Cable Joints & Terminations LV

Some 3M Scotch Electrical Tapes Tips & Skills….

September 6th, 2020

3M Scotch Electrical Tapes

-

uploaded by Chris Dodds - Thorne & Derrick Sales Marketing Manager

3M Scotch Electrical Tapes

Once upon a time, 3M introduced a revolutionary electrical tape.

That was in 1946 when the vinyl electrical tape patent was issued and since then 3M Electrical have pioneered the role of electrical tapes for maintenance and repair jobs.

So the humble PVC insulation tape was born and named Scotch 33 – this tape evolved into the mass-market over the proceeding decades to become established as the Number 1 PVC Electrical Tape.

And the rest as they say is history…

- 1951 Improved aging, higher temperature performance and wet dielectric

- 1952 Improved cold weather handling characteristics

- 1953 Improved slitting and telescoping performance

- 1957 Flame retardant properties developed

- 1961 Improved adhesive anchorage to cables, joints and splices

Quickly No. 33 Tape manufactured by 3M and branded Scotch became the new standard for insulating electrical connections and cables.

In 1966, when England were winning World Cups, the standard Scotch 33 tape became “Super” – the introduction by 3M of this new and improved electrical tape commonly called “Super 33” had a new operating temperature rating up to 176º F and was coloured black for UV resistance.

All Scotch electrical tapes exhibit smooth unwind and excellent handling characteristics.

Essentially, 3 basic qualities must be carefully evaluated when choosing your tape:

Essentially, 3 basic qualities must be carefully evaluated when choosing your tape:

- Shear Adhesion or “Holding Power”

- Peel Back or “Pull-off Strength

- Thumb Appeal or “Quick Stick”

Peel Back measures the adhesive resistance of the electrical tape to be peeled away from the surface to which it is adhered – the thumb appeal measures the quality of the adhesive to actually feel sticky and retain the bond strength without suffering departure from the surface.

This tendency for adhesive “creep” can lead to the need to remove and re-tape the application to maintain the electrical insulation and mechanical protection.

Additionally, consider the following factors when choosing an electrical tape: backing construction, tape thickness, and dielectric strength.

High tensile strength, excellent elastic memory and stable recovery – specify 3M Scotch

Taping Skills & Tips

Overtime the use of conventional electrical tapes has declined as modern product advances, such as 3M Cold Shrink Tubes, have replaced traditional taped solutions for effecting cable repairs, jointing and termination. Even though electricians are unlikely to consider “old-school” taping skills to be an important element in the engineers skill-set of today the importance of cable splice and termination taping skills for electricians, jointers and linesmen remain a focal element of training courses.

Watch the electrical taping techniques of an experienced cable jointer using 3M Scotch 33 tape to provide electrical insulation layers to the cable – neutral tails are taped up here with the cable splicer demonstrating the slick pass, stretch and apply method to the Scotch tape.

Here are several good reasons to master the craft of electrical taping.

When quick “on the spot” electrical and cable repairs are required and other products are simply not available, 3M Scotch Electrical Tapes can be real “day-savers”.

3M Electrical Tapes offer long-term performance, excellent adhesion, chemical resistance and temperature performance – their smooth unwind from the roll can provide “quick-fix” and simple solutions to electrical insulation tasks straight out the engineers pocket.

The primary 3M Scotch tapes used in electrical applications are vinyl, rubber, mastic, varnished cambric and corrosion protection.

Thorne & Derrick Stockists & Suppliers | 3M Scotch Tapes

Weatherproof & Watertight Taping

The function of moisture-sealing tapes such as vinyl, rubber, and mastic products is to exclude moisture from the insulation assembly and provide electrical insulation to cable, splices and terminations. One of these Scotch tapes — or alternatively a 3M mastic pad — generally forms the second layer of the insulation assembly. Rubber, mastic, and filler tapes are also used to pad the underlying surface by covering sharp edges.

LV Tapes

3M rubber tapes are generally non-adhesive and are either equipped with a liner (Scotch 23) or are linerless (Scotch 130C). Stretched and overlapped layers of the tape will fuse or bond together – “self amalgamating“ – to form an effective electrical insulation and moisture barrier. For low-voltage (1000V or less) applications, rubber tapes should be stretched during wrapping so that tape width is reduced to approximately 75%.

linerless (Scotch 130C). Stretched and overlapped layers of the tape will fuse or bond together – “self amalgamating“ – to form an effective electrical insulation and moisture barrier. For low-voltage (1000V or less) applications, rubber tapes should be stretched during wrapping so that tape width is reduced to approximately 75%.

Similarly, low voltage inline splices, connectors and joints can be protected using Scotch tape by wrapping the installed connector with four half-lapped layers of rubber mastic tape or rubber splicing tape, and then over-wrapping it with two half lapped layers of premium vinyl electrical tape, such as Scotch 33.

MV & HV Tapes

For high voltage (HV) and medium voltage (MV) applications — where the electrical stresses are high (e.g. connector areas, cable lug areas and cable shield semicon cut-back areas) — electrical tape should be stretched just short of its breaking point.

3M Vinyl Tape forms the final outer layer and serves several important functions in addition to electrical insulation, including abrasion protection, corrosion resistance, UV resistance and protection from chemicals including alkalis and acids.

insulation, including abrasion protection, corrosion resistance, UV resistance and protection from chemicals including alkalis and acids.

Conformable vinyl tape is tougher than the softer, stickier surfaces of rubber, mastic, and putty tapes it protects. Several grades of vinyl electrical tape are available — all of which differ in conformability, ease of unwinding, resistance of the adhesive to heat and cold, and loosening (flagging).

Brandname Scotch

The Scotch brand is a registered trademark of 3M Electrical and is synonymous with the highest levesl of quality, performance and reliability. So much so, Scotch has became a language term for the entirety of the market niche that the respective brand dominates. But unlike some lapsed and generic trademarks such as Lollipop, Trampoline or Aspirin, the Scotch brand which recognises problem-solving as the ultimate creative act continues to pervade and guide customer choice and preference.

Insulating Cables

While general-use vinyl tapes are appropriate for bundling, wire pulling and other ancillary tasks, Scotch 35 premium-grade vinyl tape is the best choice for permanent insulation work as it handles the broadest range of environmental factors and functions, such as chemical resistance – available in a rainbow rich choice of colours.

The combination of elastic backing and aggressive adhesive provides moisture-tight electrical and mechanical protection with minimum bulk. For cold weather applications down to – 18°C, Scotch 88 tape is recommended.

3M Scotch 35 and Scotch Super 88 available ex stock

Electricians should use a minimum of two half-lapped layers of 3M vinyl tape to insulate and jacket low-voltage cables, cable sheaths and electrical components. A half-lap consists of overlaying each turn by one-half the width of the tape. The general rule of thumb calls for a tape thickness of 1.5 times the thickness of existing wire or cable insulation.

Two half-lapped layers of 3M vinyl tape

In every case, tension on the electrical tape should be sufficient to conform the 3M Scotch tape evenly to the surface. A slight reduction in tension is encouraged for the final wrap. Trim the Scotch tape end and allow it to return to shape before pressing down with the thumb to avoid lifting or flagging.

Further Reading

How To Repair A Damaged Cable Jacket With 3M Mining Cable Splice Kits 3100 Series

3M Scotch Tapes – PVC Vinyl Electrical Tapes

3M Scotch Tapes

Further details on the complete range of 3M Scotch Electrical Tapes can be found here:

- 3M Scotch Insulation Tapes

- 3M Scotch Self Amalgamating Tapes

- 3M Scotch Mastic Tapes

- 3M Scotch Corrosion & Fire Protection Tapes

- 3M Scotch Glass Cloth Tapes

- 3M Scotch 24 Tape – Electrical Shielding Earthing Tape

- 3M Scotch 25 Tape – Electrical Shielding Earthing Tape

➡ The following tape application table provides an overview of the standard uses of Scotch Electrical tapes:

| Scotch Electrical Uses | Vinyl Tapes | Rubber Tapes | Varnished Fabric Tapes | Mastic & Filler Putty Tapes |

| Protective Cable Jacketing | X | X | ||

| Electrical Insulation | X | X | X | X |

| Moisture Sealing | X | X | ||

| ID & Colour Coding | X | |||

| Cable Harness Bundling | X | |||

| Mechanical Padding | X | X | X | |

| Shaping | X | X | X | |

| Re-entry | X | X |

➡ Visit 3M Electrical for further information about joints, terminations, tapes and insulation to seal, repair, splice and connect LV MV HV cables.

Cold Shrink | Joint | Terminate | Seal | Repair | Splice | LV MV HV Cables | 3M

- 3M Electrical Products Stocked By Thorne & Derrick International

LV, MV & HV Jointing, Earthing, Substation & Electrical Eqpt

Thorne & Derrick International are specialist distributors of LV, MV & HV Cable Installation, Jointing, Duct Sealing, Substation & Electrical Equipment – servicing UK and global businesses involved in cable installations, cable jointing, substation, overhead line and electrical construction at LV, 11kV, 33kV and EHV.

THORNE & DERRICK Product Categories: Duct Seals | Cable Cleats | Cable Glands | Electrical Safety | Arc Flash Protection | Cable Jointing Tools | Cable Pulling | Earthing | Feeder Pillars | Cable Joints LV | Joints & Terminations MV HV

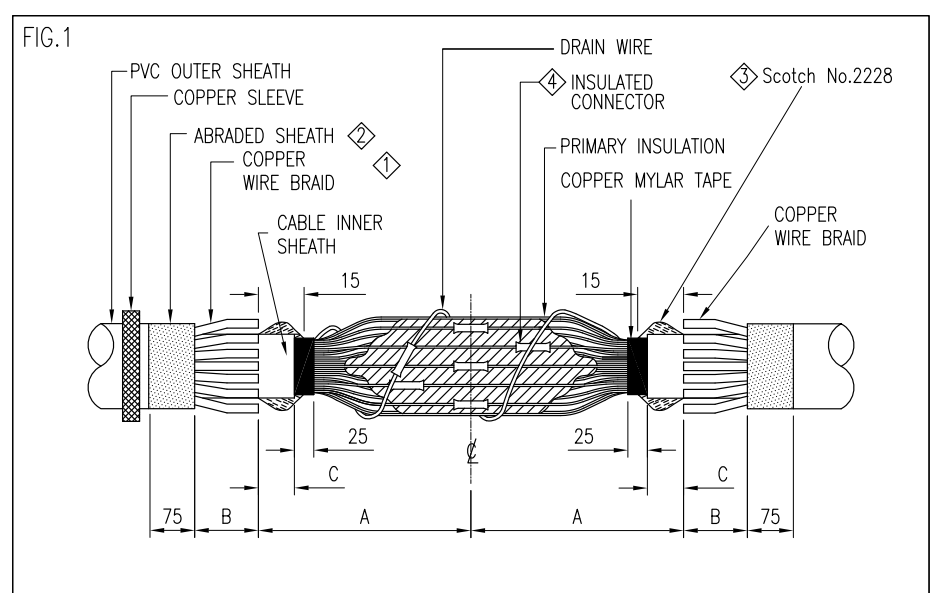

Jointing Instrumentation Cables with Mylar Screen

August 6th, 2020Thorne & Derrick supply 3M, Prysmian, Filoform and SPS low voltage cable joints suitable for connecting and jointing single and multi-core/pair power, control and instrumentation cables up to 600/1000V (3.3kV) in industrial and hazardous area locations – specialist applications include fire resistant, low smoke zero halogen, hydrocarbon resistant and utility cable joints.

Cable joints are available from stock in several technologies to suit the low voltage (LV) installation application and cable type to be repaired or jointed; this includes i) Cold Shrink ii) Heat Shrink and iii) Resin.

This includes Jointing Instrumentation Cables with Mylar Screen.

For the connection and jointing of the instrumentation cable conductors we can recommend Scotchlok 314 type Insulation Displacement Connector.

Jointing Instrumentation Cables with Mylar Screen

Cable Joints LV Low Voltage | Cold Shrink | Heat Shrink | Resin | 600/1000V 3.3kV

THORNE & DERRICK

SPECIALIST ELECTRICAL DISTRIBUTOR

Thorne & Derrick distribute the most extensive range of Cable Installation & Electrical Distribution Equipment to the Power Transmission & Distribution industry in the onshore and offshore wind, solar, rail, oil/gas, data centre, battery storage and utility sectors.

We service UK and international clients working on underground cables, overhead lines, substations and electrical construction at 11kV and up to and EHV transmission and distribution voltages.

- Key Products: MV-HV Cable Joints & Terminations, Cable Cleats, Duct Seals, Cable Transits, Underground Cable Protection, Copper Earth Tapes, Cable Jointing Tools, Feeder Pillars, Cable Ducting, Earthing & Lightning Protection, Electrical Safety, Cable Glands, Arc Flash Protection & Fusegear.

- Distributors for: 3M Cold Shrink, ABB, Alroc, Band-It, Catu, Cembre, Centriforce, CMP, Elastimold, Ellis Patents, Emtelle, Furse, Lucy Zodion, Nexans Euromold, Pfisterer, Polypipe, Prysmian, Roxtec.

LV – Low Voltage Cable Joints, Glands, Cleats, Lugs & Accessories (1000 Volts)

MV HV – Medium & High Voltage Cable Joints, Terminations & Connectors (11kV 33kV EHV)

A Lesson in Transition Jointing Cables by A Competent Jointer

March 20th, 2020

A Lesson in Transition Jointing Cables by A Competent Jointer

HEATSHRINK TRANSITION JOINT 6.35/11(12kV)

Featured Jointer: Stuart Duncan from BELAC

Shrink Polymer Systems heatshrink cable joints and terminations suit all types of standard and non-standard MV-HV Electrical Power Cables (single or multi-core) with or without armour or lead sheaths up to 33/36kV – zero halogen and fire resistant cable joints are also available.

➡ Thorne & Derrick provide competitive prices and fast delivery from stock for the complete range of Shrink Polymer Systems heat shrink cable joints and terminations.

Below shows the installation of a heatshrink transition joint by Stuart Duncan from Belac.

Stuart Duncan at Belac commented, “The cable joints were spot on. Quite enjoyed doing them to be honest. It’s a bit different from the normal so it was a nice change from the usual cold shrink. Jointing instructions were clear and well laid out. Some cable joint kits can get a bit confusing and with irrelevant info in them. I did notice that each separate component was clearly labelled with a name matching the instruction which was a nice touch and helped a lot in the trench. Some kits we use have just numbers and some kits are not labelled at all. Everything fitted well and I was happy with the way everything went together. Good joints, would definitely use them again.”

Picture 1: Stress relief mastic tape had been applied on the step down from lead to paper insulation to eliminate the air void and went on to fit the clear oil barrier sleeve (PILC side).

Picture 2: The semi conductive sleeve and stress control tube have been shrunk into place (PILC side) using a jointer gas torch kit.

Picture 3: Semi-conductive screen has been treated on the XLPE side as well as the application of the yellow stress relief mastic to assist with removing any potentially harmful amounts of electrical stresses. The cable MUST be thoroughly cleaned using a solvent, prior to applying the yellow stress relief mastic. Stress relief mastic should be applied under tension, to ensure void free application.

Picture 4: Connector is in place. Important to note that the connector insulation tubes and outer heatshrink sleeve have been parked down the core before connecting the two conductors together.

Picture 5: Stress relief mastic tape had been applied over the connector and onto the insulation at both sides to eliminate any air voids in the medium voltage cable joint.

Picture 6: CWS and earth braids connecting from the lead are joined. Copper mesh is then wrapped for the length of the cable joint.

Picture 7: Outer adhesive heat shrink sleeves are positioned and fitted to provide moisture and mechanical protection to the 11kV joint.

Thorne & Derrick

Specialist Electrical Distributor

Established since 1985, Thorne & Derrick International based in the UK distribute the most extensive range of LV, MV & HV Cable Jointing, Terminating, Pulling & Installation Equipment – contact us today for a competitive quotation.

Key Products : MV Joints & Terminations, Access Chambers, Cable Cleats, Duct Seals, Cable Transits, Jointing Tools, Feeder Pillars, Cable Duct, Earthing & Lightning Protection, Electrical Safety, Cable Glands, Arc Flash Clothing Protection & Fusegear.

Distributors for : 3M, Pfisterer CONNEX, Nexans Euromold, Elastimold, Catu, Roxtec, Emtelle, Centriforce, Lucy Zodion, Alroc, Cembre, Prysmian, Ellis Patents, ABB & Furse.

LV, MV & HV JOINTING, EARTHING, SUBSTATION & ELECTRICAL EQPT

Thorne & Derrick International are specialist distributors of LV, MV & HV Cable Installation, Jointing, Duct Sealing, Substation & Electrical Equipment – servicing UK and global businesses involved in cable installations, cable jointing, substation, overhead line and electrical construction at LV, 11kV, 33kV and EHV.

ENSTO Low Voltage Overhead Line Equipment & Earthing Connectors

February 12th, 2020-

by Chris Dodds T&D - estimated reading time 3 minutes

Thorne & Derrick | Approved Suppliers Distributors

Ensto Utility Networks offer comprehensive solutions for overhead and underground distribution of electricity and are built to withstand the toughest conditions on earth. Durable products mean uninterrupted service, lower maintenance costs and, above all, satisfied customers.

ENSTO Low Voltage Overhead Line Equipment

Ensto offers accessories and solutions for low voltage overhead lines focused on Aerial Bundled Cable Systems, medium voltage overhead lines (for bare and covered conductor lines), low and medium voltage underground cable networks, power quality and network automation including:

- Four Core System

- Insulated Messenger Wire System (IMWS)

- Uninsulated Messenger Wire System (AMKA)

- Connectors

- Copper Bars

- Bird Protectors

- Cable Lugs, Earthing Connectors and Earthing Bars

- Pole Fuse Switch Disconnectors

- Lamp Post Fixtures Fixing

- Materials for Pole and Wall Mount

- Suspension Hooks

- Stay Wire Accessories and Pole Base Reinforcers

- Tools

Ensto’s Four Core system has four insulated conductors constructed from aluminium that share the tensile load equally and have a size range of 16-185sqmm. Insulation of the cores is typically made of XLPE or PE and the cable can be supplied with one or two insulated conductors for street lighting.

An insulated messenger wire cable (IMWS) consists of one to five black, weather resistant, high density or cross-linked, polyethylene insulated conductors twisted around an insulated aluminum alloy messenger (typical tensile strength 300 N/sqmm)

The uninsulated messenger wire system (AMKA) is a reliable, safe and easy way to build a low voltage overhead line system. Because of the small amount of components and short poles it is easy to build and preferred by many professionals.

THORNE & DERRICK are national distributors LV, MV & HV Cable Installation, Jointing, Substation & Electrical Equipment – we service UK and global businesses involved in cable installations, cable jointing, substation, overhead line and electrical construction at LV, 11kV, 33kV and EHV.

Since 1985, T&D have established an international reputation based on SERVICE | INTEGRITY | TRUST.

Contact us for 3M Electrical, ABB, Alroc, AN Wallis, CATU Electrical, Cembre, Centriforce, CMP, CSD, Elastimold, Ellis Patents, Emtelle, Euromold, Filoform , Furse, Lucy Electric & Zodion, Nexans, Pfisterer, Polypipe, Prysmian, Roxtec, Sicame, WT Henley.

Invitation

Thorne & Derrick invite you to join LinkedIn’s largest LV-HV Electrical Discussion Group : Low & High Voltage Power, Cabling, Jointing & Electricals. Discussion subjects include cable installations, cable jointing, substation, overhead line and electrical construction at LV, 11kV, 33kV and EHV. Network, engage and promote your profile, company or products with over 10,000 influencers.

Nexans NX600 Alsecure Cable : Fire Resistant, Low Smoke & Halogen Free Cables

October 22nd, 2019

Nexans NX600 Alsecure Cable – Fire Resistant, Low Smoke & Halogen Free Cables

-

uploaded by Chris Dodds | Thorne & Derrick Sales Marketing Manager

Low Voltage Fire Resistant Power Cable

Nexans Alsecure NX600 fire resistant power cable is ideal for fire safety engineering systems in large multi-storey and complex buildings.

Nexans NX600 is a low smoke, halogen free and fire resistant cable which is designed to meet the requirements of the BS8491 fire test which simulates direct impact and also the effects of a high pressure water hose along with a continuous flame.

BS8491 is the British Standard regulating the method for assessment of fire integrity of large diameter power cables for use as components for smoke and heat control systems and certain other active fire safety systems.

The cable test incorporates direct fire attack, mechanical attack and water spray, over a variable time up to two hours. Several cable makers have produced enhanced fire resistant cables to meet this requirement.

Overcoming Fire Safety Cable Challenges

The increased scale and complexity of building design and architecture has made safe evacuation of the public during a fire evermore complicated.

The compounds and materials used in cable construction further complicate evacuation.

Traditional cables propagate flames and release hazardous fumes when they burn, this relates especially to halogenated PVC sheathed cables.

Fumes released during a fire can be more dangerous to human life than the flames themselves. The gases cause drowsiness, affect breathing and eventually cause death. For this reason, some installations require cables which will release low levels of smoke which is halogen free, and therefore non-toxic to humans.

Nexans Alsecure NX600 fire resistant cable is approved for 30, 60 and 120 minutes applications as detailed in BS8519 (Selection and installation of fire-resistant power and control cable systems for life safety and fire-fighting applications) and can be used in a vast variety of systems in building such as fire-fighting and evacuation lifts, sprinkler systems and wet riser pumps.

The Nexans fire resistant cable is also approved by both LPCB and BASEC to meet the requirements of BS7846-F120 to maintain circuit integrity in the event of a fire.

Nexan’s NX600 cable is available for sizes up to and including 35sqmm with circular conductors or 50-330sqmm with sector shaped conductors.

The steel wire armour (SWA) is a single layer of galvanised steel wires and the cores are identified by colours and covered with an extruded layer of polymeric compound.

NX600 Alsecure is specified for use in stadia, airports, hospitals, universities, hi-rise offices, residential and public building.

In the rail industry, fire resistant cables provide low voltage power distribution in and around train stations and security systems (video, ventilation, breakdown, emergency lighting).

Fire Resistant, Low Smoke & Halogen Free Cables

Nexans NX600 Alsecure Cable

Features & Benefits

| Standards | |

| Fire Resistance | BS 8491 120 min |

| Flame Propagation | BS EN 50266-2-4, IEC 60332-3-24 |

| Smoke Emission | BS EN 61034 |

| Design | BS 7846 |

| Certification | Certified by BASEC and LPCB |

| Characteristics | |

| Conductor Material | Copper |

| Conductor Flexibility | Standard Class 2 |

| Cable Insulation | XLPE & Mica Tape |

| Cable Outer Sheath | LSF |

| Colour | Black |

| Cable Inner Sheath | Halogen Free Compound |

| Rated Voltage Uo/U (Um) | 0.6/1kV |

| Minimum Installation Temperature | 0ºC |

| Maximum Operating Temperature | 90ºC |

| Short-Circuit Maximum Conductor Temperature | 250ºC |

| Fire Resistant | BS 8491-120 |

| Flame Retardant | IEC 60332-3 Cat.C |

Nexans NX600 Alsecure Cable – Product Range

| 3 Core Cable | |||||||

| Cross Section sqmm | Approx Insulation Thickness mm | Nominal Armour Wire Diameter | Approx Sheath Thickness mm | Approx Overall Diameter mm | Approx Cable Weight kg / km | Max Conductor Resistance at 20ºC | Min Bend Radius |

| 4 | 0.7 | 1.25 | 1.4 | 20.0 | 520 | 4.61 | 6D |

| 6 | 0.7 | 1.25 | 1.4 | 20.0 | 600 | 3.08 | 6D |

| 10 | 0.7 | 1.25 | 1.5 | 20.0 | 910 | 1.83 | 6D |

| 16 | 0.7 | 1.25 | 1.6 | 22.0 | 1150 | 1.15 | 6D |

| 25 | 0.9 | 1.6 | 1.7 | 26.0 | 1650 | 0.727 | 6D |

| 35 | 0.9 | 1.6 | 1.8 | 28.0 | 1850 | 0.524 | 6D |

| 50 | 1.0 | 1.6 | 1.8 | 31.0 | 2500 | 0.387 | 8D |

| 70 | 1.1 | 1.6 | 1.9 | 34.0 | 3100 | 0.268 | 8D |

| 95 | 1.1 | 2 | 2.1 | 39.0 | 4450 | 0.193 | 8D |

| 120 | 1.2 | 2 | 2.2 | 42.0 | 5250 | 0.153 | 8D |

| 150 | 1.4 | 2.5 | 2.3 | 47.0 | 6650 | 0.124 | 8D |

| 185 | 1.6 | 2.5 | 2.4 | 51.0 | 8050 | 0.0991 | 8D |

| 240 | 1.7 | 2.5 | 2.6 | 56.5 | 10050 | 0.0754 | 8D |

| 300 | 1.8 | 2.5 | 2.7 | 62.0 | 12150 | 0.0601 | 8D |

| 4 Core Cable | |||||||

| Cross Section sqmm | Approx Insulation Thickness mm | Nominal Armour Wire Diameter | Approx Sheath Thickness mm | Approx Overall Diameter mm | Approx Cable Weight kg / km | Max Conductor Resistance at 20ºC | Min Bend Radius |

| 4 | 0.7 | 1.25 | 1.4 | 20.0 | 610 | 4.61 | 6D |

| 6 | 0.7 | 1.25 | 1.5 | 20.1 | 890 | 3.08 | 6D |

| 10 | 0.7 | 1.25 | 1.6 | 23.5 | 1020 | 1.83 | 6D |

| 16 | 0.7 | 1.25 | 1.6 | 24.5 | 1300 | 1.15 | 6D |

| 25 | 0.9 | 1.6 | 1.7 | 28.0 | 1900 | 0.727 | 6D |

| 35 | 0.9 | 1.6 | 1.8 | 31.0 | 2430 | 0.524 | 6D |

| 50 | 1.0 | 1.6 | 1.9 | 33.5 | 3100 | 0.387 | 8D |

| 70 | 1.1 | 1.6 | 2.1 | 40.0 | 4400 | 0.268 | 8D |

| 95 | 1.1 | 2 | 2.2 | 44.5 | 5600 | 0.193 | 8D |

| 120 | 1.2 | 2 | 2.3 | 48.0 | 7100 | 0.153 | 8D |

| 150 | 1.4 | 2.5 | 2.4 | 57.5 | 8600 | 0.124 | 8D |

| 185 | 1.6 | 2.5 | 2.6 | 60.0 | 10200 | 0.0991 | 8D |

| 240 | 1.7 | 2.5 | 2.7 | 63.5 | 12800 | 0.0754 | 8D |

| 300 | 1.8 | 2.5 | 2.9 | 69.5 | 15500 | 0.0601 | 8D |

T&D are specialist distributors of fire resistant cable accessories including Ellis Patents Phoenix Cable Cleats and SPS Fire Resistant Cable Joints

Nexans Euromold Cable Connectors, Joints & Terminations

Thorne & Derrick

Nexans Main UK Stockist & Distributor

Contact us for Competitive Prices & Fast Delivery from Stocks for Heat Shrink, Cold Shrink & EPDM Rubber Connectors, Joints & Terminations up to 66kV.

Go to our Price List and contact us with your enquiries.

Thorne & Derrick International are specialist distributors of LV, MV & HV Cable Accessories, Jointing, Substation & Electrical Equipment – servicing UK and global businesses involved in cable installations, jointing, substation, overhead line and electrical construction at LV, 11kV, 33kV, 66kV and EHV.

Stocking & Supplying | Duct Seals | Cable Cleats | Cable Glands | Electrical Safety | Arc Flash Protection | Jointing Tools | Cable Pulling Eqpt | Earthing & Lightning Protection | Feeder Pillars | Cable Joints LV | Joints & Terminations MV HV

Euromold MV HV | Cable Terminations, Connectors, Elbows & Joints