Blog

Story Time | The History of Klauke

January 8th, 2024Klauke Crimping & Cutting Tools

Do you know the history of Klauke?

Klauke is a leading manufacturer of cable crimping and cable cutting tools, the company has been in business for over 140 years.

It all began in 1879, when Gustav Klauke and his brother founded the company Gustav Klauke. At that time, the production program included high-quality pliers, primarily in the watchmaker trade.

In 1924, the founder’s sons, Gustav Klauke II and Max Klauke, took over the management of the company.

In 1960, the decision was made to produce cable lugs and corresponding tools. Klauke began to focus on developing tools for the electrical industry. They pioneered the development of manual crimping and cutting tools, which quickly gained popularity due to their high quality and reliability.

The Present Day

Did you also know that the first battery-powered hydraulic tool for connecting material was manufactured in 1994?

In 2014, the Klauke Micro with PowerSense function appeared on the market.

In July 2018, the company was acquired by Emerson and is now part of the “Professional Tools” division. Klauke celebrated its 140th anniversary the following year.

Over the years, Klauke expanded its product range to include hydraulic and battery-powered crimping and cutting tools to meet the growing demand in various industries such as electrical installations, air conditioning and refrigeration, automotive, and telecommunications.

Klauke prides itself on its innovative designs and commitment to manufacturing tools that meet the highest standards of quality and precision. Their tools are designed to be ergonomic, durable, and easy to use, ensuring optimal performance and efficiency.

Let’s take a closer look at their history below:

1924 – 1879

In 1924, the founder’s sons, Gustav Klauke II and Max Klauke, took over the management of the company

1924

The sons of the founder, Gustav Klauke II and Max Klauke, take over the management. The pliers product range is continued.

1912

Hand-forged pilers have been dropped and replaced by forged pliers. Mass production has begun. The company has approx. 60 employees.

1906

The Gustav Klauke company is entered in the Commercial Register as a “General Trading Company”. The factory space covers 1,200 m2.

1879

In 1879, 24-year old Gustav Klauke and his brother found the Gustav Klauke company in Stephanstrasse in the Osterbusch area of Remscheid, Germany with 5 employees. At the time, the product range comprises high-quality pliers, which find a ready market, primarily in the watchmaker trade, due to clean hand forging.

1959 – 1925

1925, the first English language catalogue for the piler range was created

1948

Following the death of Gustav Klauke II, in keeping with old traditions, the company is managed by his son-in-law Gustav Diederichs together with Max Klauke, and is converted into a limited liability company.

1930

The sales market is expanded by translating the catalogues into French and Spanish.

1925

The first English language catalogue for the pliers range appears. From the outset, Klauke goes for high-quality tools for the international markets too.

1979 – 1960

1979 Klauke celebrates 100 years of business

1979

Gustav Klauke GmbH celebrates its centenary in Remscheid.

1978

Karl-Gustav Diederichs becomes sole Managing Director and oversees 85 employees.

1968

The production of traditional pliers is ceased. At the same time, the production of cable lugs and crimping tools is extended.

1965

Gustav Diederichs’ son, Karl-Gustav Diederichs joins the company. There are now 45 employees.

1960

Increasing electrification gives the impetus to the decision to produce cable lugs and corresponding tools.

1990 – 1980

Between 1980-1990 increased their office space and number of employees

1990

To keep up with the steady growth, an adjacent 3,000 m2 piece of land is purchased. Thanks to an existing hall, a further 2,000 m2 production area is added. Klauke now has approx. 160 employees.

1988

The entire company moves into the new premises in Remscheid-Ueberfeld. The production and storage facilities now cover some 9,000 m2.

1984

Production in the new halls is started on an area of over 4,000 m2 .

1980

Covering an area of 6,000 m2 , the original premises on Stephanstrasse are too small for continued company growth. In the Remscheid-Überfeld industrial area, land measuring about 17,000 m2 is acquired for the construction of new production, storage and office space.

1995 – 1991

1994 the first battery-powered hydrau;ic tool for connectig material is manufactured.

1995

Klauke attains ISO 9001 certification for the first time.

1994

The first battery-powered hydraulic tool for connecting material is manufactured. The development and distribution of special products for the sanitary and heating industry starts – accompanied by the first catalogue for this field of application.

1993

Klauke Austria is established in Vienna. In the same year, INDIS, headquartered in Creutzwald, is integrated into the Klauke Group as Klauke France. At the same time, Dr Peters is bought out by Klauke. It produced connecting material and tools.

1991

Following the reunification of Germany, Gustav Klauke GmbH acquires HAW in Saxony, the current Bernsdorf branch covering a total area of 10,000 m².

1999 – 1996

In 1998 Klauke expansion of distribution activities through TEXTRON’s Singapore office

1999

Karl Gustav Diederichs retires. A new product platform for hand-operated and battery-powered hydraulic crimping tools with 6 and 12 tonnes of crimping force is introduced. SAP R/3 is introduced at the Klauke headquarters in Remscheid.

1998

Expansion of distribution activities through TEXTRON’s Singapore office.

1997

Klauke starts marketing Greenlee cable pulling equipment in Europe. Hole-making, punching and cutting tools, as well as cable-pulling products are offered.

1996

Klauke is integrated into Textron , the American multi-industry group of companies. This gives the worldwide presence of Klauke and Greenlee products significant impetus. A new building with a further 5,000 m² of production and office spaces emerges on the neighbouring plot in Remscheid-Ueberfeld acquired in 1990.

2006 – 2000

In 2001, Klauke UK, the sales office for Great Britain and Ireland opened.

2006

Klauke supports the “Electric Brands. Strong Partners” initiative for increasing brand awareness and becomes a member of “E-CHECK”, the test seal for electrical installations and devices. Klauke complements the existing product range with professional tools for commercial and industrial use.

2005

Greenlee products from the testing, measuring and inspection device range are introduced and distributed through Klauke.

2004

The Klauke Group celebrates 125 years in existence in Remscheid with a big party. The Klauke Service Mobile for on-site operations at customer premises is introduced. The vehicle fleet is continuously expanded over the next few years. The activities of Tempo Europe Limited are fully integrated into Klauke.

2003

The newly defined “Klauke Production Principle” is put into practice under LEAN and KAIZEN perspectives. The cooperation with “Voltimum”, the central Internet portal for all information concerning modern electronic installation technology begins.

2002

The Klauke mini, an innovative, light and easy-to-use tool, is produced on a new hydraulic tool platform and introduced onto the market. Together with the geographical expansion, sales of the international plumbing business increases noticeably.

2001

Klauke UK, the sales office for Great Britain and Ireland is opened.

2000

The Klauke multi, the universal tool patented worldwide for crimping, cutting and hole-making is launched onto the market. Expansion of distribution activities through the TEXTRON office in Shanghai.

2012 – 2007

2009 Safety Plus Generation of battery-powered hydrauic crimping, cutting and universal tools are launched on the market

2012

The distribution office in Bangalore (India) is expanded to industrial premises with assembly capacity, Service Centre and warehouse. Development of activities according to the Lean Management Concept for Marketing/Sales and Administration. The innovative “blue connection” system for the standardised crimping of compacted, multi-stranded conductors according to VDE 0295 Class 2 is introduced onto the market.

2010

Klauke receives the FACHMETALL QM Context Award. This is in recognition of the continuously high quality of tested materials.

2009

The battery-powered hydraulic crimping, cutting and universal tools of the Safety Plus Generation are launched on the market. Klauke is certified for the first time according to ISO/TS 16949 (quality management system of the automotive industry) and ISO 14001 (environmental management system).

2008

The Klauke India sales office is opened in Bangalore. Utilux Europe, with sites in Slovakia and Great Britain, is bought out and integrated into the Klauke Group.

2007

The distribution company Klauke Russia is established in Moscow. A new central logistics centre is put into operation in Remscheid.

2016 – 2013

In 2014 Klauke Micro, the world’s first electromechanical crimping tool with PowerSense technology is launched on the market

2016

Internet of Things and Industry 4.0 are trends that Klauke has already taken up with the next generation and is thus setting new standards. The new battery-powered hydraulic tools have a Bluetooth interface for mobile data read-out and tool configuration. Klauke Bernsdorf has been producing high-quality tools for 25 years.

2015

Klauke launches sale of HDE products in EMEA and India. Introduction of the new Klauke mini for the electrical and plumbing trades. The Klauke Ideas Management Scheme celebrates its tenth anniversary and receives an award from the German Institute for Ideas and Innovation Management. Klauke supports the “Ecurie Aix” team from RWTH Aachen University by providing tools and cable lugs.

2014

The Klauke micro, the world’s first electromechanical crimping tool with PowerSense technology is launched on the market. The distribution company Klauke Polska is opened close to Warsaw. Our distribution company Klauke France has been active in the market for 25 years. Gustav Klauke GmbH receives the Bergische Training Award 2014 in the category Of Companies with more than 250 employees.

2013

Klauke Slovakia and Klauke UK introduce SAP. All Klauke companies in Europe are now migrated to SAP. Klauke Iberia, the distribution company for Spain and Portugal is opened in Madrid. Klauke opens a new production facility in China close to the city of Nantong. Greenlee celebrates its 150th anniversary. Klauke Germany and Klauke Slovakia receive an award for occupational safety to commend the low accident rate in recent years.

2019 – 2017

In 2019, Klauke celebrates 140th anniversary

2019

Klauke Remscheid celebrates its 140th anniversary. Unique in the world: In April, the battery-powered hydraulic cutting and crimping tools will be Klauke Orange are presented. These offer protection against electric shock up to 1,000 V.

2018

In May 2018, Klauke India celebrates its 10th anniversary and also moves to new premises. Mid-2018 Klauke Austria also celebrates its 25th anniversary. In July 2018, Gustav Klauke GmbH is acquired by Emerson and is now part of the “Professional Tools” division.

2017

On 4 May 2017, the ceremonial opening of our new production site in Gelnica/Slovakia takes place, so that production is now extended to another location in Slovakia with about 2,000 m². Klauke also opens another hall in the “Auf dem Knapp” industrial estate to expand the logistics area. Klauke Spain moves to its new facilities in Madrid.

2020 – 2023

2023 – Two new Managing Directors of Gustav Klauke GmbH

2023

Marc Vandevelde and Jean-Claude Wetzels become joint Managing Directors of Gustav Klauke GmbH.

2020

Timothy Reeves becomes Managing Director and a one piece flow assembly line is introduced for production at Remscheid. The aim is to achieve faster production, better delivery performance and even higher levels of quality.

Today, Klauke products are used by professionals around the world. Their extensive range includes a wide variety of crimping tools for different applications, such as cable lugs, connectors, and terminals. They also offer cutting tools for cables, pipes, and other materials.

CRIMPING CABLES, LUGS & TOOLS

Thorne & Derrick distribute Cable Lugs & Cable Connectors to terminate, splice and joint LV MV HV cables – this includes copper, aluminium and bi-metallic connectors and a complete range of crimping tools for specific use on all Low, Medium & High Voltage cable types.

➡ Associated Brands & Products | Klauke | Cembre | Pfisterer Sicon | Cable Crimping & Cable Cutting Tools

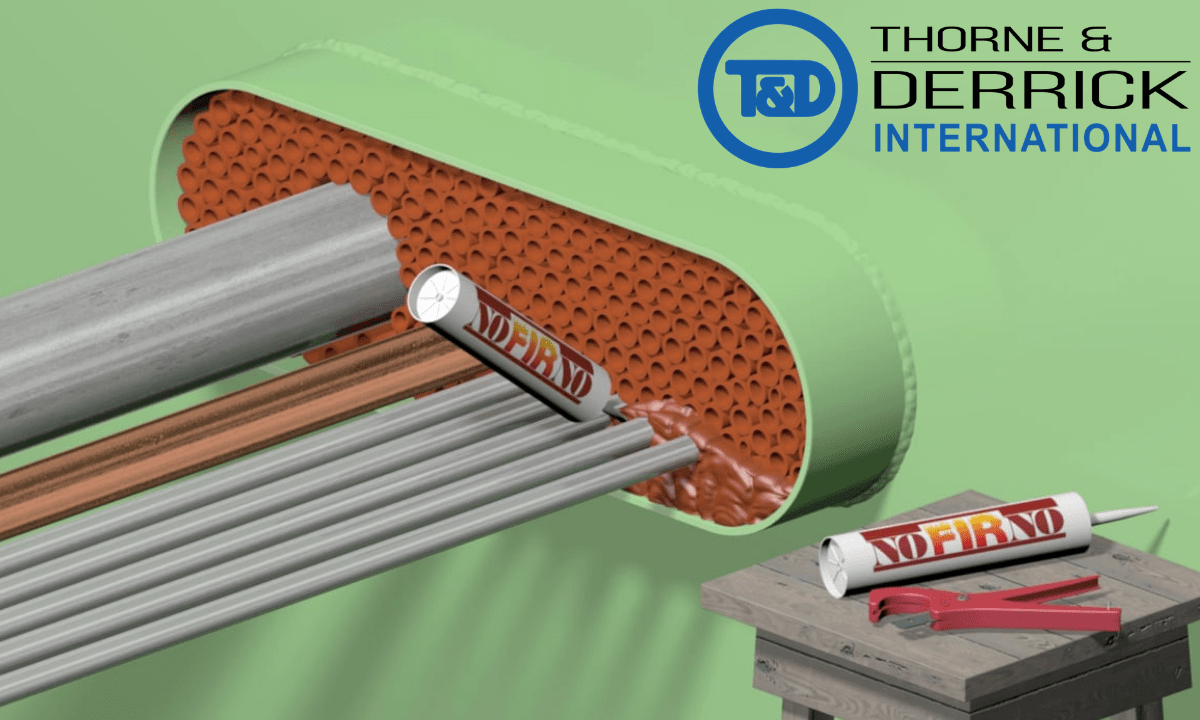

Use of NOFIRNO Duct Sealing Systems in Pump Manufacturing

January 2nd, 2024

NOFIRNO Duct Sealing

Pump Manufacturing Sealing

The CSD NOFIRNO is a Single & Multi Pipe Penetration Sealing System – one of the most adaptive systems for sealing straight and angled pipe penetrations and can even accommodate multiple pipe runs, significantly saving in space and weight.

To help adoptable pumping stations meet the required UK water authority standard, CSD’s NOFIRNO Duct Sealing system ensures that any duct sealing complies with the specifications.

It is included with many design specifications used by pump manufacturers, pump suppliers and installation contractors of adoptable pumping stations.

NOFIRNO Systems

The NOFIRNO Duct Seal system comprises of two components; 60mm rubber NOFIRNO multi-sleeves which provide cable support, ensure cable separation, and provide a backing for the second component, which is a 20mm layer of NOFIRNO Sealant.

Ensuring the NOFIRNO Sealant adheres correctly, the areas where the sealant is to be applied, should be clean and dry before application i.e., the cables and any frames/structures.

The NOFIRNO multi-sleeves are installed which provides cable separation and a firm backing for the NOFIRNO Sealant layer.

Benefits of using Nofirno dUCT SEALS

- Simple and easy to install

- Supported by inspection, design and installation services

- Stops rodents from damaging cables or equipment

Further Reading

- 66kV 72.5kV | Power Cables Accessories for Offshore Windfarms

- Supplying Cable Termination, Jointing, Pull-in & Electrical Equipment up to 66kV

- CSD Marine Grade Cable Transit Sealing System Supplied Onboard Kintra II Passenger Vessel

More Case Studies

- Sealing Cables | Windfarm & Substation Cable Sealing using CSD Systems

- Sealing Cables | 400kV Substation Cable Sealing using CSD Systems

- Sealing Cables | Decarbonisation & Storage Depot Case Study

THORNE & DERRICK are national distributors of LV, MV & HV Cable Installation, Jointing, Duct Sealing, Substation & Electrical Equipment – we service UK and global businesses involved in cable installations, cable jointing, copper earth tapes and substation earthing at LV, 11kV, 33kV and EHV.

Since 1985, T&D have established an international reputation based on SERVICE | INTEGRITY | TRUST.

Contact us for 3M Electrical, ABB, Alroc, AN Wallis, CATU Electrical, Cembre, Centriforce, CMP, CSD, Elastimold, Ellis Patents, Emtelle, Euromold, Filoform , Furse, Lucy Electric & Zodion, Nexans, Pfisterer, Polypipe, Prysmian, Roxtec, Sicame, WT Henley.

Stockists & Suppliers | UK & International Projects

ProGARM 4690 Coveralls | Arc Flash Protection for Rail Trackside & Substation Engineers

January 2nd, 2024

ProGARM | 4690 Coveralls

Progarm 4690

RIS-3279-tom tested arc flash cOVERALLS

ProGARM’S Mission is to Lead with Innovation

Introducing a new addition to the ProGARM range of Arc Flash Clothing – the ProGARM 4690 is a lightweight and comfortable high vis orange coveralls Tested to RIS 3279 Standard to protect workers in the rail industry.

These arc flash coveralls feature the improved lighter and more comfortable fabric.

Features and Benefits of ProGARM 4690 Coveralls

- Arc flash protection and flame resistant fabric

- Mandarin collar // Maximum neck protection

- Kneepad pockets // Wear with kneepacks for extra comfort

- Chest Pockets with zippers // Secure storage

- Gas monitor loop // Secure fixing point

- SafetyICON on arm // Visual EN Standards icon system

- 5cm FR AS Reflective Tape // Double Stitched for longer life

- Phone Pocket on sleeve with flap // Safe and Secure

- Cuff tabs with VELCRO Brand fasteners // Close fit around wrist or gloves

- Side access pockets with flaps // With entry inside coverall

- ThermSAFE plastic FR zippers // CE Certified

- Internal elastic 2 Point adjustable waistband // Ensures close fit

- Double stitched side seams // Lifetime quality assurance

- Easy-Stretch side panels // Maximum wear comfort

RIS-3279-TOM Tested Arc Flash Coveralls (Hi-Vis Orange) | ProGARM 4690

Arc Flash Coveralls 4690

SPECIFICATION

- Sizes: Small Regular leg, Medium Regular leg, Medium Tall leg, Large Regular leg, Large Tall leg, XLarge Regular leg, XLarge Tall leg, 2XLarge Regular leg, 2XLarge Tall leg, 3XLarge Regular leg, 4XLarge Regular leg

- Colour: HI-Viz Orange

- Open ARC Test: ARC 2

- Box Test: 4KA // Class 1

- LOI: Not applicable

- Protection Type: Antistatic // ARC Flash // Heat & Flame // Hi-visibility // Railway

- Fabric: ProGARM VXS + inherent Woven weave // 290

- Industry Sector: Industrial Electrical // Petrochemical // Rail // Utilities & Power protection

- Type: ARC Flash Coveralls

- Collection: Hi-Visibility Orange Collection

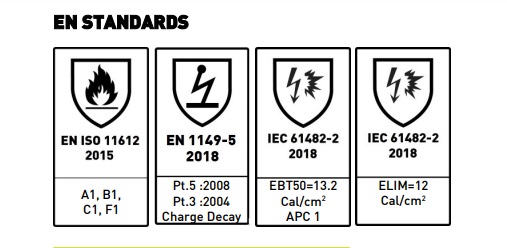

Arc Flash Clothing EN STANDARDS

ProGARM 4690 arc flash coveralls are garment Tested to the following European Standards;

- EN 1149-5:2018: Pt. 5:2008 // Pt.3:2004 // Charge Decay

- EN ISO 11611:2015:Class 1 // A1

- EN ISO 11612:2015: A1 // B1 // C1 // F1

- EN ISO 20471: 2013: Class 3

- IEC 61482-2:2018: APC 1 // ATPV=8 cal/cm² // ARC 2

- RIS 3279 : Issue 1

ProGARM for the Rail Industry | RIS-3279-TOM

What is RIS-3279-TOM?

RIS-3279-TOM (formerly known as GO-RT 3279) is a high visibility standard that only applies to the rail industry in the UK, as opposed to the EU-Wide nature of other EN standards. The aim is to ensure that rail workers on or near the trackside are sufficiently visible to trains approaching at speed or any other traffic.

High visibility clothing is the fundamental principle behind the UK Rail Industry Standard. This is based on the European Norm EN 20471:2013, and garments must comply to Class 2 High Visibility, the middle of a three class range. The standard states the following: ‘high visibility clothing worn by people on the lineside or on or near the line should conform to a single standard for the colour and luminance of background material and that this standard will accord with the detail contained within BS EN 20471:2013 high visibility clothing – Test methods and requirements (ISO 20471:2013).’

cOLOUR rEQUIREMENT sTANDARDS

However It is stated in the standard that: ‘the colour specific requirements within this standard conform to the range specified within BS EN 20471 clause 5.1.2.’ In order to confine this to a specific orange colour, and to prevent the selection of a colour at the red end of the spectrum, the precise chromaticity co-ordinates for the colour are specified as: Fluorescent orange, X:0.588, Y:0.371. with a luminance factor of at least 0.4. The accepted tolerance in colour is as laid out in EN 20471. However, there is no tolerance for the luminance factor.

Also stipulated in RIS-3279-TOM is the need of retro-reflective materials, with photometric and physical performance aligned with EN 20471.

ARC Flash Coverall Range

Mentioned in RIS-3279-TOM is the accepted use of a mini vest where the nature of the work being carried out will not obscure the high visibility clothing, and thus reduce the surface area’ that is visible. The same applies to company logos; these are permitted where they do not compromise the surface area of background colour, and compensation may have to be made for this.

ProGARM 4690 Arc Flash Coveralls

Arc Flash Coveralls, from the ProGARM range of Arc Rated garments and clothing are used to protect against arc flash accidents as the last line of defence. Arc Flash PPE will not prevent incidents, and it is therefore vital that a comprehensive electrical safety plan for maintenance, repair and diagnostic procedures (involving energised LV, MV or HV electrical equipment) is also implemented.

Thorne & Derrick distribute a range of arc flash coveralls to suit a range of requirements. Variations include ladies coveralls, designs for overhead linesmen, orange and yellow hi vis options and a wide range of sizes. Contact Thorne & Derrick with your specific PPE requirements and we will be happy to help.

The ProGARM range of Flame Resistant protective garments are designed for every-day wear and protection – the highly breathable clothing ranges are designed for comfort and safety without compromising the ability of the wearer to work productively, safely and unhampered by cumbersome garments prone to overheating.

Other garments and protection products include Arc Flash Gloves, Arc Clothing, Arc Flash Suits and Arc Flash Helmets & Visors.

💡 Did you know? – While high voltage equipment does increase the likelihood and intensity of arc flash explosions, they can occur in any live electrical environment – even low voltage.

Further Reading

Arc Flash Learning & Resources

Thorne and Derrick are proud to be distributors of ProGARM arc flash coveralls and protection.

We can help – should you require arc flash calculators or advice on the type of clothing and protection available please do not hesitate to contact us.

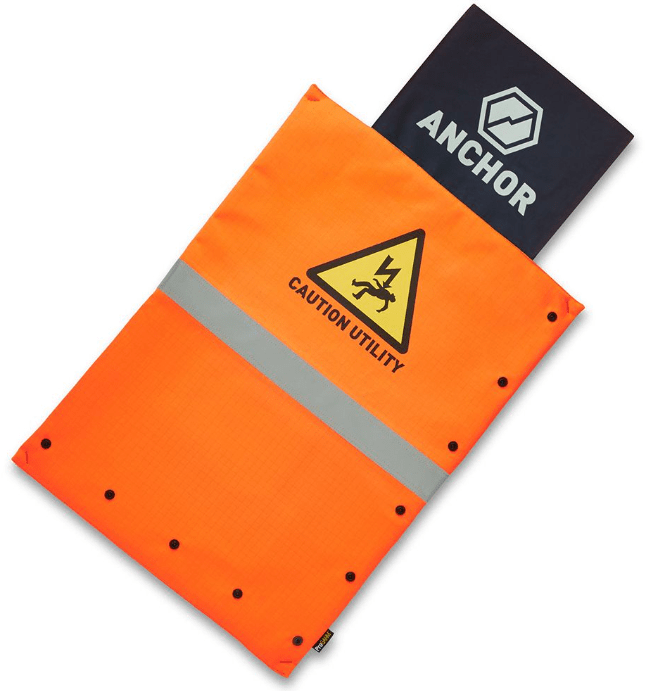

Arc Flash Protection Covers for Worker Protection Against Underground Cable Strikes

January 2nd, 2024

Arc Flash Covers | Protection Against Underground Strikes

2800 Arc Flash Protection

The ProGARM range of protective garments deliver ultimate Arc Flash clothing and protection, conforming with the relevant industry and EN standards ensuring protection from Arc Flash incidents.

The Range of ProGARM 2800 are specially engineered to provide an extra protective layer against the risk of underground cable strikes, whilst at the same time providing an important visual hazard warning for those in the vicinity.

When to use the Arc Flash Covers

The Arc Cover is used as a warning not to dig near a cable and helping prevent the cable being hit, they provide you with additional protection against the risk of underground service strikes during the core activities you carry out on a daily basis.

- When digging near a cable and it is not exposed

- Once a cable is exposed but not damaged to the side of an excavation

- When digging near an exposed cable

- To support the handover for awareness of an exposed cable or when in excavation is in close proximity to a cable

Arc Flash Covers – Features and Benefits

- Two Layer Construction featuring padding

- 50cm FR industrial wash reflective tape

- FR studs for attaching multiple covers

- Includes anchor point to hold cover in place

- Water resistance fabric layer

- Machine Washable

- Size: 68.5cm x 50cm

Arc Flash Protection – EN Standards

Polo Shirts | Jackets | Coveralls | Trousers | Sweatshirts

Arc Flash Learning & Resources

Thorne and Derrick are proud to be distributors of ProGARM arc flash coveralls and protection.

We can help – should you require arc flash calculators or advice on the type of clothing and protection available please do not hesitate to contact us.

Further Reading

- IEC 61482-2 2018 – Get Up To Speed With The New Arc Flash Standard

- Arc Flash Clothing – PPE To Protect Highways, Street Lighting & Utility Contractors

- Arc Gloves | New Arc Flash Dexterity Gloves from Protection Specialists ProGARM

- New Arc Flash Coveralls from Protection Specialists ProGARM

- IEC 61482-2 | Arc Flash Protective Clothing Standards

THORNE & DERRICK

Thorne & Derrick are national distributors of LV, MV & HV Cable Installation, Jointing, Substation & Electrical Equipment – servicing businesses involved in cabling, jointing, substation, earthing, overhead line and electrical construction at LV, 11kV, 33kV, 66kV and EHV. Supplying a complete range of power cable accessories to support the installation and maintenance of low/medium and high voltage power systems:

- Slip-on Cable Terminations

- Cold-shrink Cable Terminations

- Heat-shrink Cable Terminations

- Cable Joints – Heat & Cold-shrink

- Separable Connectors (Euromold)

- Surge Arresters & Switchgear/Transformer Bushings

Key Product Categories: Duct Seals | Cable Cleats | Cable Glands | Electrical Safety | Arc Flash Protection | Cable Jointing Tools | Cable Pulling | Earthing | Feeder Pillars | Cable Joints LV | Joints & Terminations MV

Filoform MD5 Duct Sealing System Vs DIY Expanding Foam

January 2nd, 2024Filoform MD5 Sealing System

vs DIY Expanding Foam

Most UK utilities have banned the use of expanding foam as a measure to effectively seal cable ducts against water ingress, gas migration or fire spread. Failure to correctly and safely seal cable ducts can inflict catastrophic damage to LV MV HV Electrical Distribution Networks, Substations and Power Supply.

Thorne & Derrick International are the UK distributors for Filoform, a leading manufacturer of cable joints, duct seals and special resins for installation in the utilities, telecom, traffic, rail, fibre optic, street lighting and construction industries.

Polyurethane foam (PU) has witnessed a increase in popularity as a construction material due to its versatility. PU can be applied to walls, roofs, ceilings, floors providing insulation and structural support. Technological advancements have overcome engineering challenges, allowing for low-density foam products that are easy to install on-site.

Duct Seals – Sealing Cable Ducts

uSING Filoform MD5 Duct Sealing VS DIY expanding foAM

Whilst expanding foam serves well for sealing small gaps, filling voids, cracks and insulating it falls short beyond these applications. Often comprised of subpar polyurethane, many expanding foams lack the necessary properties for effective sealing or adhesion.

The use of expanding foam in construction and maintenance projects across various industries have grown over time; however it faces major problems when applied wrong, or designed into a project where the foam specifications doesn’t match the requirements of the projects.

Comparing MD5 Duct Sealing Resin to Generic expanding foam

Assessing the particular duct seal scenario and determining the project’s goals are important when selecting an efficient seal. Taking into account elements such as :

- Cable Presence

- Water blocking specifications

- Fire Stop standards

- Building entrance points

- Gas and chemical problems

During the design phase choosing a sealing system that fits the needs of the entire project should be made easier by taking the circumstances into consideration.

Sealing Ducts require precision, a professional would strongly advise against using DIY expanding foam for this purpose due to potential complications. For guidance in your inquiries please contact us today!

| Properties | Generic expanding foam – DIY stores | MD5 Duct Sealing Resin – Two Components |

| Cell Structure | Large, Weak, soft foam – 70% closed | 100% closed, small, strong, durable |

| Expansion Rate | 35 x can volume – Very quick & controlled | 8 x volume – Slow & easy to control |

| Temperature Resistance | +194°F / +90°F | +248°F / +120°F |

| Compressive Strength | 3 Newton / cm² / 0.67 pounds of force | 60 Newtons / 14 pounds of force |

| Resistance to Hydrocarbons | No | Yes |

| Water Resistant | Yes – temporarily | Yes permanently – upto 1.5 bar / psi |

MD5 Sealing System vs DIY Expanding Foam | FILOFORM

hOW TO SELECT A DUCT SEAL SOLUTION

It is important to evaluate specific duct sealing situation and identify the objectives of the seal. For example:

- Is there cables in the duct and how many?

- Does water need to be blocked? How much water?

- Is a firestop needed?

- Does the conduit enter the building?

- Are gases or chemicals a concern?

This process should take place during the design phase aligning the seal requirements with the overall product specifications. Generally, a design specification will encompass gas, water and fire resistance along with specified chemical resistance. However any reputable seal manufacturer should be able to furnish evidence regarding the expected lifespan.

Key to an effective seal

- Training and preparation – read and follow manufacturers instructions. This requires knowledge and skill.

- Sealing system selection – most underground duct sealing systems will need to block water and gases and tolerate hydrocarbons. If the duct enters the building, a fire stop may be required so you need to select a sealing system that addresses the risk present.

- Cable separation – this is a area where most duct seals will fail ; either the product doesn’t support cable separation, or the installer has been unable to separate the cable sufficiently. Without separation, water and gases will simply wick through areas without the sealant.

- Conduit sealing – our range of conduit sealing systems have been designed to provide a simple and effective solution for watertight and gas sealing of pipes and cables in conduits, boreholes and ducts. Conduit sealing systems can be installed horizontally and vertically; they are very flexible.

Key Benefits of using an effective Duct seal

- Allows for low density foam to use

- Used in many places .

- Made of good quality polyurethane foam material

Duct sealing and sealing products manufactured by Filoform are installed to provide gas tight and watertight sealing for cable duct entries – protecting underground cables and substation ducting infrastructure against flood and migration of flammable and toxic gas hazards. Fire resistant version also available – suitable for sealing LV-HV power, telecoms and fibre optic cables.

Filoform manufacture and supply quality products and solutions to connect, seal and protect low, medium and high voltage underground cable networks.

Thorne & Derrick provide competitive prices and fast delivery from stock for the complete range of Filoform duct seals and cable joints.

View the complete range of Filoform products.

FiloSeal+HD Duct Sealing System