94 V0 | |

| UL 94 5VA | |

| BS EN ISO 4589-2 | |

| BS EN ISO 4589-3 | |

| BS EN 60695-2-12:2001 |

| References | |

| Wibe full reference | Wibe quick reference |

| Polyester Class 2 | PY2 |

| Polyester Class 1 | PY1 |

| Polyester Class 1 Anti Static | PY1C |

| Acrylic Class 0+ | MX |

GRP Cable Support Solutions

Features & Benefits

| Features | Benefits |

| Light weight Density and weight are significantly lower than steel (70% lighter than steel) with reduced handling requirements. Lightweight in design. |

Health & safety Reduced risk of staff injuries due to its lightweight, easy to cut, no hot works requirement, no deburring and no sharp edges. |

| Compression strength Despite its lower weight, tension, flexure and compression strength of GRP is almost 20 times that of steel with much greater safety factors. It does not deform permanently under high loads. Slow heat transfer allows for even stronger mechanical resistance. |

Low installation & transport costs Typically between 30-40% less than steels with easier cutting, drilling and no deburring, painting or earthing. Transportation costs are more economical and the ease of installation ensures that GRP is the more cost effective solution. |

| Slow heat transfer & resistant to electromagnetic pulses It is effective at temperatures between -140oC to +120oC. Resistant to electromagnetic pulses and transfers heat more slowly than steel. Composite materials are excellent insulators having a thermal conductivity 1/60 of a steel product, and do not require earthing. |

Long life & low maintenance Composites are corrosion resistant and maintenance free. Our GRP products are designed and manufactured to withstand a majority of chemicals & extreme weather – without requiring further maintenance. No rusting, even when exposed to salt spray, H25, acid build up from exhaust gases or brake dust. |

| Zero halogen, UV & corrosion resistance GRP cable support solution is resistant to UV and corrosion, and is zero halogen. It is also available in low smoke classified material. |

Fire performance GRP is zero halogen. It has low heat and electrical conductivity, and is available in self extinguishing and low smoke material. |

| Offer & design Available in 3m and 6m lengths. Full range of pre-manufactured bends, jointing bays and transitions available for fast installation. Dedicated design facility to support bespoke solutions. |

Installations & modifications are simpler Mita GRP solutions offer a far easier installation, without the need for painting, earth bonding or special tools. Supplying 6m or 3m lengths reduces amount of couplers required. |

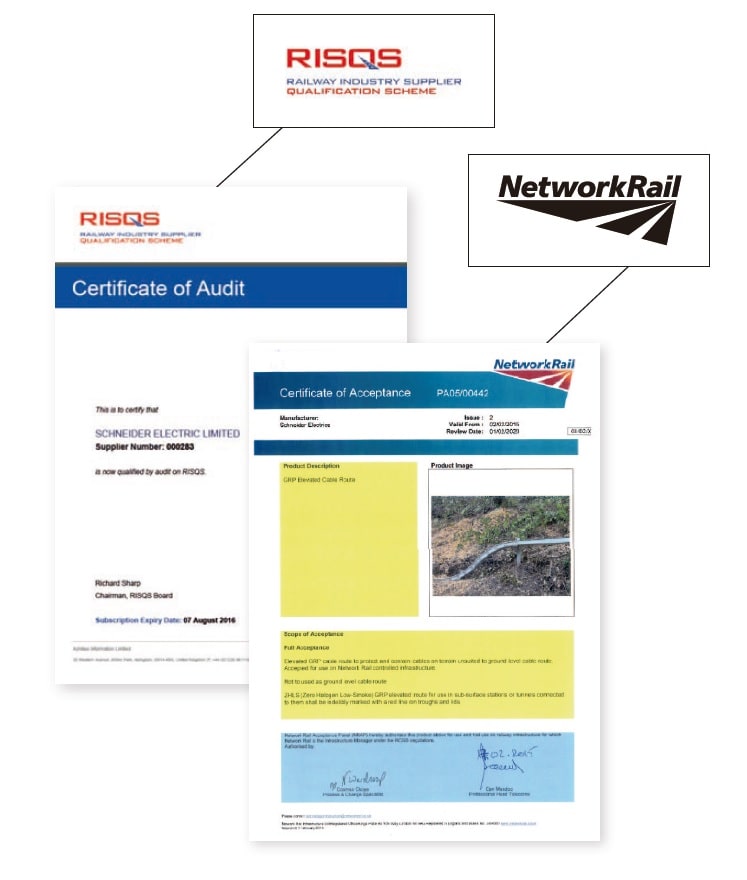

MITA, Schneider Electric + Wibe Group

In 1988, Mita Holdings Ltd was born. In a short while, the company became a leading manufacturer of corrosion resistant industrial cable support products in the UK. In 2005, the company was acquired by Schneider Electric under the name of Mita (UK) Ltd. Mita name continued as a range name under the Schneider Electric brand. Finally, in 2021 the cable support division is acquired by the Swedish group, Storskogen, and is reborn as a stand alone company, Wibe Group.

MitaR is back as a leading brand in GRP cable support solutions. MITA brand is now powered by Wibe Group.

MITA have been supporting customers through their technical journey on choosing the correct product, manufactured from GRP, in cable support applications for almost five decades. MITA are now fully separated operationally from Schneider Electric. They now have a stand alone presence in the UK market with their “Made in UK” products which are fully compliant to the related cable management standards.

MITA are marker-leaders in the manufacture of GRP non-metallic troughing, GRP cable ladders, CABSYS cable trays, ducts, cable support channels and Fibastrut as the brand continues to lead the industry towards a sustainable future for a wide range of low (LV), medium (MV) and high voltage (HV) cable installation applications.

RAIL CABLE ACCESSORIES, ELECTRIFICATION

& INSTALLATION EQUIPMENT

Thorne & Derrick supply an extensive range of 400V-33kV Rail Cable Accessories & Power Distribution Systems including feeder pillars to contractors undertaking Low Voltage Power Distribution, HV Electrification & Substations, DC Traction & Networks, OLE and Track Feeder Cable Renewals – a complete range of Network Rail PADS approved track terminations, cable joints, cable repair and connection products up to 25kV, including 3M Cold Shrink, Pfisterer CONNEX and Nexans Euromold products.

Full range of Cable Pulling Equipment & Products to ensure safe and efficient of rail cables in to cable ducts and containment infrastructure including cable troughs.

Cable Cleats | Cable Hangers | Cable Joints | Cable Glands | Cable Lugs | Cable Transits | Arc Flash Clothing

Important Factors You Need To Consider When Working With Cable Cleats

May 24th, 2022Cable Cleats

A cable cleat is designed to ensure that cables are fixed, retained and supported correctly so that in the event of short circuit fault or any other emergency, they will contain the cables without causing damage; enabling the circuit to be restored once the fault has been dealt with.

One of the most important issues to consider when specifying cable cleats is the risk of material corrosion – not just as a result of the installation environment, but also from other metals which the cable cleat may come in to contact with.

Read more about the affects of corrosion in our evidence based specification case blog – Stainless Steel Cable Cleats – Preventing Galvanic Corrosion Of Cable Fixings

All cable cleats distributed by Thorne & Derrick are undergoing testing to conform to the latest IEC 61914:2021 Standards. Certification will be in place before the deadline.

What Else Is Important To Consider When Working With Cable Cleats?

Operating Temperatures

Ellis’s standard ranges of cable cleats are designed for use in ambient temperatures ranging from -50°C to +60°C and with cable conductor temperatures up to 90°C.

Eddy Currents

Ferro-magnetic materials that completely surround single conductors in AC circuits are susceptible to heating from eddy currents.

Generally, eddy current generation at mains frequencies requires a complete electrical and ferro-magnetic circuit around each conductor. However in installations where all three phases are contained within the same cable cleat e.g. three cables in a trefoil cable cleat, the magnetic fields of the phases cancel each other out, which in turn negates the eddy currents and the heating effect.

Despite this, it is preferable to use cable cleats manufactured from non-magnetic materials such as aluminium, injection moulded polymers or stainless steel, which has only very slight magnetic properties.

ALWAYS REMEMBER: When using single cable cleats manufactured from ferro-magnetic materials care should be taken to avoid forming a complete iron loop around the cable.

Multi-core Cables

There is a commonly held belief within the electrical industry that multi-core cables will protect themselves in the event of a short-circuit, meaning their installation does not require fault rated cable cleats.

However, research shows that the forces between the conductors of a multi-core cable in the event of a fault are similar to those between three separate single core cables laid in a trefoil arrangement.

Therefore, when specifying multi-core cables it is advisable that cable manufacturer should be contacted to ascertain the ability of its specific cable to withstand these forces.

It is worth noting that whatever the withstand quoted, in the event of a significant fault an unrestrained multi-core cable will move.

Furthermore, the requirements of most wiring regulations are clear and typically state that:

“Every conductor or cable shall have adequate strength, and be so installed as to withstand the electromagnetic forces that may be caused by any current, including fault current.”

Fire

There are currently no European or IEC standards for fire rated cable clamps, although there are requirements within other standards that can be followed to prevent unsuitable products being specified.

The international standard IEC 61914 requires non-metallic and composite cable cleats to have adequate resistance to flame propagation.

UL94, the standard for Safety of Flammability of Plastic Materials for Parts in Devices and Appliances, is a plastics flammability standard that classifies plastics according to how they burn in various orientations and thicknesses. Adherence to its V-0 rating for polymers should be demanded by specifiers.

The use of the description LSF (low smoke and fume) is common terminology with regard to polymers, but is misleading as it doesn’t relate to any published standard and so can be interpreted in a wide variety of ways.

Rail Cable Cleats

To ensure complete assurance of performance in a fire, all Ellis plastic products have undergone testing at the Building Research Establishment (BRE) in line with the London Underground 1-085 specification with regard to:

- Smoke emission

- Limited oxygen index

- Toxicity of fumes

The appropriate products are listed in the London Underground Approved Products register. Identification numbers are 360, 361,362, 363, 364, 365 and 1661.

A great deal of focus is placed on fire rated (FP) cables and their performance in fire, but very little attention is given to the cable fixings used to secure these cables. Given that FP cable is typically rated for operation in temperatures ranging from 850°C to 950°C then the use of plastic cable cleats or clamps is clearly inappropriate.

Even aluminium only has a melting point of 660˚C, which means it would fail to support FP cables in a fire.

Cable Cleats | Fire Resistant Cables

To counteract this shortcoming, Ellis manufactures the Phoenix range of clamps for use with FP cables. Independently tested by Exova Warrington fire and BRE, all products in the range are proven to perform to the same level as the FP cables ensuring continuous operation in the event of fire.

UV Resistance

While wholly metal cable cleats are impervious to UV attack, composite and polymer cable cleats can be at risk.

Ellis composite cable cleats such as Emperor, Vulcan and Atlas all have polymer liners, but are designed to be impervious to UV attack because the polymer is shielded by either the cable cleat’s body or the installed cables.

Polymer cable cleats that are likely to be exposed to UV should be supplied in materials containing carbon black or other UV stabilised material.

ALWAYS REMEMBER: All cable cleats supplied by Ellis Patents for applications involving UV are provided in UV resistant materials.

Do Ellis & Thorne & Derrick provide any advice on cable cleat system designs?

As a cable cleat manufacturer, Ellis Patents do not offer advice on the design principles and choices between different types of cable installation. We will however provide expert advice on the suitability of particular cable cleats within any type of installation.

Flexible and Rigid Cable Installations

On most projects a major consideration is the constant movement of the cable due to thermo-mechanical effect. To accommodate this two principal types of installation design exist:

FLEXIBLE SYSTEMS – where the cables are “snaked” either vertically or horizontally. The cable can expand and contract freely between fixing points.

RIGID SYSTEMS – where the cables are rigidly fixed. The longitudinal thermo-mechanical force is withstood by the combination of the stiffness of the cable, the cable cleat reaction force and the rigidity of the support structure.

Cable cleats are designed to withstand the forces exerted by the cable in the ‘axial’ direction, this is relevant to both flexible and rigid systems. It is also important when the cables are installed vertically.

Flat, Trefoil and Quadrafoil Installations

Cable arrangements for three phase installations utilising single conductor cables are typically flat spaced, flat touching or trefoil.

The Wiring Regulations (BS7671) provides current ratings and voltage drop values for all these arrangements. It also contains information on grouping factors and spacing between circuits to achieve thermal independence.

Additionally, IET Guidance Note No. 6 delivers valuable advice on installation arrangements where there are multiple cables per phase.

An additional method for installing single-core cables is to use quadrafoil cable cleats where the neutral is bundled with the three phase conductors. In this arrangement, there is no advice in BS7671 but a report produced by ERA on behalf of Ellis delivered the following guidelines:

Current ratings, given in BS7671, for cables in touching trefoil formation are appropriate for cables in quad bundles

Derating factors, given in BS7671, for cables in touching trefoil formation are appropriate for cables in quad bundles

Voltage drops for circuits in quad formation should be calculated using the values tabulated in BS7671 for cables in flat touching formation

When considering multiple cables per phase, the advice given in Guidance Note No.6 for trefoil groups is applicable to quad bundles

The induced voltage in the neutral conductor of a quad group is minimal and can be ignored.

Quadrofoil Cable Cleats – Ellis Patents Vulcan Quad

How do I prevent thread galling when installing cable cleats?

Stainless steel fasteners have a propensity to “pick-up” when the two threaded surfaces slide against each other. If sufficient speed and pressure is applied to the sliding surfaces then they can weld themselves together – a phenomenon known as thread galling.

All stainless steel fixings will thread gall if there is sufficient friction.

To avoid thread galling, reduce the speed and downward pressure when closing fasteners and use lubrication where appropriate.

THORNE & DERRICK

Thorne & Derrick are national distributors of LV, MV & HV Cable Installation, Jointing, Substation & Electrical Equipment – servicing businesses involved in cabling, jointing, substation, earthing, overhead line and electrical construction at LV, 11kV, 33kV, 66kV and EHV. Supplying a complete range of power cable accessories to support the installation and maintenance of low/medium and high voltage power systems:

- Slip-on Cable Terminations

- Cold-shrink Cable Terminations

- Heat-shrink Cable Terminations

- Cable Joints – Heat & Cold-shrink

- Separable Connectors (Euromold)

- Surge Arresters & Switchgear/Transformer Bushings

Key Product Categories: Duct Seals | Cable Cleats | Cable Glands | Electrical Safety | Arc Flash Protection | Cable Jointing Tools | Cable Pulling | Earthing | Feeder Pillars | Cable Joints LV | Joints & Terminations MV

T&D Deliver Their Largest High Voltage Power Cable Cleat Order

May 24th, 2022Press Release | June 30th 2022

Thorne & Derrick, a Specialist Distributor for Ellis Patents, have delivered their largest contract to date to supply cable cleats to provide safety and reliability to high voltage power cable circuits.

The order includes a project total of over 10,000 units of their market-leader cable cleat, The Emperor. The cable cleats will be installed to provide the highest levels of short circuit protection to high voltage power cables. Following several client meetings, Thorne & Derrick were awarded the purchase contract despite market-wide challenges including raw material price volatility and supply chain strains.

This current project award is testament to our ability to utilise the in-house expertise of Ellis Patents to design project specific, bespoke solutions for customers on tight delivery schedules and builds upon recent project successes in the renewable, rail, data-centre and utility substation sectors.

“Emperor was preferred to competitors due to the products established track record and its evidenced compliance to the rigorous IEC 61914: 2015 standard. The ability to demonstrate product performance in similar harsh operating environments with past project references was critical. Ellis Patents have an international reputation to commit and meet customer delivery requirements – trust in the customer-supplier relationship was central to securing the business. We are now working with Ellis on several custom engineered cable clamps and support solutions – the commercial and technical support by Ellis Patents to Thorne & Derrick was outstanding and instrumental in securing this prestigious project order for both our companies,” comments Chris Dodds (Sales & Marketing Manager at Thorne & Derrick.

The Emperor of Cable Cleats

The Emperor is a heavy duty compact stainless steel cable cleat designed, developed, tested and manufactured in accordance with IEC 61914. The cleat is available in an extensive range of sizes with range taking ability to suit cables installed to containment in single or trefoil formation. The frame of the cleat is manufactured from corrosion resistant grade 316L stainless steel, the cable is supported by a liner manufactured form a low smoke zero halogen (LSOH) material. The closure fixings are manufactured from grade A4-70 stainless steel. The Emperor can be fixed to the supporting structure by either two M10 fixings or one M12 fixing. Non standard cleat designs can be supplied upon request.

ES Single Range | 32-150mm diameters with short-circuit test levels to 235kA at 225mm cleat spacings

ER Trefoil Range | 19-128mm diameters with short-circuit test levels to 195kA at 300mm cleat spacings

Cleating 3 Times Faster

Ellis Patents are an outstanding manufacturer innovator of products to drive down life cycle costs, including their Twist-Foot design of cable cleats which is typically 3 times faster to install than using conventional fixings.

Jonny Hewitt from Thorne & Derrick with Noman Shabir from Ellis Patents at the Dogger Bank – Meet The Buyer Event.

Key Product Categories: Connectors, Joints & Terminations MV HV | Cable Preparation & Jointing Tools | Duct Seals | Cable Transits | Cable Cleats | Cable Glands | Electrical Safety | Arc Flash Clothing & Protection | Cable Pulling | Earthing & Lightning Protection | Feeder Pillars

Thorne & Derrick distribute the most extensive range of MV HV Medium & High Voltage Cable Joints, Terminations & Connectors from manufacturers including 3M, Prysmian, Nexans Euromold, Elastimold, Pfisterer CONNEX & SEANEX.

Cable Cleats | Importance, How To Specify & International Standards

May 9th, 2022What Are Cable Cleats?

“A cable cleat is a device designed to secure electrical cables when installed at intervals along the length of the cables” – IEC 61914 Cable Cleats for Electrical Installations

“Cable cleats should:

Prevent excessive cable movement due to fault-current magnetic forces

Be rated for specific cable size and available current.”

The fifth edition of API Recommended Practice 14F (Design, Installation and Maintenance of Electrical Systems for Fixed and Floating Offshore Petroleum Facilities).

“Single core electric cables are to be firmly fixed, using supports of strength adequate to withstand forces corresponding to the values of the peak prospective short-circuit current.” – Lloyds Register. Rules and Regulations for the Classification of Ships, Part 6, Control, Electrical, Refrigeration and Fire.

“Cables are to be installed and supported in ways to avoid chafing and undue stress in the cable.” – ABS Steel Vessel Rules 4-8-4/21.9 Cable Support, 4-8-4/21.9.1 General and 4-8-4/21.9.3 Clips, Cable Saddles, Straps

“In order to guard against the effects of electro dynamic forces developing on the occurrence of a short-circuit or earth fault, single core cables shall be firmly fixed, using supports of strength adequate to withstand the dynamic forces corresponding to the prospective fault current at that point of the installation.” DNV Rules for Ships / High Speed Light Craft and Naval Surface Craft, Pt. 4 Ch. 8 Sec.10 – page 68, C50

ALWAYS REMEMBER: Any power cable system designer or installer has an obligation to consider the method of securing cables in order to restrain their movement whether caused by an electrical fault or any other reason – a job that can only be safely and securely done with correctly specified cable cleats.

HOW TO SPECIFY A CABLE CLEAT?

- Calculate the system peak fault current

- Identify the specification of the cable to be used including the nominal cable diameter and the manufacturing tolerance

- Identify the support structure type e.g. Ladder ( including rung spacing), basket, individual steel structure etc

- Consider support structure material type e.g. stainless steel, galvanised steel etc

- Consider the environmental conditions

- Consult with Ellis Patents who will provide you with the most cost effective solution for your needs

WHAT IS THE INTERNATIONAL STANDARD FOR CABLE CLEATS?

IEC 61914 Cable cleats for electrical installations outlines a series of tests that can be used to assess the performance of a cable cleat’s design.

Although the standard does not define pass or fail levels, it allows manufacturers to define the performance characteristics of their products, and specifiers to compare products from different manufacturers.

The aspects of construction and performance covered by the standard include:

- Material type – i.e. metallic, non-metallic or composite

- Minimum and maximum declared service temperatures

- Resistance to impact at the minimum declared operating temperature

- The ability of the cable cleat to withstand axial slippage forces

- Resistance to electro-mechanical forces – i.e. the ability of the cable cleat to withstand the forces between the cables in the event of a short-circuit

- Resistance to UV and corrosion

- Flame propagation

TRANSPORT FOR LONDON PROJECT

Working with Ellis Patents we completed the specification and have now moved into manufacturing for our largest contract to date to supply TfL (London Underground) approved cable hangers across several depot modernisation projects.

Thorne & Derrick in consultation with the Asset Manager at Transport for London and their appointed Telecoms & Power contractor secured formal Authorisation & Approval for the Pegasus range of non-metallic cable support hangers. The product will provide safe cable management of the cable route within the Bridges & Structures category – over 1000 hangers with proven lifecycle performance and utilising the standard J-type design for support of multiple cable runs including single, 3-way and 5-way configurations are now scheduled for delivery.

Thorne & Derrick are Approved Vendors to both Network Rail and Transport for London

THORNE & DERRICK

Thorne & Derrick are national distributors of LV, MV & HV Cable Installation, Jointing, Substation & Electrical Equipment – servicing businesses involved in cabling, jointing, substation, earthing, overhead line and electrical construction at LV, 11kV, 33kV, 66kV and EHV. Supplying a complete range of power cable accessories to support the installation and maintenance of low/medium and high voltage power systems:

- Slip-on Cable Terminations

- Cold-shrink Cable Terminations

- Heat-shrink Cable Terminations

- Cable Joints – Heat & Cold-shrink

- Separable Connectors (Euromold)

- Surge Arresters & Switchgear/Transformer Bushings

Key Product Categories: Duct Seals | Cable Cleats | Cable Glands | Electrical Safety | Arc Flash Protection | Cable Jointing Tools | Cable Pulling | Earthing | Feeder Pillars | Cable Joints LV | Joints & Terminations MV