Cable Joints & Terminations LV

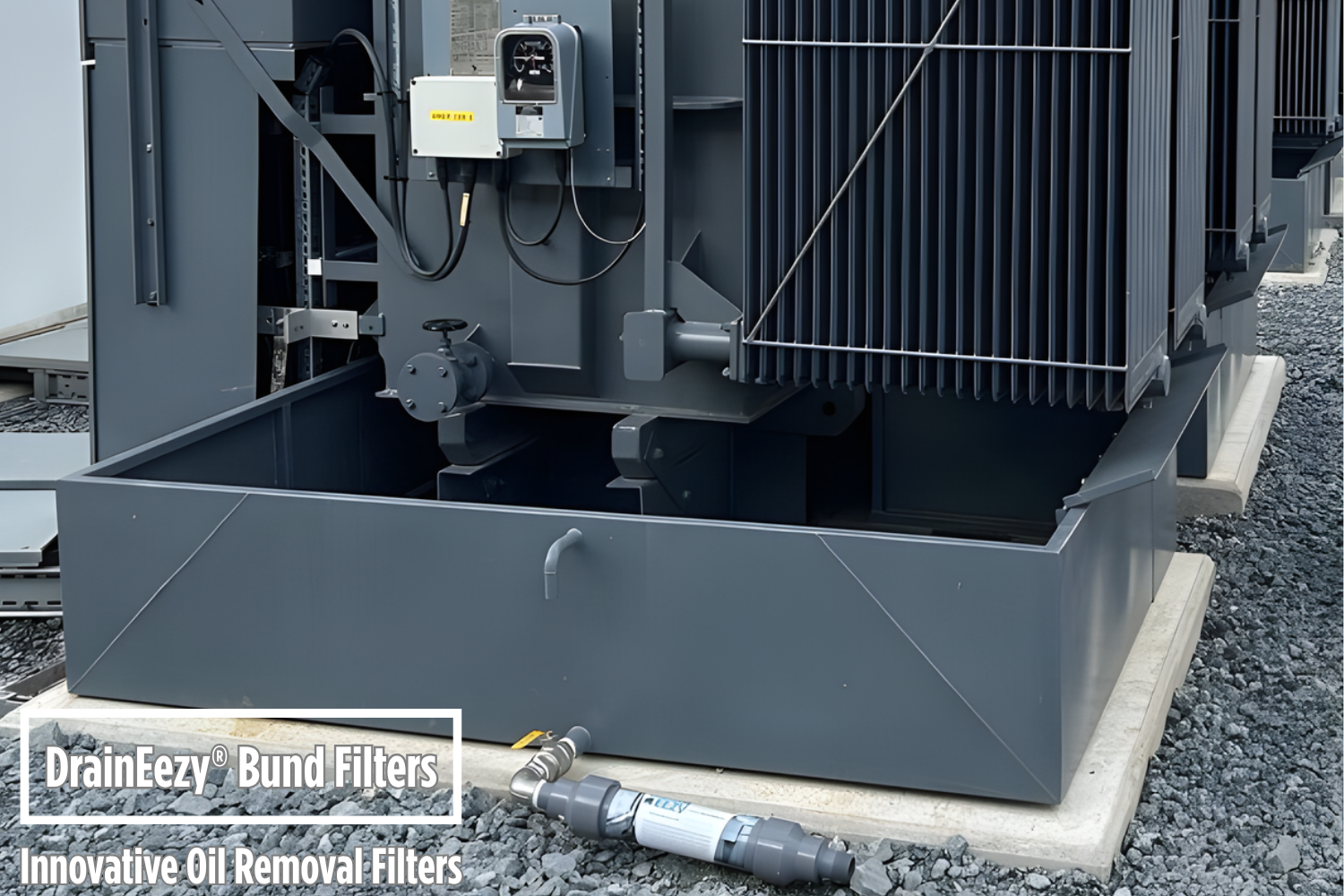

What Is a Transformer Bund Filter?

November 25th, 2025

Transformer Bund Filter

A Complete Guide for Asset Managers

Environmental protection around LV, MV and HV transformers is a growing priority for utilities, renewable energy developers, industrial sites and BESS operators. With increasing regulatory pressure around oil containment, many sites are upgrading to modern Transformer Bund Filters—a passive, low-maintenance system that allows clean rainwater to drain while preventing oil from escaping a transformer bund.

What Is a Transformer Bund Filter?

A Transformer Bund Filter is a passive drainage system installed on oil-filled transformer bunds to let clean rainwater escape while automatically sealing if the filter becomes inundated with oil.. These systems contain hydrocarbon-absorbing media and a self-activating shut-off valve that prevents any contaminated water from leaving the bund.

Why Transformer Bund Filters Are Becoming Industry Standard

DrainEezy Bund Filters are now widely used across:

- Solar farm transformers and inverter skids

- Battery Energy Storage Systems (BESS) sites

- Wind farm transformers

- Data Centre transformers

- Secondary substations

- Industrial transformers

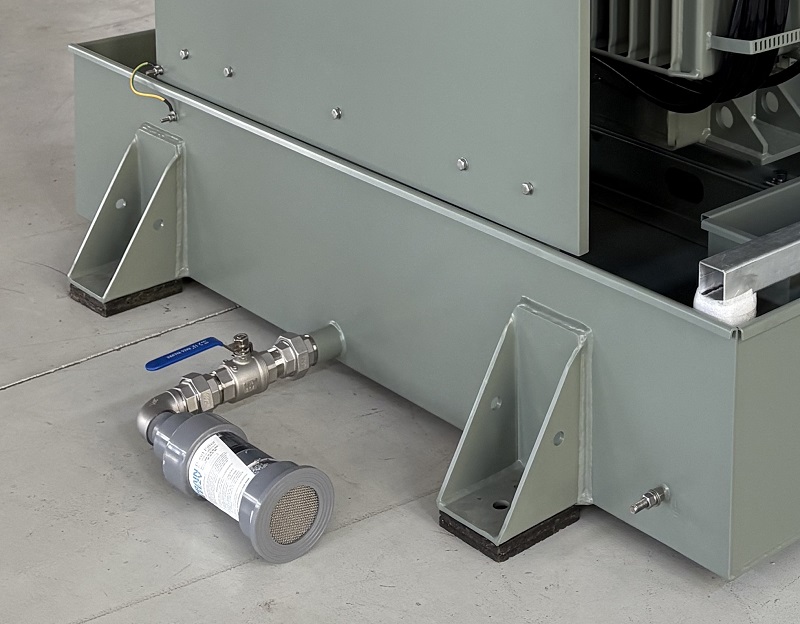

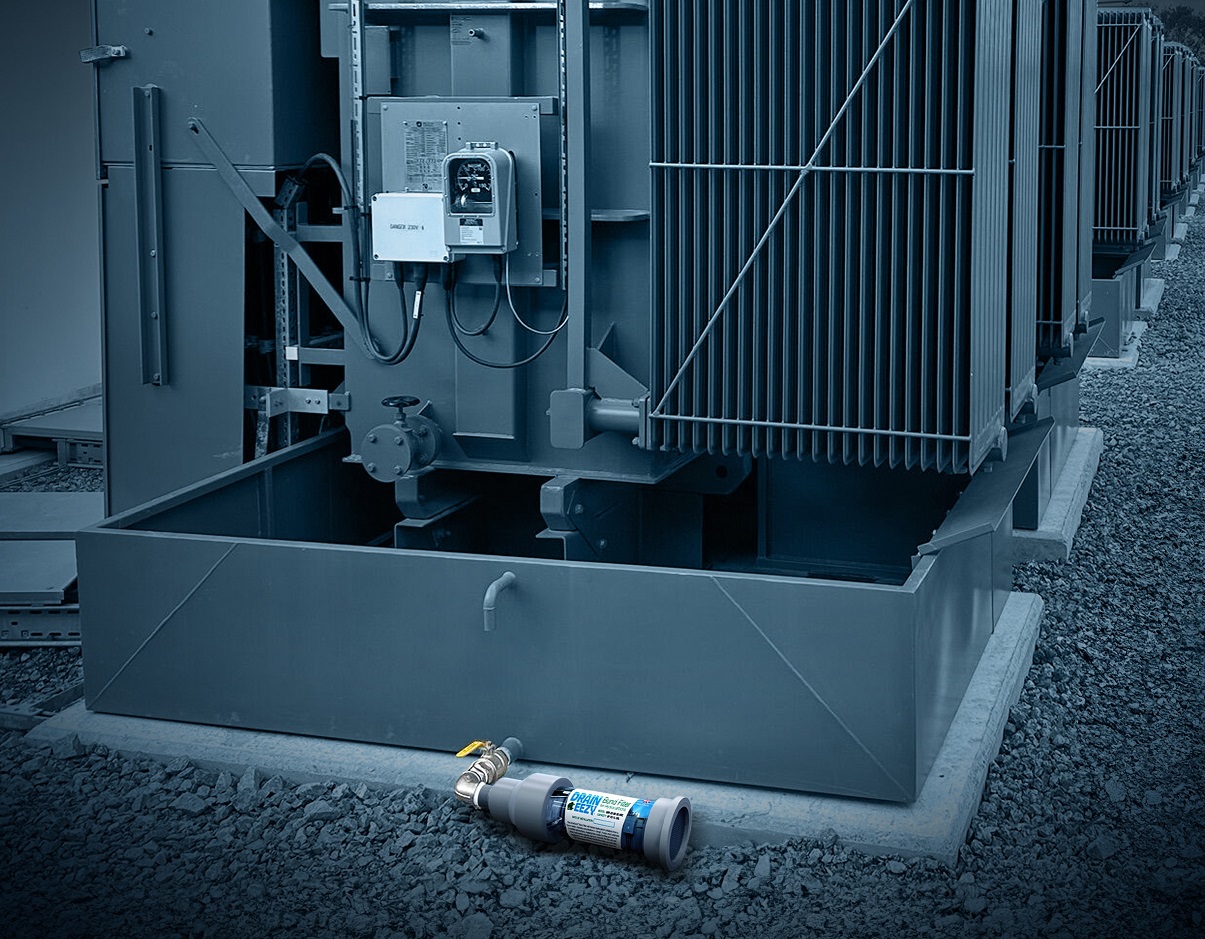

Key Advantages

- Zero power requirement – fully passive filter system

- Automatic oil shut-off – the bund filter seals when inundated with transformer oil

- Low installation costs – quick, easy, field-ready and retro-fittable

- Minimal maintenance – no moving parts

- Ideal for remote sites – extensively installed to steel bunded transformers in the Renewable Energy sectors

How the Draineezy Transformer Bund Filter Works

The DrainEezy system uses hydrophobic media ensuring:

- Allows clean rainwater to pass freely

- Captures hydrocarbons instantly from oil transformer leaks

- Triggers an automatic shut-off valve when inundated with transformer oil

- The filter prevents any oil discharge from the transformer bund

Draineezy BUND FILTERS vs Traditional Oil-Water Separators

| Features | Draineezy Bund Filter | Oil-Water Separator |

|---|---|---|

| Power Required | No | Yes |

| Maintenance | Low | High |

| Installation Cost | Low | High |

| Environmental Risk | Very Low | Medium |

| Response to Oil Spill | Automatic Shut-off | Manual Intervention |

Applications Across Energy & Utilities

- Wind turbine transformer bunds

- Solar farm transformer/inverter bunds

- BESS sites

- DNO/IDNO substations

- Industrial HV transformer bunds

- OEM bund installations

Transformer Bund Filter

Need a Transformer Bund Filter?

Thorne & Derrick supply the full range of Draineezy Transformer Bund Filters, fitting kits, pre-filters and technical support.

|

|

|

| DrainEezy Bund Filter | DrainEezy New Design | Oil Filled Transformers |

LV MV HV Transformers, Cables & Electrical Equipment

Thorne & Derrick distribute the most extensive range of 11kV 33kV Cables, Cable Jointing, Terminating, Pulling & Installation Equipment – we service UK and international clients working on underground cables, overhead lines, substations and electrical construction at 11kV 33kV and up to and EHV transmission and distribution voltages; approved stockists and suppliers of 3M Electrical (ColdShrink), Nexans (Euromold), Pfisterer (CONNEX) and Lovink cable accessory and connection products.

Joints, Terminations & Connectors | MV HV | 11kV 33kV 66kV

Connecting the Circuit | One Woman’s Journey to Rewire the HV Jointing Industry

September 18th, 2025

In an industry where women in High Voltage Engineering careers is rare, Francesca Distefano is rewiring the possibilities for what it means to be a leader in this male-dominated workplace.

With several years major projects experience and proven competency for the installation of market-leading brands including Pfisterer Connex, Nexans Euromold and NkT, Fran is excelling in her field and hopefully inspiring more women to write their own future and likewise thrive in the electrical power industry.

Francesca’s work powers our world; employed on critical infrastructure projects from data centres to digitise our economy and offshore wind farms that power our planets renewable energy future towards the global goal of Net Zero 2050.

Her personal journey, fuelled by resilience and the support of allies, highlights both the challenges women still face in the industry and the immense opportunities ahead.

Q&A WITH FRAN

HV Jointer | 66kV GWO’s | Gold Card Electrician | SSTS | 18th Edition

Jointing LV HV Cables UK & International Projects | Onshore & Offshore

Q: Fran, you’ve carved out an impressive career in the traditionally male-dominated role of HV Jointer. What inspired you to pursue this path, and how did you overcome challenges as a woman in the industry?

Fran: My journey began with the support of my family, especially my Dad, who’s a carpenter. He encouraged me to break away from traditional norms and pursue what made me happy. When I started I faced scepticism—some wrongly assumed I couldn’t handle the job as Jointer simply because of my gender.

But I focused on proving my skills through hard work, dedication and investment in training. Being physically fit and confident in my abilities helped me earn respect. Surrounding myself with supportive colleagues, like mentors Steve and Paul, and my boyfriend Ian, who brought me into HV, made all the difference.

Q: What aspects of your work bring you the most satisfaction?

Fran: The tangible impact of my work is incredibly rewarding. Whether it’s helping power hospitals, schools or data centres, knowing I’m contributing to essential infrastructure is fulfilling. I take pride in delivering high-quality work, and when others admire the results, it’s a great feeling.

Q: You’ve highlighted the importance of mentorship. How did these relationships shape your career?

Fran: Mentors like Steve, Paul, and Ian were pivotal. They taught me the ropes, stood by me during tough times, and helped me grow into the professional I am today. Their belief in me gave me the confidence to push forward, even when I doubted myself.

Q: What are the biggest challenges women still face in the industry today?

Fran: The lack of facilities, like female changing rooms and toilets, is a glaring issue. Many sites aren’t designed with women in mind, which adds unnecessary stress. There’s also the constant feeling of being “watched” or underestimated. But I’m optimistic—more women joining the field will drive change and companies are starting to adapt.

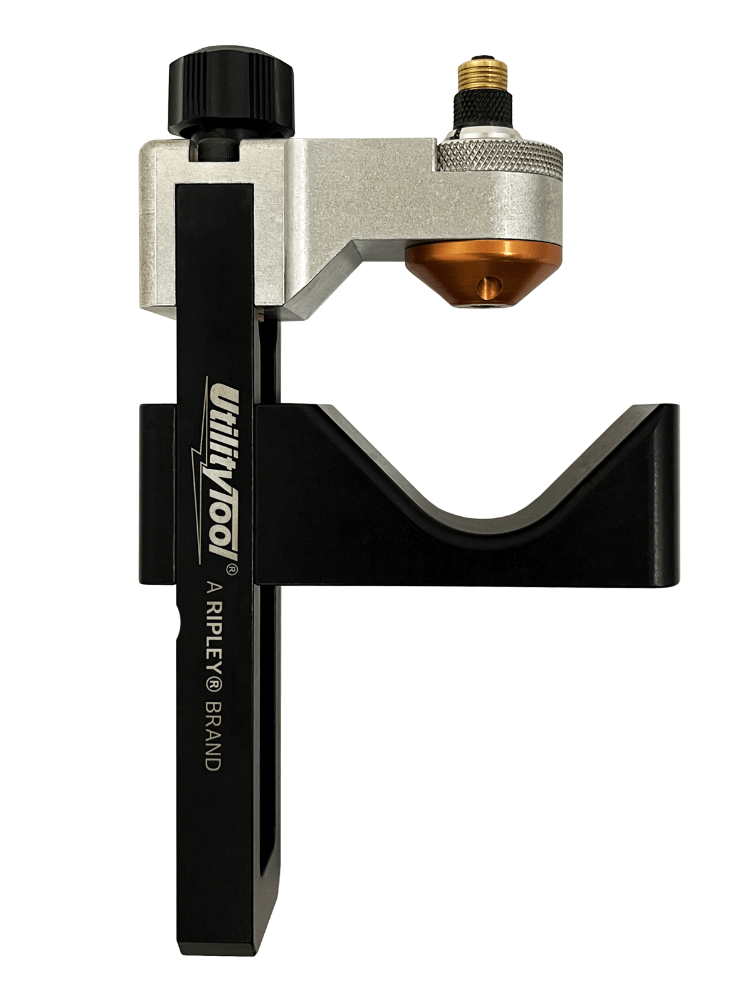

Q: As an HV Jointer which tools are indispensable to your work?

Fran: The Ripley US15 and US02 are my go-to Jointing Tools – the professionally engineered tools make stripping outer sheaths and cable semi-cons effortless, ensuring clean, precise work. These cable preparation tools have revolutionised efficiency especially in highly critical projects including offshore wind power and renewable energy.

|

|

| US02 Bonded Semicon Shaving Tool | US15 Sheath Stripping Tool |

Q: What advice would you give to women considering a career in HV Cable Jointing?

Fran: Don’t let fear hold you back. Yes, it’s intimidating at first, but the opportunities are endless—from joining to management or testing. The industry needs skilled workers, and women bring unique perspectives. Stand your ground, prove your worth, and don’t let anyone deter you.

Q: How can we encourage more women to join this field?

Fran: Showcasing the job’s rewards—travel, financial stability, and the pride of creating something lasting—is key. Breaking stereotypes and highlighting trailblazers can inspire others. Companies should also improve on-site facilities and actively recruit women.

Q: Where do you see opportunities for women in HV engineering over the next decade?

Fran: With global projects booming, women can make their mark internationally. As pioneers, we can reshape perceptions and inspire the next generation. I’ve already seen positive changes, and I hope the trend continues—more inclusivity, better facilities, and a stronger female presence on sites.

Q: Any final words for aspiring women engineers?

Fran: Go for it 100%. This industry is tough but incredibly rewarding. Be the change you want to see, and remember—you belong here just as much as anyone else.

Thorne & Derrick are Specialist Distributors of LV HV Cable Installation, Jointing, Substation & Hazardous Area Electrical Equipment to international energy providers, EPC’s and HV Jointing Contractors working on the design, construction and maintenance of UK, European and international projects – T&D are servicing the utilities, wind, solar, battery storage, rail, oil/gas, hydrogen and the explosive atmosphere sectors.

T&D are Main UK Distributors of Medium Voltage Cable Joints, Terminations & Connectors from 3M Electrical, Lovink, Nexans Euromold, Pfisterer Connex and Sudkabel.

How To Repair Damaged Cables Using Wraparound Cable Repair Kits

May 20th, 2025Installing Filoform cable repair kits

Integrity of the cable is of prime concern in mission-critical infrastructure.

Whether maintenance is being performed in utilities, telecommunications, or industrial power systems, damaged jacket cables significantly degrade operations and safety. Filoform Heat Shrinkable Reinforced Wrap Around Cable Jacket Repair Sleeves offer a tough, field-proven repair solution for on-site repair of cables, offering durability, environmental sealing, and mechanical protection.

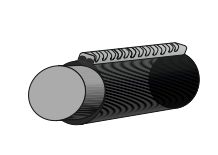

Filoform Jacket Repair Sleeve

The Filoform cable repair sleeve is engineered for reliability in hostile environments. This metal-reinforced, heat-shrinkable wraparound sleeve enables fast, permanent cable jacket repair without cable movement or disconnection.

Cable Repair Product Features

- Heat-activated seal with hot melt adhesive

- Metal channel closure for mechanical reinforcement

- Extensive cable diameter compatibility

- Application for indoor and outdoor use when repairing damaged cables

Cable Repair Installation Guide

Important: Use a soft yellow flame (not pencil type). Always direct heat in the direction of shrinking and maintain a sweeping motion to avoid scorching. Begin shrinking from the centre outward. Ensure uniform shrinking and proper adhesive oozing.

Ensure performance perfection with this precise installation procedure:

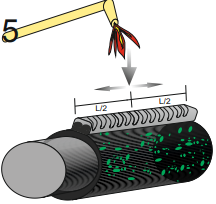

Step 1:

Action: Degrease, clean, and dust the cable surface where the sleeve will be applied.

✅ Use solvents that are compatible with the cable material.

✅ Clean 100 mm on both sides of the damaged section.

Step 2:

Action: Abrade the outer jacket of the cable using abrasive tape or sandpaper.

✅ Roughen 100 mm on each side of the damage for optimal adhesion.

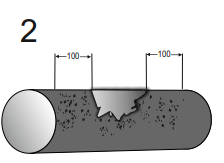

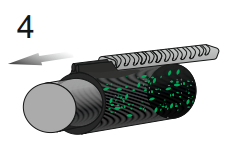

Step 3: Remove the Adhesive Film

Step 3: Remove the Adhesive Film

Action: Peel off the release liner from the adhesive-coated inner surface of the sleeve.

Step 4: Apply the Sleeve and Insert the Metal Channel

Step 4: Apply the Sleeve and Insert the Metal Channel

Action: Wrap the sleeve around the cable and slide the metal channel along the overlap to lock it.

✅ Extend the channel 10 mm beyond both ends of the sleeve.

✅ Confirm that the sleeve fits snugly around the cable.

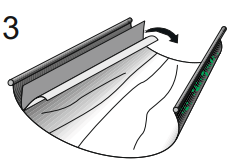

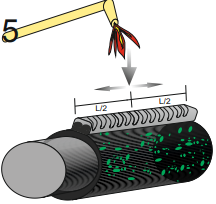

Step 5: Start Heat Shrinking at the Center

Step 5: Start Heat Shrinking at the Center

Action: Begin applying heat at the centre of the sleeve and work outward.

✅ Apply uniform heat all around the sleeve.

✅ Focus extra heat along the metal channel.

✅ If necessary, bend the channel to follow the cable’s contours.

Step 6 Monitor Adhesive Flow

Action: Look for hot melt adhesive uniformly oozing from all edges.

✅ This indicates a secure and sealed installation.

✅ Let the sleeve cool fully before applying any mechanical stress.

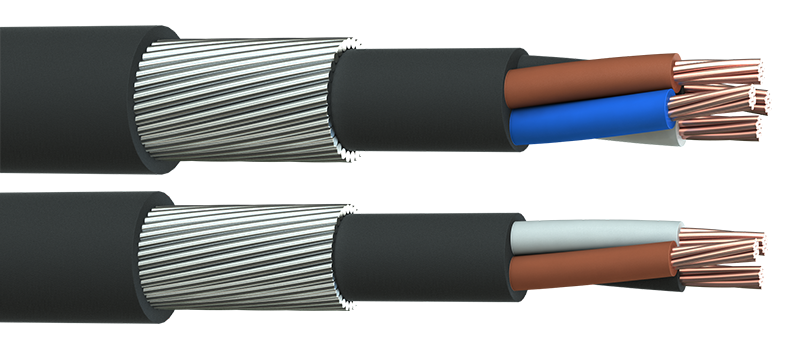

Earthing Armoured Cables To Safely Protect LV AC Cables In The Solar Industry

February 28th, 2024Challenge | This week a Solar EPC client of Thorne & Derrick engaged our Technical Sales Department to assist with ongoing O&M issues relating to the termination connection of steel wire armour (SWA) on 450off 4 core x 240sqmm LV AC cables, 0.6/1kV – the outdoor location cables are connected to a string inverter and the MV station at the remote end on a UK based 50MW solar farm in Derbyshire. The cable armouring provides mechanical protection but is not intended to circulate electrical current.

SWA Cable Steel Wire Armoured Cables | Image FS Cables

BS7671 Clause 522.8.10

“Except where installed in a conduit or duct which provides equivalent protection against mechanical damage, a cable buried in the ground shall incorporate an earthed armour or metal sheath or both, suitable for use as a protective conductor. The location of buried cables shall be marked by cable covers or a suitable marker tape. Buried conduits and ducts shall be suitably identified. Buried cables, conduits and ducts shall be at a sufficient depth to avoid being damaged by any reasonably foreseeable disturbance of the ground.”

Earthing Armoured Cables

Solution

Initially, from the viewpoint of the above British Standard the client considered connecting the wire armour at the MV station to ensure that during a fault (e.g.cable strike) an earth path exists to allow safe disconnection of the cable. Earthing the armours of buried SWA cables is important for safety – this prevents/reduces the severity of electric shocks and equipment damage should a person dig inadvertently into the cable. The cable wire armours provide a complete earth path around the cable. Utilizing a single phase within a 4 core cable as earth is not sufficient as it does not offer complete protection around the circumference of the cable. Also, in solar farm installations un-earthed wire armours can have induced voltage from excessive current generated. Therefore, the contractor should always consult the circuit designer.

Customer Service

From initial application, to concept, to design and to sample acceptance by the end client we subsequently completed the despatch and delivery of their order in 5 working days for 450off Armour Earthing Kits.

Important Note

Solderless earth kits that are intended for copper tape screens (MV cables) are a substandard method to earth SWA cables. Solderless earth kits utilize a constant force spring which do not offer a secure earth bond for SWA’s. Also, the cross sectional area of the braid within these kits is inadequate which is why you should always use an armour earth kit for this application. Contact us to discuss your application.

Innovative Connection & Grounding Solutions for LV Cables

Excerpt from Installation Instruction

Heat Shrink Outdoor Armour Earth Kit To Suit

XLPE SWA PVC

The Heat Shrink Outdoor Armour Earth Kit includes medium wall adhesive lined heat shrink tubes, mastic tapes, solder-blocked earth braids and clamps. Contact us for further information, technical support or for a quotation.

THORNE & DERRICK are Specialist Distributors of LV HV Solar Cable Accessories, Jointing, Termination, Earthing & Electrical Equipment 1500V DC to 33kV – we service UK and global businesses involved in cable installations, jointing, substation and electrical construction.

Since 1985, T&D have established reputation based on SERVICE | INTEGRITY | TRUST – we are highly customer responsive and absolutely committed to providing a world-class service.

We provide expert technical support and supply from a multi-million pound stock holding:

- Cable Joints, Terminations & Connectors

- Earthing & Lightning Protection

- Cable Accessories – Lugs & Glands

- Circuit Protection & Fuses

- Cable Cleats & Clamps

- Electrical Safety Equipment

- Cable Pulling & Laying Equipment

- Arc Flash Protection & Clothing

- Cable Duct Seals & Transit Systems

- Surge Arresters & Bushings

- MV HV Overhead Line & Substation Power Products

>> MORE INFO <<

Further Reading

Thorne & Derrick are Specialist Distributors of Innovation Tooling & Accessories for LV HV Power Systems to facilitate safe and reliable cutting, crimping, preparation, termination and installation of cables, 600V to 132kV.

Overcoming Cable Corrosion On Steel Wire Armoured & Braided Cables

April 24th, 2023

Cable Corrosion Solutions & Products

-

uploaded by Chris Dodds - Thorne & Derrick Sales & Marketing Manager

Solutions To Cable Corrosion

3M Electrical Products provide an extensive range of cable repair solutions to prevent and overcome cable corrosion for the utilities, renewable energy, solar, construction, rail, mining, offshore, oil, gas and petrochemical industries – cable corrosion tapes and protection products are available to suit both direct burial (underground) and cables located onto containment in both indoor and outdoor installations.

Cable repair solutions are available for low and medium voltage cables suffering advanced cable damage caused by atmospheric steel corrosion – both onshore and offshore galvanised steel wire armoured and wire braided cables are especially vulnerable.

The Problem

Formation of Rust

The overall chemical equation for the formation of rust is:

Iron + Water + Oxygen → Rust

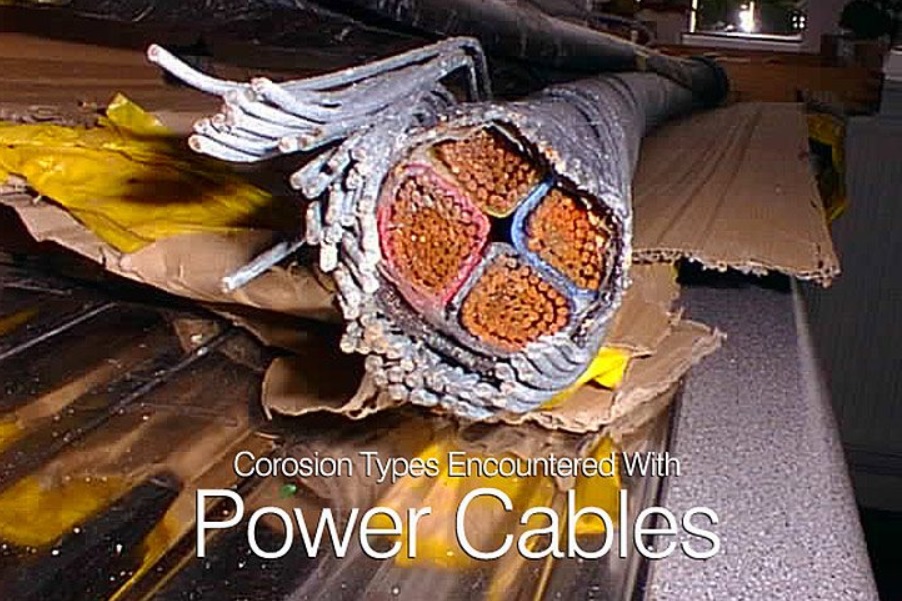

Advanced Cable Corrosion & Degradation

The pictured low voltage cables evidently have serious damage caused by long-term cable corrosion effects. The cable sheathing has been aggressively damaged and stripped back down to the galvanised steel wire armours. Steel typically corrodes or rusts rapidly in moist or humid conditions and the rate of corrosion accelerates with exposure to salt water, for instance in the marine and offshore industry.

The cable sheath should provide both waterproof and corrosion protection to the steel wire armours and copper conductors – in this case there is an urgent demand to prevent further cable corrosion damage to both the accessible and inaccessible cables strapped and cable cleated to the cable tray.

The complexity of the cable repair is compounded two-fold : the area is a “no-heat” zone designated a hazardous area location Zone 2 according to the ATEX Directive therefore traditional heat shrink cable repair kits are precluded from consideration due to the presence of a potentially explosive atmosphere. Furthermore due to the brittleness of the cables, resultant from significant corrosion damage, it was not an option to man-handle and subject the cables to further physical movement and mechanical strain.

Chemical Corrosion of Cables In Industrial

& Hazardous Area Locations

Hydrocarbons in the onshore and offshore oil/gas exploration and production sector seriously impact upon the integrity and ability of cables and cable accessories to provide uninterrupted service – standard polyurethane cable repair and jointing products would overtime degrade to destruction in the presence of aggressive chemicals.

Consequently, 3M Electrical have developed a chemical resistant cable joint utilising their 1402FR resin for harsh and hazardous cable installation environments where hydrocarbon exposure is expected under normal conditions – the Scotchcast resin cable joints have been adopted as specification standard by international oil and gas companies including Exxon Mobil, Chevron, Total and Royal Dutch Shell.

➡ Read our Blog for further information about the selection and specification of cable joints according to the ATEX Directive.

Cable Corrosion – 3M Solution

2 solutions to suppress future cable corrosion using 3M Electrical cable repair products :

- Accessible Cables – 3M Scotchrap 50 Tape provides advanced corrosion protection to cables exhibiting excellent resistance to abrasion, moisture, corrosive salt water, soil acids, alkalis and salts.

3M Scotchrap tapes are UV resistant and also resist impact punctures and tears with a very high weather and corrosion proofing performance for use on underground cables.

3M Scotchfil Electrical Putty can also be used to build-up irregular surfaces to provide a smooth, waterproof taping surface around cables where there is localised pitting type corrosion.

Scotchfil putty provides a versatile corrosion resistance solution to general cable and electrical equipment applications, the Scotchfil putty can be wrapped, stretched or moulded to conform to both standard and irregular surfaces.

3M Scotchfil Electrical Putty when over wrapped with either Super 33+ or Super 88 Vinyl Electrical Tape. Scotchfil™ electrical putty can also be used to build up cable joints and fill out major irregularities and voids.

- Inaccessible Cables – where cable access is limited 3M 1603 Insulation Spray can be used to protect cables and surfaces (including galvanised steel cable tray) against weather, moisture, corrosion, oil, alkalies and acids. 3M 1603 sprays provide easy access to hard-to-reach spots. eabling versatile on-site cable repairs without specialist tooling or requirement to disconnect or isolate cable circuits. 3M insulating spray sealers to spray over insulation on wire and cable splices, as a general-purpose sealer, or for touch-up insulation on motor windings and frames. Precautionary and first aid information for this product may be found in its Material Safety Data Sheet and on the product container.

Another type of cable failure is evidenced by visual indication of burning or arcing on the surface of the semiconductive layer of medium voltage cables. If the burning or arcing becomes extensive, the MV cable can fail from the outside in (pictured below).

The MV cable failure cause was determined to be a damaged cable sheath or jacket, which created a flowpath for corrosive ground water to penetrate the cable and cause severe corrosion to the metallic shield.

Scotch 70 silicone rubber electrical tape is a high temperature arc-and track-resistant tape composed of self-fusing, inorganic silicone rubber and easy-tear and easy-strip liner – the Scotch 70 tape is used as an over-wrap for protection of high voltage terminations and cables against arcing and tracking.

Some Further Reading : Corrosion Types Encountered With Power Cables : Underground Cables and Anodic Corrosion (Stray DC Currents), Cathodic Corrosion, Galvanic Corrosion, Chemical Corrosion, AC Corrosion, Local Cell Corrosion. By Edvard Csanyi (Electrical Engineering Portal EEP).

Whatever the cable condition or type of installation, 3M can provide innovative cable corrosion protection solutions based on Scotch electrical tapes, Scotchcast resin, heat shrink, cold shrink or spray based technology.

LV Cable Joints (Low Voltage Cables)

Thorne & Derrick stock and distribute LV Joints in Cold Shrink, Heat Shrink or Resin Cast technologies – multicore and multi-pair cable joints are available for immediate backfill and energisation of Low Voltage power, control and instrumentation cables 600V/1000V 3.3kV.

Complete range of LV Cable Accessories ➡

Cable Breakouts | Cable Caps | Cable Lugs | Cable Cleats | Cable Trough | Cable Duct | Feeder Pillars | for 11kV/33kV/66kV networks see MV HV Joints & Terminations

Pfisterer | Nexans Euromold | Prysmian | Cable Joints & Terminations MV HV

Cold Shrink by 3M | Joints | Abandonment | Terminations | Low Voltage LV Cables