Blog

DC Solar Cable Joints – General Cable Harmohny All Ground XZ1 (S)

September 7th, 2018

Resin Cable Joints

- Product Category: Cable Joints Low Voltage LV

- Cable Joint Type: Heat Shrink | Cold Shrink | Resin Cast

- Cable Voltage: Low Voltage | Medium Voltage | High Voltage | Other – 600V 1000V

- Cable Joint Manufacturer: 3M Electrical

- Cable Manufacturer: General Cable Harmohny All Ground XZ1 (S) Aluminium

- Cable Type: DC Solar Cables

Cable Joint Application Notes – 3M Scotchcast cable joints are suitable to connect, repair and joint DC solar cables – this includes solar cables with XLPE insulation and halogen-free polyolefine outer sheath and semi-rigid Class 2 aluminium conductors to the following standards. The low voltage power distribution cable is suitable for direct buried installations.

3M straight connection joints provide excellent electrical insulation and mechanical protection – high weathering, tear, abrasion and impact resistant DC solar cable joints for unamoured and armoured (AWA SWA) type power cables.

- UNE-HD 603 5X Design & Test Standards

- UNE-EN 60332-1-2 IEC 60332-1-2 Flame Retardant Cable

- UNE-EN 60754-1 IEC 60754-1 Fire Retardant Cables

- UNE-EN 60754-2 IEC 6-754-2 Low Acidity & Corrosivity Of Evolved Gases

- UNE-EN 61034 IEC 61034 Low Opacity Of Evolved Fumes

DC Solar Cable Manufactured by General Cable

Cable Joint Installation

♦ Cable Joint Installation Instruction – for further please see 3M LVI Scotchcast Cable Joints.

Electrical Conductor Connectors – both crimped or mechanical shearbolt connectors are suitable for use with resin cable joints. The following selection table for the DC solar cable joints includes the appropriate Pfisterer Sicon type mechanical connector, however Cembre connectors could also be used.

DC Solar Cable Joints Selection Table

| DC Solar Power Cables | Cable Conductor Size | Outside Cable Diameter | 3M Scotchcast Cable Joint | Pfisterer Sicon Connector |

| 0399402 | 70sqmm | 20.7mm | 3M LVI 1/2C Up to 25mm Dia Cables | 332-601-010 |

| 0399401 | 95sqmm | 22.3mm | 3M LVI 1/2C Up to 25mm Dia Cables | 332-601-010 |

| 0399403 | 120sqmm | 24.0mm | 3M LVI 1/2C Up to 25mm Dia Cables | 332-607-010 |

| 16901A4 | 150sqmm | 25.8mm | 3M LVI 1/3 Up to 32mm Dia Cables | 332-607-010 |

| 0399404 | 185sqmm | 27.7mm | 3M LVI 1/3 Up to 32mm Dia Cables | 332-592-010 |

| 16901A5 | 240sqmm | 30.5mm | 3M LVI 1/4 Up to 45mm Dia Cables | 332-592-010 |

| 0399405 | 300sqmm | 32.8mm | 3M LVI 1/4 Up to 45mm Dia Cables | 332-603-010 |

| 0399406 | 400sqmm | 35.9mm | 3M LVI 1/5 Up to 45mm Dia Cables | 332-603-010 |

DC Solar Cable Joints

General Cable

General Cable powers and connects our world – headquartered in Highland Heights, Kentucky, the company was founded in 1927 with many legacy products tracing back to the Industrial Revolution. General Cable is a global leader in the development, design, manufacture, marketing and distribution of copper, aluminium and fiber optic wire and cable products for energy, construction, industrial, automotive, specialty and communications segments.

Cable Joints

Thorne & Derrick International can specify and supply standard and bespoke LV cable joints utilising heat shrink, cold shrink or resin cast type jointing kits.

Should you have a specific application for LV, MV, HV up to 33kV cable joints please contact us. For further information:

Cutting SWA Cables – Recommended Cable Cutting Tool For Steel Wire Armoured Cables

September 5th, 2018

LV-HV Cable Cutting Tools For Copper, Aluminium & Telecommunication Cables

-

uploaded by Chris Dodds - Thorne & Derrick Sales & Marketing Manager

This Post addresses a customer query received earlier today by Thorne & Derrick, the stockist and supplier of Cembre, and highlights suitable cutting tools for use with SWA Armoured Cables.

Question About Cutting SWA Cables

Is the Cembre B-TC950E capable of cutting a Steel Wire Armoured cable?

The cable has a outside diameter of approximately 70mm. The cable has 3 triangular (sector) aluminium cores, the cores cross sectional area is unknown but it is suggested that they would be approximately 240sqmm. If the Cembre B-TC950E cable cutter is suitable could you advise of the approximate number of cuts that the blades could do on this cable before needing replacing. Or would you recommend an alternative cable cutting tool?

The SWA (steel wire armour) wraps completely around the outside of the cable under the outer layer of PVC – each steel wire in the armouring is approximately 3mm in diameter.

We require 5 cable tools.

Cembre reply:

Cembre B-TC950E is capable of cutting up to 240sqmm 3 core SWA cable (with 2 cuts at 90 degree angles) – this includes LV MV HV cables up to 11kV/33kV.

Hydraulic type cable cutting tools are also available.

With regards to an approximate number of cable cuts before the tool blades need replacing, we would not be able to provide this information as there are too many variable and external factors involved to give a definite answer.

We can quote for spare cable cutting blades as applicable for use with all Cembre manufactured tools.

Should you also need to terminate the same specification cable using cable lugs we would recommend the Cembre HT131-C tool which is a hydraulic crimping tool for use up to 400sqmm using hexagonal die sets.

When it comes to cutting and crimping cables the trusted world-market leading manufacturer of cable tools is Cembre.

Cable Lugs & Connectors LV HV

LV Lugs & Connectors – complete range of copper crimp connectors suitable for use with joints and terminations for low voltage cables | Cable Lugs | Cable Splice Connectors | Aluminium Lugs | Aluminium Splices | Bi-Metallic Cable Lugs

HV Lugs & Connectors – complete range of copper crimp connectors suitable for use with joints and terminations for medium/high voltage cables | Cable Lugs | Transformer Lugs | 2 Hole Lugs | Pin Stalk Connectors | Through Connectors | 11kV 33kV

DIN 46234 Solderless Terminals

September 4th, 2018

Manufacturers of Cable Lugs, Electrical Connectors & Tools

-

uploaded by Chris Dodds - Thorne & Derrick Sales & Marketing Manager

Terminating & Crimping Cables To DIN SPEC

What Is DIN Standard or SPEC?

DIN, the German Institute for Standardisation, founded in 1917 is the independent platform for standardisation in Germany and worldwide – for DIN Standard cable lugs the scope is similar to British Standard BS7609 providing quality and safety guidance for electrical cable termination, connection and also crimping cables.

A DIN Specification, or DIN SPEC, is a document that specifies requirements for products, services and/or processes. However, in contrast to standards, DIN SPECs do not require full consensus and the involvement of all stakeholders. These DIN Specifications or SPEC’s are drawn up in temporary bodies called workshops. DIN SPECs are a trusted strategic instrument for quickly and easily establishing and disseminating innovative solutions into the electrical industry market.

Solderless terminals used for cable terminations to conform to the DIN 46234 standard must satisfy specific application, dimensional and marking requirements – the main application for solderless terminals is to connect, terminate or crimp round type multi, fine and superfine stranded conductors.

Note: DIN 46234 solderless terminals are not suitable for the termination or for use with single-stranded solid conductors – please refer to compression or crimp cable lugs to DIN 46235 for this particular application.

The conductor cross-sections of solderless terminals to DIN 46234 range from 0.5sqmm to 240sqmm, the bore diameter for the connecting bolt from M2 to M16 stud holes.

Solderless terminals are used in panel building and control cabinet manufacturing.

Similar to conventional crimp/compression and tubular cable lugs the solderless terminals are manufactured from electrolytic copper. For production, however, a different source material is used: while compression cable lugs are manufactured from tubes, solderless terminals are made from copper sheets. So by virtue of their design, rounded and soldered from a metal sheet, they have a distinctive soldered joint.

The quality of the soldered joint is key to the crimp result.

Poor-quality soldered joints carry the risk of opening during the crimping process.

Unlike the compression cable lug to DIN 46235, solderless terminals are not processed by hexagonal crimping, but instead by indent crimping.

Klauke manufactures various cable crimping tools to install cable lugs, connectors and splices to both DIN 46235 and DIN 46234 standard – please call us to discuss your specific application or review the catalogue downloads below.

Solderless Terminals

Solderless Terminal Crimped With Indent Crimp

Solderless Lug Crimped Terminal With Indent Crimping Die

Solderless Terminals

Klauke are a market-leading manufacturer of electrical connection products including copper connectors and solderless terminals for round conductors including to DIN EN 60228 Class 2, 5 and 6.

Klauke terminals with grooved profiles for improved electrical contact are tin-plated to protect the terminals against corrosion. Suitable for the following nominal cross section area conductors (sqmm): 0.5-1sqmm, 1.5-2.5sqmm, 25sqmm, 4-6sqmm, 35sqmm, 50sqmm, 70sqmm, 95sqmm, 120sqmm, 150sqmm, 185sqmm and 240sqmm.

Manufactured from copper with a high quality brazing process in the cable crimp area.

DIN 46234

Terminal Ends for Solderless Connections: Ring Type, Without Insulating Sleeve, For Copper Conductors

- Standard by Deutsches Institut Fur Normung E.V. (German National Standard), 03/01/1980

DIN 46234 Standard Solderless Terminals – Manufactured by Klauke

Crimping Cables, Lugs & Tools

Thorne & Derrick distribute Cable Lugs & Cable Connectors to terminate, splice and joint LV MV HV cables – this includes copper, aluminium and bi-metallic connectors and a complete range of crimping tools for specific use on all Low, Medium & High Voltage cable types.

➡ Associated Brands & Products | Klauke | Cembre | Pfisterer Sicon | Cable Crimping & Cable Cutting Tools

Electromechanical Crimping Tools For High Volume Applications

September 4th, 2018

Electromechanical Crimping Tools Manufactured by Klauke

-

uploaded by Chris Dodds - Thorne & Derrick Sales & Marketing Manager

Thorne & Derrick International, based in the UK, are leading suppliers of cable crimp lugs and associated crimping tools for Low, Medium & High Voltage Cables and Power Systems – this series of articles by Klauke discusses the theory and practise of installing compression type cable lugs and connectors using ratchet, hydraulic, battery-operated or electromechanical crimping tools.

Klauke cable lugs and crimping tools are used by Jointers, Linesmen, Panel Builders and Electrical Engineers to install underground cables and overhead line conductors on power, transmission and distribution networks including LV MV & HV systems, 11kV-33kV.

➡ Download 2018 Klauke Cable Lugs catalogue and see the complete range of tools for cutting and crimping cables.

In this Article we cover the advantages of using Electromechanical Crimping Tools:

- With a manual force of up to 20 kilograms per crimp, excessive strain in the wrist and forearm can occur over time when cable crimping

- There is a good case here for taking measures to safeguard against such conditions and prevent expensive employee absences and injury

- Electromechanical cable crimping tools reduce the physical effort, achieve the best crimping results and also guarantee the consistently high quality

- For specialist operations in which large numbers of crimped connections have to be processed quickly, purchasing such crimping tools is justified

- DIN 46234 standard compliance and cable lug connector installation

Cable Crimping & Health & Safety

It usually begins innocuously: first a numb feeling in the thumbs, index and middle fingers during the night. But then later, pain and sensory disorders throughout the day too. The hand becomes less sensitive, the fine motor skills start to dwindle and the hand gets weaker.

Day-to-day tasks become increasingly difficult and certain professional activities are difficult or even impossible to accomplish. This is caused by what is known as carpal tunnel syndrome. A nerve in the hand is permanently trapped against a constricted area that is inflamed – here are the typical signs and symptoms:

Carpal Tunnel Syndrome – Cable Crimping

One suspected cause of this widespread condition is one-sided strain, which is often encountered in the electrical trade for example. There is a good case here for taking measures to guard against such conditions and prevent expensive employee absences.

Choosing the correct electromechanical crimping tools can help reduce workplace injuries and improve site and worker Health & Safety.

One of the most commonly recurring tasks in switch cabinet construction and installing LV cable joints is the crimping of cables. This task is usually carried out using mechanical type, ratchet crimping tools and in most cases, is completed without any problem at all. It can be become critical, however, when it has to be carried out by employees on a recurring basis. With a manual force of up to 20 kilograms per crimp, excessive strain in the wrist and forearm can occur over time.

Employee Health & Safety – less physical effort with electrically-driven cable crimping tools

One key factor is considered to be the number of cable crimp operations that are carried out on a regular basis. While a young and healthy employee who has not previously experienced excessive strain can easily achieve 100 to 150 crimps per day without their health being adversely affected, the use of a cable crimping tool with motorised drive is recommended for higher numbers of repetitive crimps.

Leading manufacturers now recommend tools that allow work to be carried out much more comfortably with far less physical strain.

The electromechanical crimping tool Klauke Micro with 10.8 V lithium-ion battery, for example, requires a manual force of just two kilograms per crimp.

In other words: the force that needs to be delivered from the hand and forearm is around 90% less than that required for a crimping tool operated purely by hand.

“When we developed our Electromechanical Micro, the aim was to manufacture a cable crimping tool that is easy to use and would allow ergonomic and health-promoting work, thereby combining the benefits of a manual crimping tool with the ease of a cordless one in a single cable tool device”, explains Lutz Remmel, Product Manager at Klauke.

To make the day-to-day tasks of a qualified electrician easier and benefit from the time-saving, the selected crimping tool should cover the broadest range of tasks possible.

The electromechanical tool from Klauke is able to process cable cross-sections from 0.14 to 50sqmm with a cable crimping force of up to 15KN, with a long-term time saving compared to the mechanical crimping tool.

Because, in terms of the system concept, the electromechanical crimper tool is designed to take the interchangeable die sets from Klauke’s 50 series, it is also suitable for crimping various cable types, cable end-sleeves, and also tubular cable lugs, insulated solderless terminals and pin cable lugs.

This not only makes the cable tool a versatile companion for switch cabinet construction, it is also gentle on the installer physicals joints and allows consistently fast operations for numerous other manual, industrial and high voltage cable crimping applications.

The sequence is always the same: first, the manual pre-clamping. When the operating lever is actuated, the crimping jaws of the tool close in order to fix the electrical cable connectors.

During this particular step, the cable lug or connector material can be precisely aligned and positioned. In the second step, the cable crimp is achieved by the force of the motor.

The operating lever simply needs to be depressed fully and the crimping tool automatically starts the crimp process, which takes no more than 1.5 seconds, depending on the material.

Once the cable crimp has been made, the operating lever is released to initiate the return movement, also fully-automatic, into the original position.

Electromechanical Crimping Tool Operation

Electromechanical crimping tools reduce the physical effort, and offer the following advantages: they achieve the best crimping results for minimum force, they also guarantee the consistently high quality of these electrical connection results for years afterwards.

This is because a suitable cable crimping tool in faultless condition (properly maintained) is crucial to avoiding under-crimps and over-crimps. Otherwise, the consequences can be hazardous: incorrectly-made crimps can, for example, increase joint resistance which can in turn cause temperature rises and ultimately trigger cable fires.

When choosing a crimping tool, simple and reliable operability is the key to ensuring safety.

Cable Tools & Costs v Benefits

When Is Investment Returned?

Profitability, of course, is the question posed by any investment. The cost of a branded electromechanical crimping tool is around 180 Euro (?), or more for a manual crimping tool.

Any concerns about the durability and reliability of the electrical variant of crimping tools are unfounded. For its Micro model, for example, Klauke states a long service life if the service intervals are maintained (at 35,000 press or crimp cycles).

The cable crimping tool is equipped with a multi-function LED for maintenance display and data transfer, which can also be used to transfer crimp and tool data to a PC via a USB adapter from the tool accessories range. Test reports showing date and time can readily be created as a PDF for recording completed crimp operations. An effective way of demonstrating a safe and correct working method.

Purely mechanical manual crimping tools do not offer this option of displaying wear and creating documentation.

And also the lithium-ion batteries now used in most cable crimping tools give no cause for technical concern. These energy sources conform to a perfected technical standard that applies today in practically all sectors in which rechargeable batteries are used. Lithium-ion batteries are set apart by short charging times without memory effect and a constant, uniform power output.

DIN 46234

The charging time for the battery installed in the Klauke tool is around 40 minutes. A fully-charged battery, can then achieve some 300 crimps on copper cables with a cross-section of 10sqmm in accordance with DIN 46234. Despite this high efficiency, the total weight of the tool, including the battery, is just 960 grammes.

- DIN 46234 Standard – Terminal Ends For Solderless Connections, Ring Type, Without Insulating Sleeve (Copper Conductors)

Yet a far more important factor for assessing profitability, is sustaining the employee’s physical strength. The cost of sick leave due to carpal tunnel syndrome, which is mentioned at the beginning, tendinitis or tennis elbow, far outweigh those of procuring electromechanical crimping tools in the short-term.

Electromechanical crimping tools are preferred by panel builders for carrying out the termination and connection of LV MV HV cable conductors into electrical control panels.

Conclusion

Electromechanical Crimping Tools

The decision to invest in an electromechanical crimping tool should be made according to economic calculations. For specialist operations in which large numbers of electrical cable connections or cable lugs have to be processed quickly, purchasing such cable tools makes is clear sense.

Electromechanical crimping tools not only increase the efficiency of work processes but also protect the health of employees. Since maintaining good health also means sustaining physical strength, such an added investment can benefit employer and employee in equal measures. Especially in light of demographic change and the shortage of specialists this brings about, physical fitness has become an economically valuable asset which must be sustained for as long as possible.

Contact Thorne & Derrick to discuss the optimum Electromechanical Crimping Tools for your budget, application or to arrange a product demonstration.

Further Reading

Review other Blogs in this series of articles about Cable Lugs, Crimping Cables & Tools:

Cable Lugs – Crimping Applications & Standards

Copper Cable Lugs For Special Applications

Indent Crimping Of Cables – Benefits & Limitations

Cable Lugs & Crimps – Hexagonal v Indent Methods of Crimping

Cable Lugs & Crimping Using The Hexagonal Crimp Method

DIN Standard – Crimping & Compressing Aluminium Cable Lugs & Connectors

Copper & Aluminium – Crimping CU-AL Cables

LV MV HV Cable Accessories & Substation Electrical Equipment

Thorne & Derrick are Specialist Distributors of leading manufacturers of Cable Accessories, Jointing & Installation Equipment.

LV MV HV cable accessories used to joint, terminate, connect, cleat and gland power cables to air and gas insulated substations, transformers, switchgear and overhead line networks.

Hover over our Interactive Electricity Grid to learn more about our product ranges.

LV 600/1000V ◊ MV 11kV 33kV ◊ HV 66kV 132kV

|

|

|

|

|

|

|

|

|

|

Substation & Overhead Line Electrical Safety Equipment

Manufactured by CATU Electrical to enable the safe construction, maintenance and repair of underground cables and overhead lines network up to EHV (400kV).

T&D - CABLES ♦ JOINTS ♦ TERMINATIONS ♦ CONNECTORS ♦ GLANDS ♦ CLEATS ♦ CRIMPS & LUGS ♦ DUCT ♦ SEALS ♦ ARC FLASH PPE

EARTHING ♦ FEEDER PILLARS ♦ JOINTERS TOOLS ♦ CABLE CUTTING & CRIMPING TOOLS ♦ COLD SHRINK ♦ HEAT SHRINK ♦ FUSES

DIN Standard – Crimping & Compressing Aluminium Cable Lugs & Connectors

September 4th, 2018

DIN Standard – Crimping & Compressing Aluminium Cable Lugs & Connectors

-

uploaded by Chris Dodds - Thorne & Derrick Sales & Marketing Manager

Thorne & Derrick International, based in the UK, are leading suppliers of cable crimp lugs and associated crimping tools for Low, Medium & High Voltage Cables and Power Systems – this series of articles by Klauke discusses the theory and practise of installing compression type cable lugs and connectors.

Klauke cable lugs and crimping tools are used by Jointers, Linesmen, Panel Builders and Electrical Engineers to install underground cables and overhead line conductors on power, transmission and distribution networks including LV MV & HV systems, 11kV-33kV.

➡ Download 2018 Klauke Cable Lugs catalogue and see the complete range of tools for cutting and crimping cables.

In this Article we cover the following:

- Hexagonal crimping: the most common type of crimp for cable lugs and connectors

- Indent crimps – the traditional electrical cable crimp profile

- Intensive indent crimping – permanent and “deep acting” connection will be achieved

- Quad point crimps: centric force application and no crimping dies are needed

- Gastight oval crimps are being used predominantly in aggressive environments

Aluminium Cable Lugs & Crimping According To DIN

Best Practise for Installation

Material properties of aluminium cable are very different from those of copper cables and conductors. For safe electrical connections, solely compression cable lugs or connectors manufactured from aluminium are to be used. In addition, due to certain specific material properties the installation procedure has to be carefully observed.

The advantages of aluminium are increasingly coming to the fore in LV MV HV power distribution applications, due to the lower material weight and simple handling.

Power utilities tend to install more and more aluminium cables, for instance medium/high voltage ring main units for urban power supplies.

In principle, it is recommended to use solely high quality aluminium compression cable lugs with tube dimensions according to DIN Standard & DIN 46329 and aluminium connectors with tube dimensions according to DIN 46267 Part 2. Products of renowned cable lug and connector manufacturers such as Klauke are made from premium electrolytic aluminium alloy.

- DIN 46329 Cable Lugs – Compression Connections, Ring Type, For Aluminium Conductors. Standard by Deutsches Institut Fur Normung E.V. (German National Standard), 07/01/1983.

The barrier design with oil stop prevents leakage of oil from the paper insulated conductor.

These cable lugs feature a constant material thickness, exact diameter and a correct fit which ensures simple installation and absolute safety. Standard cross sections range from 10sqmm up to 500sqmm.

Installation of compression cable lugs and connectors for aluminium conductors is very different from installation of copper conductors. Failure of vital installation procedures can lead to a severe lack of safety and power outages.

Special sized cross sections are available up to 1000sqmm, for instance for subsea cables with high transmission capacities in the onshore and offshore wind and renewable energy sectors. Aluminium compression cable lugs feature a barrier design (according to DIN 46239) which allows installation on oil impregnated, paper insulated cables and consequently provides a firm water/oil block.

Aluminium Conductors & Cables

Aluminium conductors are available in four different types which in some cases require special installation procedures. These are as follows – should you require technical guidance, clarification or advice on crimping of aluminium cables and correct cable lugs and relating tools to use please do not hesitate to contact us:

- RE = Solid Round Conductors

- SE = Solid Sector Conductors

- RM = Round Stranded Conductors

- SM = Sector Stranded Conductors

Different types of aluminium conductors

These abbreviations can be found on aluminium compression cable lugs to make sure the correct cable lug is used with the appropriate aluminium conductor.

All markings on aluminium compression cable lugs are in conformity with those on copper cable lugs and indicate the manufacturer, dimensions and type of product.

For example marking “KL 18 10-70 /rm/sm 95 re/se” denotes:

- KL: manufacturer (in this case Klauke)

- 18: die set code

- 10: metric bolt size (bolt M 10)

- • 70: nominal cross section of conductor in sqmm

- rm/sm: for round stranded and sector stranded conductors

- 95: nominal cross section of conductor in sqmm

- RE/SE: for solid round conductors and solid sector conductors

Important: The nominal cross sections of SE and RE conductors are always one cross section size above the cross sections of SM and RM aluminium conductors.

This is due to solid conductors having a smaller diameter than their stranded equivalent type. Special attention should be given to the crimp tool and die set code.

For a professional installation the crimping dies of the appropriate crimping tool must be matched with the code of the cable lugs. Die codes on crimping dies are mirror-inverted – after the crimping operation the die code is clearly visible for quality control and documentation.

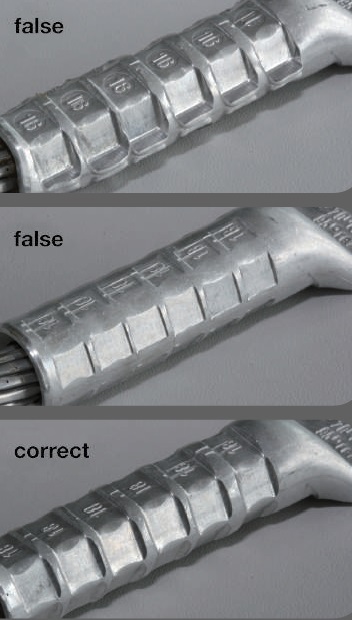

Imprint of die code “18” on the cable lug (above) indicates the crimping die used. Completed crimp (below) with marking “18” on the cable lug refers to the correct crimping die.

For a professional installation hexagonal crimping dies (according to DIN 48083 Part 4) are recommended.

Over compression (above) is the result of a crimping die which is too small, whilst under compression (middle) is caused by the use of a crimping die which is too large. The picture below shows a correct crimp using an appropriate crimping die.

The visible signs of a correctly crimped lug are the same for copper connectors as they are for aluminium.

In order to achieve a professional installation – with no over or under-crimping – the use of the appropriate cable crimping tool is essential.

An incorrect installation can result in increased joint resistance and even in fire.

To avoid such consequences Klauke recommends to use the same manufacturers tool as the lug or connector. This ensures a Matched Crimping System.

For instance the specific dies for aluminium cables have a crimping ‘bite’ width of 7mm, which is 2mm wider than for copper lugs and connectors.

The contact surface (bite width) of crimping dies for aluminium cable lugs (left) are 2 mm wider than their copper equivalent (right).

The reason for this is that wider compression areas result in better conductivity and therefore compensate for the poorer electrical properties of aluminium. In order to determine the different dies required Klauke manufacture the aluminium dies in silver and the copper dies in a yellow gold colour.

Compound for Aluminium Connectors

Cable lugs and connectors for aluminium are supplied with a special compound within the barrel.

Compounds with additives like corundum generate a “grinding effect”.

During crimping, this compound destroys the non-conductive oxide layer on the aluminium in the crimping area increasing the contact properties and ensuring the correct electrical connection. In addition the cable lug compound prevents entry of oxygen and consequently avoids any further oxidation.

The compound seals the joint and prevents oxidation.

To maintain the functional properties brand-name cable lugs are sealed with a plastic plug to prevent the compound from drying out and leaking from the cable lug.

Plastic plugs prevent compound from drying-out and leaking during storage.

Compounds for aluminium connectors contain additives such as corundum, a material similar to sand, which exhibits high resistance and hardness, temperature stabilising properties and extreme wear and corrosion resistance. A grinding effect is generated during crimping which cracks the hard oxide layer on the cable.

In addition, the compound aids the dynamic friction between the cable conductor and sleeve, which prevents jamming of materials and helps to provide a clean contact surface. When used on stranded conductors, the oxide inhibitor compound is distributed between the individual wires or cable strands during the crimping process and seals them against oxygen and moisture ingress.

It is also important to understand that aluminium crimp connections installed using compound perform much better when subjected to high current loads than those without compound.

To guarantee a safe connection, at high or low loads, Klauke recommends compression cable lugs and connectors with compound.

Installation of Aluminium Compression

Cable Lugs & Connectors

In order to accommodate the special characteristics of aluminium material, the following five installation steps are essential:

- Remove insulation of aluminium conductor

- Clean the blank conductor ends with a wire brush to remove an oxid film and to provide a clean surface

- Insert the conductor into the cable lug or connector to the recommended length

- Some compound will emerge from the mouth of the cable lug or connector which is now hermetically sealed to prevent further oxidation of the conductor

- Start the hexagonal crimping operation with a suitable crimping tool

- Important: Sector shaped conductors need to be pre-rounded with appropriate crimping dies

- Remove any excess compound emerging from the lug or connector

Please note: All DIN compression cable lugs show markings on the outside of the lug barrel for the correct crimp position and consequently number of crimps required. This is dependent on if the installer is using narrow or wide crimping dies.

Markings on the cable lugs indicate number and position of crimps as per manufacturers recommendation.

Always crimp in the direction of the conductor.

Start the first crimp at the lug end and progress towards the conductor to ensure that compacted material expands in this direction.

Aluminium & Copper Cable Lugs

A further important technical issue is the correct method of connecting aluminium and copper conductors – contact us for the jointing, connection and splicing of dissimilar conductor cables.

Further Reading

Review other Blogs in this series of articles about Cable Lugs, Crimping Cables & Tools:

Cable Lugs – Crimping Applications & Standards

Copper Cable Lugs For Special Applications

Indent Crimping Of Cables – Benefits & Limitations

Cable Lugs & Crimps – Hexagonal v Indent Methods of Crimping

Cable Lugs & Crimping Using The Hexagonal Crimp Method

Copper & Aluminium – Crimping CU-AL Cables

Electrically Driven Crimping Tools For High Volume Applications

LV MV HV Cable Accessories & Substation Electrical Equipment

Thorne & Derrick are Specialist Distributors of leading manufacturers of Cable Accessories, Jointing & Installation Equipment.

LV MV HV cable accessories used to joint, terminate, connect, cleat and gland power cables to air and gas insulated substations, transformers, switchgear and overhead line networks.

Hover over our Interactive Electricity Grid to learn more about our product ranges.

LV 600/1000V ◊ MV 11kV 33kV ◊ HV 66kV 132kV

|

|

|

|

|

|

|

|

|

|

Substation & Overhead Line Electrical Safety Equipment

Manufactured by CATU Electrical to enable the safe construction, maintenance and repair of underground cables and overhead lines network up to EHV (400kV).

T&D - CABLES ♦ JOINTS ♦ TERMINATIONS ♦ CONNECTORS ♦ GLANDS ♦ CLEATS ♦ CRIMPS & LUGS ♦ DUCT ♦ SEALS ♦ ARC FLASH PPE

EARTHING ♦ FEEDER PILLARS ♦ JOINTERS TOOLS ♦ CABLE CUTTING & CRIMPING TOOLS ♦ COLD SHRINK ♦ HEAT SHRINK ♦ FUSES