Cable Joints & Terminations LV

Cable Jointing of Signalling Power Cables – What’s It All About?

November 15th, 2022

Jointing Signalling Power Cables

Cable Jointing

Signalling Power Cables

-

Special thanks to Paul Darlington from Rail Engineer for kind permission to republish this article

The Network Rail standard for enhanced unarmoured Signalling Power Distribution cables – NR/L2/SIGELP/27408 was introduced to tighten the specification for signalling power cables and support the introduction of Class II methodology.

The cable standard introduced several key requirements that drive the need to correctly specify the cable and the associated accessories – specifically the cable joints and jointing methodology used.

The cable standard re-introduces the use of aluminium as a conductor of choice alongside the traditional and more expensive stranded copper option. For the aluminium option NR/L2/SIGELP/27408 specifies solid conductors up to 95sqmm and allows both solid and stranded conductors for sizes equal or greater than 120sqmm.

To protect the cable from water and rodent-related degradation, the cable standard requires the use of water blocking tapes and fibreglass-woven rodent resistant tapes.

To supplement NR/L2/SIGELP/27408 and support the required target asset life of 35+ years, specific accessories standards have been written. NR/L2/SIGELP/27423 covers the requirement for cable joints and connectors. The standard says that, to achieve the target asset life, joints using resinous compounds are preferred.

Previous Cable Jointing History

The history of jointing signalling power cables is chequered – at one end of the scale there are manufacturer assembled, fully compatible and tested rail cable joints, which include connectors designed and tested to meet the Network Rail requirements of the day.

At the other end of the scale are cable joints assembled by third parties at the last minute to try to fulfil a particular urgent need, and which may or may not have been approved by Network Rail.

At both ends of this scale there would be a mix of technologies which may or may not produce a reliable installed joint capable of protecting the cable and meeting the Network Rail asset life expectations. This chequered history might have influenced the cautious approach of the industry related to the speed of the reintroduction of aluminium conductors.

Next generation cable joints

The standard NR/L2/SIGELP/27423 relates to joints intended for connecting signalling power cables, where the electrical system is either TN or IT and the nominal voltage is up to 650V AC. The cable types are defined as follows:

a) Enhanced unarmoured cable to NR/L2/SIGELP/27408.

b) B2 ethylene propylene rubber (EPR) cable to RT/E/PS/00005.

c) Armoured cable to BS 5467.

d) Armoured cable to BS 6346.

Within the joints standard, particular attention has been focussed on the conductor connectors or splices which requires full compliance with BS EN 61238-1 for both aluminium and copper conductors:

“Connector resistance, temperature, mechanical strength and short-circuit behaviour shall be in accordance with a Class A connector as specified in BS EN 61238-1.” (Network Rail, 2015)

In particular, connections between dissimilar metals, i.e., copper and aluminium, are specified to be made using bi-metallic connectors. These are required by NR/L2/SIGELP/27423 to be made by friction welding and similarly tested and approved to BS EN 61238-1.

Mixed experience

Network Rail has mixed experience with the aluminium conductor type cables leading to a previous preference for the copper conductors. However, driven by the recent high copper prices these cables are significantly more expensive and more liable to theft.

Looking outside of the rail sector it was noted that the UK power utilities had been using aluminium conductors and their associated joints and connections without significant problems for over 40 years. It was also recognised that the industry had tight product specification and training requirements in place.

To ensure an equivalent success rate on the product specification, the Network Rail joint standard sets out specific requirements for conductor connections and their installation:

“Unlike copper conductor based distribution systems, aluminium cable is very intolerant of poorly designed and badly made-up connectors. Failure of a connector can lead to loss of the power distribution system, which in turn can cause severe operational disruption. This specification has been developed to ensure that connectors used in signalling power distribution systems are made to a consistent standard and the measures identified in this standard, when adhered to, prevent premature failure.” (Network Rail, 2015)

Focussing on installation, the Network Rail accessory standard requires that all connectors supplied shall be suitable for installation in accordance with BS 7609. This is the ‘Code of practice for Installation and inspection of uninsulated compression and mechanical connectors for power cables with copper or aluminium conductors’ and covers installation methodology, tooling and the maintenance and calibration of tooling.

The Network Rail standard says that the preferred crimping tools are either battery-powered or electro-hydraulic and includes requirement for auto-checking. It also requires that manufacturers of connectors, such as Cembre or Klauke, provide the necessary training packages to support their use.

Wire electric cable on wooden coil or spool isolated

Prysmian Group

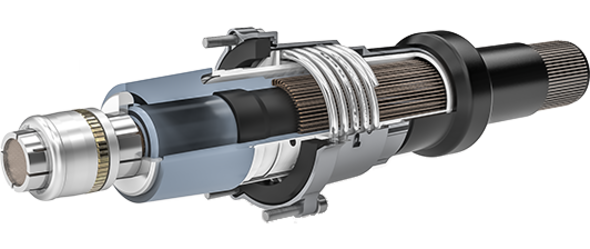

Prysmian Group has over 40 years’ experience in the development and testing of crimp connectors, including our in-house friction welding facility. To fulfil the Network Rail requirements the company has developed, tested, and qualified a completely new range of copper, aluminium, and bi-metallic connectors specifically to fully meet the Network Rail requirements.

These Network Rail-approved connectors are fully compatible with the new Prysmian Group joint range. This means that all of its signalling power joints are supplied with the correct connectors for their application.

The Network Rail standard requires that all joints are compliant with BS EN 50393 and are classified as rigid Type II. As noted, in order to fulfil a target asset life of 35+ years, joints made using resinous compounds are preferred. In addition, to provide adequate flood resistance, the joints must demonstrate that they meet the water immersion tests defined in BS EN 50393. (Note: BS EN 50393 requires joints to function within their parameters after being subjected to immersion for 21 days with a 1 metre head of water.)

In order to ensure useability and safety the Network Rail standard specifically requires that the resinous compounds used shall be classification LMP/LI-LT (Low voltage, Mechanical Protection / Low voltage, Insulation protection and Low Temperature curing) as per the requirements defined in BS 7933-1. In a move to maintain the highest levels of health and safety, the standard requires that the resinous compounds and joint capsules used shall be non-toxic and non-hazardous.

Prysmian Group & Network Rail

Working in collaboration with the Network Rail approvals team, Prysmian Group has developed and fully product approved a completely new range of NR/L2/SIGELP/27423 and BS EN 50393 compliant joints. These joints utilise the company’s enhanced, low hazard, JEM jointing resin. Over 30 million litres of Prysmian Group JEM has been used extensively by many of the UK power utilities, with no electrical failures reported.

Prysmian Group’s JEM resin can be mixed and will cure at temperatures as low as -15°C, meeting the Network Rail low temperature curing requirements that may be encountered in the UK climate. It is also a low viscous material which makes it extremely easy to mix, and also extremely searching, minimising any voids that can occur with traditional resins.

Prysmian JEM Resin For Low Voltage Cable Jointing

JEM resin is supplied in clear pouches which allows mixing to be observed during the process enabling the jointer to ensure mixing is complete prior to filling the joints. Another benefit of the JEM system is that when poured the filled joints, if undisturbed, may be energised immediately. From a safety perspective JEM resin is non-volatile, non-flammable, non-irritating and non-sensitizing in line with Network Rail expectations.

In order to meet the Network Rail reliability requirements, the joint system was put through the Network Rail product approval process which not only required the product to be fully compliant to BS EN 50393 type II but, by using tools like DFMEA and reliability and maintainability analysis throughout the development process, looks at ensuring the robustness of the product.

In order to support this robust approach, it is a requirement that the joints are supplied with a detailed set of installation instructions which include stage-by-stage photographs and instructions of the installation.

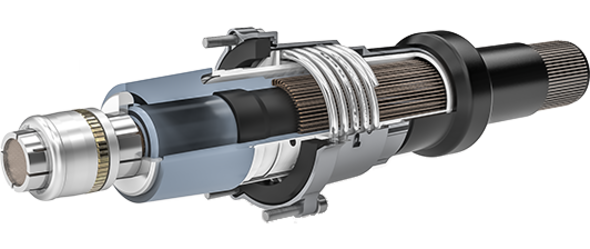

Low Voltage LV Industrial Cable Joints – Prysmian MPJEM-U

Jointing System Training

As part of the Network Rail accessories standard NR/L2/SIGELP/27423, Network Rail has included a specific requirement for training and competence on the accessory:

“Manufacturers shall have a comprehensive training programme that supports their product range. Note: Human factors and good workmanship drive asset life, without which the risk of premature failure becomes increasingly high. Successful completion of the training course shall be recorded in the candidate’s parent company’s competence management system.” (Network Rail, 2015)

It is clear that in order to meet the +35 years life expectancy of Network Rail the approved joints must be installed exactly as those tested and approved. Therefore, the requirement for specific training on the approved jointing system makes perfect sense. For some this training will be a refresher but, for those new to the industry, this training will be an entry point into the world of cable jointing.

The Prysmian Group training course is designed to give the delegates the knowledge and practical skills to joint two core and four core aluminium and copper rail signalling power distribution cables using the approved Prysmian Group RPJ enhanced cold pour resin joint kits. The course includes both classroom theory and practical sessions to ensure that the trainees can correctly and safely specify and install the Prysmian Group RPJ joints.

The course includes transferable skills such as:

- Electrical site safety.

- Best practice for reliable jointing of 1kV power cables.

- Understanding the risks of poor cable jointing and how to mitigate them.

- Understanding the perceived issues associated with jointing aluminium conductors.

- Safe cable handling methods (during jointing process).

- Identifying types of rail signalling power cable and understanding how to prepare them using the correct cable preparation tools and materials

The course also offers system specific skills such as:

- Selection of the correct joint kit for a specific installation and cables.

- Conductor preparation – particularly to overcome aluminium oxide build up prior to crimping.

- Demonstrating the correct crimp and die selection to produce reliable compression connections.

- Mixing and pouring of the approved JEM cold pour resin.

- Construction of the RPJ series joint kits in accordance with the Network Rail approved Prysmian Group jointing instructions.

Over the two-day course, trainees will receive both classroom theory and hands on practical sessions whereby, following expert demonstrations, they will get the opportunity to practice making their own cable joints. The course is concluded with an assessed multiple-choice theory questionnaire and the preparation of an assessed cable joint. Successful participants will receive a certificate of competence and the commensurate level of CPD hours.

Vertical coils industrial wires. Many turns of main electrical cable is closeup. Roll of outdoor fiber optic signal shielded cables. Wooden Coils of powerful black telecommunications wire

Network Rail has developed a robust set of standards for cables and accessories for signalling power cables. These standards are ensuring the networks of the future are robust and live up to the high expectation of the UK travelling public and Network Rail itself.

With the direction of Network Rail, Prysmian Group has developed a range of cable joints that facilitate the requirement for a long lasting, robust, and easily maintainable signalling power network.

From training courses that have been completed to date, feedback suggests such an event adds value to the already approved product and enhances the probability of making better joints on the Network Rail system.

Original Source Rail Engineer Magazine article written by Paul Darlington

About Rail Engineer

Rail Engineer is the leading independent quality monthly magazine for engineers, project managers, directors and leading rail executive decision makers.

Besides publishing the latest up-to-date rail engineering news, our team of engineer writers report on the engineering and technical aspects of many of the major projects being undertaken day in, day out, above and below ground, and across the globe.

In the UK we work in close consultation with Network Rail, Docklands Light Railway and the Underground, where our team of rail engineers actively visit the project sites, meet project engineers and provide in-depth analysis on the engineering skills being used and the latest innovations.

From trams and fleet refurbishment to new rolling stock and high speed rail, the rail engineer reports on the engineering and environmental challenges for manufacturers and operators. Our engineers visit factories and depots, meeting with specialist engineers to bring you the latest engineering updates on all aspects of rolling stock, whether onboard technology or mechanical enhancements focussing on safety, energy and the passenger experience.

To Subscribe Click Here

RAIL ENGINEER SEPT / OCt 2022

View the latest edition below or click the following link where the original Jointing of Signalling Power Cables – What’s All The Fuss About? can be found https://www.railengineer.co.uk/rail-engineer-september-october-2022/

RAIL CABLE ACCESSORIES, ELECTRIFICATION

& INSTALLATION EQUIPMENT

Thorne & Derrick stock and distribute an extensive range of 400V-33kV Rail Cable Accessories & Power Distribution Systems including feeder pillars to contractors undertaking Low Voltage Power Distribution, HV Electrification & Substations, DC Traction & Networks, OLE and Track Feeder Cable Renewals – complete range of Network Rail PADS approved track terminations, cable joints, cable repair and connection products up to 25kV, including 3M Cold Shrink, Pfisterer CONNEX and Nexans Euromold products.

Cable Joints, Terminations & Connections | Distributors & Stockists for 3M Cold Shrink | Nexans Euromold | Pfisterer CONNEX

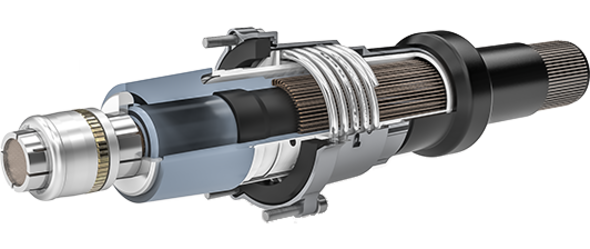

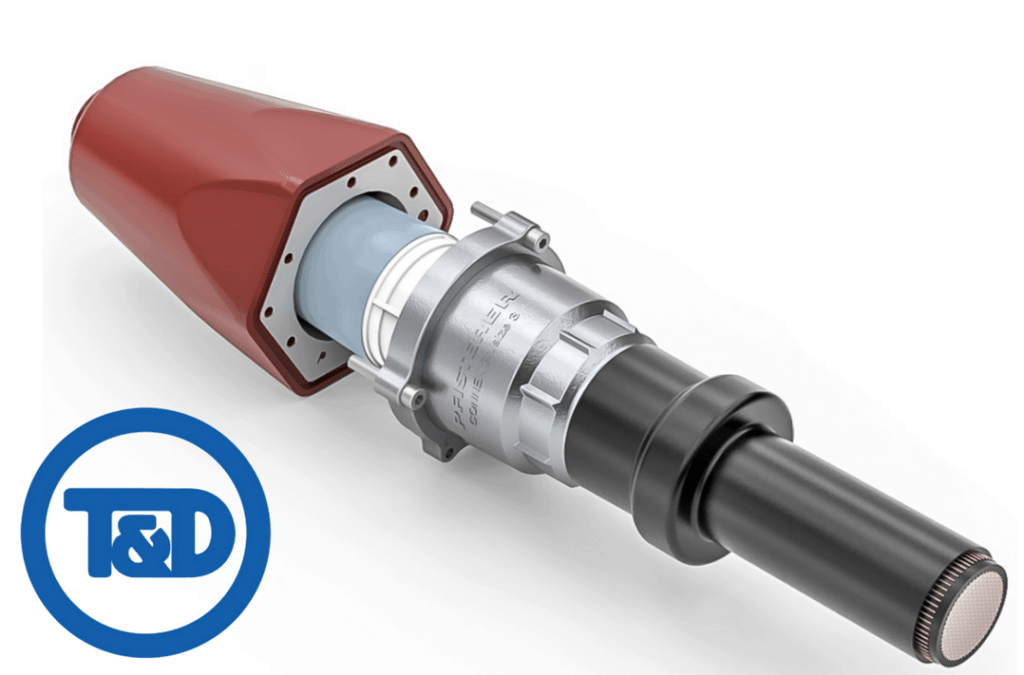

Pfisterer SICON CopperTop | Aluminium To Copper Conductor

October 12th, 2022![]()

SICON CopperTop by Pfisterer

332 907 082

Secure Conductor Material Transition From Aluminium To Copper

PFISTERER Sicon offer a range of mechanical shearbolt cable connectors with stepless shear-off bolts providing the right connector for any termination application for medium voltage power cables up to 66/72kV.

For years now, bolted clamps, connectors and cable lugs have been gaining ground as bolted connectors offer technical and practical advantages that conventional cable crimping and compression technology such as copper tube lugs cannot match.

With the Sicon CopperTop range of electrical connectors PFISTERER connects both the well-known SICON technology and the material transition from aluminium to copper in one cable lug. At the same time the copper/aluminium material transition is shifted to an area that easily can be covered with a heat shrink tube and can be secured against environmental impacts.

![]()

This allows for example a safe and corrosion resistant connection to copper bus bars, especially in outdoor use. Additionally, the SICON CopperTop 332 907 082 is an alternative for connections in elbow connectors from aluminium cable to copper connection elements.

SICON technology

Like all other SICON connectors the CopperTop can be used independently of the conductor material and type*. The special aluminium alloy allows a safe and corrosion resistant connection of both aluminium and copper material with perfect electrical characteristics.

Thanks to the patented SICON step-less shear off bolts, optimal contact force is always achieved and avoids mounting failures.

SICON CopperTop Benefits

- Al/Cu transition in the cable lug

- Safe and reliable connection of copper connection elements, especially in outdoor use

- Proven SICON technology

- Material transition easy shrinkable

- Reliable connection for all conductors

- Optimal contact force for all conductors

- No damage to individual strands

- Installation with standard tools

![]()

| Conductor type | Cross section aluminium conductor | Cross section copper conductor | ||

| mm² (mm) | AWG / kcmil (inch) | mm² (mm) | AWG / kcmil (inch) | |

| SM 120° / sector stranded 120° | 185 (240 rounded) | 185 (240 rounded) | 185 (240 rounded) | |

| SE 120° / sector solid 120° | 185 – 240 | |||

| SM 90° / sector stranded 90° | 185 – 240 | 185 – 240 | 185 – 240 | |

| SE 90° / sector solid 90° | 185 – 240 | |||

| RE / round solid | 185 – 500 (Ø 14,5-25,1) | 350 – 1000 (Ø 0.59“-0.99“) | 185 – 500 (Ø 14,5-25,1) | 350 – 1000 (Ø 0.59“-0.99“) |

| RMV / round stranded and compressed | 185 – 400 (Ø 15,3-24,6) 3 | 350 – 800 (Ø 0.65“-1.01“) | 185 – 400 (Ø 15,3-24,6) 3 | 350 – 800 (Ø 0.65“-1.01“) |

| RM / round stranded | 185 – 400 (Ø 17,0-26,1) | 350 – 800 (Ø 0.67“-1.03“) | 185 – 400 (Ø 17,0-26,1) | 350 – 800 (Ø 0.67“-1.03“) |

THORNE & DERRICK

Thorne & Derrick stock and distribute PFISTERER CONNEX Connectors for medium / high voltage cable connection and termination to electrical systems up to 33kV – we provide competitive prices for PFISTERER CONNEX connectors used to terminate and connect polymeric insulated MV-HV cables into gas insulated switchgear and electrical equipment from extensive UK stocks.

Thorne & Derrick are national distributors of LV, MV & HV Cable Installation, Jointing, Substation & Electrical Equipment – servicing businesses involved in cabling, jointing, substation, earthing, overhead line and electrical construction at LV, 11kV, 33kV, 66kV and EHV. Supplying a complete range of power cable accessories to support the installation and maintenance of low/medium and high voltage cable systems:

- Slip-on Cable Terminations

- Cold-shrink Cable Terminations

- Heat-shrink Cable Terminations

- Cable Joints – Heat & Cold-shrink

- Separable Connectors (Euromold)

- Surge Arresters & Switchgear/Transformer Bushings

Key Product Categories: Duct Seals | Cable Cleats | Cable Glands | Electrical Safety | Arc Flash Protection | Cable Jointing Tools | Cable Pulling | Earthing | Feeder Pillars | Cable Joints LV | Joints & Terminations MV

The SEANEX inner cone solution is an offshore variant of the successful Connex HV connection system that is specially adapted for 66kV inter-array cabling.

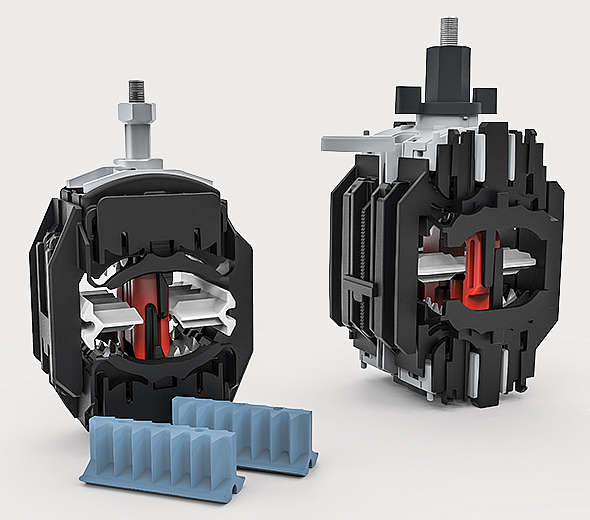

Insulation Piercing Connectors LV for Low Voltage Live Working & Cable Jointing

July 27th, 2022

Thorne & Derrick | Approved Pfisterer Supplier | UK & Export Sales

Insulation piercing connectors LV

Safe & Easy Live Line Working at Low Voltage Networks & Cables

Live line working is increasingly essential in low voltage networks. Bolted connectors used for this purpose should be easy to install and ensure the best possible occupational safety. The LV piercing connector family from PFISTERER has been developed to meet today’s practical requirements. Durable contacts come as standard, and have been a PFISTERER core competence for nearly 100 years.

Conductor does not have to be stripped

Insulation piercing connectors connect and make electrical contact with conductor ends, whatever the conductor cross-section, type and insulation. Because they pierce the insulation during installation, preparatory work on the conductor, such as stripping or brushing the contact area, is eliminated when live working.

The shear bolts on insulation piercing connectors LV are based on patented SICON technology. The electrical connector bolts are equipped with a piercing system that reliably penetrates the conductor insulation during installation by the cable jointer. A rotatable disc at the base of the bolt prevents damage to individual strands and ensures the correct contact force for all conductor materials.

New installations or repairs LV piercing connectors easily and safely connect all low voltage cables – even under voltage

Good occupational safety

The insulating body and plastic cover caps provide IP2X protection against finger contact in accordance with EN 60529. On type 3 and above, plastic flaps prevent inadvertent contact with the inside of the conductor channel. The elastomer insert ensures protection against contact after the bolts shear off.

Low shear off torque

The shear off bolts are tightened using standard tools. Once the optimal contact force is reached, the bolt gently breaks away at a torque of between 2.5 and 27 Nm, depending on the type. This prevents common installation errors and makes live line working much safer.

Compact and well designed

Once installed, the small size of LV piercing connectors makes subsequent work easier. Compact cable joints with cast resin mean that fewer resources are needed for the final installation. The connectors can be placed close to each other without any further accessories.

Type 1 and 2 are equipped with a push together system: multiple connectors can be joined together to form a compact unit. With type 3 to 5, the elimination of the cover caps ensures the smallest possible dimensions.

Connector Benefits

- Insulation does not have to be stripped from individual conductors

- Easy, safe installation – ideal for live line working

- Shear-off bolts prevent installation errors

- IP2X protection against electrical hazards

- Consistent operational reliability, according to IEC 61238-1 Class A

- Compact design – less cast resin when jointing cables

- Creepage distance conform to EN 60664, Pollution Degree 1

LV Piercing Connectors In Figures

- Voltage: up to 1 kV

- Conductor cross-section: 1 to 240 mm²

- Conductor category: class 1 and 2

- Shear torque: 2.5 to 27 Nm

Further Reading

- ISICOMPACT from PFISTERER | Branch Terminals for LV Cables & House Service Connections

- 2DIREKT from PFISTERER | Cable Connections & Terminal Clamps for Transformer Bushings & Busbars

THORNE & DERRICK

Thorne & Derrick stock and distribute PFISTERER CONNEX Connectors for medium / high voltage cable connection and termination to electrical systems up to 33kV – we provide competitive prices for PFISTERER CONNEX connectors used to terminate and connect polymeric insulated MV-HV cables into gas insulated switchgear and electrical equipment from extensive UK stocks.

Thorne & Derrick are national distributors of LV, MV & HV Cable Installation, Jointing, Substation & Electrical Equipment – servicing businesses involved in cabling, jointing, substation, earthing, overhead line and electrical construction at LV, 11kV, 33kV, 66kV and EHV. Supplying a complete range of power cable accessories to support the installation and maintenance of low/medium and high voltage cable systems:

- Slip-on Cable Terminations

- Cold-shrink Cable Terminations

- Heat-shrink Cable Terminations

- Cable Joints – Heat & Cold-shrink

- Separable Connectors (Euromold)

- Surge Arresters & Switchgear/Transformer Bushings

Key Product Categories: Duct Seals | Cable Cleats | Cable Glands | Electrical Safety | Arc Flash Protection | Cable Jointing Tools | Cable Pulling | Earthing | Feeder Pillars | Cable Joints LV | Joints & Terminations MV

The SEANEX inner cone solution is an offshore variant of the successful Connex HV connection system that is specially adapted for 66kV inter-array cabling.

MV Connex Products | Ex Stock Thorne & Derrick | Inner Cone Cable Connectors 33kV

ISICOMPACT from PFISTERER | Branch Terminals for LV Cables & House Service Connections

July 27th, 2022

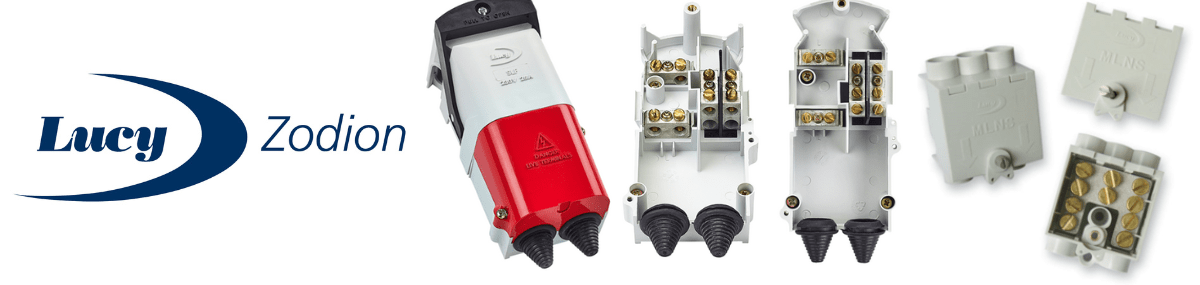

ISICOMPACT – Tap Connector for Low-Voltage Networks

Thorne & Derrick | Approved Pfisterer Supplier | UK & Export Sales

ISICOMPACT from PFISTERER

Branch Terminals for LV Cables & House Service Connections

Practical installation, good occupational safety and high levels of operational reliability are fundamental criteria for home power connections. ISICOMPACT by PFISTERER – the inventor of multi-conductor cable branch technology is the perfect solution.

With the invention of the compact screw terminal in 1968, PFISTERER set the standard in house connection technology. Well over 20 million SCK have been installed since then. Fast forward 30 years and the time had come for further development – ISICOMPACT technology.

The ISICOMPACT establishes all contacts for a 4-conductor cable branch using a single screw connection. When the screw connection is tightened, contact is established by piercing the insulation on the main line and branch lines.

Once the required clamping force has been achieved, the screw shears off and thereby ensures successful installation. By providing protection against contact and thus against electrical hazards, the ISICOMPACT is designed for live line work.

It is currently the only cable tap connector that also meets the strict requirements of BSI 862 – a German approval that enables a process for live line work without additional PPE and requires LLW electricians to undergo special training and the LV power network provider to be approved.

Six screws become ONE

ISICOMPACT reliably creates a branch connection from the supply cable to the end customer with just one screw. This simplifies and speeds up installation.

Where as conventional “clamping rings” have at least six screws, one or more of which are usually poorly accessible, the single screw on the ISICOMPACT can be placed on the cable to suit conditions, and conveniently tightened from above or from the side.

Simple & safe installation

Tightening the screw establishes all conductor contacts reliably and safely to form the cable branch. Insulation does not have to be removed from the conductor; contacts are established by piercing the insulation.

Spring pressure plates on both sides of the clamp ensure permanent contact force. The design and installation sequence ensure protection against contact with live parts throughout all work steps.

Live line working

Providing shock-proof protection against electrical hazards, ISICOMPACT is designed for live line working. The “green” version ISICOMPACT plus is the only cable tap connector approved by employer’s liability insurance association BG ETEM for live line work without additional PPE. It meets the strict requirements of DGUV Information 203-031 (formerly BGI 862).

ISICOMPACT – Reliable home connection with just one screw

High flexibility

Compared to conventional cable tap connectors, ISICOMPACT offers significantly larger clamping ranges and high flexibility in use. Altogether there are two standard sizes and seven variants. ISICOMPACT multi combines the S, M and 3 1/2 variants in one product.

As a result, electricians are equipped for all eventualities. At the same time, the smaller number of variants reduces the risk of using the wrong type and cuts inventory costs.

Unique shear-off technology

ISICOMPACT features a specially developed shear nut which performs two tasks during fitting. It defines the installation end-point and minimises the clamp’s dimensions. Once the optimal contact force is reached, the shear nut operates and the protruding section of the screw breaks away burr-free. Subsequently, ISICOMPACT fits into all commercially available cast resin joints.

Currently used by all major energy suppliers. ISICOMPACT cable branch technology

Everything from a single source

Clamping ring and cast resin joints from the inventor of multi-conductor cable branch technology. As a contact technology specialist and solution-oriented system provider, PFISTERER offers a wide selection of cast resin joints to complement the ISICOMPACT connection system, as well as complete matching sets comprising a cast resin joint and the cable tap connector. Our proven two-component cast resins with excellent flow characteristics are available in tins or in a practical two-chamber bag.

ISICOMPACT Benefits

- No stripping of conductors

- Insulation does not have to be removed from the conductor

- Shock-proof protection against electrical hazards

- One-Screw solution with defined shear torque

- Consistent operational reliability, tested to DIN VDE 0220 part 3

- Reduced range of variants due to large area of application

- Ideal for live line work

ISICOMPACT in Numbers

- Main conductor cross-section: 25-240 sqmm

- Branch conductor cross-section: 6-185 sqmm

- Voltage: up to 1 kV

Further Reading

- 2DIREKT from PFISTERER | Cable Connections & Terminal Clamps for Transformer Bushings & Busbars

- Insulation Piercing Connectors LV for Low Voltage Live Working & Cable Jointing

THORNE & DERRICK

Thorne & Derrick stock and distribute PFISTERER CONNEX Connectors for medium / high voltage cable connection and termination to electrical systems up to 33kV – we provide competitive prices for PFISTERER CONNEX connectors used to terminate and connect polymeric insulated MV-HV cables into gas insulated switchgear and electrical equipment from extensive UK stocks.

Thorne & Derrick are national distributors of LV, MV & HV Cable Installation, Jointing, Substation & Electrical Equipment – servicing businesses involved in cabling, jointing, substation, earthing, overhead line and electrical construction at LV, 11kV, 33kV, 66kV and EHV. Supplying a complete range of power cable accessories to support the installation and maintenance of low/medium and high voltage cable systems:

- Slip-on Cable Terminations

- Cold-shrink Cable Terminations

- Heat-shrink Cable Terminations

- Cable Joints – Heat & Cold-shrink

- Separable Connectors (Euromold)

- Surge Arresters & Switchgear/Transformer Bushings

Key Product Categories: Duct Seals | Cable Cleats | Cable Glands | Electrical Safety | Arc Flash Protection | Cable Jointing Tools | Cable Pulling | Earthing | Feeder Pillars | Cable Joints LV | Joints & Terminations MV

The SEANEX inner cone solution is an offshore variant of the successful Connex HV connection system that is specially adapted for 66kV inter-array cabling.

MV Connex Products | Ex Stock Thorne & Derrick | Inner Cone Cable Connectors 33kV

Lucy Zodion Awarded Tender by Scottish Power Energy Networks

June 15th, 2022

-

Uploaded By - Chris Dodds (Thorne & Derrick Sales & Marketing Manager)

Press Release: Thorne & Derrick and Lucy Zodion | 17.6.22

STREET LIGHTING CUT OUTS

Thorne & Derrick, a Specialist Distributor for Lucy Zodion the market-leading manufacturer of Street Lighting & ICP Connection Solutions, are delighted to announce that Scottish Power Energy Networks (SPEN) have awarded a 2-year tender to Lucy Zodion to supply the following G81 approved products:

- Lucy 0260009009 SLF 25A Street Lighting Cut Out TYPE 1 SNE Boxed

- Lucy 0350012009 5 Way Connector Box

The Lucy Zodion range of street lighting cut-outs, controls, feeder pillars and isolators are specified and installed by ICP’s throughout the UK providing reliable and effective street lighting and electrical connections to our utility network.

Thorne & Derrick are Approved Vendors to SPEN and their Lloyds NERS accredited ICP’s, you can contact us for competitive prices and stock availability for the complete range of Lucy Zodion Street Lighting Equipment.

➡ For further information about how Lucy Zodion provide control and power distribution products for street lighting applications, please review the Lucy Titan (Cut-outs) and Lucy Trojan (Isolators) ranges of products.

Should you require any technical support or have any commercial requirements about G81 Approved 11kV/33kV Cables & Accessories please do not hesitate to contact Thorne & Derrick Sales Team.

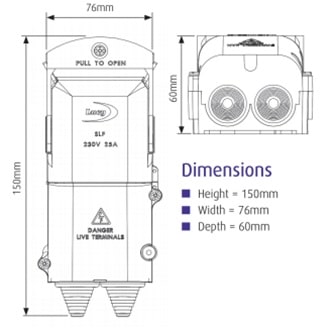

Lucy Zodion SLF fused cut out

- Separate neutral and earth (SNE) cut out

- Maximum continuous load 25A

- Simple cam lever fuse carrier removal

- Single fuse

- Double pole

- Cut-out full conformity to BS7654

- Terminals accept cables up to 25sqmm

- IP22

- 2 x 20mmØ cable entry- grommets

Lucy Zodion Cut Outs | The SLF cut out range is approved by all Distribution Network Operators (DNO’s) throughout England, Scotland and Wales – G81 approved versions are available for ICP/IDNO connections.

Lucy Zodion Cut Outs

| SPEN SAP Code* | Lucy Zodion Part Code | Description* |

| 30980590 | 0260009009 | CUT OUT 25A STREET LIGHTING TYPE 1 SNE: 25 AMP STREET LIGHTING CUT OUT, SNE CONSTRUCTION |

SLF

Lucy Zodion MLNS – 5 Way connector block

MLNS

- Maximum continuous load 100A

- Suitable for phase, neutral or earth conductors

- Serrated cable bores accept conductors up to 35mm² section

- Two M8 slotted head cable pinching screws per conductor

- Sealing wire facility

- IP22

- Removable shields for unused cable entries

- Robust thermoplastic housing

| SPEN SAP Code* | Lucy Zodion Part Code | Description* |

| 30980639 | 0350012009 | 100 A, 5 WAY SINGLE POLE CONNECTOR BLOCK. SUITABLE FOR TERMINATING PHASE, NEUTRAL OR EARTH CONDUCTORS |

*The SPEN part codes and descriptions in the tables are taken directly from the tender document.

Lucy Zodion’s SLCOs are compliant with BS7654, which covers all aspects of the cut out from the materials in which it is manufactured, to a series of tests relating to temperature, ingress protection, current and mechanical strength.

BS 7654 | 10th Edition, May 15, 2020 | Specification for single‑phase street lighting cut-out assemblies for low-voltage public electricity distribution systems – 25 A rating for highway power supplies and street furniture | purchase copy.

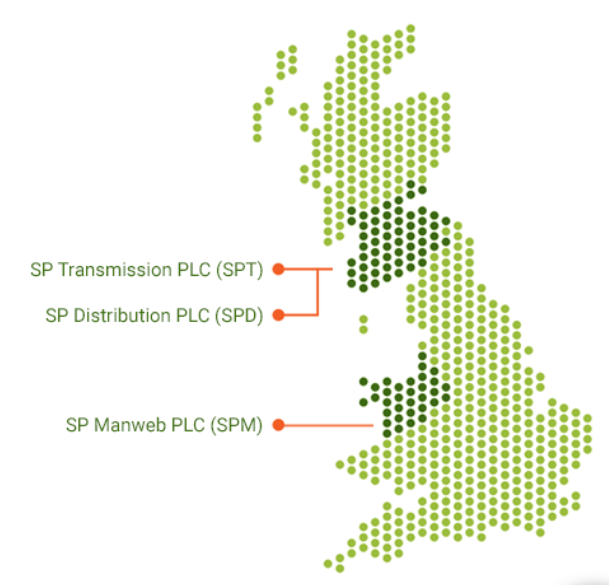

About SPEN

SP Energy Networks are a Distribution & Transmission Network Operator keeping electricity flowing to homes and businesses throughout Central and Southern Scotland, North Wales, Merseyside, Cheshire and North Shropshire – this is achieved via a network of Overhead Lines & Underground Cables which they own and maintain.

This includes over 30,000 substations, 40,000km overhead lines and 65,000km underground cables.

3 SPEN Regulated Electricity Businesses

- SP Transmission PLC (SPT)

- SP Distribution PLC (SPD)

- SP Manweb PLC (SPM)

THORNE & DERRICK

T&D are Specialist Distributors to UK Distribution Network Operators (DNO’s), NERS Registered Service Providers, ICP’s and HV Jointing Contractors of an extensive range of LV, MV & HV Jointing, Earthing, Substation & Electrical Eqpt – this includes 11kV/33kV/66kV cable joints, terminations and connectors for both DNO and private network applications.

Contact our UK Power Team for competitive quotations, fast delivery from stock and technical support or training on all LV-HV products.

Key Product Categories: Duct Seals | Cable Cleats | Cable Glands | Electrical Safety | Arc Flash Protection | Cable Jointing Tools | Cable Pulling | Earthing | Feeder Pillars | Cable Joints LV | Joints & Terminations MV HV