Blog

Marconite – Electrically Conductive Earthing Compound

November 14th, 2018

Marconite

-

uploaded by Chris Dodds - Thorne & Derrick Sales & Marketing Manager

Low Resistance Earthing Compounds

for Substations

Marconite is developed and manufactured specifically for use in electrical earthing installations enabling electrical engineers and earthing system designers to achieve permanent, stable and low resistance earthing solutions even in difficult ground or soil conditions – typically used for substation earthing applications.

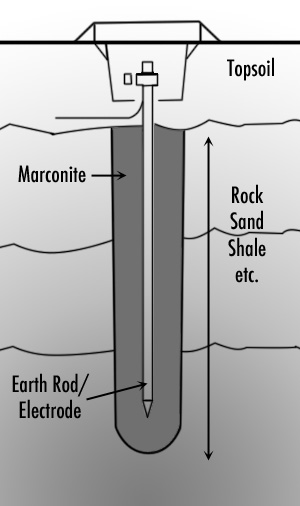

Adding Bentonite and similar earthing compounds, such as Marconite, in a trench or larger drilled hole around the electrode, typically an earth rod, has the effect of increasing the surface area of the earth conductor, assuming the resistivity of the added material is lower than that of the surrounding soil.

Earthing Compunds

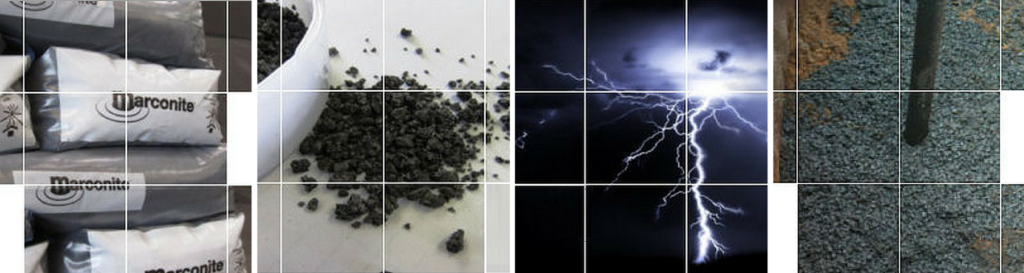

Marconite compound is a precisely measured, granular material, dark grey in colour, that is virtually dust free and with exceptional electrical properties.

| Marconite Earthing Compound Benefits | |

| Low Resistivity | 0.001 ohm.m is extremely low when compared to Bentonite’s 3 ohm.m |

| Versatile | Suitable for most ground conditions and becomes a permanent, solid structure that it is not prone to shrinking, drying out or being washed away |

| Cost Effective | It is a permanent solution; there is no need to remove and replace or ‘maintain’ it with additional water / salts every few years in order to achieve the desired earth values |

| Chemically Inert | Is non-corrosive to steel or copper, does not attack cement structures and has a pH within the neutral range |

| High Strength | Can be used as part of the building structure itself and can achieve strengths higher than Grade 25 concrete |

| Easy To Use | Forms a concrete like material that from first pour, achieves a low resistance earth, no need to wait or return to test |

More About Marconite

Marconite is essentially a conductive concrete in which a carbonaceous aggregate replaces the normal aggregate used in the conventional concrete mix – Marconite earthing compound has some similar properties to Bentonite, i.e. causes minimal corrosion with certain metals and has a low resistivity. It was developed as a process which started in 1962 when Marconi engineers sought a material which conducted by movement of electrons rather than ions. It contains a crystalline form of carbon and the overall material has a low sulphur and chloride content.

There is stated to be some corrosion of ferrous metal and copper whilst the Marconite is in slurry form, but it is suggested that a thin protective layer forms. When the concrete has set, corrosion is said to cease. Metal should ideally be painted with bitumen or a bitumastic paint as it enters the Marconite structure to prevent corrosion at this point. Aluminium, tin coated or galvanised steel should not be installed in Marconite.

When Marconite is mixed with concrete, its resistivity can fall to as low as 0.1 Ohm-metre. It will retain its moisture even under quite dry conditions so has been used in the hotter climates as an alternative to Bentonite compound. Its principle application in the UK is at locations where theft or third party interference is likely to be a problem, or to enclose copper electrodes in bore-holes or voids within rock when driven into the ground.

When surrounding an earth rod with Marconite which has been installed in rock, the resistance of the copper earth rod will be reduced as the volume of Marconite used is increased. For example, if a 1 metre earth rod is installed at the centre of a hemisphere of Marconite of radius 1.5m, it would have a resistance of approximately 2,000 Ohm if the surrounding rock is of 2,000 Ohm-metres.

Call T&D for Copper Earthing Tapes | Best Prices | Large Stocks

If the radius of the hemishere is increased to 3 metre and then 5 metre, the resistance would fall to 1,080 Ohm and 650 Ohm respectively. Because of the prohibitive cost of removing such a volume of rock, it makes sense to make use of existing cavities for this purpose, where possible. Also, the void is likely to be part filled with other materials (such as concrete) to reduce the amount of proprietary material required. Marconite is normally considered as having a resistivity of 2 Ohm-metres.

T&D provide fast delivery and competitive prices for genuine Marconite brand earthing compounds.

Marconite – Electrically Conductive Aggregate Material

SUBSTATION EARTHING & MV HV CABLE JOINTING

To complement Earthing & Lightning Protection & Exothermic Welding products we stock and distribute the most extensive range of copper earthing equipment.

132kV Termination Using Pfisterer IXOSIL EST SUB Self Supporting Cable Termination

November 12th, 2018

- Application: 132kV Cable Termination – Pfisterer EST SUB Self Supporting Type

- Cable Type: Pfisterer EST SUB Self Supporting Cable Termination

- Cable Jointer: Andy O’Malley (IBEW 258 EHV Cable Jointer / Cable Splicer – Allteck)

- Featured Manufacturer: Pfisterer

Pfisterer EST SUB

Self Supporting Cable Termination

Pfisterer oil-free and gas-free cable terminations for high voltage cables are environmentally friendly and reduce installation times by the HV Jointer – the cable terminations are available for voltage levels ranging from 52kV to 170kV and conductor cross-sections up to 2500sqmm.

The self-supporting Pfisterer EST design replaces conventional oil-filled and gas-filled outdoor cable terminations both in overhead line towers and transformer stations – the cleverly designed head fitting allows for any thermal expansion in the conductor.

The mounting frame on overhead line towers is now no longer needed since the cable termination can be installed onto the HV cable on the ground and then lifted onto the tower – this leads to very short turn-off periods of the overhead lines.

Pfisterer IXOSIL EST SUB Advantages

- Oil- and gas-free

- Leak-proof

- Compensation of cantilever forces

- Enables installation on the ground, no mounting frames required

- Time savings of up to 50% during cable preparation due to new technology

- 100% electrically routine-tested termination

- Low weight cable termination

Pfisterer MV HV cable plugs and terminations are suitable for all voltage levels and applications where medium or high voltage power must be reliably distributed within the electricity supply industry.

Pfisterer Ixosil

ESF 52-170kV v EST SUB 123-170kV

ESF & EST SUB Terminations

Should you require any assistance with the selection or specification of cable joints or terminations please do not hesitate to contact us.

See Also 132kV ➡

- 132kV Link Boxes & Bonding Leads For High Voltage HV Cable Systems

- Sealing Cables, Switch Hall & Grid Transformer Bases On 132kV Wind Farm

- 132kV Cable Covers – Protecting High Voltage Power Cables In Cable Trench

- Drum Heating & Cable Straightening Jackets For 132kV Cable Terminations

- 132kV Surge Arresters

See also Surge Diverters | Sheath Voltage Limiters

Thorne & Derrick Specialist Electrical Distributor

LV ♦ MV ♦ HV

T&D distribute the most extensive range of LV, MV & HV Cable Jointing, Terminating, Installation & Cable Pulling Equipment – we service UK and international clients working on underground cables, overhead lines, substations and electrical construction at LV, 11kV, 33kV and EHV transmission and distribution voltages.

- Key Products: MV-HV Cable Joints & Terminations, Cable Cleats, Duct Seals, Cable Transits, Underground Cable Protection, Cable Jointing Tools, Feeder Pillars, Cable Ducting, Earthing & Lightning Protection, Electrical Safety, Cable Glands, Arc Flash Protection & Fusegear.

- Distributors for: 3M, ABB, Alroc, Band-It, Catu, Cembre, Centriforce, CMP, Elastimold, Ellis Patents, Emtelle, Furse, Lucy Zodion, Nexans Euromold, Pfisterer, Polypipe, Prysmian, Roxtec.

LV – Low Voltage Cable Joints, Glands, Cleats, Lugs & Accessories (1000 Volts)

MV HV – Medium & High Voltage Cable Joints, Terminations & Connectors (11kV 33kV EHV)

Cable Laying – Underground Cable Covers, Ducting, Seals & Cable Pulling Equipment

More…

T&D’s Power Blog covers: LV MV HV & EHV Transmission & Distribution, Substations, Switchgear, Cable Jointing & Termination, Cable Fault & Repair, Underground Cables

➡ Visit Power Blog.

Marconite Earthing – Conductive Concrete, Mixing & Use Of Marconite

November 12th, 2018

-

uploaded by Chris Dodds - Thorne & Derrick Sales & Marketing Manager

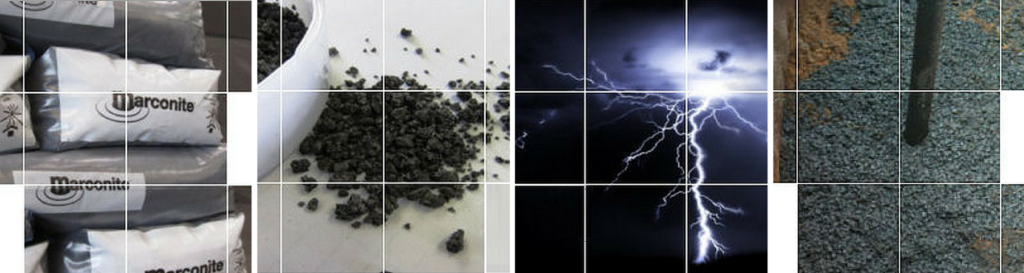

Marconite is the world’s leading premium electrically conductive backfill material which significantly enhances the effects of copper earth electrodes to reduce the resistance of a lightning protection or copper earthing system.

Marconite is a dark grey, granular material that replaces traditional sand and aggregate materials used within concrete mixes – it should be mixed in the ratio of 3 parts of Marconite to 1 part cement by weight with addition of 1 litre of water per 4kg of total mix:

Mixing Marconite

3 x 25 Kg bags of Marconite

1 x 25 Kg bag of Cement

25 litres (25 Kg) of Water

Ground enhancement materials such as Bentonite and Marconite earthing compounds are used to lower the resistance to earth of Earthing & Lightning Protection Systems – simple to install and used as backfill for earth electrodes, including earth rods or earth mats.

When mixed as described above, the Marconite forms a relatively dry material with an ‘as poured’ density of around 1300 Kg / m³ for earthing purposes.

The water content may be adjusted as the application requires, but this will affect the concretes final compressive strength and the drying times accordingly.

Typically Marconite concretes are touch dry within hours but can be several days before being fully cured.

Marconite is chemically inert with very low soluble sulphate content. It can be used with all conventional types of cement, as well as most proprietary resin-based cements, adhesives and gypsum plasters – due to the inert structure Marconite is non-corrosive to steel or copper and with a pH level in the neutral range will not degrade or erode cement structures.

Marconite Conductive Concrete is a registered product of the James Durrans Group and is solely produced by their subsidiary company Carbon International Limited.

Resistivity of Marconite

Marconite earthing aggregate provides exceptional resistivity with a resistance level of .001 ohm.m – even when mixed with cement the resulting resistance level is only 0.19 ohms.m.

Reducing Earth Electrode Resistance

Marconite is a conductive carbonaceous aggregate which, when mixed with conventional cement, has the effect of increasing the surface area of the earth electrode, thus helping to slightly lower its resistance. These earthing back-fill materials can provide a significant improvement to earthing system performance but also provide several secondary functions: maintain the resistance value at a more constant level throughout the year, to provide protection against 3rd party damage, or to protect the earthing electrode from corrosion.

Marconite is also useful for surrounding electrodes installed in rock.

Where a decision is taken to use FurseCEM, Bentonite, Marconite or any other special back-fill material, the design engineer should ensure that this information is passed to the construction staff – construction methods can be used to limit the amount used and therefore associated cost.

Examples are mixing Bentonite with local clay, reducing the hole diameter drilled (for vertical copper electrodes) and minimising the width and volume of the horizontal trench section into which the earth electrode will be installed.

Contact T&D for Copper Earthing Tapes – Bare Tape & Covered

Marconite – Electrically Conductive Aggregate Material

SUBSTATION EARTHING & MV HV CABLE JOINTING

To complement Earthing & Lightning Protection products we stock and distribute the most extensive range of copper earthing equipment.

FurseCEM Earthing Conductive Aggregate Concrete

November 12th, 2018-

uploaded by Chris Dodds - Thorne & Derrick Sales & Marketing Manager

FurseCEM

FurseCEM is an earthing conductive aggregate concrete, manufactured by Furse, offers a convenient and permanent solution to Furse earthing problems by obtaining a reliable earth resistance even in installations that require a very low resistance regardless of ground conditions – this includes low LV, medium MV and high HV substations.

A conductive concrete is formed when FurseCEM is added in place of sand and aggregate. This electrically conductive medium has many applications in the electrical/construction industry including RF and microwave screening, static control and of course earthing for which it was specifically developed.

FurseCEM concrete used as a backfill for conventional earth rod to achieve a lower earth electrode resistance

When used as a backfill for an earth electrode or earth rods, FurseCEM impregnated concrete greatly increases the electrodes’ surface area. For example, increasing the effective diameter of a copper earth rod from typically 15mm to 200mm, could lower its resistance to earth by as much as 50% (see graph below).

Resistance versus Diameter

FurseCEM Features & Benefits

- Permanent earth reading – resistivity that will remain constant over the life of the installation without the requirement for maintenance

- Constant volume – regardless of water content, FurseCEM will not shrink or expand, thus maintaining constant contact between the earth electrode and the soil

- Cost effective – reduces drilling, saves on earthing materials, and requires no expensive maintenance

- Non leaching – FurseCEM is a conductive concrete and therefore cannot be washed away

- Chemically inert – completely non-corrosive, and will not in any way damage earth electrodes, steelwork or concrete

- Fast drying properties – allows for quick and easy installation

- Mechanical strength – provides high compressive strength where required

- Long shelf life – can be stored for long periods without deterioration

- Versatile installation – suitable for use in boreholes and trenches

FurseCEM Earthing Conductive Aggregate Concrete

Earthing Conductive Aggregate Concrete

FurseCEM Part Numbers

FurseCEM should be mixed in a 3:1 ratio by weight (not volume).

| Description | Sack Weight | Part Number |

| FurseCEM | 25kg | CM025 |

| FurseCEM (supplied with cement) | 25kg | CM030 |

Contact T&D for Copper Earthing Tapes | Large Stocks | Best Prices

FurseCEM versus other methods of earth improvement

Chemical solutions — such as copper sulphate, sodium carbonate, calcium sulphate and sodium chloride (table salt) mixed with charcoal are sometimes poured into the ground to improve earth readings, but these have the disadvantages of:

- being required in large quantities to make a difference

- requiring constant moisture to remain effective

- drying out if moisture is not present

- eventually leaching out of the soil, returning the earth to its former high value, unless regularly and expensively maintained

- causing corrosion of the earth electrode system and deterioration of concrete (particularly relevant to transmission towers).

Chemical earth rods — perforated metal tubes packed with a with a chemical compound are also sometimes used but these:

- are costly

- are subject to leaching or washing away of the chemicals unless maintained

Bentonite — and certain other compounds intended to absorb and retain moisture in and around an earth electrode.

- rely on constant moisture to maintain volume and hence work effectively

- without moisture, drying and shrinkage occur, causing loss of contact with the surrounding soil and a deterioration in the earth reading

- regular checking and/or maintenance may be required

FurseCEM is a non-corrosive permanent solution to earthing problems, providing a fixed earth reading that will not very significantly regardless of seasonal factors, and without maintenance.

SUBSTATION EARTHING & MV HV CABLE JOINTING

To complement Earthing & Lightning Protection products we stock and distribute the most extensive range of copper earthing equipment.

Further Reading

Crimping Copper & Aluminium Cables

November 12th, 2018

Copper & Aluminium – Crimping CU-AL Cables

-

uploaded by Chris Dodds - Thorne & Derrick Sales & Marketing Manager

Cable Crimps

Thorne & Derrick International, based in the UK, are leading suppliers of cable lugs and associated crimping tools for Low, Medium & High Voltage Cables and Power Systems – this series of articles by Klauke discusses the theory and practise of installing compression type cable lugs and connectors when jointing and terminating copper or aluminium cables at Low (LV), Medium (MV) or High (HV) voltages.

Klauke cable lugs and crimping tools are used by Jointers, Linesmen, Panel Builders and Electrical Engineers to install underground cables and overhead line conductors on power, transmission and distribution networks including LV MV & HV systems, 11kV-33kV.

➡ Download 2018 Klauke Cable Lugs catalogue and see the complete range of tools for cutting and crimping cables.

In this Article we cover the following:

- Crimping copper and aluminium conductors integral to LV MV HV cables up to 33kV

- Types of bi-metallic cable lugs for connecting aluminium cables to copper busbars

- Aluminium conductors – 4 different types which require cable preparation for crimping

- Connecting compound for aluminium connecting material to improve contact properties

- Al/Cu connectors for a correct crimp connection of aluminium and copper conductors

Accurately Crimping

Copper & Aluminium Cables

Copper, due to its outstanding electrical conductivity properties, is always the first choice when selecting a conductor for an electrical connection.

A practicable alternative in many cases is aluminium particularly because of its low weight and easy application. In practice however the electrician can find it challenging to connect both these materials in a professional and electrically safe manner using crimping tools.

A copper-aluminium connection is used for instance in an industrial estate where local businesses use copper conductor power supply cables which are then fed off an aluminium ring main unit. But also in LV MV HV electrical substations it is necessary to connect aluminium conductors to copper busbars.

The main problem here is that connecting aluminium and copper is not straightforward – to ensure a safe and correct connection the use of special aluminium/ copper cable lugs and connectors is essential.

Use of an incorrect crimping die and/or an incorrect crimp will result in an over compression (right) or an under compression (left) and in the worst case in fire.

Infographic: Properties & Uses of Copper Materials For Electrical Applications

Property of https://copperalliance.org.uk/

Aluminium-Copper: A problematic connection

Generally aluminium is a reactive material that oxidises easily, but in practice it has proved to offer good corrosion resistance. This characteristic is due to a chemical reaction that takes place when in contact with atmospheric oxygen resulting in a very thin but also very resistant oxide layer being formed (oxide barrier).

When metals are connected to those with a higher electrical potential such as copper in the presences of an electrolyte (condensed water) will result in an electrochemical reaction taking place.

During this process the differences caused in electrochemical potential can have a significant impact. An electrical circuit is generated by the copper electrode (anode), the electrolyte (water) and the aluminium electrode (cathode).

The voltage generated in this copper and aluminium circuit “semi metallic” state results in a short circuit. As a result of the current generated the aluminium surface breaks down causing the metal to electrolytically decompose.

This destructive process is visible as a kind of blooming oxidation and begins already with the existence of tiny copper particles on the aluminium; this ongoing reaction itself does not cause the copper to corrode.

In an electrical connection however the resistance is increased leading to increased temperatures which then in the worst case lead to a fire. Therefore when connecting copper and aluminium it is important to ensure that no moisture can enter the connections.

In an environment where moisture is present the contact points between the copper and aluminium need to be protected by using accurate operating procedures.

The construction of Al/Cu cable lugs prevents any gaps which would allow the accumulation of liquid to take place which would start the oxidation process.

Primarily this requires the use of aluminium/ copper cable lugs and connectors. Due to the design of these cable lugs areas where moisture could accumulate and where the oxidation process could start have been avoided. For this reason aluminium/copper cable lugs and connectors are specified for the use in offshore wind power stations.

Aluminium/copper compression cable lugs

Leading manufacturers of high quality compression cable lug such as Klauke or Cembre, for connecting aluminium connectors with copper bus bars consist of an electrolytic aluminium (E-Al) compression and are joined to a copper palm (to EN 13600).

A professional connection of an aluminium conductor with a copper busbar is done by means of an aluminium cable lug and a copper palm.

The available cross sections range from 16sqmm up to 400sqmm. The field of application covers in principle all non-tension connections of aluminium cables acc. to DIN 48201, Part 1, and aluminium ropes acc. to DIN 50182 (Conductors For Overhead Lines – Round Wire Concentric Lay Stranded Conductors).

Specifications and processing of aluminium/copper compression cable lugs are the same as those for pure aluminium versions. Quality products manufactured by market leaders such as Klauke feature a consistent material thickness, exact diameters and correct fit and are a prerequisite for ensuring high electrical safety standards are always met.

Like aluminium cable lugs conforming to DIN 46239, aluminium/copper compression cable lugs feature a barrier design allowing the use of oil soaked and paper insulated cables which prevents oil leakage.

Aluminium Cable Conductors At A Glance

Aluminium conductors are available in four different versions which require in some cases special processing.

These are:

- round solid cable conductors (re)

- sector solid cable conductors (se)

- round stranded cable conductors (rm)

- sector stranded cable conductors (sm)

Different types of aluminium conductors

These abbreviations will be found next to other markings on all Al/Cu compression cable lugs and identify which conductors will suit the appropriate cable lug.

The markings on the cable lug provide information relating to the crimps, the manufacturer, cross section and allocation of cable.

Markings on the product provide the installer with essential information. Marking “16 KL25 150 rm/sm 185 re/se” stands for

- 16: Metric bolt size for connecting bolt – size M16

- KL: Manufacturer (in this case Klauke)

- 25: Die code

- 150: Cross section of conductor in sqmm

- rm/sm: for round multi-stranded and sector stranded conductors

- 185: Cross section of conductor in sqmm

- re/se: for round single stranded solid and single sector solid conductors

The die code also needs special consideration. For an accurate and safe crimp the die reference should be the same as that shown on the cable lug. The die code can be seen on the die face as a mirror image so that after compression the die code is visible on the cable lug for final control and inspection.

For an accurate processing of Al/Cu cable lugs it is generally recommended to use hexagon crimping dies acc. to DIN 48083 Part 4. In order to ensure an accurate and professional crimp avoiding over or under compression is the use of appropriate crimping tools.

Poor crimps can result in an increase in joint resistance and temperatures that can lead to fires. To prevent such issues Klauke solely recommend using the manufacturers crimping tools to crimp their cable lugs.

For instance the special crimping dies for aluminium have a crimp width of 7mm, i.e. 2mm wider than the crimping dies for copper cable lugs and connectors. This, however, only applies to 60 kN crimping dies.

The reason for this is that cable crimping dies with a larger crimp width are able to connect a wider conductor surface area with the cable lugs and balance the poor conductivity of aluminium. To easily identify which die should be used, Klauke manufactures aluminium dies in a silver colour while dies for copper are yellow-gold coloured.

Connecting compound for aluminium connecting material

All cable lugs and connectors for aluminium conductors come with a special compound.

High quality aluminium cable lugs come with a special compound which improves the contact properties and ensures a perfect electrical connection.

This aggravates the non-conductive oxide layer which is quickly formed on the surface of the cable lug – this compound improves the electrical contact properties of the cable crimped lug and enables a perfect electrical connection preventing further oxygen penetrating the contact joints where further oxidation could take place.

To maintain the functional capability of the compound all leading brand cable lugs are sealed with a plastic plug to prevent the compound from drying-out and leakage.

Al/Cu Connectors & Joints

For a correct connection of aluminium and copper conductors leading manufacturers such as Klauke offer reduction compression joints with a cross section range from 10sqmm up to 300sqmm.

Aluminium and copper conductors with different cross sections are being connected using reduction sleeves.

These products serve mainly the reconstruction of power lines, i.e. non-tension connections of aluminium conductors acc. to DIN EN 60228 resp. aluminium wires acc. to DIN EN 50182 with copper cables acc. to DIN 48201, part 1 and copper conductors acc. to DIN EN 60228.

These compression joints consist of interconnected aluminium (E-Al) and copper parts (acc. to EN 13600).

Normally the aluminium part of the cross section has a much larger diameter to compensate for the poor conductivity of aluminium.

Normally the aluminium section (right) has a larger diameter than the copper section (left) to equalize the poor conductivity of aluminium.

As with the cable lugs here too plastic plugs are used to prevent drying-out and leakage.

Important: The use of Al/Cu compression joints requires that the correct processing guidelines for copper and aluminium are observed.

Consequently the aluminium section needs to be crimped like an aluminium compression cable lug (see picture on the below).

Characteristically for Al/Cu compression joints are the different crimping marks which are 7mm on the aluminium section and 5mm on the copper section for crimping dies up to 60kN. The procedure for the copper section is absolutely identical as on copper compression cable lugs. The crimping marks on the product give detailed information as to origin and application of the Al/Cu compression joints.

The marking “KL14 50 rm/70 re/se” signifies:

- KL: Manufacturer (in this case Klauke)

- 14: Die code

- 50: Cross section of designed conductor in sqmm

- rm/sm: for round stranded and sector stranded conductors

- 70: cross section of solid conductor in sqmm

- re/se: for round solid and sector solid conductors

The marks on the copper section also indicate the correct procedure. The standard suggests crimping dies acc. to DIN Standard 48083 Part 1, 3 and 4 for solid, fine and fine stranded conductors; for braided round wires the standard refers to specifications of the manufacturer.

Generally Klauke recommends using hexagon crimping dies according to DIN 48083 Part 4 for processing the copper section of their compression joints.

Advice: When using crimp connections in the ground it should be strictly observed that the connecting joints should be protected against moisture. For this application Klauke recommends use of resin cable joints.

When used in the ground cast-resin joints, such as Scotchcast, protect the connections against moisture. It is important to consider that the connection is not subject to bending to avoid the risk of fracture.

Should you require guidance or technical support to use the correct cable lug or connector using either compression or shearbolt technology please do not hesitate to call us.

Further Reading

Review other Blogs in this series of articles about Cable Lugs, Crimping Cables & Tools:

Cable Lugs – Crimping Applications & Standards

Copper Cable Lugs For Special Applications

Indent Crimping Of Cables – Benefits & Limitations

Cable Lugs & Crimps – Hexagonal v Indent Methods of Crimping

Cable Lugs & Crimping Using The Hexagonal Crimp Method

DIN Standard – Crimping & Compressing Aluminium Cable Lugs & Connectors

Electrically Driven Crimping Tools For High Volume Applications

LV MV HV Cable Accessories & Substation Electrical Equipment

Thorne & Derrick are Specialist Distributors of leading manufacturers of Cable Accessories, Jointing & Installation Equipment.

LV MV HV cable accessories used to joint, terminate, connect, cleat and gland power cables to air and gas insulated substations, transformers, switchgear and overhead line networks.

LV 600/1000V ◊ MV 11kV 33kV ◊ HV 66kV 132kV

|

|

|

|

|

|

|

|

|

|

Substation & Overhead Line Electrical Safety Equipment

Manufactured by CATU Electrical to enable the safe construction, maintenance and repair of underground cables and overhead lines network up to EHV (400kV).

T&D - CABLES ♦ JOINTS ♦ TERMINATIONS ♦ CONNECTORS ♦ GLANDS ♦ CLEATS ♦ CRIMPS & LUGS ♦ DUCT ♦ SEALS ♦ ARC FLASH PPE

EARTHING ♦ FEEDER PILLARS ♦ JOINTERS TOOLS ♦ CABLE CUTTING & CRIMPING TOOLS ♦ COLD SHRINK ♦ HEAT SHRINK ♦ FUSES