Blog

3M Electrical Tapes – Scotch Brand Electrical Tapes From 3M

March 4th, 2019

3M Scotch Electrical Tapes

-

uploaded by Chris Dodds - Thorne & Derrick Sales & Marketing Manager

Electrical Tapes Manufactured by 3M

The following informative video courtesy of 3M Electrical discusses the requirements and of – this video of short clips will show you how to use, the features and benefits of a variety of 3M Electrical Products.

Cable Hooks & BS7671 18th Edition Wiring Regulations – Essential Changes Explained

March 1st, 2019

Steel Cable Hooks | Power Cable & Trailing Cable Support | BS7671 Regulations

-

uploaded by Chris Dodds - Thorne & Derrick Sales / Marketing Manager

Cable Hooks

by Tidi-Cable

The 18th Edition of the IET Wiring Regulations (BS7671) is effective as of January 1, 2019.

That means construction site managers, health and safety managers, electricians and electrical contractors need to be fully compliant and up-to-date with the new BS7671 wiring regulations – especially in relation to how cables are supported in the event of a fire whether using cable hooks, ties or hangers.

The new 18th Edition wiring regulations include updates designed to reduce the risk of death from the placement of hanging cables. The aim is to improve installation safety using the adequate placement of metal clips, hooks or cable hangers to support hanging power or trailing cables – this includes adequate, reliable and safe support for single and multi-core armoured (SWA) cables according to BS5467.

Other updates in BS7671 include new RCD protection requirements and recommendations for installing Arc Fault Detection Devices (AFDDs).

If you’re a construction site manager or a health and safety consultant or manager, it pays to be fully aware of the new wiring regulations – especially if you’re responsible for cable fixing installation across a site.

Electricians or electrical contractors installing, hanging or suspending electrical cabling will need to meet full wiring regs compliance by January 1, 2019.

This article explains what the new 18th Edition wiring regulations mean in terms of fixing and suspending electrical cables.

Picture by Hampshire Fire and Rescue. Via BBC.

BS7671?

Why Have The 18th Edition Wiring Regulations (BS7671) Been Changed?

BS 7671 (IET Wiring Regulations) sets the standards for electrical installation in the UK and many other countries. The IET co-publishes BS7671 with the British Standards Institution (BSI) and is the authority on electrical installation.

Known as Regulation 521.10.202, the aim of the new wiring regulations regarding the fixing of hanging LV cables is to reduce the risk posed by suspended cables in the event of a fire – typical cable hanging methods include hangers, hooks or conventional Ty-Raps, cable ties.

The change of wiring regs follows the tragic death of two firefighters at Shirley Towers in 2010 who became entangled in fallen cables.

Two firefighters also lost their lives in 2005 at Harrow Court Tower Block where one of the firefighters had become fatally entangled in fallen electrical cables.

The 18th Edition wiring regulations aim to avoid similar incidents. This is especially true with high-rise building developments, where fires have devastating potential – a priority for construction site managers or a health and safety consultant or managers.

The risk of fire on construction sites should also be a consideration when managing cables.

Although not common, when construction sites fires occur the materials exposed and contained within a site mean that fire can spread rapidly. Knowing how cables can be better managed can reduce to risk to workers on site as well as emergency service crews.

What Do The 18th Edition Wiring Regulations (BS7671) Require?

The new wiring regs come into effect in January 1, 2019.

The 18th Edition states that plastic fixings cannot be used as the sole use of holding up and hanging of cables. However, the IET states:

“Suitably spaced steel or copper clips, saddles or ties are examples that will meet the requirements of this regulations.” This means that plastic fixings such as hooks, hangers or cable ties can be supplemented with metal types – but that electricians and electrical contractors cannot rely exclusively on plastic clips, saddles or ties.

Temporary Cables

The 18th Edition wiring regulations apply to all types of cable installation and not just escape routes such as fire exits.

Regulation 521.10.202 now requires cables to be adequately supported against their premature collapse in the event of a fire. It applies to all types of cable that could fall in the event of a fire.

This means that cables fixed against a wall (that don’t cover a doorway) can be supported fully by plastic fixings as if the cable fell in a fire, it would fall to the corner of the corridor and not trap anyone.

What Type Of Cable Supports Does The 18th Edition Wiring Regulations Allow?

This part is left open to interpretation – Regulation 521.10.202 calls for ‘adequately supported’ cables – and we feel that it would be better if the IET would clarify with a clear definition of what ‘adequately supported’ means.

However, experts consider the new wiring regs call for metal cable supports to ensure compliance. This includes all cable supports such as cable trays, baskets, hangers and hooks.

Does The 18th Edition Ban The Use Of Plastic Cable Fixings?

Plastic fixings are not banned and can be widely used throughout the industry as a cost-effective way to manage cables. However, plastic cabling fixings can no longer be used as the sole means of securing cables in place. This will affect the sole use of products such as:

- Cable ties

- Cable clips

- Cable hangers

- Plastic conduit (with plastic fixings)

- Plastic trunking

- Plastic fixings holding up cable tray

- Plastic cable hooks and hangers

Existing plastic cable management solutions will need to be supplemented by metal fixings to ensure they’re not the ‘sole means of supporting’ cables.

Plastic Cable Ties Holding Up Cables

Does The 18th Edition Wiring Regulations Apply To Existing Cable Installations?

The Regulations apply to the design, erection and verification of electrical installations, as well as additions and alterations to existing electrical cable installations.

The good news for construction site managers and health & safety consultants/managers is that existing installations that have been installed in accordance with earlier editions of the Regulations do not need to be replaced.

This change is not retrospective and any installations fitted before 1st January may still be compliant.

The new regulations have been welcomed by the fire services. According to Charlie Pugsley of the London Fire Brigade’s Fire Investigation Team:

“We believe it’s essential [521.10.202] because … we’ve lost three firefighters in the course of firefighting operations, where the clips have become damaged by fire and cables have dropped and then crews have become entangled. We feel this is a really good, positive step to improve safety for our officers and also for the public”.

How has Tidi-Cable prepared for the 18th Edition wiring regulations (BS7671)?

Tidi-Cable is fully supportive of the 18th Edition wiring regulations.

Tidi-Cable has developed a range of metal cable supports and fixings to help ensure construction site managers responsible for electricians and electrical contractors are fully compliant of the new wiring regs.

The range of steel cable supports and fixings are re-usable, strong and effective for installing and pulling cables on construction sites.

Tidi-Cable have been developing these new products over the past 12 months in preparation for the new regulations – the high-quality cable fixing and hanging ranges are safe, easy-to-use and cost-effective while meeting 18th Edition wiring regulations.

Tidi-Cable have a range of products including Tidi-Hooks and Tidi-Hangers suitable for construction sites, factories, festivals, events and other industry sections – the S shaped cable hooks provide temporary cable support to construction site cable installations.

Tidi-Cable Tidi-Hooks

Tidi-Cable has been at the forefront of manufacturing cable management solutions for over six years and feel that the below additions to the range further secure their position in the cable support and fixings market. Benefits include:

- Full 18th Edition wiring regulations compliance. The new product range is 18th Edition compliant. Steel cable fixings and supports can be used either completely in the place of plastic products or use to supplement them.

- Heavy duty cable fixings. The added benefit of the metal cable supports is the versatility to support and fix heavier items such as armoured cables, pipework and compression hoses that often need to be managed properly to keep sites safe.

- Temporary and permanent installation. The steel cable supports are ideal for both temporary and permanent cables. Cable supports been created to manage temporary power and lighting distribution in order to keep leads safely above head height, and to help eliminate slip, trip and fall risks.

- Cable security. Pulling cables has its own problems and using hooks historically can be problematic in that cables often fall out of hooks. The customers asked for versions where cables can be contained more within a hook. Tidi-Cable are pleased that in the development of the new fire proof range they have addressed this issue by creating systems that keep cables secured in place.

Safe cable management is a priority at Tidi-Cable and Thorne & Derrick International.

As construction site managers, health and safety managers or electrical contractors looking to comply with 18th Edition wiring regulations, our products are compliant, trusted, easy-to-use and cost-effective.

With more sectors needing electrical cable management – from theatres to music venues with increased power and lighting demands – our ranges will ensure you meet the new wiring regulations.

LV, MV & HV Jointing, Earthing, Substation & Electrical Eqpt

Thorne & Derrick International are specialist distributors of LV, MV & HV Cable Installation, Jointing, Duct Sealing, Substation & Electrical Equipment – servicing UK and global businesses involved in cable installations, cable jointing, substation, overhead line and electrical construction at LV, 11kV, 33kV and EHV.

THORNE & DERRICK Product Categories: Duct Seals | Cable Cleats | Cable Glands | Electrical Safety | Arc Flash Protection | Cable Jointing Tools | Cable Pulling | Earthing | Feeder Pillars | Cable Joints LV | Joints & Terminations MV HV

MULETAPE v Rope : Pulling Cables Into Cable Ducts To Avoid Duct Cutting

February 27th, 2019

Manufacturers of MULETAPE

-

uploaded by Chris Dodds - Thorne & Derrick Sales/Marketing Manager MULETAPE | Made in USA | Distributed in the UK & Europe by Thorne & Derrick

Burn Through

The Case for MULETAPE vs. Rope

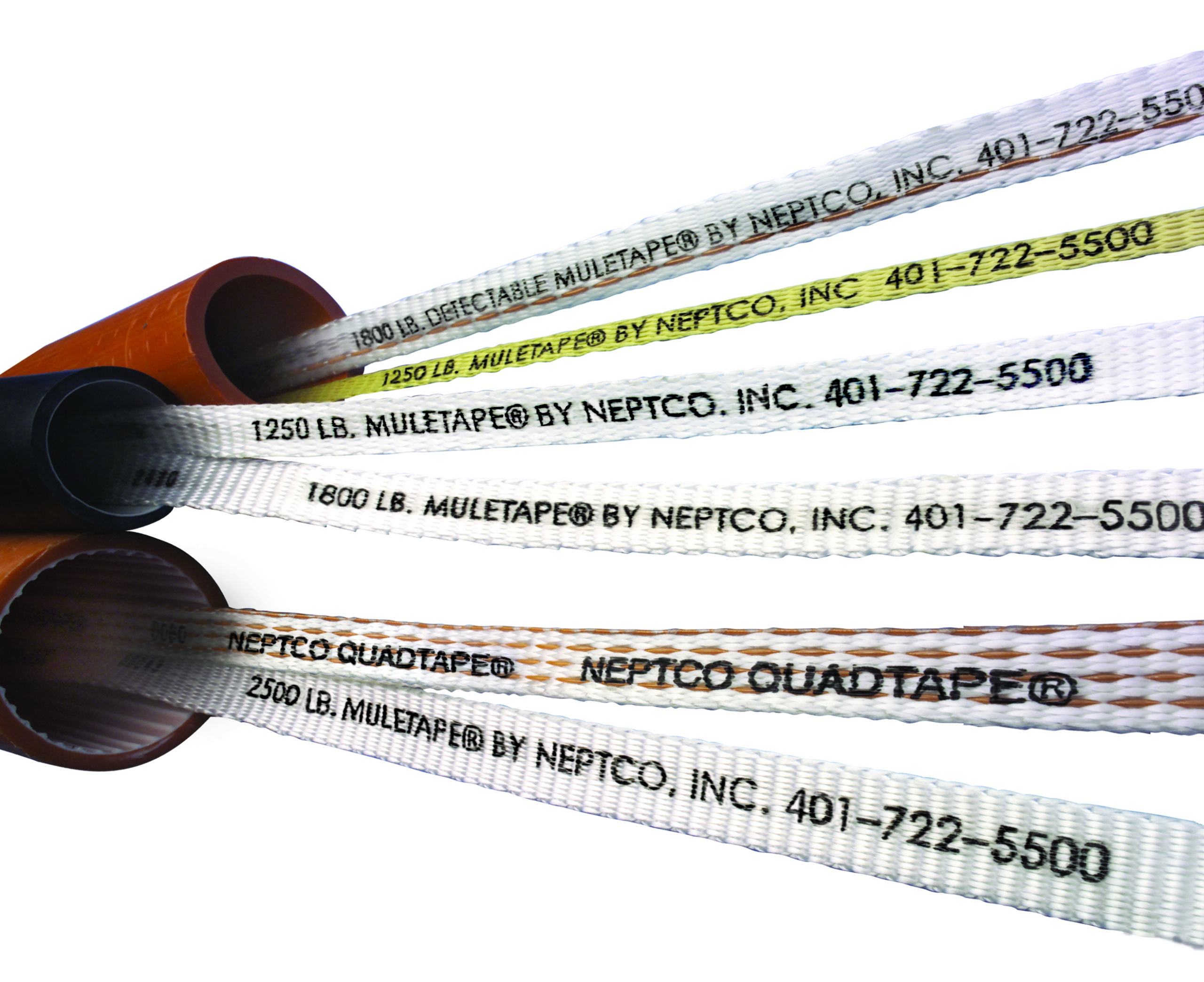

NEPTCO is a global leader in the manufacturing of materials used for the Detection & Pulling of Cables for a wide variety of commercial and industrial applications.

In this Blog, NEPTCO answer questions regarding their advanced specification MULETAPE which includes a comparison to using traditional cable pulling ropes.

NEPTCO’s range of measuring and pulling tapes substantially reduce cable installation labour, materials and stock holding costs by providing a threading line, a measuring tape and a winch line all in one product – this reduces damage to underground plants, improves efficiency and enhances worker safety.

NEPTCO’s range of measuring and pulling tapes substantially reduce cable installation labour, materials and stock holding costs by providing a threading line, a measuring tape and a winch line all in one product – this reduces damage to underground plants, improves efficiency and enhances worker safety.

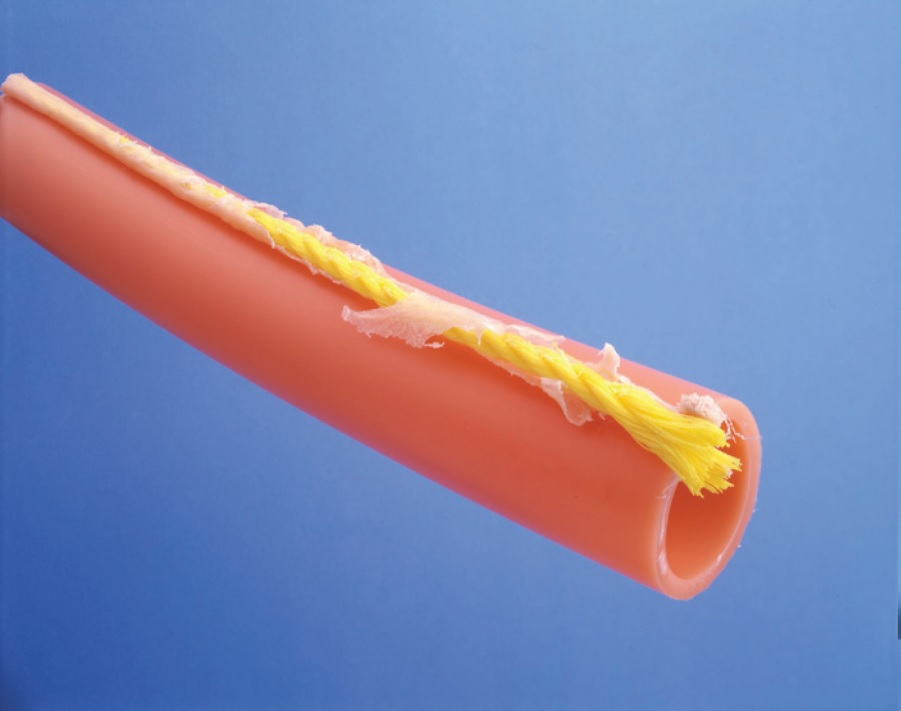

Q: What is “burn through?”

A: When polypropylene rope is pulled through PVC or polyethylene duct, the friction generated by the rope rubbing against the conduit wall creates enough heat to actually “burn through” the cable ducting or conduit – this can occur with or without cable lubricant

“Burn Through” caused by the friction from cable pulling rope.

Q: Why should this matter to me?

A: Aside from damaging the conduit or cable duct and creating opportunities, the jagged edges of the burned conduit pose a real threat to the cable installed by the contractor.

Cable surging through the damaged conduit or duct at an average rate of 100 ft. per minute will catch on the damaged areas of conduit, shredding the outer jacket. Fibre Optic cables are particularly vulnerable since the situation which can lead to excess tension and can cause micro-bending. As a result, the cable may fail prematurely, or simply not function at all.

A damaged cable as a result of using cable pulling rope.

Q: How does NEPTCO know these things happen? After all, you can’t see what’s happening underground!

A: NEPTCO has gone to great lengths to test this theory by duplicating installation conditions in the lab and in the field. Their research engineers designed the Duct Cut Tester to evaluate the performance of various conduit materials and winch lines under typical installation conditions.

The results tabulated on the reverse side of this sheet are conclusive: pre-lubricated MULETAPE out-performs polypropylene rope in every installation scenario.

Q: Why does MULETAPE work so much better than cable pulling rope?

A: MULETAPE is pre-lubricated, which helps reduce friction and the heat it generates, but MULETAPE’s wide and flat profile is also important. A round rope will concentrate all heat and energy on the small area where the rope comes in contact with the innerduct. MULETAPE is flat, and therefore spreads this heat and energy across a wider area, reducing the chance of burn through.

|

|

| MULETAPE by NEPTCO | Cable Pulling

|

|

NEPTCO Duct Cut Tester

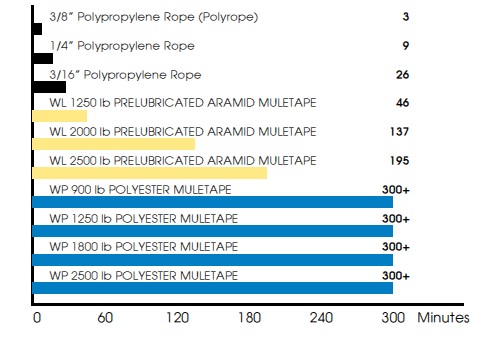

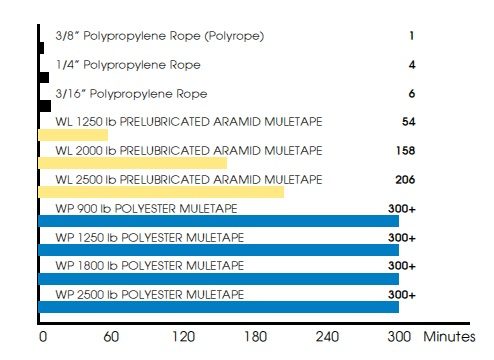

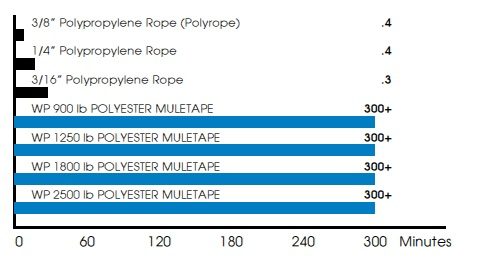

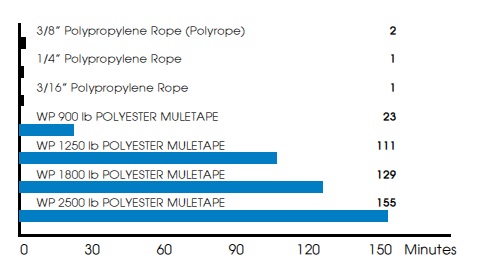

The charts below indicate the time elapsed before conduit experiences damage due to burn through:

Duct Cutting in Corrugated 1.5” ID HDPE Subduct |

Duct Cutting in Smooth Walled 1.5” ID HDPE Subduct |

Duct Cutting in Corrugated 1.5” ID PVC Subduct |

Duct Cutting in 2” Schedule 40 PVC 90° Subduct |

Q: Okay, I understand that burn through is a problem, but I’m still not convinced this is really happening in the field. Do you have any evidence that cable can actually be damaged in a real installation?

A: Absolutely. If you have ever experienced a rope breaking during a pull, it is caused by the cable getting snagged on a duct that has been burned through. The rope is usually narrower than the cable and pulling sock and is able to make its way back into the duct, however, because the cable and pulling sock are wider they may not be able to make their way back into the duct. When this happens, the tension rises, the pull becomes more difficult and the rope may break. This not only causes a health and safety hazard, the possibility that the cable is damaged is extremely high. In 1999, NEPTCO recreated a typical installation scenario in an above-ground test. The results were just as expected – the rope burned through the conduit in seconds, while the MULETAPE caused no damage.

To request a video of this experiment in CD or VHS format, please contact [email protected]

MULETAPE Features & Benefits

- Eliminates the potential for cable duct cutting

- Lower elongation reduces snap-back and enhances

- Worker safety reduces tension at the start of a cable pull

- Sequential footage or metric markings

- Reduces material, inventory and freight costs

- Cable pulling strength – 200 lbs. to 6000 lbs

- Patent pending

MULETAPE Ordering Information

| Item | MULETAPE Part Number | Strength (kg) | Typical Bowline Strength (kg) | Typical Muleknot Strength (kg) | Pail Quantity (km) | Approx Pail Weight (kg) | Pails Per Pallet |

| 41271 | WP400P | 182 | 86 | 136 | 1.4 | 6 | 27 |

| 41325 | WP1800P | 818 | 377 | 636 | 0.4 | 6.4 | 27 |

Request Your FREE MULETAPE Sample

Our products substantially reduce cable installation labour, materials, and inventory costs by providing a threading line, a measuring tape, and a winch line all in one product. Reduces damage to underground plants, improves efficiency, and enhances worker safety.

You can’t miss this opportunity if you are a Utility Company or a Contractor. Weather you are looking for pulling tapes, or a tracer wire, before you invest a large amount, we are giving you the option to see our products look and feel.

MULEGLIDE Cable Blowing & Cable Pulling Lubrication

NEPTCO‘s long-lasting silicone cable blowing/pulling lubricant called MULEGLIDE is an ideal LV, MV & HV cable lubricant, available as low-viscosity Underground Cable Blowing Lubricant or MV HV Underground Cable Pulling Lubricant, which allows for swift and safe underground cable installation.

Further Reading

- MULETAPE CALCULATOR | How To Select The Right Cable Pulling Tape For The Job

- Thorne & Derrick Appointed Approved Stockist for UK Leading Cable Pulling Equipment Manufacturer

Cable Pulling & Laying Equipment

Suppliers & Distributors

Thorne & Derrick distribute the most extensive range of Low & High Voltage Cable Installation & Electrical Distribution Equipment to the Power Transmission & Distribution industry in the onshore and offshore wind, solar, rail, oil/gas, data centre, battery storage and utility sectors – this includes the most extensive range of Cable Pulling & Cable Laying Equipment to enable the installation of low, medium and high voltage power cables into underground trench or duct.

We service UK and international clients working on underground cables, overhead lines, substations and electrical construction at LV, 11kV/33kV and up to EHV transmission and distribution voltages.

Key Products: MV-HV Cable Joints & Terminations, Cable Cleats, Duct Seals, Cable Transits, Underground Cable Protection, Copper Earth Tapes, Cable Jointing Tools, Feeder Pillars, Cable Ducting, Earthing & Lightning Protection, Electrical Safety, Cable Glands, Arc Flash Protection & Fusegear.

Distributors for: 3M Electrical, ABB, Alroc, Band-It, Cembre, Centriforce, CMP, Elastimold, Ellis Patents, Emtelle, Furse, Lucy Zodion, Nexans Euromold, Pfisterer, Polypipe, ProGARM, Prysmian, and Roxtec.

- Scope –single-source supply of extensive range of products

- Stock – a multi-million pound stock holding provides complete global supply solutions

- Staff – technical support from a trained, proactive and friendly team

- Delivery – UK stock turnaround with express logistics to all international destinations

Do You Think That Concentric Neutral Wires That Are Not Evenly Spaced Are Acceptable Or Not?

February 27th, 2019A Guest Contribution by

Steven F. Thomas - High Voltage & Interconnection Engineer at Origis Energy

Concentric Neutral Wires

Concentric Neutral Wires

What Are Concentric Neutral Cables?

Concentric Neutral Cables (CN Cables) are suitable for use above ground in open air, in conduit in air, directly buried, in underground cable duct, or aerially when suspended on a messenger wire. CN cables are suitable for continuous operation at 90ºC wet or dry, and are sunlight resistant. Typical applications include residential, commercial and industrial main underground feeders where cable voltages of 5kV to 46kV are required.

CN cables can also be used in Wind and Solar power distribution when medium/high voltage cables MV HV are to be used in an underground application.

The following Comments have been provided from an original LinkedIn post by Steven F Thomas in February 2019 and include thoughts and opinions from the professional social network on the subject of concentric neutral wires and the process of cable manufacturing, jointing, splicing and termination.

Image: Texcan

➡ Steven F Thomas. A lot of great responses. This cable was for a wind farm that had approximately 1 million linear feet of three phase cable, 3 million feet of single phase cable. What may not be obvious is that 3 core cables aren’t very useful. The size and weight of the overall cable would create an inordinate amount of cable joints or splices – and splices are failure points. We mandated no splices, unless absolutely necessary and must be approved by owner. The normal installation is direct buried, bundled, single phase cables. The US National Electric Code requires that cables be buried at least 1 meter (3 feet) underground, or a physical barrier be installed above. Our common requirement was 4 feet. In this case, these wires are considered concentric neutral wires, not a shield. Although they also provide an electrical screen, they are mostly a neutral/fault path back to the wye-grounded source. The construction of the cable is that the XLPE has a semi-conductor wrapped around it, and the neutral cables are in contact with that. Since the semi-con screen provides a complete non-metallic cover, is it important for the concentric wires to be evenly spaced?

➡ Kai Zhou (Senior Research Engineer at UL). Cable splice is usually the weakest point due to improper installation, contamination introduction, etc. Most of the cable joint failures in cable systems are from installation NOT from cable splice or cable terminations themselves. Since you have a really long run, what is your grounding design? The concentric neutral is also designed for shielding for power cable. To provide a uniform zero potential in case of cable semi-con problem. We have seen cable semi-con losing conductivity after aging, material absorption, etc. This kind of situation could be avoided by proper factory inspection and order inspection.

➡ Reply Steven F Thomas. You are correct, my experience is that splice failures are almost always installation error. The most common Root Cause was overheating, of which analysis showed that electricians were skipping the wire brushing to remove the aluminium-oxide layer that is not visible to the eye. It “looked” clean and shiny, so they skipped that step, I have seen papers from both 3M Electrical and Tyco Electronics indicating that renewable sources are much more susceptible to cable failure from this mode due to the high load cycling inherent in renewables. Both independently indicated that shear bolts splices & connections are much less likely to do this. If you can’t ensure the electricians will do an important step – then you need to change the step. We now mandate shear-bolt connections.

➡ Paul Knapp (Principal Engineer at UL). This can cause issues because the shield is not uniformly divided around the cable and arcing may occur in the unshielded space under the right conditions.

➡ Ben Lanz (MV HV Cable Reliability Consultant). Paul, I agree. At steady state an uneven concentric wire system might work but wide enough gaps and during transient conditions increased voltage across the outer semiconducting shield might start burning, arcing and pitting from the outside inwards. In addition the velocity of propagation will change with the variation in the wire spacing making fault and PD location difficult.

➡ Tony Haggis (Director at Tony Haggis Consulting Ltd). It would be illegal in the UK as the Electricity Safety Quality and Continuity Regulations (UK Law) requires that all live conductors be surrounded by an earthed metallic screen. The primary reason is to prevent electrocution in the case of a cable strike. The earth gets pierced first so the current is diverted to earth rather than through the person holding the cable cutting tool.

➡ Martin Stephenson (Business Development Manager Cable Services). Tony there are also “protected hydraulic cutters on the market” which have extra long hoses and non conductive oil to protect the operator should they mistakenly go through an energised cable. Also insulated cable cutters are used typically by Jointers on LV cables.

➡ Rick Moynihan (Cable Jointer – Director Certus Cable Jointing Pty Ltd). The semiconductive layer and screen wires are at the same potential. The screen wire should be rated according to fault current carrying capacity, therefore the termination of the screen wires as required per onsite earthing specification is the critical factor. The screen wire distribution in this cable does not look nice, however I cannot see how it would affect the electrical performance of the cable if it meets the specifications for its use.

➡ John Szabados, PE (Senior Manager at Sargent & Lundy). Rick, I disagree with this. We are talking two separate functions. The screen is there for voltage gradients and keeping a zero references. The neutral is for line to ground faults which with proper protection employed and sizing is there for a very short time frame. There is no test verifying the neutral and shield are touching. According to IEEE, failures of cable mid span are primarily due to manufacturing defect. Of course contributing factors are the cable splices and inadequate installation by the Jointer but this rarely explains faults in midspan. If the cable is specified properly, having an asymmetrical neutral layout by itself is not an issue. However, it does bring to question the QC in the manufacturing process. Based on this, I would ask more questions and initially reject the cable.

➡ Craig Horn (EHV Cable Jointer). That cable would work better without any screen wires rather than random bunches of wires. If cost is such a issue why not opt for aluminium foil screen? I’d like to see the cable manufacturers specification Vs a type test.

➡ Steven F. Thomas Craig, I think we’re talking about two different systems. A grounded wye system requires a neutral ground path for fault current, an ungrounded delta system does not. An ungrounded delta does not short circuit when one phase goes to ground, it takes two phases before a short circuit occurs. The “shield” on an ungrounded system cannot provide an adequate path for fault current, whereas the concentric neutrals on a grounded wye can provide fault path as well as electrical “shielding” and mechanical protection. In this case, an aluminum foil is totally inadequate as fault current would vaporize the shield. We don’t use tape or foil shields normally, except for control wiring, but I’m doubtful of the ability of an aluminum foil to provide mechanical protection.

➡ Craig Horn (EHV Cable Jointer) Steven, I would not buy this cable no matter what system it was to used for. The spacing of the screen/ neutral wires will have a negative affect on the efficiency of the conductor due to poor stress control. Aluminium screens can be manufactured with specific current carrying capabilities to avoid vaporisation.

➡ Dan James (Technical Services Engineer – HV Senior Authorised Person at NG Bailey). It would affect the shields ability to handle the field uniformly I would think.

➡ Steven F. Thomas Dan, this concurs with what a cable expert at Tyco Electronics informed me that essentially the semi-con and concentric wires are creating a Faraday cage. If the wires are severely bunched as these are here, the electrical field is not evenly distributed and when it’s not evenly distributed PD can occur which is how XLPE insulated cables fail.

➡ Dan James (Technical Services Engineer – HV Senior Authorised Person at NG Bailey). Steven, what I would imagine would happen, not a expert though. Areas without evenly spaced ground wires would have a higher field. Deteriorating that part more so than areas with more and any imperfections, degradation would be amplified.

➡ Satish Buddhawar (Electrical High Voltage, Offshore). Dan I think yes, this would result in the field concentration near to the unevenly spaced concentric wires, leading to local heating and degradation. In the cables I have seen, there is usually a layer of aluminium foil over the copper wires to radially block the water and also to provide the complete shielding (Faraday cage).

➡ Kai Zhou (Senior Research Engineer at UL). Regarding the electrical shielding, it can be a problem, or not a problem. There is cable insulation semi-con for electrical shielding function. For good semi-con layer, this probably won’t give you an “electrical problem”, as long as your terminating the semi-con and copper shielding wire properly. But for bad semi-con (losing conductivity over time), it could be. In any case, you are losing mechanical shielding protection, one of the major functions for copper shielding wire. From a design point, this should not be accepted since it is not per the design. If I was the user, I would ask the manufacturer to resolve the issue.

➡ Matthew Hadsell (Manager of Engineering at Blattner Energy). First, this really depends on voltage. At 34.5kV (assumed because it is for wind farm), this cable will likely not have any issues. Some independent cable testing laboratories have evaluated this for wind farm applications and come to this conclusion. Neutral bunching happens with many manufacturers over my years of installing cable and a good rule of thumb is as long as there is at least one strand in each of the 90 degree quadrants of the circle the cable will perform as advertised. This is of course not ideal, but it also isn’t a disaster of a problem at this voltage level. Bunching typically happens at cable ends and you can cut off 20 feet or so to remove the problem, so good QAQC when installing can catch and eliminate the concern. If this is encountered on a project, don’t panic and call a reputable cable testing laboratory for a custom report and analysis.

➡ Dan James (Technical Services Engineer – HV Senior Authorised Person at NG Bailey). Matthew, I have only seen one independent 3rd party analysis, submitted to us by the cable manufacturer to show bunched neutrals was not critical, and we rejected it as a faulty report for several reasons. Some cable experts have said this is critical; others seem to think it wise to evenly space the neutral wires, but not critical.

➡ Joe Dowds. Well spacing should not matter the neutral or ground is there to take the current if the cable faults that’s it’s main purpose.

➡ Steven F. Thomas. Joe, is it reasonable to assume that the current form a fault shares equally on every wire? Perhaps not to start if it is truly a fault from inside the cable, but eventually it would spread to all. This would imply that heating from the individual wires would be a percentage per wire. In the case of the one picture, where about 50% of the wires are all bunched at the bottom, would this not also imply that 1/2 of all the heating from a fault was concentrated in that spot? Rather than spread in all directions, the majority of the heating is concentrated in that one spot – so what happens to the thermal limits of the cable jacketing material? I think spacing does matter, particularly if neutral sizing is reduced to limit induced losses, and is closely sized to not overheat the jackets.

➡ Roger Lauricella (Vice President Technical Services & Support MV & Substation Specialist at WECS Renewables). Seen examples over the years from various wind farm customers just like that, it’s usually overseas cable that does not get the rigorous testing and quality production you see in North America, definitely not something one should have excepted or utilised. There are enough challenges with UG cable on wind farms and this is not an acceptable one to allow to go through.

➡ Steven F. Thomas. Roger, I also have seen this with off-shore manufacturers, but this one was not. This was an American supplier.

➡ Arie M (Senior Technical Expert at Consolidated Edison New York). I enjoyed the comments and depth of knowledge of engineering community for this very specific cable construction topic. All aspects of this issue including operating voltage, specific design, normal and transient mode, and specific installation issues (cable cut and shielding wires displacing) were addressed.

➡ Uxio Ramos (Technical Sales Director in Behr Bircher Cellpack Iberica). Not acceptable at all. That will lead to failure sooner or later. Furthermore, we have seen CWS (copper wire screen) cables without the additional Cu copper tape and the screen wires would eventually be all displaced to the lower side of the cable once laid on the ground… then failure. Poor quality, in my opinion.

➡ Charles Shannon (Senior Application Engineer at IMCORP). Uxio, have you seen the bunching you mentioned when using Cu JCN or CIC?

➡ Uxio Ramos. Charles sorry, can you explain JCN and CIC?

➡ Charles Shannon. Uxio, JCN Jacketed Concertric Neutral cable and CIC Cable In Conduit in essence it’s JCN without the J and instead it’s in a flexible conduit like HDPE or something but the neutrals are exposed to any water that enters the conduit.

➡ Uxio Ramos. Charles many thanks for the clarification. The case happened in single core CWS 16sqmm 36 kV cable. As I stated, the screen did not have the additional Cu copper tape applied in this cases. The cable sheath was PE, the cable isolation was HEPR and there was a plastic foil separating the screen from the sheath.

➡ Thorsten Rösch (Technical Director bei HvCable Solution). The earth wire which are not spaced cannot bare 360 centigrade short circuit temperature the cable is not acceptable. One correction copper screen temp is 250 centigrade.

➡ Protection Engineer). Everyone correctly points out that the shield will effect and cable may get heated. But, that happens only in multi core cables due to proximity effect but what is shown here is a single core cable. So, if the cable is laid in perforated tray and the other cores are kept at 50D spacing, how will this non-uniform armour cause the cable to heat?

➡ Steve Park (Electrical Power System Testing, Maintenance, and Engineering Executive Leader). Just saw in an earlier post that this cable also has a separate shield so that makes my earlier comments moot. Perfectly distributed concentric wires are probably not absolutely necessary for full life as they are in contact with a semiconductor material that will aid in creating a uniform ground plane to evenly distribute the electric field. However, here we have a significant non-uniformity that is not acceptable. There are large areas that appear not to have any concentric wires and likely to result in a non-uniform electric field leading to accelerated insulation deterioration.

➡ Ivan Jovanovic (Managing Director Cable Accessories at G&W Electric Co). Hi Steven, this looks like a shielded XLPE cable with extruded semicon screen over insulation. Theoretically there should be no field outside the screen but practically in transient and impulse conditions semi con screen is not acting as a perfect conductor and you really want to have these copper screen wires evenly spaced and in good contact with screen so you don’t build voltage gradient that can lead to pitting. There may be an issue from thermal perspective as well. Wires are sized to carry short circuit current and if they are not evenly spaced it is possible to have a hot spots which can thermally degrade both outer jacket but even more critically cable insulation. So from both perspectives if I was in charge of the project I would not accept it.

➡ Kerry Willert (Executive Construction Manager/Director Operations). No substitute for quality products!

➡ Rakesh Pandey (Negotiator/Electrical Engineer/Global Sourcing). Is it underground cable? seems aluminum core with copper neutral. If the sizing of copper is correctly considered then I guess we can use it. ANSI/ICEA S-94-649.

➡ Sjoerd Keijzer (Infratechniek) Not acceptable. There will be a wrong magnetic field around the cable. There will be a concentration on the places where the wires still are and there will be a higher temperature so therefore the insulation value will decrease. The insulation ages much faster and the lifetime of the cable will decrease enormously.

➡ Actually had this exact thing happen to us on a project a few years back. WTEC cable. It made us from that point on photo the ends of each cable prior to any cable terminations. Dan James is right it effects the shielding ability and I think a heating aspect of the cable too? I can’t remember 100%.

➡ Marcin Ruta (Power Systems Engineer). Aren’t those neutral wires twisted around cable? It will be random but is it acceptable? What standard do you follow normally for it?

➡ Brian Kolker (Carpenter). Marcin, No I would think not evenly distributed any extra energy that the wires may pickup from lightning strikes or from the ground it’s buried in.

➡ Noel Chamberlain. I personally like uniform in everything I worked on , I am not a cable jointer, I am a linesman, though it does not look the best on the end view, if the cable meets all pre-commissioning requirements I do not see an issue, though I agree it does look a little shoddy.

➡ Concentric neutrals have two purposes, as the neutral, as well as distribute the electric field around the cable. Spacing is important from the field perspective only.

➡ Mark H (Technical Manager for Electrical Engineering). One would have issues with the EMC of the cable, also the fault carrying capacity for the cable as the earth fault travels down the screen. It would also seriously distort the zero phase sequence, so if your specification asked for it to the IEC standards then it is best advised to reject the cable based on quality grounds under the FATs and SATs. With that kind of screen you may get additional heating due to the effects of circulating currents. Therefore your current carrying capacity would be compromised, but how much more would depend on the HV cable lay too, and what other cables it may cross. It may kill someone also for obvious reasons as the conductor is not covered completely thus you would be found liable under the EAWA.

➡ Paul Churnock, PE (Project Manager at McClure Engineering-St. Louis MEP) Ignoring the electrical characteristics and performance issues, I would reject this cable on the merits of the manufacturer’s lack of proper quality controls. If this visible issue exists, what other less readily apparent issues exist with such a cable. As noted, the shear quantity of cables necessitates proper material meeting the specified characteristics. The subsequent cost and down time necessary to mitigate and remedy potential failures far outweighs allowing non-conforming product.

➡ Faran Kaplan (Vice President, Sales Engineering). It’s not a neutral, it’s a ground. It’s designed to allow for equal radial distribution of corona discharge so that the insulation integrity is maintained.

➡ Axel Born (Cost and Value Engineering bei Siemens / Kabelexperte). At the cable ends the wires will be displaced by the cutting process. The real arrangement could be found by opening the cable some cm distance away from the cut end of cable.

➡ Abdul Kader (Business Manager HV/EHV Middle East). Axel, you nailed it.

Cable Terminations | Heat Shrink | Cold Shrink | Push-On | MV HV Medium & High Voltage

Nexans

Thorne & Derrick distribute the complete range of medium/high voltage electrical equipment manufactured by Nexans – this includes Euromold bushings for use with oil fluid or gas insulated switchgear or transformers and associated screened separable connectors according to both IEC (Euromold) and IEEE (Elastimold) for the termination, connect+disconnect of MV-HV cables onto power distribution systems. To protect power systems against high voltage surges resulting from lightning or switching a complete range of surge arresters are available to be used with Euromold connectors in 11kV/12kV, 24kV and 33kV/36kV voltage classes.

Key Product Categories: Duct Seals | Cable Cleats | Cable Glands | Electrical Safety | Arc Flash Protection | Cable Jointing Tools | Cable Pulling | Earthing | Feeder Pillars | Cable Joints LV | Joints & Terminations MV HV

➡ Read: Thorne & Derrick Announce Distribution Agreement & Contract With Nexans

Stainless Steel Cable Cleats

February 14th, 2019

Cable Cleats Manufactured from Stainless Steel by Ellis Patents

Cable Cleats

-

uploaded by Chris Dodds - Sales & Marketing Manager

Thorne & Derrick International, based in the UK, stock and distribute the most extensive range of Stainless Steel Cable Cleats manufactured by Ellis Patents and Prysmian.

➡ Review the ranges of non-corrosive cable cleats manufactured from stainless steel provide retention of LV (Low Voltage), MV (Medium Voltage) and HV (High Voltage) cables for single, trefoil, quad and bundled applications – typically used to cleat and clamp cables in contaminated and industrial installations including hazardous area locations with potentially explosive atmospheres.

Specialist cable cleats for fire resistant, zero halogen and Triplex type cables are available.

To select and specify the correct cable cleat for single cable applications consider: i) cleat spacing ii) cable diameter iii) peak short circuit current calculated according to IEC61914 and the installation environment – these factors could include ambient temperature, atmospheric corrosion, humidity, water, vibration, dust and solar radiation.

Why Stainless Steel ?

316 & 304 Grades of Stainless Steel

In general, cable cleats are manufactured from austenitic stainless steel due to its non-magnetic and corrosion resistant properties – the former ensuring the cable cleat won’t induce eddy currents or localised heating of the LV MV HV cable.

Austenitic stainless steel does become a little magnetic as a result of work hardening when processed. This magnetism can barely be detected with a magnet and so is not significant from an eddy current perspective.

There are many different types of stainless steel, but there are two principal variants when it comes to cable cleats.

304 austenitic stainless steel, often referred to as A2, is one of the most commonly used stainless steels. It has excellent corrosion resistant properties in most circumstances, although is susceptible in atmospheres where chlorides are present, making it unsuitable for use in coastal or marine environments.

316 austenitic stainless steel, often referred to as A4, contains Molybdenum, which provides resistance against chlorides. 316 is often referred to as marine grade stainless steel due to its suitability for use in coastal and offshore applications. If unsure a simple chemical test can determine whether Molybdenum is present and so differentiate between 304 and 316.

04 and 316 stainless steel are available in low carbon variants, namely 304L and 316L. These variants are immune to sensitisation (grain boundary carbide precipitation).

Any cable cleat which is manufactured from stainless steel and includes welding in the manufacturing process should be made in a low carbon (L) variant.

In a previous Blog we provided an evidence based case for stainless steel cable cleats where levels of atmospheric corrosion preclude use of other cable fixing materials.

Should you require technical specification support or a commercial quotation in order to place an order please do not hesitate to contact us.