Blog

LV Jointer Training – LV3 Course LV Transition Polymeric (Wavecon) to PILC STA Mains Cables

January 29th, 2019

Jointer Training Course Accreditation – EUSR

Cable Jointer Training Courses

LV Transition Polymetric (Wavecon) to PILCSTA

(3 Phase) Mains Cable Jointing Course (LV3)

Jointer Training & Competency Cards

Sustained Skills For Specialist Services

The provision of Jointer Training is a contentious topic in the UK Power Industry – standards are collapsing, craftmanship is devalued, pockets are hurting and an illusion clouds the market that some Trainers can wave a magic wand and create the perfect Jointer in 4 days.

OK, it’s not quite the Wild West but as a UK leading distributor of Jointing Equipment at Thorne & Derrick we hold a duty of responsibility to support the safe and reliable installation of these products by promoting excellent standards of workmanship.

Accredited training courses can protect power and people against the danger of fatal Volts.

LV3 Course

This Jointer Training Course is written by and delivered on behalf of EUSKILLS. This organisation is an awarding body which works extensively with Distribution Network Operators and their associates.

EUSkills and partners have ascertained the correct level of training provision and agreed the standard across the Cable Jointing Industry.

Successful trainees receive Competence Cards detailing their skill set directly from EUSKILLS upon completion of the course. Backing from EUSkills gives clients confidence that their jointers will be trained up to the perfect standards as agreed across the board.

Delivered In Partnership With Energy Utility Skills

EUSKILLS mission is to make excellence the standard through trusted partnerships and ensure that the UK Utility Industry develops and retains a sustainable skilled workforce now and in the future – they are a provider of choice for employer solutions and registering and assessing competency standards within the energy, gas, waste management and water networks industries.

Training Course Duration 5 days

This Jointer Training course will enable a Jointer to confidently carry out a range of live low voltage electrical cable jointing procedures on underground cables in accordance with company procedures and to demonstrate a safety conscious approach to the control of hazards associated with the activity whilst working and communicating effectively with other team member to achieve tasks.

This course is designed to give existing jointers the, knowledge and understanding to fulfil the role as a Cable Jointer and to be able to make both transition straight and breeches joints using paper insulated lead covered steel tape armoured cables and subsequent electrical tests in a safe manner.

Jointer Training Course Aims

On successful completion of this course, delegates will be able to demonstrate and understand:

- Correct and safe working practices and procedures

- Correct use of PPE and specialist tools and equipment

- The installation of three phase PILCSTA cable transition straight and breeches joints and mains pot-ends

- Test procedures relevant to LV Jointing

Jointer Training Course Content

The course includes the following:

- Review jointing practices and procedures.

- Review Health, Safety and Environment legislation in relation to electrical cable jointing.

- Electrical theory

- PPE and specialist tools and equipment.

- Understanding the role and responsibilities of the relevant person/s involved in the control of jointing procedures and the associated safety documentation and procedures.

- Awareness of the health and safety risks of the work environment

- Identification of underground cable and apparatus

- Understanding of manufacturers specifications

- Electrical testing of the cable to confirm its integrity, including insulation and continuity testing and protection from the ingress of moisture and mechanical damage

The Jointer Training course will enable a Cable Jointer to:

- Confidently carry out a range of live LV electrical cable jointing procedures on underground cables

- Work in accordance with company procedures

- Demonstrate a safety conscious approach to the control of associated hazards

- Work & communicate effectively with other team member to achieve tasks

Practical Work

- Prepare and carry out a transition main straight joint – wavecon cable to PILCSTA three-phase cable

- Prepare and carry out a transition main straight joint with crossed cores – wavecon cable to PILCSTA three phase cable

- Prepare and carry out a transition main breeches joint – wavecon cable to PILCSTA three phase cable

- Prepare and carry out mains pot-end PILCSTA mains cable three phase

Cable Jointer Training Courses – CONTACT US FOR FURTHER INFORMATION

More LV Jointer Training Courses:

Cable Jointers Assessment

The courses offered by Pragmatic Consulting are Jointer Training training assessments and not industry authorisations. Therefore, after the successful completion of the course and assessment the delegate will then need to complete a period of supervised work experience, before returning with his/her portfolio and undertake a formal cable jointing skills and knowledge assessment.

On successful completion of their assessment each candidate will then be eligible to have their achieved competence modules registered on the Energy and Utility Skills Register (EUSR) for acceptance as a level of competence by member Companies of the industries Competency Accord scheme.

This is done to preserve trade integrity and protect employers against under-skilled labour causing reputational damage to their industry.

Certificates

After successful completion of the Jointer Training course assessments and portfolio an EUSR Card will be issued.

Jointer Training Course Duration 5 days

Accreditation – EUSR Competency Accord Power Unit 060 – LV3

Pre-Requisites

This 5 day course is designed for existing jointers who have experience of Wavecon jointing and/or have completed Pragmatic Consulting Training’s LV2 jointing course and has or is in the process of taking a suitable electrical qualification i.e. C&G 2339 or equivalent.

Delegates to be assessed as competent in this skill area should have completed the modules shown below or have evidence demonstrating an equivalent level of competence.

- SHEA Power – providing basic health, safety and environmental awareness and an introduction to specific health, safety and environmental factors relating to the power sector

- Access, Movement and Egress (Underground Cables) – an industry assessment of a person’s competence to enter, move around and exit an underground cable work area in a safe manner

- Location and Avoidance of Utilities – an industry assessment of a person’s competence to identify and locate utilities using electronic location equipment

- Safe Excavation of Utilities – an industry assessment of a person’s competence to safely excavate and maintain excavations.

Maximum Delegates: 8

Seaton Power Solutions work in partnership with training provider Pragmatic Consulting to meet the needs of the Utilities Industry.

With accredited courses in Construction, Water, Electrics, Health & Safety and specialised training for National Grid; clients are able to to fulfil their business opportunities with a properly qualified workforce.

Medium & High Voltage Jointer Training 11kV 33kV 66kV

Thorne & Derrick can support directly your MV HV Jointer Training requirements working in close partnership with UK Centres including Pfisterer CONNEX and Nexans Euromold – these training courses provide successful Jointers with Competency Certification issued by the manufacturer to cover the installation of their ranges of cable joints, terminations and connectors up to 66kV.

Medium & High Voltages | Nexans Training | Pfisterer Training

LV Cable Joints (Low Voltage Cables)

Thorne & Derrick stock and distribute LV Joints in Cold Shrink, Heat Shrink or Resin Cast technologies – multicore and multi-pair cable joints are available for immediate backfill and energisation of Low Voltage power, control and instrumentation cables 600V/1000V 3.3kV.

Complete range of LV Cable Accessories ➡

Cable Breakouts | Cable Caps | Cable Lugs | Cable Cleats | Cable Trough | Cable Duct | Feeder Pillars | for 11kV/33kV/66kV networks see MV HV Joints & Terminations

Pfisterer | Nexans Euromold | Prysmian | Cable Joints & Terminations MV HV

Cold Shrink by 3M | Joints | Abandonment | Terminations | Low Voltage LV Cables

LV Jointer Training – LV2 Course LV Polymeric (Wavecon) Mains Cable 3 Phase Cable Jointing

January 29th, 2019

Jointer Training Course Accreditation – EUSR

Cable Jointer Training Courses

LV Polymeric (Wavecon) Mains Cable

3 Phase Cable Jointing Course (LV2)

Jointer Training & Competency Cards

Sustained Skills For Specialist Services

The provision of Jointer Training is a contentious topic in the UK Power Industry – standards are collapsing, craftmanship is devalued, pockets are hurting and an illusion clouds the market that some Trainers can wave a magic wand and create the perfect Jointer in 4 days.

OK, it’s not quite the Wild West but as a UK leading distributor of Jointing Equipment at Thorne & Derrick we hold a duty of responsibility to support the safe and reliable installation of these products by promoting excellent standards of workmanship.

Accredited training courses can protect power and people against the danger of fatal Volts.

LV2 Course

This Jointer Training Course is written by and delivered on behalf of EUSKILLS.

This organisation is an awarding body which works extensively with Distribution Network Operators and their associates.

EUSkills and partners have ascertained the correct level of training provision and agreed the standard across the Cable Jointing Industry.

Successful trainees receive Competence Cards detailing their skill set directly from EUSKILLS upon completion of the course. Backing from EUSkills gives clients confidence that their jointers will be trained up to the perfect standards as agreed across the board.

Delivered In Partnership With Energy Utility Skills

EUSKILLS mission is to make excellence the standard through trusted partnerships and ensure that the UK Utility Industry develops and retains a sustainable skilled workforce now and in the future – they are a provider of choice for employer solutions and registering and assessing competency standards within the energy, gas, waste management and water networks industries.

Training Course Duration 5 days

This Jointer Training course will enable a Jointer to confidently carry out a range of live low voltage electrical cable jointing procedures on underground cables in accordance with company procedures and to demonstrate a safety conscious approach to the control of hazards associated with the activity whilst working and communicating effectively with other team member to achieve tasks.

The course is designed to enable the delegate make Wavecon main straight and Breeches joints with both straight and crossed cores, make Wavecon pot ends with services and terminate a Wavecon cable into a pillar or cut-out, and subsequent electrical tests in a safe manner.

Jointer Training Course Aims

On successful completion of this course, delegates will be able to demonstrate and understand:

- Correct and safe working practices and procedures

- Correct use of PPE and specialist tools and equipment

- The installation of three phase wavecon mains straight and breeches joints and mains pot ends

- Terminating wavecon into a pillar or cut-out

- Test procedures relevant to LV Jointing

Jointer Training Course Content

The course includes the following:

- Review jointing practices and procedures

- Review Health, Safety and Environment legislation in relation to electrical cable jointing.

- Electrical theory

- PPE and specialist tools and equipment

- Understanding the role and responsibilities of the relevant person/s involved in the control of jointing procedures and the associated safety documentation and procedures

- Awareness of the health and safety risks of the work environment

- Identification of underground cable and apparatus

- Understanding of manufacturers specifications

- Electrical testing of the cable to confirm its integrity, including insulation and continuity testing and protection from the ingress of moisture and mechanical damage

- Practical Work:

The Jointer Training course will enable a Cable Jointer to:

- Confidently carry out a range of live LV electrical cable jointing procedures on underground cables

- Work in accordance with company procedures

- Demonstrate a safety conscious approach to the control of associated hazards

- Work & communicate effectively with other team member to achieve tasks

Practical Work

- Prepare and carry out wavecon mains straight joints – straight core

- Prepare and carry out wavecon mains straight joints – crossed core

- Prepare and carry out wavecon breeches joints

- Prepare and carry out a wavecon mains cable pot end including a single phase service connection

- Prepare and carry out a cut-out or pillar termination on wavecon mains cable

Cable Jointer Training Courses – CONTACT US FOR FURTHER INFORMATION

More LV Jointer Training Courses:

- LV Jointer Training – LV1 Course Introduction to LV Cable Jointing (Wavecon) – Single & 3 Phase Services

- LV Jointer Training – LV3 Course LV Transition Polymeric (Wavecon) to PILC STA Mains Cables

Cable Jointers Assessment

After the successful completion of the Jointer Trainingcourse and assessment the delegate will then need to complete a period of supervised work experience, before returning with his/her portfolio to undertake a formal cable jointing skills and knowledge assessment. The courses offered are trainee assessments, not industry authorisations.

On successful completion of their assessment each candidate will then be eligible to have their achieved competence modules registered on the Energy and Utility Skills Register (EUSR) for acceptance as a level of competence by member Companies of the industries Competency Accord scheme.

This is done to preserve trade integrity and protect employers against under-skilled labour causing reputational damage to their industry.

Certificates

After successful completion of the Jointer Training course assessments and portfolio an EUSR Card will be issued.

Jointer Training Course Duration 5 days

Accreditation – EUSR Competency Accord Power Unit 060 – LV2

Pre-Requisites

This 5 day course is aimed at existing crafts persons and jointers mates who have previous electrical qualification or in the process of taking a suitable electrical qualification i.e. C&G 2339.

Delegates should have previous jointing experience e.g. LV1 and have taken or be in the process of taking a suitable electrical qualification i.e. C&G 2339

Delegates to be assessed as competent in this skill area should have completed the modules shown below or have evidence demonstrating an equivalent level of competence.

- SHEA Power – providing basic health, safety and environmental awareness and an introduction to specific health, safety and environmental factors relating to the power sector

- Access, Movement and Egress (Underground Cables) – an industry assessment of a person’s competence to enter, move around and exit an underground cable work area in a safe manner

- Location and Avoidance of Utilities – an industry assessment of a person’s competence to identify and locate utilities using electronic location equipment

- Safe Excavation of Utilities – an industry assessment of a person’s competence to safely excavate and maintain excavations.

Maximum Delegates: 8

Seaton Power Solutions work in partnership with training provider Pragmatic Consulting to meet the needs of the Utilities Industry.

With accredited courses in Construction, Water, Electrics, Health & Safety and specialised training for National Grid; clients are able to to fulfil their business opportunities with a properly qualified workforce.

Medium & High Voltage Jointer Training 11kV 33kV 66kV

Thorne & Derrick can support directly your MV HV Jointer Training requirements working in close partnership with UK Centres including Pfisterer CONNEX and Nexans Euromold – these training courses provide successful Jointers with Competency Certification issued by the manufacturer to cover the installation of their ranges of cable joints, terminations and connectors up to 66kV.

Medium & High Voltages | Nexans Training | Pfisterer Training

LV Cable Joints (Low Voltage Cables)

Thorne & Derrick stock and distribute LV Joints in Cold Shrink, Heat Shrink or Resin Cast technologies – multicore and multi-pair cable joints are available for immediate backfill and energisation of Low Voltage power, control and instrumentation cables 600V/1000V 3.3kV.

Complete range of LV Cable Accessories ➡

Cable Breakouts | Cable Caps | Cable Lugs | Cable Cleats | Cable Trough | Cable Duct | Feeder Pillars | for 11kV/33kV/66kV networks see MV HV Joints & Terminations

Pfisterer | Nexans Euromold | Prysmian | Cable Joints & Terminations MV HV

Cold Shrink by 3M | Joints | Abandonment | Terminations | Low Voltage LV Cables

A60 H120 Pipework Fire Protection For Offshore Bulkheads & Decks

January 29th, 2019

A60 Sealing

-

uploaded by - Chris Dodds Thorne & Derrick Sales & Marketing Manager

NOFIRNO

Sealing Cables & Pipes Offshore

A flexible pipe penetration sealing system, using NOFIRNO, for single or multiple metallic and GRP pipe applications, providing fire protection in A60 to H120 and uninsulated A0 and H0 bulkheads and decks. The NOFIRNO sealing system will reduce vibration, stress and cathodic corrosion and is age tested to prove 50 years of cable and pipe sealing protection.

NOFIRNO is also proven to provide a blast rating and fire protection during a 2 hour jet fire test and will ensure watertight integrity even after exposure to a 1 hour (A60) fire.

NOFIRNO Flexible Pipe Sealing System is one of the most adaptive systems for sealing straight and angled pipe penetrations and can even accommodate multiple pipe runs. The system is  designed to maintain the safety of vessels providing fire protection and ensuring bulkheads and decks remain gas and watertight when pipes need to pass through them. It consists of only two components: NOFIRNO sealant; a silicone based fire resistant, water repellent sealant and NOFIRNO multi-filler sleeves, supplied in bonded strips to make the system easy to install.

designed to maintain the safety of vessels providing fire protection and ensuring bulkheads and decks remain gas and watertight when pipes need to pass through them. It consists of only two components: NOFIRNO sealant; a silicone based fire resistant, water repellent sealant and NOFIRNO multi-filler sleeves, supplied in bonded strips to make the system easy to install.

NOFIRNO – A Brand of CSD Sealing Systems | Distributed by Thorne & Derrick

A60 H120 Fire Resistance

Some Technical Guidance

The NOFIRNO system from CSD Sealing Systems is tested against fire resistance to both A (A60) and H (H120) Classification – the temperature regime in the furnace during an A-Class fire is similar to that of a cellulose fire and during an H-Class fire similar to that of an oil fire. In a H-Class fire the increase in temperature is much faster than that of an A-Class fire. The cable penetration must be tested both Vertically and Horizontally in order to be approved for general usage by the leading certifying authorities.

Fire Protection Integrity

The integrity of the cable penetration must be maintained throughout the test period (A60 A-Class 60 Minutes, H120 H-Class 120 Minutes) – the occurrence of flaming on the unexposed face or ignition of a cotton wool pad applied to any gap or fissure that appears in the test specimen constitutes a loss of integrity.

Insulation

The limit of temperature increase on the non fire side of the penetration is stipulated in EN 1366-3 or IMO A754(18). The maximum acceptable temperature increase at any point on the penetration during the test is 180 °C. An approved fire test gives the penetration a classification where the fire is specified (A-H-Class Fire) and the time for which the penetration was able to resist the fire in respect of the maximum allowed temperature increase on the non fire side of the penetration (180°C).

For example, a penetration that withstands an H-Class fire for 120 minutes is classed as H120 and a penetration that withstands an A-Class fire for 60 minutes is classed A60.

Fire Classes

If the 180 °C temperature increase is not exceeded during the stipulated time the penetration is approved and can be classified.

* A0 and H0 relates to no temperature restriction on the non-fire side. H0-400 °C relates to a restriction of 400°C maximum temperature increase on the non-fire side. A0-H0 and H0-400 °C must also meet the division integrity requirements, not allowing cracks or opening to develop through which flames or hot gasses can pass.

| Class | Fire Test Requirements Attained | |

| Integrity (minutes) | Insulation (minutes) | |

| A0 | 60 | 0* |

| A15 | 60 | 15 |

| A30 | 60 | 30 |

| A60 | 60 | 60 |

| H0 | 120 | 0* |

| H0-400 C | 120 | 120* |

| H60 | 120 | 60 |

| H120 | 120 | 120 |

| JET | ||

| J15 | 60 | 15 |

| J30 | 60 | 30 |

| J45 | 60 | 45 |

| J60 | 60 | 60 |

A60 & H120 Fire Rating

NOFIRNO is for A0 – A60, H0 – H120, Jet Fire, Blast, Watertight & Gastight ratings:

• Simplified design through standardisation of all bulkhead penetrations and a significant reduction in components

• Allows design changes without the need for additional hotwork

• Space reduction

• Faster installation

• Allows for misalignment of pipe work due to build tolerances

• Significant reduction in number of pipe spools

• Vibration stress and cathodic corrosion reduced increasing the life of pipe systems and reducing the failure rate

• Easy replacement of pipe systems

• Vibration & noise reduction – reducing noise signature

• Significant weight saving over bulkhead fittings making more energy efficient

Jet Fire Testing

➡ NOFIRNO – Jet Fire Testing For Cable Duct & Pipe Penetration Sealing Systems

Fire Performance A60

• Certified for use in A60 boundaries (A60 – min length 180mm), tested & approved without any insulation for A0 applications, (A0 – min length 250mm)

• Proven watertight even after A60 fire test

• 2 hour hydrocarbon fire test – both with and without insulation, rated H0 and H120

• 2 hour Jet Fire test – with no additional insulation

• Shock tested to 850g to DEF STAN 08-120 including post test pressure test to 6.9 bar

• Blast rated sealing system

• Low Smoke and Toxicity – DEF STAN 02-711 and DEF STAN 02-713

NOFIRNO is for A0 – A60, H0 – H120, Jet Fire, Blast, Watertight & Gastight Ratings. INSTALLATION GUIDE.

NOFIRNO

Some further benefits of the sealing system include:

• Ensuring ATEX, DSEAR & WIMES compliance

• Age tested to prove 50 years of sealing protection

• Quick and easy to install in both horizontal and vertical cable ducts

• Easy re-entry for adding, removing or replacing cables LV MV HV

• Installed in any sized or shaped opening, penetration or duct

• Resistant to submersion in petrol and diesel

• Resistant to methane, hydrogen sulphide and chlorine

• Suitable for trefoil and large diameter 11kV/33kV power cables

• Prevents rat and rodent ingress into low, medium and high voltage substations

➡ Read More: NOFIRNO – Sealing Systems Explosive Environment Sealing Systems For Hazardous Areas (ATEX Directive) Sealing Systems

➡ Contact Thorne & Derrick to discuss the NOFIRNO Duct Seal System – 0191 4104292.

Sealing Pipes, Cables & Ducts Using NORFIRNO

Watertight & Gastight Sealing For Building Entries & Cable Duct Terminations

A simple and long term solution designed for sealing cable ducts and building entries against ingress of water, gas or flooding – the NOFIRNO system is used extensively across the utilities and construction sectors to protect LV MV HV electrical substations, equipment rooms and cabinets, wind turbines and critical infrastructure.

Some site installation photographs of NOFIRNO ➡

Marine & Offshore Power

Cable Accessories

THORNE & DERRICK are international distributors of LV, MV & HV Offshore & Marine Cable Installation, Jointing, Substation, Earthing & Electrical Equipment – we supply Joints, Glands, Cleats & Cable Accessories specified for use in harsh and hazardous areas to support the installation of marine and offshore power cables.

Since 1985, T&D have established an international reputation based on SERVICE | INTEGRITY | TRUST.

DNV

DNV is a rigorous approval system for cable accessories including joints, glands and cleats – the DNV approval process assesses all of the evidence offered by the manufacturer and compares it to the requirements of the international standard, IEC61914. Once full compliance is proven DNV Type Approval is offered.

Cable Joints

DNV Approved

Hydrocarbon Resistant | Zero Halogen & Fire Resistant

Cable Glands

Hazardous Area Explosion Proof | Zero Halogen

Cable Cleats

Zero Halogen | Fire Resistant | Stainless Steel

Also ➡ Cable Labels, Cable Ties, Cable Transits and Cold Shrink

Contact Thorne & Derrick for further information and customer service – extensive range of DNV Approved Marine & Offshore Cables & Cable Accessories available for delivery to UK and international projects.

LV MV HV – 3.3kV 6.6kV 11kV 33kV

More IEC Offshore & Marine Cables

T&D ⇒ CABLE ♦ JOINT ♦ TERMINATE ♦ CONNECT ♦ GLAND ♦ CLEAT ♦ CRIMP ♦ DUCT ♦ SEAL ♦ REPAIR

Invitation

Thorne & Derrick invite you to join LinkedIn’s largest LV-HV Electrical Discussion Group : Low & High Voltage Power, Cabling, Jointing & Electricals. Discussion subjects include cable installations, cable jointing, substation, overhead line and electrical construction at MV, HV, 11kV, 33kV and EHV. Network, engage and promote your profile, company or products with over 10,000 influencers.

LV Jointer Training – LV1 Course Introduction to LV Cable Jointing (Wavecon) – Single & 3 Phase Services

January 29th, 2019

Jointer Training Course Accreditation – EUSR

Cable Jointer Training Courses

Introduction to Low Voltage Cable (Wavecon) Jointing

Single & Triple Phase Cable Jointing Services (LV1)

Jointer Training & Competency Cards

Sustained Skills For Specialist Services

The provision of Jointer Training is a contentious topic in the UK Power Industry – standards are collapsing, craftmanship is devalued, pockets are hurting and an illusion clouds the market that some Trainers can wave a magic wand and create the perfect Jointer in 4 days.

OK, it’s not quite the Wild West but as a UK leading distributor of Jointing Equipment at Thorne & Derrick we hold a duty of responsibility to support the safe and reliable installation of these products by promoting excellent standards of workmanship.

Accredited training courses can protect power and people against the danger of fatal Volts.

LV1 Course

This Jointer Training Course is written by and delivered on behalf of EUSKILLS. This organisation is an awarding body which works extensively with Distribution Network Operators and their associates.

EUSkills and partners have ascertained the correct level of training provision and agreed the standard across the Cable Jointing Industry.

Successful trainees receive Competence Cards detailing their skill set directly from EUSKILLS upon completion of the course. Backing from EUSkills gives clients confidence that their jointers will be trained up to the perfect standards as agreed across the board.

Delivered In Partnership With Energy Utility Skills

EUSKILLS mission is to make excellence the standard through trusted partnerships and ensure that the UK Utility Industry develops and retains a sustainable skilled workforce now and in the future – they are a provider of choice for employer solutions and registering and assessing competency standards within the energy, gas, waste management and water networks industries.

Training Course Duration 5 days

This Jointer Training course is designed to give new jointers who may have limited experience; the knowledge and understanding to fulfil the role as a Low Voltage Service Cable Jointer. Technicians will learn to create single and triple phase sub-service cable joints using Wavecon Cables and to make both single and three phase service joints onto a Wavecon main cable in a safe manner.

Jointer Training Course Aims

On successful completion of this course, trainees will be able to demonstrate and understand:

- Correct and safe working practices and procedures

- Correct use of PPE and specialist tools and equipment

- The installation of single phase and three phase cut-outs

- The installation of single and three phase sub-service straight joints using live working methods

- The installation of single and three phase service joints using live working methods onto a Wavecon main using mechanical connectors

- Test procedures relevant to LV Jointing

Jointer Training Course Content

The course includes the following:

- Jointing practices and procedures.

- Health, Safety and Environment legislation in relation to electrical cable jointing.

- Electrical theory

- PPE and specialist tools and equipment.

- Understanding the role and responsibilities of the relevant person/s involved in the control of jointing procedures and the associated safety documentation and procedures.

- Awareness of the health and safety risks of the work environment

- Identification of underground cable and apparatus

- Understanding of manufacturers specifications

- Electrical testing of the cable to confirm its integrity, including insulation and continuity testing and protection from the ingress of moisture and mechanical damage

The Jointer Training course will enable a Cable Jointer to:

- Confidently carry out a range of live LV electrical cable jointing procedures on underground cables

- Work in accordance with company procedures

- Demonstrate a safety conscious approach to the control of associated hazards

- Work & communicate effectively with other team member to achieve tasks

Practical Work

- Prepare and carry out single phase cut-out

- Prepare and carry out single phase sub-service pot end

- Prepare and carry out single phase sub-service straight joint

- Prepare and carry out single phase service joint on to three phase Wavecon mains

Cable Jointer Training Courses – CONTACT US FOR FURTHER INFORMATION

More LV Jointer Training Courses:

Cable Jointers Assessment

After the successful completion of the Jointer Training course and assessment the delegate will then need to complete a period of supervised work experience, before returning with his/her portfolio to undertake a formal cable jointing skills and knowledge assessment. The courses offered are trainee assessments, not industry authorisations.

On successful completion of their assessment each candidate will then be eligible to have their achieved competence modules registered on the Energy and Utility Skills Register (EUSR) for acceptance as a level of competence by member Companies of the industries Competency Accord scheme.

This is done to preserve trade integrity and protect employers against under-skilled labour causing reputational damage to their industry.

Certificates

After successful completion of the Jointer Training course assessments and portfolio an EUSR Card will be issued.

Jointer Training Course Duration 5 days

Accreditation – EUSR Competency Accord Power Unit 060 – LV1

Pre-Requisites

This 5 day course is aimed at an existing Crafts Person or Cable Jointers Mate who has a previous electrical qualification or is in the process of taking a suitable electrical qualification i.e. C&G 2339.

Delegates are not required to have any previous jointing experience but would benefit from prior electrical knowledge and numeracy experience to enable them to successfully complete the course.

Delegates to be assessed as competent in this skill area should have completed the modules shown below or have evidence demonstrating an equivalent level of competence.

- SHEA Power – providing basic health, safety and environmental awareness and an introduction to specific health, safety and environmental factors relating to the power sector

- Access, Movement and Egress (Underground Cables) – an industry assessment of a person’s competence to enter, move around and exit an underground cable work area in a safe manner

- Location and Avoidance of Utilities – an industry assessment of a person’s competence to identify and locate utilities using electronic location equipment

- Safe Excavation of Utilities – an industry assessment of a person’s competence to safely excavate and maintain excavations.

Maximum Delegates 8

Seaton Power Solutions work in partnership with training provider Pragmatic Consulting to meet the needs of the Utilities Industry.

With accredited courses in Construction, Water, Electrics, Health & Safety and specialised training for National Grid; clients are able to to fulfil their business opportunities with a properly qualified workforce.

Medium & High Voltage Jointer Training 11kV 33kV 66kV

Thorne & Derrick can support directly your MV HV Jointer Training requirements working in close partnership with UK Centres including Pfisterer CONNEX and Nexans Euromold – these training courses provide successful Jointers with Competency Certification issued by the manufacturer to cover the installation of their ranges of cable joints, terminations and connectors up to 66kV.

Medium & High Voltages | Nexans Training | Pfisterer Training

LV Cable Joints (Low Voltage Cables)

Thorne & Derrick stock and distribute LV Joints in Cold Shrink, Heat Shrink or Resin Cast technologies – multicore and multi-pair cable joints are available for immediate backfill and energisation of Low Voltage power, control and instrumentation cables 600V/1000V 3.3kV.

Complete range of LV Cable Accessories ➡

Cable Breakouts | Cable Caps | Cable Lugs | Cable Cleats | Cable Trough | Cable Duct | Feeder Pillars | for 11kV/33kV/66kV networks see MV HV Joints & Terminations

Pfisterer | Nexans Euromold | Prysmian | Cable Joints & Terminations MV HV

Cold Shrink by 3M | Joints | Abandonment | Terminations | Low Voltage LV Cables

NOFIRNO – Sealing Systems

January 29th, 2019

NOFIRNO – A Brand of CSD Sealing Systems | Distributed by Thorne & Derrick

-

uploaded by Chris Dodds - Thorne & Derrick Sales & Marketing Manager

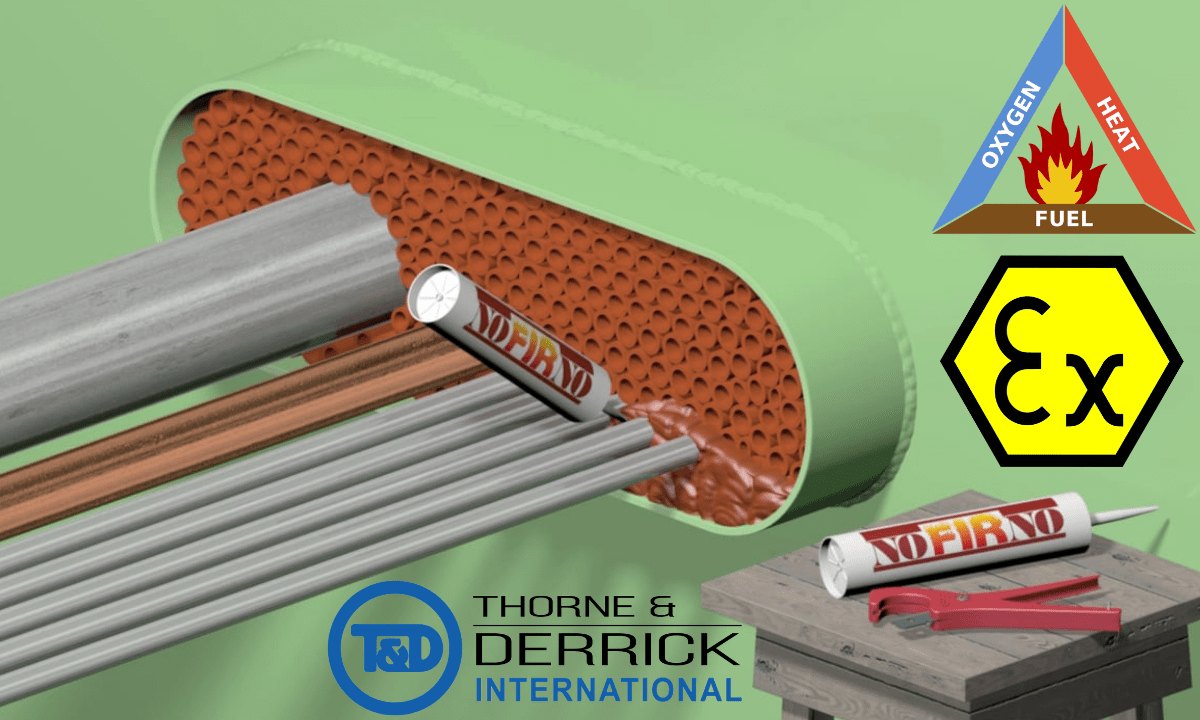

Explosive Environment Sealing Systems For Hazardous Areas (ATEX Directive)

Sealing systems for cables and pipes are used in a diverse range of industry sectors including hazardous area locations and potentially explosive atmosphere applications in the onshore and offshore oil and gas industries. ATEX Directive requirements can be imposed for specific uses in hazardous area environments where there is a risk of explosion.

Kiwa has thus investigated the extent to which the NOFIRNO sealing system fulfils ATEX Directive 2014/34/EU – Kiwa is an autonomous global organisation in Testing, Inspection and Certification (TIC), Training and Consultancy services.

What is ATEX?

ATEX is the name given to the two European Directives for controlling explosive atmospheres in designated hazardous area locations:

1) Directive 99/92/EC (also known as ‘ATEX 137’ or the ‘ATEX Workplace Directive’) on minimum requirements for improving the health and safety protection of workers potentially at risk from explosive atmospheres.

2) Directive 94/9/EC (also known as ‘ATEX 95’ or ‘the ATEX Equipment Directive’) on the approximation of the laws of Members States concerning equipment and protective systems intended for use in potentially explosive atmospheres.

The NOFIRNO systems is comprised of rubber and filler sleeves and sealant, the system is used to treat transit openings for cables and pipes in walls, floors, bulkheads or decks, so that they are fire-resistant and sealed against gas, smoke and water.

Kiwa’s research has shown that NOFIRNO, from CSD Sealing Systems, is extremely suitable for use in environments such as those covered by the ATEX Directive and described in the European standard EN 1127-1 ‘Explosive Atmospheres – Explosion Prevention & Protection – Part 1: Basic Concepts & Methodology’.

Because the NOFIRNO sealant, NOFIRNO rubber sleeves and the complete NOFIRNO sealing system do not fulfil an autonomous role and are not equipment in the sense of the ATEX Directive, the risk evaluation focused on use of the NOFIRNO in cable and pipe transits. All possible ignition sources related to the sealing system were also investigated.

Among the possible ignition sources which were assessed, were hot surfaces, flames and hot gases (including hot particles), mechanically-generated sparks, electrical equipment and power leakages, cathodic corrosion protection, static electricity, lightning, electromagnetic and ionising radiation, ultrasonic sound waves, adiabatic compression and shockwaves and exothermic reactions, including materials self-igniting.

How? A 20mm thick layer of NOFIRNO sealant is applied to each side of the conduit – clean and dry the conduit opening and pipe thoroughly to remove all dirt, rust or oil residue to ensure excellent adhesion of the NOFIRNO to the conduit. The conduit should be overfilled with NOFIRNO sealant as some sealant will be pushed between and into the empty filler sleeves during finishing and completion of the pipe or cable seal.

Conclusion

Safe Cable & Pipe Sealing Solution For Hazardous Area & Explosive Atmospheres

Kiwa concluded that for all hazardous situations as described in EN 1127-1, there is no ignition source for NOFIRNO sealant, NOFIRNO rubber sleeves, NOFIRNO rubber filling sleeves and the complete, installed NOFIRNO system.

NOFIRNO is manufactured by Beele Engineering.

Contact us for duct sealing systems for onshore and offshore sealing of medium/high voltage (MV-HV) substation cables.

NOFIRNO

Some benefits of the sealing system include:

• Ensuring ATEX, DSEAR & WIMES compliance

• Age tested to prove 50 years of sealing protection

• Quick and easy to install in both horizontal and vertical cable ducts

• Easy re-entry for adding, removing or replacing cables LV MV HV

• Installed in any sized or shaped opening, penetration or duct

• Resistant to submersion in petrol and diesel

• Resistant to methane, hydrogen sulphide and chlorine

• Suitable for trefoil and large diameter 11kV/33kV power cables

• Prevents rat and rodent ingress into low, medium and high voltage substations

NOFIRNO cable duct and pipe penetration sealing system is jet-fire tested for offshore applications.

➡ Contact Thorne & Derrick to discuss the NOFIRNO Duct Seal System – 0191 4104292.

Sealing Pipes, Cables & Ducts Using NOFIRNO

Watertight & Gastight Sealing For Building Entries & Cable Duct Terminations

A simple and long term solution designed for sealing cable ducts and building entries against ingress of water, gas or flooding – the NOFIRNO system is used extensively across the onshore utilities and construction sectors to protect LV MV HV electrical substations, equipment rooms and cabinets, wind turbines and critical infrastructure.

➡ For marine and offshore applications see: A60 H120 Pipework Fire Protection For Offshore Bulkheads & Decks

Jet Fire Testing

➡ NOFIRNO – Jet Fire Testing For Cable Duct & Pipe Penetration Sealing Systems

Some site installation photographs of NOFIRNO ➡

THORNE & DERRICK SPECIALIST ELECTRICAL DISTRIBUTOR

LV ♦ MV ♦ HV

Thorne & Derrick distribute the most extensive range of LV, MV & HV Cable Jointing, Terminating, Pulling & Installation Equipment – we service UK and international clients working on underground cables, overhead lines, substations and electrical construction at LV, 11kV, 33kV and EHV transmission and distribution voltages.

- Key Products: MV-HV Cable Joints & Terminations, Cable Cleats, Duct Seals, Cable Transits, Underground Cable Protection, Copper Earth Tapes, Cable Jointing Tools, Feeder Pillars, Cable Ducting, Earthing & Lightning Protection, Electrical Safety, Cable Glands, Arc Flash Protection & Fusegear.

- Distributors for: 3M Cold Shrink, ABB, Alroc, Band-It, Catu, Cembre, Centriforce, CMP, Elastimold, Ellis Patents, Emtelle, Furse, Lucy Zodion, Nexans Euromold, Pfisterer, Polypipe, Prysmian, Roxtec.

LV – Low Voltage Cable Joints, Glands, Cleats, Lugs & Accessories (1000 Volts)

MV HV – Medium & High Voltage Cable Joints, Terminations & Connectors (11kV 33kV EHV)

Cable Laying – Underground Cable Covers, Ducting, Seals & Cable Pulling Equipment

T&D, CATU Electrical Safety & Arc Flash Protection Specialists for SAP’s, Linesmen, Jointers & Electrical Engineers – Largest UK Stockist

INVITATION

Thorne & Derrick invite you to join LinkedIn’s largest LV-HV Electrical Discussion Group : Low & High Voltage Power, Cabling, Jointing & Electricals. Discussion subjects include cable installations, cable jointing, substation, overhead line and electrical construction at LV, 11kV, 33kV and EHV. Network, engage and promote your profile, company or products with over 10,000 influencers.