Blog

Rail Cable Labels with Network Rail & London Underground (LUL) Approval

April 5th, 2019

Cable Labels

-

uploaded by Chris Dodds (Sales & Marketing Manager - Thorne & Derrick International)

Rail Cable Labels

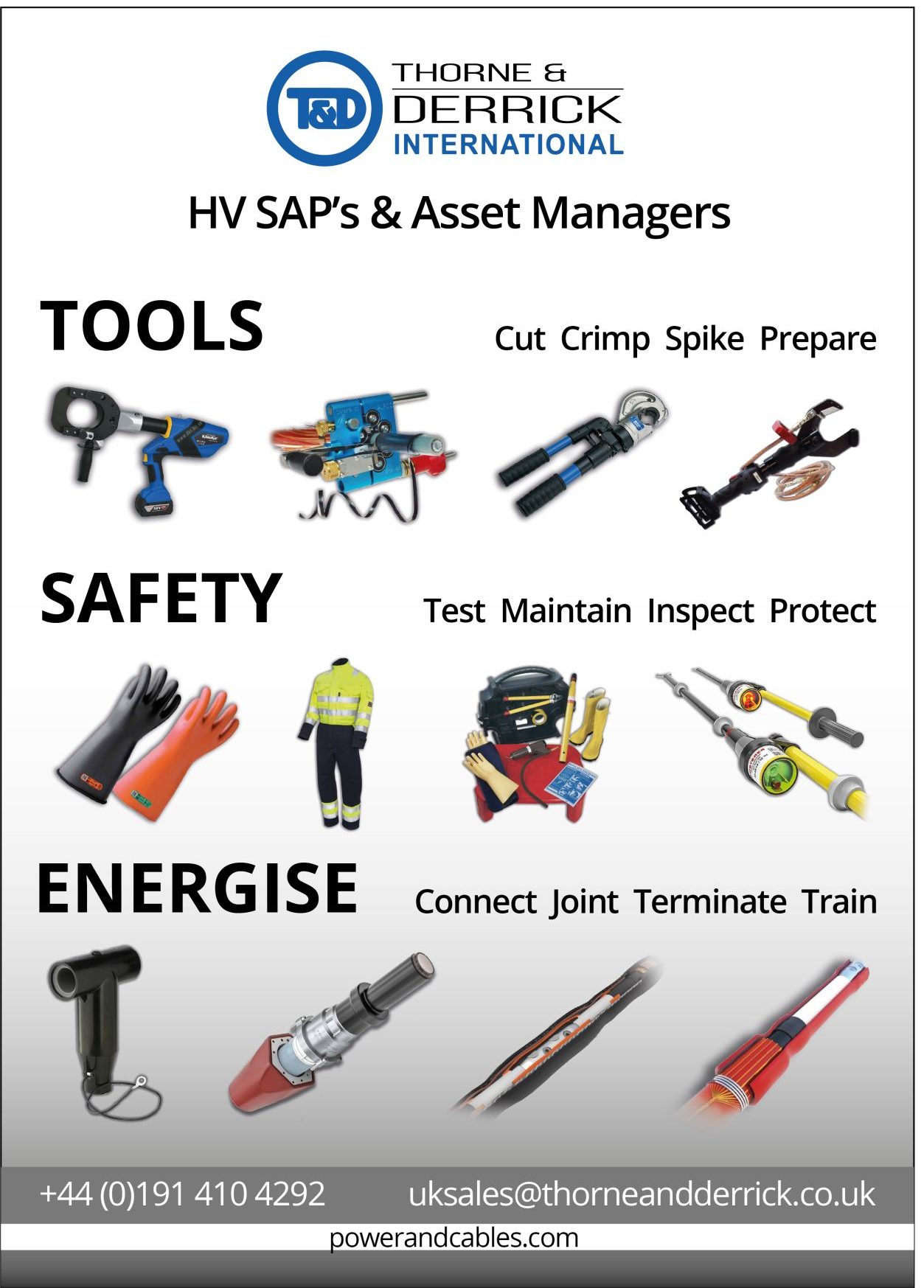

T&D are Main Distributors for Silver Fox, the UK leading manufacturer of Wire & Cable Labelling Systems for the identification of LV MV HV Electrical, Instrumentation, Security, Data & Telecoms cables in the rail industry.

Key to the specification selection process for rail cable labels is the ability to demonstrate low smoke zero halogen performance in the event of a fire.

LU-1-085 Compliant Cable Labels

for London Underground

LU 1-085 is the current approval document which details the requirements of fire safety materials to be used on London Underground and Transport for London (TfL).

LU 1-085 includes rigorous fire and safety tests to ensure only the safest materials are installed onto a rail network that transported over 1 billion passengers in 2012.

Compliance of any cable or cable accessory with LU 1-085 is a hallmark of advanced technical specification and product performance.

The stringent performance testing of Silver Fox cable labels has ensured successful installation in high voltage electrical substations where long-term and durable cable labelling is essential on mission-critical power circuits at 11kV and 33kV voltages.

Silver Fox-Flo Tie-on LS0H Cable Labels

A range of products have been approved by both Network Rail and London Underground (LUL) including the Silver Fox-Flo Tie-on LS0H Cable Labels and the Silver Fox Legend Low Smoke Zero Halogen Heatshrink Cable Labels which are available in a continuous roll or ladder format.

Silver Fox-Flo Tie-on LS0H Cable Labels, Legend Ladder Heatshrink & Heatshrink Roll in Box

Test, Test & Test Some More

Silver Fox cable labels go through rigorous independent testing to ensure their safety and reliability. These tests include:

- MIL – STD – 202G Method 106G – Moisture Resistance

- MIL – STD – 810F Method 502.4 – Low Temperature -25°C

- MIL – STD – 810F Method 502.4 – Low Temperature -40°C

- IEC60068 – 2 – 52 Test kb Salt Mist (Cyclic)

- H2S Exposure (Sour Ageing)

The Silver Fox Fox-Flo® Tie-On cable labels have also undergone specific testing for:

- UL 94 Section 8 ‘Vertical Burning Test’ Rating V0

- UV Weathering 8000 hours ISO 4982 Part 3 Method A Cycle 1

- IMO FTPC Part 2 – Smoke and Toxicity

- IMO FTPC Part 5 – Surface Spread of Flames

All this testing is part of Silver Fox’s continuing resolve to ensure their customers profit from effective and innovative cable labelling products, enabling them to use time productively, whilst also benefiting from high quality and durable solutions.

All Silver Fox Thermal Labels are printed using One Software, One Printer and One Ribbon.

- Tie-on LS0H Cable Labels

- Tie-on Cable Labels (PVC)

- Premium Heatshrink Cable Labels (Polyolefin)

- Tie-on Cable Labels (Durable Polyester)

- Low Smoke Zero Halogen Heatshrink Cable Labels (Polyolefin)

- Non-Shrink Cable Labels (PVC Tubing)

- 2 Part Cable Labels (Flexible Polyester)

- Wrap Around Cable Labels (Self Laminating Polyethylene)

Silver Fox Thermal Cable Labels

Video : How To Print 25,000 Cable Labels In 4 Hours

Rail Cable Accessories, Electrification & Installation Equipment

Thorne & Derrick stock and distribute an extensive range of 400V-33kV Rail Cable Accessories & Power Distribution Sytems including feeder pillars to contractors undertaking Low Voltage Power Distribution, HV Electrification & Substations, DC Traction & Networks, OLE and Track Feeder Cable Renewals – complete range of Network Rail PADS approved track terminations, cable joints, cable repair and connection products up to 25kV, including 3M Cold Shrink, Pfisterer CONNEX and Nexans Euromold products.

Full range of Cable Pulling Equipment & Products to ensure safe and efficient of rail cables in to cable ducts and containment infrastructure including cable troughs.

Cable Cleats | Cable Hangers | Cable Joints | Cable Glands | Cable Lugs | Cable Transits | Arc Flash Clothing

Utilising Distribution Transformers To Optimise Solar

April 5th, 2019

Manufactured & Designed In UK | Short Lead Time | Transformers LV 11kV

-

uploaded by Chris Dodds - Thorne & Derrick International Sales & Marketing Manager

Transformers

The importance of distribution 11kV transformers as part of electrical infrastructure can not be overstated. As an asset that is always energised, regardless of whether they carry a load, transformers are critical assets and pivotal to ensuring that a safe level of voltage is supplied to businesses across the UK.

It is surprising then to consider that the performance and operation of them has been left offline and unknown apart from when subjected to annual manual inspections, particularly as Industry 4.0 gathers momentum and the UK continues to undergo digitalisation.

Fortunately, the advent of smart transformers has revolutionised this crucial asset and enables companies to access real-time insights into asset performance and operation through remote monitoring capabilities, ultimately enabling a holistic energy management system to be achieved.

The value of such characteristics is apparent in applications such as that of grid tied solar photovoltaic (PV) applications. In these applications, distribution transformers are utilised to directly connect generation from solar PV sources to the grid.

A benefit of grid tied solar (PV) applications is its ability to transform the DC power generated from solar modules into AC power that can be used on the network in a smooth transition without overvoltage.

This transition minimises wasted energy and therefore heightens energy efficiency, whilst the protection against overvoltage allows electrical equipment to continue operating at an optimal level and therefore minimise the risk of premature breakdown and the costs of early repair or replacement.

Additionally, the connection to the network allows those with grid tied solar to take part in the decentralisation of the energy network that forms a key part of the energy transition. This is because the grid connection through a transformer allows for the selling of excess generation to the grid and the asset owner to become what is known as a prosumer – an organisation that both consumes and produces energy.

When the site is utilising solar power, the energy has to be transmitted to the area of consumption, this is when the assets will transform the energy to ensure it is at the correct voltage either to export to the grid or to supply the site. Any interruption caused by a malfunction of a distribution transformer during this process can have significant consequences including wasted solar generation and loss of revenue if during a time of paid export to the grid.

Therefore, the ability to gain valuable insights relating to asset performance and operation can protect against such scenarios by allowing for preventative maintenance to be deployed when anomalous activity is detected, such as a rising temperature of the core.

The real-time responsiveness of the remote monitoring capabilities, such as those found within Powerstar SO-LO a super low loss amorphous core smart transformer with remote monitoring capabilities, enable detailed and easier management of all assets connected to the transformer and can highlight areas of further optimisation. These remote monitoring capabilities can deliver details, 24/7, on grid information, conditional performance data, energy efficiency reports and more from anywhere with a secure internet connection.

Super Low Loss Transformers Up To 11kV By Powerstar SO-LO

This takes on even greater importance in grid tied applications when considering the intensity of PV generators and the role they can play in the security of supply to a site and towards carbon neutrality goals.

Furthermore, smart transformers like Powerstar SO-LO provide greater efficiencies than traditional transformers due to the materials which they use. Instead of using cold rolled grain-oriented (CRGO) silicon steel like traditional distribution transformers, Powerstar SO-LO uses an amorphous alloy core. This is a more flexible material than CRGO and allows for easy magnetisation and demagnetisation to take place which leads to greater efficiencies, with up to 75% lower core losses achievable when using amorphous core compared to CRGO. This greater efficiency further enhances the benefits of grid tied PV.

It is clear that, as the energy transition progresses, the use of onsite generation such as solar PV is likely to become more widespread. However, to obtain the most benefit from onsite generation, particularly given the intermittent and often unreliable nature of renewable sources, it needs to be made as efficient as possible.

Grid tied PV through smart transformers represents a proven and reliable way of enhancing the efficiency of solar PV and maximising the benefits of onsite generation.

To find out more about Powerstar, please visit https://powerstar.com.

Photo caption: (L-R) Chris Dodds of Thorne & Derrick meeting with Lindsay Brownless (Head of Commercial and Marketing at Powerstar) recently at T&D’s offices in Durham, UK.

Further Reading

11kV Transformers | Introducing Amorphous Core HV Transformers

Powerstar Partners With Renowned Specialist Distributor Thorne & Derrick

THORNE & DERRICK SPECIALIST ELECTRICAL DISTRIBUTOR

The 11kV Specialists

Thorne & Derrick distribute the most extensive range of 11kV Cable Installation & Electrical Distribution Equipment to the renewable energy sector – we service UK and international clients working on underground cables, overhead lines, substations and electrical construction at 11kV and up to and EHV transmission and distribution voltages.

- Key 11kV Products: MV-HV Cable Joints & Terminations, Cable Cleats, Duct Seals, Cable Transits, Underground Cable Protection, Copper Earth Tapes, Cable Jointing Tools, Feeder Pillars, Cable Ducting, Earthing & Lightning Protection, Electrical Safety, Cable Glands, Arc Flash Protection & Fusegear.

- Distributors for: 3M Cold Shrink, ABB, Alroc, Band-It, Catu, Cembre, Centriforce, CMP, Elastimold, Ellis Patents, Emtelle, Furse, Lucy Zodion, Nexans Euromold, Pfisterer, Polypipe, Prysmian, Roxtec.

LV – Low Voltage Cable Joints, Glands, Cleats, Lugs & Accessories (1000 Volts)

MV HV – Medium & High Voltage Cable Joints, Terminations & Connectors (11kV 33kV EHV)

Cable Laying – Underground Cable Covers, Ducting, Seals & Cable Pulling Equipment

T&D, CATU Electrical Safety & Arc Flash Protection Specialists for SAP’s, Linesmen, Jointers & Electrical Engineers – Largest UK Stockist

Schneider Electric Crimp Lugs for Copper & Aluminium Cables

April 4th, 2019

-

uploaded by Chris Dodds - Sales & Marketing Manager | Thorne & Derrick

Electric Crimp Lugs for Copper & Aluminium Cables

Compact & Vigicompact Crimp Lugs

Thorne & Derrick International, based in the UK, distribute the most extensive range of cable lugs in both crimp/compression and shearbolt types from leading manufacturers including Cembre and Pfisterer Sicon.

Cable lugs are available to connect, terminate and joint copper and aluminium conductor cables into control panels, junction boxes, feeder pillars, switchgear and transformers distributing electrical power at LV (Low Voltage), MV (Medium Voltage) and HV (High Voltage).

This article covers the Schneider Electric range of cable crimp lugs for copper and aluminium conductors with following cross section area: 120sqmm, 150sqmm, 185sqmm.

Crimp Lugs for Copper Cable

Schneider Electric Crimp Lugs

For Copper Cable Specifications

➡ see further information about copper cable lugs.

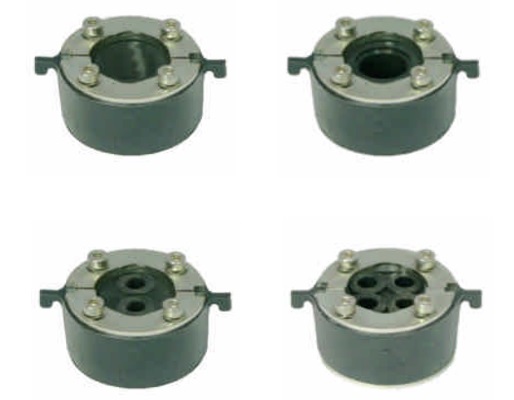

| Product Type | Cable Size | No. Of Lugs In Set | Poles Description | Rated Current | Crimp Lug Image |

| Schneider Electric LV429252 Crimp Lug | 120 mm² | 3 | 3P | 250A |  |

| Schneider Electric LV429256 Crimp Lug | 120 mm² | 4 | 4P | 250A |  |

| Schneider Electric LV429253 Crimp Lug | 150 mm² | 3 | 3P | 250A |  |

| Schneider Electric LV429257 Crimp Lug | 150 mm² | 4 | 4P | 250A |  |

| Schneider Electric LV429254 Crimp Lug | 185 mm² | 3 | 3P | 250A |  |

| Schneider Electric LV429258 Crimp Lug | 185 mm² | 4 | 4P | 250A |  |

Crimp Lugs for Aluminium cable

Schneider Electric Crimp Lugs

For Aluminium Cable Specifications

➡ see further information about aluminium cable lugs.

| Product Type | Cable Size | No. Of Lugs In Set | Poles Description | Rated Current | Crimp Lug Image |

| Schneider Electric LV429504 Crimp Lug | 150mm² | 3 | 3P | 250A |  |

| Schneider Electric LV429505 Crimp Lug | 150mm² | 4 | 4P | 250A |  |

| Schneider Electric LV429506 Crimp Lug | 185mm² | 3 | 3P | 250A |  |

| Schneider Electric LV429507 Crimp Lug | 185mm² | 4 | 4P | 250A |  |

Review other Blogs in this series of articles about Cable Lugs, Crimping Cables & Tools:

- Copper Cable Lugs For Special Applications

- Indent Crimping Of Cables – Benefits & Limitations

- Cable Lugs & Crimps – Hexagonal v Indent Methods of Crimping

- Cable Lugs & Crimping Using The Hexagonal Crimp Method

- DIN Standard – Crimping & Compressing Aluminium Cable Lugs & Connectors

- Copper & Aluminium – Crimping CU-AL Cables

- Electrically Driven Crimping Tools For High Volume Applications

LV Cable Joints (Low Voltage Cables)

Thorne & Derrick stock and distribute LV Joints in Cold Shrink, Heat Shrink or Resin Cast technologies – multicore and multi-pair cable joints are available for immediate backfill and energisation of Low Voltage power, control and instrumentation cables 600V/1000V 3.3kV.

Complete range of LV Cable Accessories ➡

Cable Breakouts | Cable Caps | Cable Lugs | Cable Cleats | Cable Trough | Cable Duct | Feeder Pillars | for 11kV/33kV/66kV networks see MV HV Joints & Terminations

Pfisterer | Nexans Euromold | Prysmian | Cable Joints & Terminations MV HV

Cold Shrink by 3M | Joints | Abandonment | Terminations | Low Voltage LV Cables

Prysmian ESDF4 | Fibre Splices (FO Cables) – ESDF4 In Line Joints & Enclosures

April 4th, 2019

Prysmian Fibre Splices (FO Cables) – Joints & Enclosures from Prysmian

-

uploaded by - Chris Dodds Sales & Marketing Manager (Thorne & Derrick International)

ESDF4

Prysmian Fibre Splices

Thorne & Derrick | Distributed from Stock | Approved Supplier | UK & Export Sales

Enclosures, Joints & Splices for FO Cables

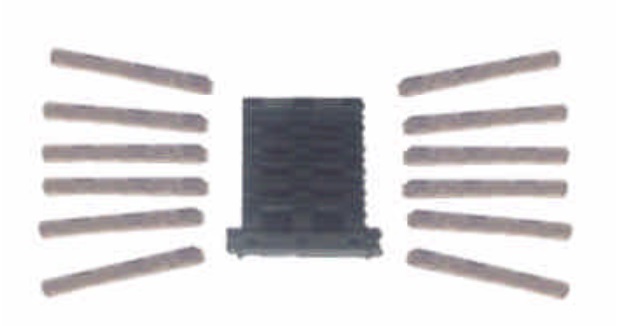

The Prysmian ESDF4 In Line Joint is an underground cable joint suitable for direct burial and underground chamber applications. The fibre splices/joints, manufactured by Prysmian, are used for the jointing, splicing and branching of optical cables with a total capacity of 72 fibres.

The Prysmian joint kit is supplied with six splice trays each able to accommodate up to 12 fibre splices. Cable entry glands, splice protectors and mounting brackets are ordered separately to suit the application requirements.

Note: Four Cable Entry Kits must be ordered per joint. If only two cables are required blank entry kits must be used to seal the fibre splicde or joint.

Prysmian ESDF4 In Line Joint

Features & Benefits

- Installation in an underground chamber or direct buried

- Six splice trays are each able to accommodate 12 spliced fibres

- Maximum spliced fibre capacity is 72 fibres

- Between 4 and 16 cable entries dependent on cable diameter

- Mechanical cable sealing of the fibre optic splice

- Cable anchor system allows cables to be prepared away from the joint

- Continuous addition of branched cables possible for up to 4 cables per port

- Reliable sealing of the box using a mechanical gasket allows easy entry

- Splices/joints are suitable for direct buried applications

- Pole and wall mounting brackets available

- Earth point for cables metallic parts

Prysmian ESDF4 In Line Joint Technical Data

- Prysmian Part Number: XJTSC00083

- Number of cable ports: 4 – 16 (depending on diameter)

- Maximum cable diameter (mm): 25

- Maximum number of trays: 6

- Maximum fibre capacity: 72

- Required space envelope (mm): (l) 500 x (w) 160 x (d) 90

- Operating temperature: -20oC to + 50oC (5 to 95% RH)

Splice or Joint Closure Material:

- Closure: Glass Filled Nylon

- Splice trays: FR ABS

Splice or Joint Closure Testing:

- Closure Sealing IP68

- Optical: Tested at 1310nm, 1550nm and 1625nm

- Drop: EN 60068-2-32

- Salt Mist: NF C 20 – 711

- Vibration: EN 60068-2-6

- Shock: EN 50 102

Logistics:

- Packing Dimensions (mm): (l) 580 x (w) 180 x (d) 110

- Packed Weight of Splice (kg): 3.3

- Net weight of Splice (kg): 3.0

- Installation Instructions included

Cable Joints | Cable Cleats | Cable Terminations | Cable Glands | Power & Fibre Cable Accessories LV MV HV Networks

Prysmian Fibre Splices (FO Cables) Additional Items

| Prysmian Part Number | Product Description | Product Image |

| ESDF4 ILJ Cable Entry Kits | ||

| XJTSC00084* | Blank Entry – to seal unused ports |  |

| XJTSC00085* | Single Entry – for one cable up to 25mm | |

| XJTSC00086* | Double Entry – for two cables up to 12.5mm each | |

| XJTSC00087* | Quad Entry – for four cables up to 9mm each | |

| Wall Mounting Bracket | ||

| XJTSC00088 | The ILJ Wall Mounting Bracket is used for mounting the In Line Joint to a wall. The bracket is supplied with the appropriate fixings. |

|

| Pole Mounting Bracket | ||

| XJTSC00089 | The ILJ Pole Mounting Bracket is used for mounting the In Line Joint to a Pole. The bracket is supplied with the appropriate fixings. |

|

| Heat Shrink Splice Protectors | ||

| XPESC00053 | Splice protectors are used to protect the fibre splice. They are 2.2mm in diameter and 45mm in length. |

|

| XKTSC00050 | ||

| Crimp Splice Protectors | ||

| XKTSC00020 | The Crimp Splice Protector Kit is used to convert the splice tray in an In Line Joint to accommodate crimp splice protectors. One kit is required for each splice tray. The kit contains an insert to house the splice protectors and 12 crimp splice protectors. |

|

*ILJ Cable Entry Kits are used to install cables into an In Line Joint. One kit contains all of the components required to prepare, install and route the fibres of one cable to the splice trays. Four Cable Entry Kits must be used. If only two cables are required to be installed, then two blank kits must be ordered also. (Kits are available for installing one, two or four cables into a port, depending on the cable diameter).

LV, MV & HV Jointing, Earthing, Substation & Electrical Eqpt

Thorne & Derrick International are specialist distributors of LV, MV & HV Cable Installation, Jointing, Duct Sealing, Substation & Electrical Equipment – servicing UK and global businesses involved in cable installations, cable jointing, substation, overhead line and electrical construction at LV, 11kV, 33kV and EHV.

THORNE & DERRICK Product Categories: Cable Ties | Duct Seals | Cable Cleats | Cable Glands | Electrical Safety | Arc Flash Protection | Cable Jointing Tools | Cable Pulling | Earthing | Feeder Pillars | Cable Joints LV | Joints & Terminations MV HV

Further Reading

Fibre Optic FO Splice Trays & Junction Boxes for Offshore Wind Farms

Emperor Cable Cleats | Gwynt y Mor Offshore Wind Farm

On-line Partial Discharge Monitoring & Location on a 33kV Offshore Wind Farm Export Cable

Q/ Can 3M Electrical Offer MV Cable Joints For Hazardous Areas?

April 4th, 2019-

uploaded by Chris Dodds - Sales & Marketing Manager at Thorne & Derrick

MV Cable Joints

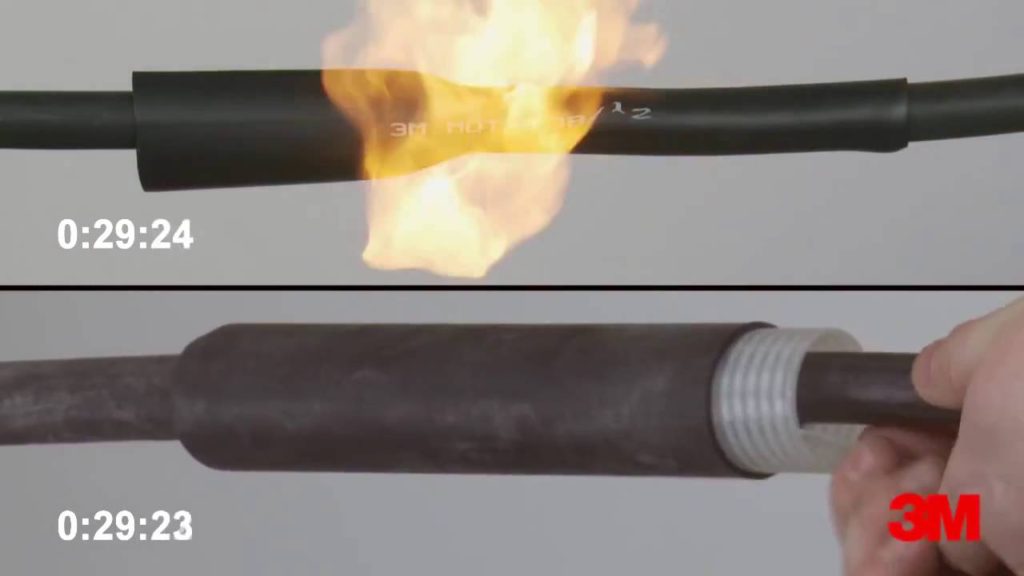

A/ All 3M Electrical Cable Accessories which utilise 3M Cold Shrink technology are inherently safe to install in potentially  explosive atmospheres as they do not pose a risk of ignition to flammable gases in hazardous area workplace locations as designated Zone 1 or Zone 2 according to the ATEX Directive.

explosive atmospheres as they do not pose a risk of ignition to flammable gases in hazardous area workplace locations as designated Zone 1 or Zone 2 according to the ATEX Directive.

For clarification on the relationship and application of ATEX with respect to Cold Shrink cable accessories for LV MV applications refer to our Blog ➡

ATEX & Cold Shrink | Certification & Safe Working In Zone 1 / Zone 2 Hazardous Areas

Hydrocarbon Resistant Cable Joints

Thorne & Derrick stock and supply 3M Electrical cable joints for MV cables with 3 core cable construction for both XLPE/EPR type cables – these are polymeric insulated cables.

For single core cables where the cables to be jointed are located in hazardous areas with hydrocarbons present the cable joints can be encapsulated using a joint mould/shell and Scotchcast 1402FR resin – the joint would be installed according to the Jointing Instruction as usual apart from the final cold shrink outer tube which would be substituted with the cable joint mould/resin.

Typically, installers have used the 92-NA-6U cable joint kit, manufactured by 3M Electrical, which is designed for LV unarmoured cables – the mould shell fits over the cable stripping dimensions of the 3M 92-AG Cold Shrink range of MV joints for single core polymeric cables (XLPE EPR). The larger 1451-PET mould can also be used in conjunction with appropriate volume of 3M resin using the Mix Pack 7 litre packs. This solution would provide excellent protection of the cable joint against the deteriorative effects of prolonged exposure to hydrocarbons in either air installations on cable containment or direct burial where the joint is to be buried in underground contaminated ground or cable trench.

➡ Further reading: 3M Cold Shrink vs Heat Shrink

Cold Shrink

LV, MV & HV Jointing, Earthing, Substation & Electrical Eqpt

For Use In Hazardous Areas & Explosive Atmospheres

Thorne & Derrick International are specialist distributors of LV, MV & HV Cable Installation, Jointing, Duct Sealing, Substation & Electrical Equipment – servicing UK and global businesses involved in cable installations, cable jointing, substation, overhead line and electrical construction at LV, 11kV, 33kV and EHV.

THORNE & DERRICK Product Categories: Duct Seals | Cable Cleats | Cable Glands | Electrical Safety | Arc Flash Protection | Cable Jointing Tools | Cable Pulling | Earthing | Feeder Pillars | Cable Joints LV | Joints & Terminations MV HV

Pfisterer | Nexans Euromold | Prysmian | Cable Joints & Terminations MV HV