Blog

Transition Joint EHV – Oil To XLPE NKT Cable Joint

September 24th, 2019- Application: Transition Joint EHV – Oil To XLPE NKT Cable Joint

- Cable Joint Type: Transition Joint EHV

- Cable Jointer: Dean Wilson Owner Director at D C Jointing Ltd

- Featured Manufacturer: NKT Cables

Weighted piano wire was used for the chamfer. Connectors are sweated on with solder. Hand skills are very important and not so much tooling for the oil.

Oil Cable

Sweated Ferrule & Paper Insulation Chamfered Prepared For Taping

XLPE Cable

Cable Crimped, Insulation Chamfered & Polished Prepared For Taping

XLPE Cable

Cable Crimped, Insulation Chamfered & Polished Prepared For Taping

Knitmesh screens applied over cores

Basting with hot oil prior to taping

All three cores taped

Plumbed ready for vacuum

Opening up the lead

Cut

Cores

XLPE side ready for oil side

Connectors sweated

Basting as you are taping

Crepe taping

NKT cable Joints & Terminations Overview

- Outdoor cable terminations (porcelain or composite)

- Non-self-supporting outdoor cable terminations

- Cable terminations for gas-insulated switchgears (GIS)

- Transformer cable terminations

- Straight-through cable joints

- Insulating joints/cross-bonding cable joints

- Transition cable joints, XLPE-insulated/oil-filled cables

- CabSnap accessories for preassembled cable connection systems

NKT Straight Three Piece Joints – Cross Bonding Cable Joints

High Voltage Cable Accessories 72kV to 245kV

Further Reading

Jointing Oil Filled EHV Cables Using NKT Fluid-Filled Accessories

Should you require any assistance with the selection or specification of cable joints or terminations please do not hesitate to contact us.

Jointers blog

Subscribe now to our POWER NEWSLETTER– a monthly email circulation packed with news, projects, videos, technical tips, training information, promotions, webinars, career opportunities and white papers.

Includes access to our popular JOINTERS BLOG with contributions from utility professionals, linesmen and cable jointers working on MV HV EHV cables and overhead lines typically at 11kV, 33kV, 66kV and up to 132kV.

Cable Pulling & Installation | Advice for LV HV Cable Installations

September 24th, 2019

Cable Pulling & Installation | Advice for LV HV Cable Installations

Cable Delivery, Pulling and Installation

Top Do’s & Don’ts

-

Article Contribution Thanks to BASEC

BASEC is an independent accredited certification body for the cable industry worldwide.

BASEC’s name is synonymous with cable quality and safety.

Although present everywhere, cables seldom impact their users; they are usually hidden from view, and, if they are fulfilling their role correctly, require no attention. They should perform reliably for many decades if they have been correctly specified, conform to relevant standards and specifications, carry BASEC or another recognised approval, and have been carefully maintained. Protection from environmental and mechanical stress is also essential.

However, even cables that are sourced responsibly are at risk during initial delivery and installation. During this phase, they will be subjected to movements, stresses and strains – and if these exceed the cable design limits, damage becomes a strong possibility. Even simple issues like snagging on sharp edges can have serious consequences.

Installation damage during the cable pulling and laying process can lead to customer dissatisfaction, significant delays in project completion, extra resources being needed, and in particular, additional costs imposed on installers for removing and replacing damaged cables. These problems can be exacerbated if the effects of any damage do not become apparent, potentially affecting the supply of power, control or communications, until after the installation has gone into service.

Below are some top tips for a clean, trouble-free installation:

Cable delivery and cutting to length: Safe handling of cable starts with the supplier, often a distributor or wholesaler. Manufacturers will deliver cables on an appropriately sized drum or reel, loaded under controlled factory conditions. Cutting the cable to length, and redrumming onto an often-smaller delivery drum can result in over-bending if the drum belly diameter is too small; additionally, the cable may suffer external scuffing damage.

End caps: If suitable end caps are not fitted onto the cut length, water may penetrate the cable during storage or on site.

Bend radius – armoured cables: Bend radius is a key consideration, particularly for SWA cables and for higher voltages of 11kV or more. Minimum bend radius is generally defined by cable standards, or is advisory; it should be communicated by manufacturers and passed on by suppliers to the installers. Sometimes two figures are used; a dynamic radius for the pull, and a possibly smaller final static radius for when the cable is no longer under tension.

Maximum cable tension and sidewall pressure limits can both cause damage if exceeded when pulling cables. To prevent this, cable installation routing should be closely assessed, and several rollers or guides used at any bend points. A single cable roller or guide’s external radius is always likely to be much lower than the cable’s minimum bend radius. As a simple rule of thumb, for a four-core armoured cable larger than 40mm OD, a full-sized bicycle wheel should fit within the bend.

Bend radius – screened cables: With screened cables such as BS 7629-1- rated fire alarm types, the minimum bend radius must be maintained to ensure fire integrity. Kinks in the screening or over-tight entry into accessories may compromise fire performance. All such cables will have been fire tested at a specified bend radius, which the manufacturer should communicate to their suppliers and users.

Bend radius monitoring: Monitoring the bend radius on site is not straightforward. Many installers use simple go / no-go templates, but these can sometimes miss the tight parts of bends. Purpose-designed radius gauges can measure extremely accurately, providing reassurance that a cable installation has been completed correctly and safely.

Cable pulling: Problems can occur where cables are pulled in two directions from a common mid-point. Some cable is initially pulled in one direction, then the remaining cable is laid out from the drum before being pulled in another direction. This approach can cause significant damage to a cable that cannot twist freely during installation, or where loops of cable introduce twists. Damage to armour can result in bird-caging and sheath splits.

Workers pulling cable across pipes to supply energy to a neighbourhood

Avoiding cable torsion when pulling is important, and is largely addressed by using rotating pulling heads and a suitable cable pulling sock. Pulling the cable through a rope will restrict rotation and can create problems. Tension built up around each bend will propagate back down the cable, causing issues nearer the drum.

Conclusion

Competent and experienced cable installation teams, using the correct equipment including tension-monitored winches, pulling socks, and a generous quantity of rollers and guides, should experience fewer problems while ensuring a trouble-free installation.

Top 10 Articles | Thorne and Derrick & BASEC #CABLEQUALITY

With a shared passion and ambition to enhance electrical safety through the education and encouragement of industry stakeholders to specify and buy accredited, tested and certified Quality Cables & Cable Accessories.

#CableQuality is the hashtag – securing public safety through the specification and installation of BASEC approved and verified LV MV HV electrical cables by competent and qualified electricians is the objective.

Read on………

- Promoting Good Practices For Cable Products Following The Grenfell Tower Report

- End User Specification Of Approved Cable Products: Where Is The Value?

- Fire Testing Of Cables Is Important, But Not At The Expense Of Other Characteristics

- Top Dos And Don’ts – Cable Delivery, Pulling And Installation

- How To Write A Good Cable Specification

- New Testing and Certification Scheme Launched for YY, SY, CY Control Cables

- Specifying Quality Cable For Your Projects

- When Quality Matters: Early Indicators Of Error

- Tratos Supplies BASEC Approved Medium Voltage Cables Into WPD

- Electricians Guide to CPR

THORNE & DERRICK

Cable Pulling Equipment

Thorne & Derrick distribute an extensive range of Cable Pulling & Laying Equipment to enable the safe installation of fibre and copper cables within the telecommunications industry. Safely installed cables reduces operational and maintenance requirements to the network and reduced service interruption to telecom cables, wires, ducts, cabinets and exchanges – products include cable spiking tools, conduit rods, cable lubricant, cable socks and cable rollers.

Video : Solution to Terminating & Connecting Photovoltaic Solar Aluminium Cables

September 24th, 2019Solution to Terminating & Connecting Photovoltaic Solar Aluminium Cables

-

uploaded by Chris Dodds - Thorne & Derrick Sales | Marketing Manager

Pfisterer Sicon Cable Lugs

Cable Lug Installation

Bolted mechanical cable lugs should only be installed by qualified and trained specialist personnel.

The cable lug installation must be carried out in dry and clean conditions.

Pfisterer Sicon cable lugs are specially designed for both copper and aluminium conductors with range taking acceptance of conductors, rated up to 72kV.

Cable lugs, straight connectors, branch connectors (with or without oil stop/water block) are available for the connecting and jointing of LV-HV cables.

![]()

5 Key Safety Rules For Pfisterer Sicon Installation

- Do not screw or unscrew the shear-off bolt

- Do not use an extension key

- Do not remove the grease from the cable lug

- Do not use if the product is soiled or damaged

- Covering caps are not heat resistant. Do not use with heat shrink material.

Pfisterer Sicon Cable Lugs & Solar PV Cables

Demo Video

DC string solar panel and combiner to inverter connection cables can be effectively terminated using Pfisterer Sicon cable lugs. In the following video the Pfisterer Sicon cable lug is secured in place using the Boddingtons Connector Holding Tool and then installed in seconds using a Milwaukee impact wrench.

LEONI Studer AG is based in Switzerland, founded since 1939 and is part of the LEONI Group which has been around since 1569 manufacturing gold wires for over 400 years.

PV Solar Aluminium Power DC Cable. BETAflam® Solar Cable

Pfisterer Sicon Cable Lug 332-605-011

Sicon In Solar – Pfisterer Project Experience

By Steve Cooper (Pfisterer UK Sales Engineer)

“Just under a year ago Pfisterer received a call from a major UK solar EPC who were looking to use aluminium cable on the upcoming round of projects. They had major concerns with oxidisation of aluminium conductors – the technical benefits of Sicon soon brushed these issues aside. Usually my work would be done now the specification would be in place and I would move on to my next project.

Not this time, the next issue was the combiner box (these combine the strings from the solar panels with a DC output). The combiner boxes were fitted with a pressure plate connection that was not suitable for aluminium conductors.

After many conversations with the combiner box manufacturer the only solution was to offer a Pfisterer 332 601 010 (10-95sqmm Sicon mechanical through connector) and a heatshrink joint to connect the aluminium conductor to a 50sqmm flexible copper conductor. The substation was quite simple in comparison, the customer purchased Pfisterer 332 604 010 (10-95sqmm Sicon cable lugs) used in conjunction with heatshrink cable lug seals.

Pfisterer Sicon cable lugs and connectors are now established into the solar industry.

As project installations transfer from copper to aluminium cable systems the requirement for mechanical shearbolt connectors, manufactured from aluminium alloy, has risen fast.

Since their introduction, Sicon connectors and lugs have been used by a host of major solar EPC’s and installers. Pfisterer have built up an extensive knowledge of the solar industry and have been involved in many technical conversations with investors, contractors and solar equipment manufacturers.

The rewards of solar can be great with over 20,000 Pfisterer Sicon units sold over the last 6 months in the UK alone. An average installation uses 30+ Pfisterer lugs per M.W. With an estimated UK market for 2015 of 3.2GW and globally 53GW then the future looks bright for Sicon.”

Pfisterer Sicon Cable Lugs – Containerised Substation

![]()

Pfisterer Sicon Cable Lugs – Combiner Box

Sicon

The First Cable Connector System With Stepless Shear Bolts

What Is a Combiner Box?![]()

The combiner box’s role is to bring the output of several solar strings together. Daniel Sherwood, director of product management at SolarBOS, explained that each string conductor lands on a fuse terminal and the output of the fused inputs are combined onto a single conductor that connects the box to the inverter.

“This is a combiner box at its most basic, but once you have one in your solar project, there are additional features typically integrated into the box,” he said. Disconnect switches, monitoring equipment and remote rapid shutdown devices are examples of additional equipment.

- Read full article Solar Power World

![]()

Inside the World’s Largest Solar Power Plant. Article TIME

THORNE & DERRICK SPECIALIST ELECTRICAL DISTRIBUTOR

The LV HV Specialists

Thorne & Derrick distribute the most extensive range of Cable Installation & Electrical Distribution Equipment to the renewable energy sector – we service UK and international clients working on underground cables, overhead lines, substations and electrical construction at 11kV and up to and EHV transmission and distribution voltages.

- Key 11kV Products: MV-HV Cable Joints & Terminations, Cable Cleats, Duct Seals, Cable Transits, Underground Cable Protection, Copper Earth Tapes, Cable Jointing Tools, Feeder Pillars, Cable Ducting, Earthing & Lightning Protection, Electrical Safety, Cable Glands, Arc Flash Protection & Fusegear.

- Distributors for: 3M Cold Shrink, ABB, Alroc, Band-It, Catu, Cembre, Centriforce, CMP, Elastimold, Ellis Patents, Emtelle, Furse, Lucy Zodion, Nexans Euromold, Pfisterer, Polypipe, Prysmian, Roxtec.

LV – Low Voltage Cable Joints, Glands, Cleats, Lugs & Accessories (1000 Volts)

MV HV – Medium & High Voltage Cable Joints, Terminations & Connectors (11kV 33kV EHV)

Cable Laying – Underground Cable Covers, Ducting, Seals & Cable Pulling Equipment

T&D, CATU Electrical Safety & Arc Flash Protection Specialists for SAP’s, Linesmen, Jointers & Electrical Engineers – Largest UK Stockist

How To Carry Out A 230kV Pipe Type Pothead Replacement /Cable Freeze

September 24th, 2019

-

uploaded by Chris Dodds - Sales & Marketing Manager | Thorne & DerrickAll Images Courtesy Of: Douglas Page (Instructor & Cable Splicer at Hydro One Training and Development Services).

Douglas Page is not a stranger to our Jointers Blog having blazed a trail over the past few weeks with some real ripsnorting, hardcore, high voltage images.

Let’s treat ourselves to a quick whistlestop tour of Doug’s recent contributions to the Jointers Blog as an appetite whetter to the latest serving up of his captivating EHV skills.

➡ See Also: How To Find A Single Drip Of Oil In Approximately 12km Of LPOF PILC 115KV Direct Buried Cable

115kV Straight & Stop Joint On LPLF, PILC Cables In Cable Vault

EHV Cable Splicing – 115kV Stop Joint (Taped)

Jointing 44kV High Voltage Submarine Cables Using 3M Cold Shrink Splices

Water Treeing in High Voltage Cables : A 230kV HPPT Termination Repair

Time for the Main Course. Bon Appetit…

The following are the steps involved to replace the insulator on a 230kV pipe type cable.

1. All of the insulation (rubber and compound) must be removed from the single conductor stainless steel pipe

2. Once the single conductor goes underground, it goes to a trifurcating cable splice, and then the three conductors are in one pipe

3. With the pipe exposed the jointer starts wrapping the the copper tube

4. Continue to wrap, leaving a space in the middle and then duplicate the first section of wrap

5. Once all the tubing is applied, thermocouple probes are placed at the middle and both “outside” points of the freeze to monitor temperature, and a moisture barrier is applied

6. Heavy duty pipe insulation is installed (several layers)

7. With the wrap completely installed, another moisture barrier is applied

8. Before the freeze can be initiated, the oil pressure must be greatly reduced, to just above ‘static’ pressure, or the constant force of the oil would prevent the cable from freezing

9. Depending on pipe size, conductor size, length of pipe, time of year, once the liquid nitrogen is applied, it takes various amounts of time to freeze any particular cable. All three thermocouples are constantly monitored

10. With the desired temperature reached, the freeze plug is active. The termination (pothead) is drained, and the old insulator is removed

11. The cable termination is meticulously inspected and cleaned. Flushed several times with hot cable oil

12. The new porcelain is installed

13. Once the new glass is bolted back on to the cable and sealed, the Liquid Nitrogen can be shut down, and the cable begins to thaw

14. Once cable has thawed the cable termination (pothead) is slowly filled with cable oil, under vacuum

THORNE & DERRICK

Thorne & Derrick are national distributors of LV, MV & HV Cable Installation, Jointing, Substation & Electrical Equipment – servicing businesses involved in cabling, jointing, substation, earthing, overhead line and electrical construction at LV, 11kV, 33kV, 66kV and EHV. Supplying a complete range of power cable accessories to support the installation and maintenance of low/medium and high voltage voltage power systems:

- Slip-on Cable Terminations

- Cold-shrink Cable Terminations

- Heat-shrink Cable Terminations

- Cable Joints – Heat & Cold-shrink

- Separable Connectors (Euromold)

- Surge Arresters & Switchgear/Transformer Bushings

Key Product Categories: Duct Seals | Cable Cleats | Cable Glands | Electrical Safety | Arc Flash Protection | Cable Jointing Tools | Cable Pulling | Earthing | Feeder Pillars | Cable Joints LV | Joints & Terminations MV HV

How To Find A Single Drip Of Oil In Approximately 12km Of LPOF PILC 115KV Direct Buried Cable

September 24th, 2019

-

uploaded by Chris Dodds - Thorne & Derrick Sales | Marketing Manager

All Images Courtesy Of: Douglas Page (Instructor & Cable Splicer at Hydro One Training and Development Services).

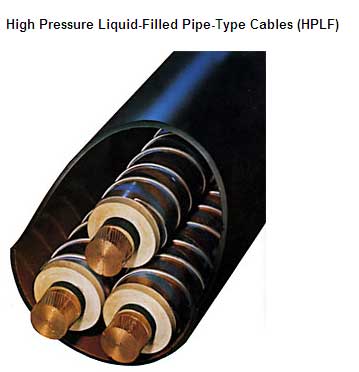

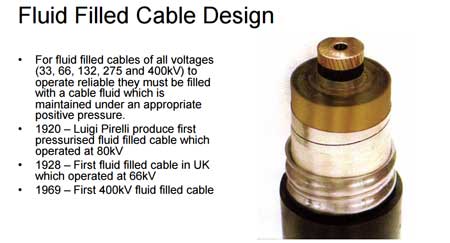

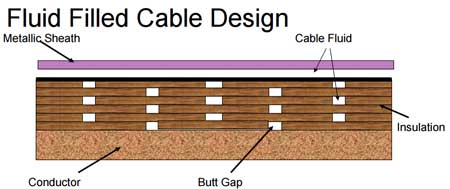

Fluid Filled Cables

Fluid filled high voltage cables have been used for over 80 years with some circuits installed in the 1930’s still operating successfully today without any deterioration.

The fluid contained within a fluid filled cable has to be kept at a positive pressure under all conditions of loading and ambient temperature change.

Fluid filled cables rely on the presence of pressurised cable fluid to work efficiently – if the circuit suffers an oil leak the cable network is compromised.

The pressure used depends on a number of factors:

- Voltage and size of cable

- The length of the cable

- The route the cable follows

- Whether the cable has a leak

High Voltage Cables

The fluid forms an integral part of the high voltage cable insulation and prevents the formation of voids in the lapped papers around the conductor – also the cable fluid aids the conduction of heat away from the conductor allowing the cable to be run efficiently than a cable without it.

The following photo sequence shows how to find a single drip of oil in approximately 12km of Single Core LPOF PILC 115KV direct buried cable.

LPOF Low Pressure Oil Filled

PILC Paper Insulated Lead Covered

1. Cathodic lead erosion is clearly visible on the EHV power cable – this is usually caused by ground factors such as gas mains, neighbouring cable circuits, water mains etc. The aged underground EHV cable is suffering natural degradation and overtime a deterioration in the cables normal cathodic protection has caused service issues with the cable circuit – the cable becomes the sacrificial anode and starts to break down.

2. Cable type : Transmission & Distribution Voltage – 115kV LPOF PILC Single Core.

3. LPOF EHV cables are monitored by gauges and pressurized by pre-pressurized tanks with internal baffles, that expand and contract with the cable, maintaining a constant pressure. If the pressure cannot be maintained, an alarm is triggered.

4. To find the oil leak in 10, 15, 20, or 100km of cable, it all starts the same way. Find the approximate centre of the cable circuit, excavate safely and install a cable freeze.

5. Very similar to a pipe type freeze, the coil must be installed on the bare lead.

6.

7. Along with a freeze, to monitor the temperature, the EHV jointer/splicer must install thermocouple temperature monitors which consist of two conductors of dissimilar metals that react to the temperature change differently allowing the monitors to display the actual temperature.

8.

9.

10. Once the freeze has been initiated, the gauges are monitored, the side that loses pressure, is flagged and deemed the side that requires further attention

11. Freeze pit – once the leak has been narrowed to 50-100m length, the final excavation begins. Until signs of leaking cable oil are found

13. After a lengthy search, this is what you are looking for, although opinions vary, constant drip can yield various amounts of accumulation. Some say it could fill a bathtub in 72 hours

14. Once located a temporary EHV cabl repair is made, while environmental remediation is done

15. “Tinning” of the cable repair, so the lead will adhere to the cable

16. The EHV cable repair is complete – after this the jointer must solder a copper lead connected to a sacrificial “anode” that erodes before the cable

Further Reading

THORNE & DERRICK

Thorne & Derrick are national distributors of LV, MV & HV Cable Installation, Jointing, Substation & Electrical Equipment – servicing businesses involved in cabling, jointing, substation, earthing, overhead line and electrical construction at LV, 11kV, 33kV, 66kV and EHV. Supplying a complete range of power cable accessories to support the installation and maintenance of low/medium and high voltage voltage power systems:

- Slip-on Cable Terminations

- Cold-shrink Cable Terminations

- Heat-shrink Cable Terminations

- Cable Joints – Heat & Cold-shrink

- Separable Connectors (Euromold)

- Surge Arresters & Switchgear/Transformer Bushings

Key Product Categories: Duct Seals | Cable Cleats | Cable Glands | Electrical Safety | Arc Flash Protection | Cable Jointing Tools | Cable Pulling | Earthing | Feeder Pillars | Cable Joints LV | Joints & Terminations MV HV