Blog

Klauke EK 30 IDML | The Compact Crimping Tool for Panel Builders

July 9th, 2021

Cable Crimping Tools

Klauke EK 30 IDML

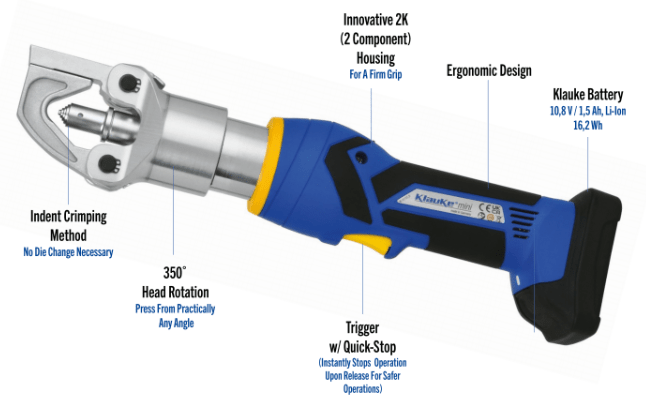

The latest cable crimping tool from Klauke, the EK 30 IDML is now available. The Klauke EK 30 IDML is the ideal tool to crimp a wide range of cable lugs with reduced cost, it features the familiar indent crimping method, meaning a change of dies is not required with the tool.

Klauke EK 30 IDML battery-powered hydraulic crimping tool makes it possible to crimp all commonly used cable lugs of the R-, L-, F- and Q-series for conductor Classes 2, 5 and 6 without requiring a change of die. The head of the tool is designed to only accept cable lugs to protect the user from any potential misapplications.

The lightweight Klauke EK 30 IDML is ideal for working in areas where space is tight and the 10.8V Li-Ion, 1.5Ah rechargeable battery will last a full working day on just one charge. Battery operated cable crimping tools are equipped with LED indicators to display the remaining battery life at any time by pressing the adjacent button.

Klauke EK 30 IDML – Features

Compact Crimping Tools

Features

- Closed head, flip top style, rotatable tool

- Simple and safe: one-button operating concept for controlling all tool functions

- Comfortable and secure one-hand operation thanks to 2-component plastic housing with soft lining

- Effortless operations thanks to low weight

- Automatic retraction when cable crimping operation is complete

- Maintenance display via LED

Crimping Tool Suitable for

- Very well suited for compacted conductors

- Especially for fine strand conductors according to DIN VDE 60228

Klauke EK 30 IDML

Specification

| Order Code | EK 30 IDML |

| Manufacturer | Klauke |

| Description | Battery-powered hydraulic crimping tool 6 – 120 mm² |

| Crimping Force | 30 kN |

| Stroke/Opening Width | 22 mm |

| Crimping Range | 6 – 120 mm² (Solderless cable lugs up to 95mm²) |

| Crimping Cycle | 2.5 s to 5 s (depending on cross-section) |

| Number of Crimps | approx. 150 |

| Battery Voltage | 10.8V |

| Battery Capacity | 1.5 Ah, Li-Ion |

| Battery Charge Time | approx. 40 mins |

| Weight Including Battery | 1.95 kg |

| Ambient Temperature | -10°C to +40°C |

Klauke EK 30 IDML Battery powered hydraulic crimping tool 6 – 120 mm²

Compatibility

| Suitable For | Connecting Material | Crimping Range mm² | Crimping Profile |

| Tubular Cable Lugs & Connectors – Cu | |||

| Tubular cable lugs and connectors, standard type, tubular cable lugs for switch cabinet connections |  |

6 – 120 |  |

| Tubular cable lugs and connectors for fine stranded conductors |  |

6 – 120 |  |

| Solderless Terminals, Connectors & Pin Terminals to DIN – Cu | |||

| Solderless terminals (DIN 46234) and pin terminals (DIN 46230) according to DIN – Cu, solderless connectors (DIN 46341) according to DIN – Cu |  |

6 – 95 |  |

Klauke EK30IDML | Cable Crimping Tool

Further Reading

Further Reading

Review other Blogs in this series of articles about Cable Lugs, Crimping Cables & Tools:

- Cable Lugs – Crimping Applications & Standards

- Copper Cable Lugs For Special Applications

- Indent Crimping Of Cables – Benefits & Limitations

- Cable Lugs & Crimping Using The Hexagonal Crimp Method

- DIN Standard – Crimping & Compressing Aluminium Cable Lugs & Connectors

- Copper & Aluminium – Crimping CU-AL Cables

- Electrically Driven Crimping Tools For High Volume Applications

LV MV HV Jointing, Earthing, Substation & Electrical Eqpt

Crimping Cables, Lugs & Tools

Thorne & Derrick distribute Cable Lugs & Cable Connectors to terminate, splice and joint LV MV HV cables – this includes copper, aluminium and bi-metallic connectors and a complete range of crimping tools for specific use on all Low, Medium & High Voltage cable types.

➡ Associated Brands & Products | Klauke | Cembre | Pfisterer Sicon | Cable Crimping & Cable Cutting Tools

HV Cable Jointing Preparation Using Cable Spiking Gun

July 8th, 2021

Spiking Cables

Spiking Cable

Pictured: One of Quartzelec’s cable jointers is applying a spiking gun to a cable on a recent substation installation project in Chester, UK in preparation for HV cable jointing. Cable spiking is the Quartzelec approved method of proving that any HV cables are not live before they are released for work.

Image Courtesy of: Quartzelec Limited

Quartzelec

Quartzelec Limited provide a unique range of contracting services to a diverse range of clients in the industrial, infrastructure and commercial and services sectors. They offer design, construction, commissioning, inspection and maintenance of distribution networks from 415V to 33kV.

Press Release | Thorne & Derrick Appointed Approved Stockist for UK Leading Cable Pulling Equipment Manufacturer

Further Reading

- Cable Drums | Recommended Transport & Storage

- How to Prepare Cables To Avoid Cable Damages & Faults

- Cable Pulling | Safe Pulling of Cables Using Motorised Pullers

- Cable Pulling | Safe Pulling of Cables Using Manual Laying

- Installation of Cable Sleeves | Jointing & Splicing Cables

- Installation of Rail Foot Cables

Cable Pulling Equipment

Thorne & Derrick distribute an extensive range of Cable Pulling & Laying Equipment to enable the safe installation of fibre and copper cables within the telecommunications industry. Safely installed cables reduces operational and maintenance requirements to the network and reduced service interruption to telecom cables, wires, ducts, cabinets and exchanges – products include cable spiking tools, conduit rods, cable lubricant, cable socks and rollers.

Jointers blog

Subscribe now to our POWER NEWSLETTER– a monthly email circulation packed with news, projects, videos, technical tips, training information, promotions, webinars, career opportunities and white papers.

Includes access to our popular JOINTERS BLOG with contributions from utility professionals, linesmen and cable jointers working on MV HV EHV cables and overhead lines typically at 11kV, 33kV, 66kV and up to 132kV.

Cable Grips | Supporting Inter-array, Export, Umbilical & Subsea Cable Installations

July 8th, 2021

Cable Grips

uploaded by Chris Dodds | Sales Marketing Manager at Thorne & Derrick International

Cable Grips

Pulling & Supporting Power & Subsea Cables in the Wind Sector

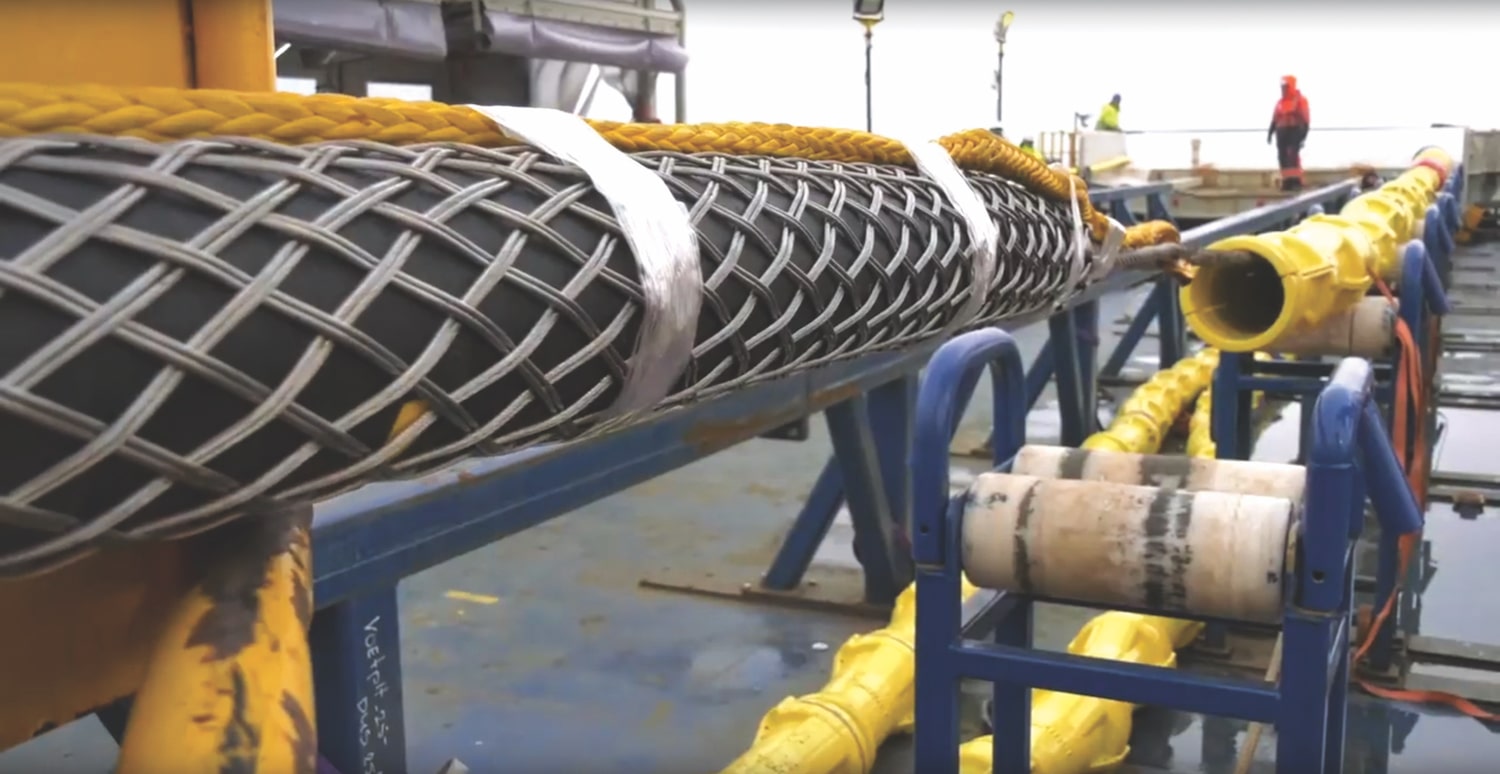

Slingco have developed a range of cable grips (commonly referred to as cable socks) specifically tailored to the needs of the renewable energy sector – working with Slingco we have produced engineered and customised solutions using cable grip innovation for Boskalis, NKT, Nexans, DEME and other major cable laying contractors for the connection of wind farm projects globally.

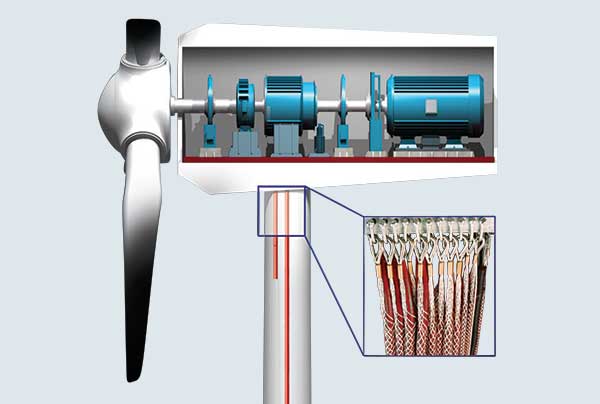

Thorne & Derrick have extensive ranges of marine cable grips and hose restraint grips – applications including LV MV HV EHV cable installation (onshore and offshore), support and gripping of cables inside wind turbines, pulling cables shore-to land, substation cable laying and general cable management. We have also developed a range of cable pulling grips for use in the installation and pulling of inter-array and export cables from offshore windfarm installations. We offer a complete range for cable diameters up to 350mm , 10Te to 90Te+ MBL in galvanised steel, stainless steel and aramid fibre.

Cable Grips | Standard Double Eye Cable Support Grips are available for low/medium/high voltage power cable pulls and support with approximate break loads up to 27,000kgs, stainless steel 316 grade option and outside cable diameter capacity of 250mm. Customer Application Cable Grips available on request.

Marine Grip Options

Option 1 – Limited Lay Down

Galvanised cable grips with aluminium ferrules are suitable for cable installation / loading and typically used for OSS pull in.

Option 2 – Limited Lay Down / Wet Storage

Galvanised grips with galvanised steel ferrules for installation / loading with limited wet storage that can be further extended for longer wet storage with the addition of an anode.

Option 3 – Lay Down / Wet Storage up to 1000 Hours

Stainless steel cable grips with stainless steel ferrules for laying and limited wet storage up to <1000 hours, subject to inspection after such time elapsed.

Option 4 – Lay Down / Wet Storage over 1000 Hours

Non-metallic grips in Aramid for used for cable laying and wet storage applications over >1000 hours, these would be the preference of the leading installation contractors based in the Netherlands and Europe, degradation was not seen other than some signs of salt on the surface. Non-metallic cable grips are specified to provide safe cable handling and are used for offshore saltwater environments when prolonged lay down durations are required.

Supplied by Thorne & Derrick

Wind Energy Cables

Pulling & Supporting Power & Subsea Cables in the Wind Sector | These cable socks manufactured from offshore/marine grade type 316 Stainless Steel are suitable for use in the renewable energy sector in applications such as cable installation (onshore and offshore), cable support inside wind turbines and cable management – used to pull, protect and support wind turbine cables. Pictured: June 2020 : the first of two export cables, each 37 kilometres in length, has been installed at the nearshore of Thorntonloch Beach as part of construction of the Neart na Gaoithe (NnG) Offshore Wind Farm.

Wind Turbine Support Grip

- Cable supports designed for minimal contact with the actual cable

- High working loads and cable support

- Manufactured from 316 stainless steel for corrosive atmospheres

- Rounded copper ferrules

- Bespoke cable grip design options available

For wind turbines, special features have been included to allow for minimal contact with the actual cable while still allowing impressive working loads and cable support. The range of cable support grips for wind turbines are woven from 316 stainless steel and feature rounded copper ferrules, offering reduced cable contact for high vibration environments. In addition to the standard range of catalogued cable grips and pulling socks we can offer a custom design service to suit your cable support requirements.

Cable Grips, Socks & Support products for the Renewable Industry

Single Eye | Double Eye | Lace-Up Grips for Marine Offshore Cable Support & Pulling | Extreme Heavy Duty for Underwater Application up to 550mm Cable Diameters

- Hose Restraint Cable Grips

Hose Restraint Grips | Heavy Duty Hose Restraint Grips | Hose Armour Grips for Hose Protection | 316 Stainless Steel U Type Hose Grips | Prevents Whipping From Detached Pressure Hoses

- Non-Metallic Cable Grips (Aramid)

- Wind Turbine Support Grips

- Extended Thimble Eye Heavy Duty Stainless Steel Cable Grips

Slingco has 40 years of experience manufacturing marine cable grips via their Distributor Network including Thorne & Derrick serving customers in over 70 countries worldwide – they are an award-winning supplier of high-quality cable grip, cable sock and wire rope products, having won the Queen’s Award for Export International Trade in both 2016 and 2020.

Large Cable Project Capacity & Delivery

Slingo and Thorne & Derrick are known for their excellent customer service, technical support and on-time order fulfilment – additionally we have the skills, experience and manufacturing capacity to deliver on the most challenging demands. From initial product design and manufacture to technical support and customer service, our aim is to become a partner you can trust for the safe installation, support and pulling of cable in the wind energy sector.

Client Confidence | Test Reports Certification

Quality matters in all industries, but none more so than those we serve. Every Slingco product is designed, manufactured and tested to exacting standards to ensure safe and reliable operation under the most challenging conditions – this level of customer service is backed-up with detailed test reports and relevant certification, all available on request.

Aramid | non-metallic / non-conductive marine grip manufactured from Aramid recommended for array / export cable installation were the cable needs to be laid down for a prolonged duration before installation.

fURTHER iNFORMATION

- Cable Pulling | 37km Offshore Cable to Connect NnG to Onshore Substation

- Slingco Take A Firm Grip on The Future With Cable Socks

- MV HV Cable Laying, Installation & Support Products | Offshore Windfarms

Image Courtesy | Max States Site Engineer at Balfour Beatty plc (Viking Link) – here the EHV 526kV cable is pictured being pulled from a 62 tonne cable drum (1240m circuit) into the cable trench via rollers in July 2021. Viking Link is a 1,400 MW HVDC submarine power cable under construction between the United Kingdom and Denmark.

Cable Pulling & Laying Equipment

Suppliers & Distributors

Thorne & Derrick distribute the most extensive range of Low & High Voltage Cable Installation & Electrical Distribution Equipment to the Power Transmission & Distribution industry in the onshore and offshore wind, solar, rail, oil/gas, data centre, battery storage and utility sectors – this includes the most extensive range of Cable Pulling & Cable Laying Equipment to enable the installation of low, medium and high voltage power cables into underground trench or duct.

We service UK and international clients working on underground cables, overhead lines, substations and electrical construction at LV, 11kV/33kV and up to EHV transmission and distribution voltages.

Key Products: MV-HV Cable Joints & Terminations, Cable Cleats, Duct Seals, Cable Transits, Underground Cable Protection, Copper Earth Tapes, Cable Jointing Tools, Feeder Pillars, Cable Ducting, Earthing & Lightning Protection, Electrical Safety, Cable Glands, Arc Flash Protection & Fusegear.

Distributors for: 3M Electrical, ABB, Alroc, Band-It, Cembre, Centriforce, CMP, Elastimold, Ellis Patents, Emtelle, Furse, Lucy Zodion, Nexans Euromold, Pfisterer, Polypipe, ProGARM, Prysmian, and Roxtec.

- Scope –single-source supply of extensive range of products

- Stock – a multi-million pound stock holding provides complete global supply solutions

- Staff – technical support from a trained, proactive and friendly team

- Delivery – UK stock turnaround with express logistics to all international destinations

Further Reading | Cable Drum Handling & Laying Cables | A Guide from Nexans

Arc Flash Survivor Story – Jason Brozen

July 6th, 2021 Arc Flash Survivor Story

Arc Flash Survivor Story

Arc Flash Coat

-

Special thanks to Jason Brozen for sharing his story & ESPCO for the kind permission to republish

After surviving an arc flash accident, Jason Brozen made it his mission to share his experience to help others stay safe on the job. Jason is proud to join EPSCO and their industry-leading electrical safety team.

Jason shares EPSCO’s passion for safety and dedication to electrical safety training that’s on-the-level, comprehensive, and collaborative. We hope that his story will help increase your awareness and attention to electrical safety.

See the full interview and other stories from survivors by taking your next Electrical safety training course with One Moment.

Jason’s Survival Story

The morning started just like any other for Jason Brozen.

He showed up to work, got his assignment, and arrived at the job site thinking he’d get it done, punch out, and be back home with his family for dinner.

Jason had been a Master Electrician for over a decade and was fascinated with electricity for a long time before that. As a kid, he would ask for electronic toys for holidays and birthdays, just so he could take them apart.

He’d never had a major accident at work, so there was no reason for him to question his approach. This was a straightforward job installing a breaker he’d done hundreds of times before – and he’d gotten them all done without cutting power or wearing any PPE.

All Jason had to do was remove the breaker from the box, inspect it, fit the new breaker and bolt it in. But there were loose parts on the bus bar. As he tried to fit the breaker, the bars got too close and triggered a massive arc flash explosion.

Everything fell into slow-motion. Jason could feel the cycles of electricity ripping through his body. The arc flash was over in an instant but blasted him with more firepower than the surface of the sun.

The next thing Jason knew, he was on the floor in a pitch black room, choking on the smoke with the fire alarm blaring. He didn’t know if he was on fire, but realized he was severely burned as firefighters arrived on scene.

He knew right away he’d been involved in an arc flash incident, but he didn’t realize what it meant to be an arc flash survivor.

Here is the coat Jason was wearing when the ARC flash happened. It’s a miracle that it wasn’t fatal. Typically non rated clothing will ignite and glue itself to you or engulf your torso in flames.

He was one of the lucky ones. With only 14% burns he had a better chance for survival than most arc flash victims. But he never realized it would mean two weeks in an induced coma in the ICU and seven months of rehab before he could even think about returning to work.

Third degree burns destroyed everything down through his nerves, requiring skin grafts on his face and hands. Breathing in the hot gas left him coughing up soot from his lungs for weeks. In the hospital, Jason was immobile and had to rely on the nurses and staff for the simplest things. When he got released Jason couldn’t use his hands for anything. He couldn’t drive. Couldn’t get dressed on his own. Couldn’t even hold his own fork at dinner.

But the thing that caused Jason the most pain, was that he wasn’t able to provide for his family. It was a long and tough road for Jason to get back onto the field, but he did it. And now, he wants to share his story so that others won’t make the same mistake he did.

Jason was brave and generous enough to share his experience with EPSCO as part of our ONE MOMENT online electrical safety training series. We went in depth to create the most comprehensive arc flash survivor story out there. We had access to never before seen footage taken moments after Jason’s arc flash accident. But we want everyone to understand the damage goes far beyond the physical injuries – It effects your psychology, your family, your company and co-workers, and their clients too.

View the video and see how arc flash changed Jason’s life forever. See how being an arc flash survivor taught him to — “Plan your work. Work your plan. Follow through with that plan. And do not make exceptions on anything when it comes to safety.”

➡ Read Video Transcript here

The watch Jason was wearing when the accident occurred.

PROGARM, THE ARC FLASH SPECIALISTS

Arc Flash Protection | Arc Clothing | Polo Shirts | Jackets | Coveralls | Trousers | Helmets | Gloves

Thorne and Derrick distribute a range of LIFESAVING Arc Flash Protective Clothing from ProGARM – the leading UK manufacturer of high quality Flame Resistant & Arc Flash clothing, garments and workwear.

T&D are national distributors LV, MV & HV Cable Installation, Jointing, Substation & Electrical Equipment – we service UK and global businesses involved in cable installations, jointing, substation, overhead line and electrical construction at LV, 11kV, 33kV and EHV.

“At ProGARM our mission is protect lives through the manufacture and supply of exceptional quality Arc Flash and Flame Resistant Clothing. Being the only specialist Arc Flash protection manufacturer in the UK we focus on providing the best protection possible to those who work at risk of Arc Flash on a daily basis with our inherent, specialist garments and industry-leading innovation. Supporting Utilities, Power Generation, Rail & Petrochemical industries we work with Thorne & Derrick to educate, inform and supply those who work at risk everyday allowing us to keep protecting lives throughout the UK & beyond.”

Arc Flash Learning & Resources

Thorne and Derrick are proud to be distributors of ProGARM arc flash coveralls and protection.

We can help – should you require arc flash calculators or advice on the type of clothing and protection available please do not hesitate to contact us.

Closing Thought – statistics show that between eight and ten arc flash accidents occur in the UK every week. Protect yourself, contact us to learn how.

Arc Flash Kit | Making Your Electrical PPE Work Even Harder

July 6th, 2021

ELECTRICAL PPE

Arc Flash Kits & Arc Flash Clothing

Investing in the highest quality arc flash kit and electrical PPE is exactly that – an investment. Whether purchasing for a small number of specially-trained people or as part of a broader procurement strategy in large volumes, the value-for-money aspect is a necessary part of the conversation.

Regardless of overall spend, there are significant commercial benefits in having the right specification kit for high-risk electrical operatives at risk of an arc flash. As if saving lives isn’t enough, here are our top five areas for potential cost-savings to help make your ProGARM investment work even harder.

1. Reduced Insurance Premiums

Getting caught up in an arc flash could have devastating consequences. Yes, you have business insurance but should the worst happen, most policies expect that every reasonable safety precaution is being taken and it’s your responsibility to make sure this is the case. There are ways that you can show you’re doing all you can to reduce your risks, and investing in specialist electrical PPE is definitely one of those things that could mean a win when it comes to business insurance costs.

2. Increased Durability Means Less Replacement Costs

There’s a saying: buy cheap, buy twice. In challenging economic times, a cheaper alternative can feel like the sensible choice. Beware though, as the compromise could end up being costlier in the long run. With such high stakes, it’s important to have confidence in the performance and durability of the clothing you purchase. At ProGARM, we’re obsessed with every single detail meaning we know our clothes are built to last. But not all arc flash clothing is made equal.

3. Making Clothes That Operatives Choose To Wear

If your people don’t like the kit you give them because it’s uncomfortable, you face an uphill battle getting them to wear it. We know that wearability is key, especially in a role that demands flexibility and movement to get the job done. The entire range of ProGARM arc flash clothing is designed with real people in mind. We know comfort counts, so it’s always a key part of our product development process, creating clothes people want to wear.

4. Increased Productivity

When your teams know you’ve invested heavily in their safety through kit that’s not only high-spec but also comfortable to wear, they’re more likely to be focused on getting the job done without distraction. There’s also the great British weather to contend with, meaning comfort factors such as breathable panels, the ability to layer, and freedom to move without discomfort are all hugely important. They’re also features of the entire ProGARM product range.

5. Increasing Your Employer Appeal

To attract the best talent, especially in specialist or technical fields, employers need to stand out for the right reasons. Demonstrating the importance of health and safety – which translates as the way you value your people – through the choice of specialist electrical PPE, is definitely one of the right reasons. Your investment in ProGARM arc flash PPE could be one of the strongest levers in employee retention as well as the difference between top talent applying for your roles, or those of your competition.

If you’d like to explore how to make your specialist electrical PPE budget work even harder, why not get in touch?

💡 Did you know? – While high voltage equipment does increase the likelihood and intensity of arc flash explosions, they can occur in any live electrical environment – even low voltage.

Further Reading

- Arc Flash | Don’t Let the Summer Sun Compromise Your Electrical PPE

- Arc Flash Risks In The Rail Industry

Arc Flash Learning & Resources

Thorne and Derrick are proud to be distributors of ProGARM arc flash coveralls and protection.

We can help – should you require arc flash calculators or advice on the type of clothing and protection available please do not hesitate to contact us.