Blog

Cable Clamps by BAND-IT

March 22nd, 2022Clamping Cables

From traditional metal cutting, stamping and forming, to robotic precision forming and sorting, BAND-IT is paving the way for new manufacturing solutions.

BAND-IT’s in-house engineering team expands the traditional applications and invites the challenges new opportunities have to offer.

Thorne & Derrick have stocked and supplied the BAND-IT range of cable clamps, ties and fasteners since 1985.

With over 75 years’ experience in stainless steel clamping, strapping, banding, bundling, fastening, and identification solutions, we can modify standard clamping systems or develop new solutions for your specific project needs. From customized clamp selection to in-depth field testing and specification, BAND-IT’s engineered applications team and Thorne & Derrick can meet the exacting requirements for your specialized needs.

- Standard and state-of-the-art high speed production tools and fastening solutions

- Unrivalled R&D and engineering support for the BAND-IT product range

- Worldwide manufacturing and distribution facilities

- On call Engineered Applications Team to meet your project needs

Need a custom solution to solve your cable fastening challenge?

All of BAND-IT’s custom stainless steel clamping and cleat solutions for cables are manufactured to provide the highest level of quality and can be customized to:

- Cable clamp easily conformable to any shape

- Securely fasten dissimilar materials, odd shapes and difficult objects

- Withstand extreme temperatures and corrosive conditions

- Stainless steel, high-strength, cable fastening and fixing clamps resist vibration

BAND-IT has engineered cable clamping and fastening solutions for applications in areas such as LV MV HV cable management, hose attachment, identification, insulation and pole and tower mounting in the utility, power and transmission distribution sectors.

More from BAND-IT

- Solar Farms Replace Nylon Cable Ties With Metal Cable Ties

- BAND-IT Band Clamps Used In TR-343 Transducer Assembly

- BAND-IT ULTRA-LOK Cable Clamps Reduce Cable Theft | Case Study

- Securing Fire Resistant Sleeves On Hoses & Wires With BAND-IT JS Clamp

Cable Clamps by BAND-IT

Thorne & Derrick distribute the most extensive range of Low & High Voltage Cable Installation & Electrical Distribution Equipment to the Power Transmission & Distribution industry in the onshore and offshore wind, solar, rail, oil/gas, data centre, battery storage and utility sectors – this includes Joints, Terminations & Connectors to enable the installation of low, medium and high voltage power cables into underground trench or duct.

Klauke Orange Insulated Tools | Innovation That Ensures Safety

March 22nd, 2022

Klauke Orange Tools

Klauke Orange

Cable Cutting & Crimping Insulated Tools

Launched at ENERGYx2020 the KLAUKE Orange range of fully insulated tools manufactured by Klauke has set the standard within the global utility industry. Offering increased safety this range is the world’s first battery operated cable cutting and crimping tools with Tri-Insulation Barrier technology.

The orange housing of the battery powered cable crimping tool makes it easily differentiated from standard crimping tools and the built-in display allows user to view all tool data instantly.

Health & Safety is a main pillar of Energy Network Events and the KLAUKE Orange range is a huge leap forward in the development of battery-powered cabling tools for the cutting and crimping of overhead lines and underground cables.

You can find out more about ENERGYx2022 here: ➡ ENERGYx2022

You can view the complete range of KLAUKE Orange tools here ➡ insulated cable crimping and cutting tools.

Cable Cutting & Crimping

Insulated Tools & Total Safety

The world‘s first battery hydraulic crimping and

cutting tools with Tri-Insulation Barrier technology that provides users with 1.000V protection against

electrical shocks.

There have been several recent advances in cable cutting and crimping tool technology including data recording, bluetooth remote controls and pressure sensors.

All tools have become more compact making them more efficient for jointing and terminating cables in confined spaces as well as enhancing safety features.

Training, supervision, testing and PPE are all standards but what the KLAUKE Orange implements is another layer of electrical safety into the process.

➡ Download Brochure Klauke Cutting & Crimping Tools

- You frequently work in close proximity of live lines and parts. You cannot take any chances.

- You have ergonomic issues due to use of manual insulated tools. You want to work safe but with faster and more ergonomic tools.

- Cables you perceive as not live, can turn out to be live. You want to be protected at all times.

- Live line cutting is one of your safety critical tasks. You have to use safer tools for more protection.

The Klauke Orange battery hydraulic Cutting- and Crimp Tools are VDE Approved in accordance to IEC 60900 and fully VDE Certified to IEC 62841-1. See the full Klauke Orange range in the video below.

Tri Insulated Barriers on Klauke Tools

During the interview below, Paul stresses the importance of safe working practices including the physical aspect of the tool e.g. the body insulation of the cable crimping or cutting tool. The new Orange Line Tool uses a 3 level or tri-insulation system – the 3 level includes creepage distance, insulation material and oil within the system.

Energyxtra Interview

Paul Morrow describes how Klauke was started in 1879 by two brothers in Germany originally making high quality pliers for the watch-making industry employing only 5 people. In 1960 when electrification become more popular Klauke shifted to developing cable lugs.

In 2018 they were acquired by Emerson and along with Greenlee and Rigid, Klauke can now service all the mechanical, electrical and plumbing requirements in the market.

For even more safety, Klauke has now developed the world‘s first battery hydraulic crimping and cutting tools with Tri-Insulation Barrier.

Before exhibiting at ENERGYx2020 Paul Morrow, UK & Ireland Manager from Klauke, part of the Emerson Group took part in an informative interview with Paul from Energy Network Events discussing electrical safety and the recent launch of the KLAUKE Orange range of fully insulated tools that have set the standard within the global utility industry.

Paul Morrow

Thorne & Derrick Testimonial

“Since 1985, Thorne & Derrick have gained a solid reputation for contributing to improvements in Workplace Electrical Safety throughout the industry – this includes assisting the launch of product innovations into the market, such as the Greenlee LS50 & Klauke VDE Orange and being a “go-to” supplier of electrical safety equipment to power industry contractors working with underground cables or overhead lines.

launch of product innovations into the market, such as the Greenlee LS50 & Klauke VDE Orange and being a “go-to” supplier of electrical safety equipment to power industry contractors working with underground cables or overhead lines.

Increasing sales of our Strut Channel Cutter are an excellent example of a success story – the RIDGID STRUTSLAYR is recognised as the strongest and safest strut channel cutter on the market and is available from Thorne & Derrick stocks.

The sales and marketing staff at Thorne & Derrick worked hard and smart on introducing the STRUTSLAYR product to their clients and marketplace during COVID and are now seeing the impressive sales results.

Together during 2022 we welcome the opportunity to jointly promote more Workplace Electrical Safety improvements to be delivered through product innovations including the first remote-controlled cable cutters. For example, the Klauke ESG105RMCCFM and ESG65RMCCFM battery-powered, hydraulic cutting tools which will allow the user to maintain a safe distance whilst cutting cables,” comments Paul.

ENERGYx2022

Energy Network Events exists to safely promote and further the interests of everyone working in and supplying the electricity industry. The management team have years of experience working in industry, organising and promoting events and use their experience and contacts to win the support of Legislators, Regulators, Senior Managers, World Class Suppliers and Inspirational Figures.

VISIT

ENERGYx2022 Visitor Delegate FREE Tickets

EXHIBIT

ENERGYx2022 South Exhibitor Booking Form

ENERGYx2022 is the industry-leading Exhibition & Conference for anyone working within the Electricity Industry

LV, MV & HV Jointing, Earthing, Substation & Electrical Eqpt

Thorne & Derrick International are specialist distributors of LV, MV & HV Cable Installation, Jointing, Duct Sealing, Substation & Electrical Equipment – servicing UK and global businesses involved in cable installations, cable jointing, substation, overhead line and electrical construction at LV, 11kV, 33kV and EHV.

THORNE & DERRICK Product Categories: Duct Seals | Cable Cleats | Cable Glands | Electrical Safety | Arc Flash Protection | Cable Jointing Tools | Cable Pulling | Earthing | Feeder Pillars | Cable Joints LV | Joints & Terminations MV HV

Thorne & Derrick | Stockists & Suppliers | Joints Terminations Connectors up to 66kV

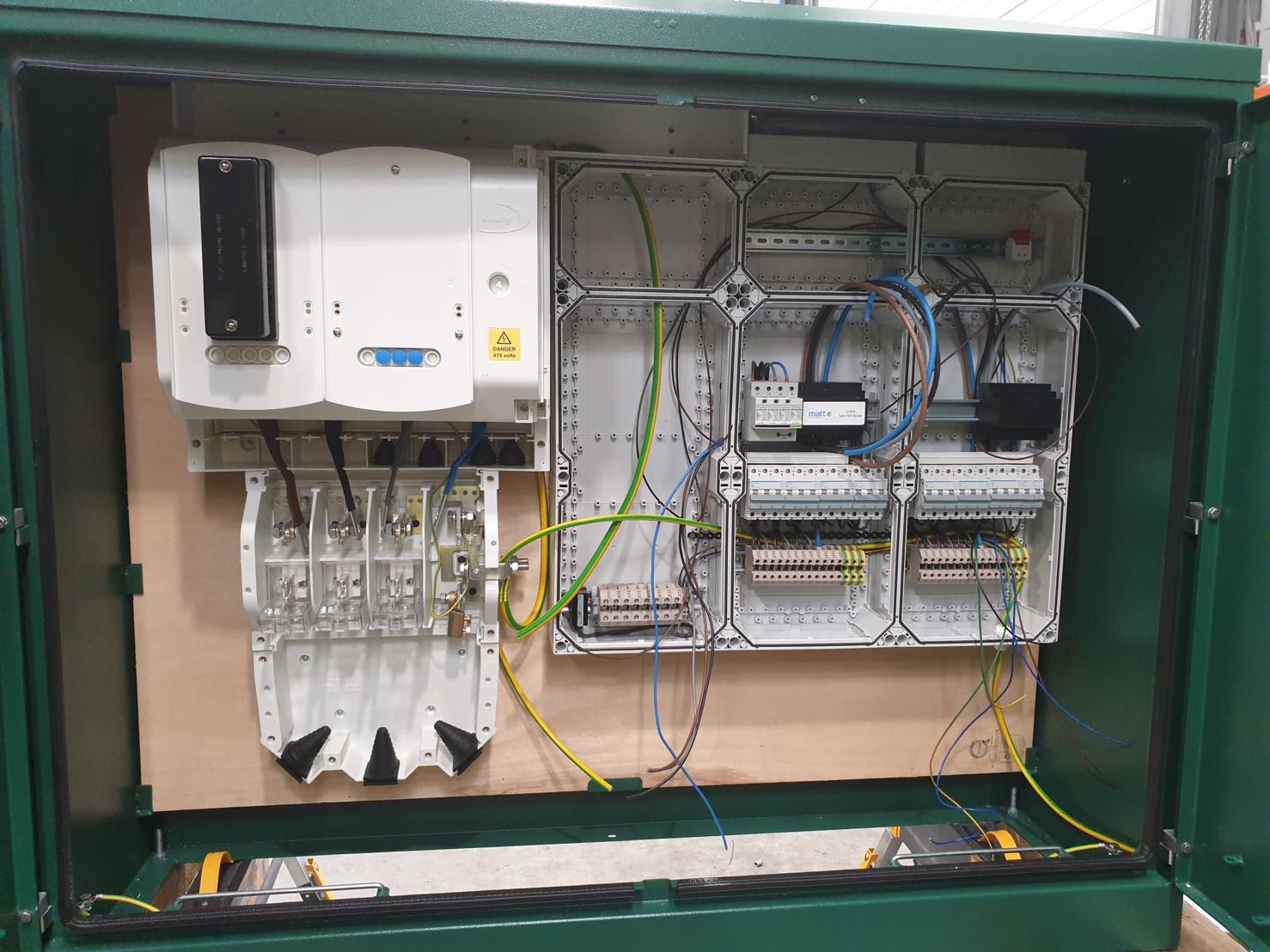

EV Pillars | Taking Charge of Safe & Reliable On-street EV Infrastructure

March 22nd, 2022

EV Pillars by Lucy Zodion

Background

With a key driver for the electrification of vehicles being the environmental benefits they promote, electric vehicles (EV) are becoming pivotal parts of urban regeneration.

Reducing emissions and improving the carbon footprint of both individuals and communities, EVs and their supporting infrastructure, such as EV Pillars, are now vital assets for cities and towns throughout the world.

There are a number of initiatives throughout the UK that are helping to drive the uptake of EV. One of these initiatives is the ‘Go Ultra Low City Scheme’ (GULCS) procurement framework, which has been set-up by London Councils, TfL and the GLA, to ensure the Capital’s transport network meets its aim to be the Ultra-Low Emission Vehicles (ULEV) capital of Europe.

The Scheme has four main streams of work which focus on making residential charging available, increasing the provision of rapid chargers and increasing the provision of charging infrastructure in car club bays. This increased uptake means solutions are required that not only make EV charge points more accessible, but ensure the supporting infrastructure is capable of providing a consistent, safe and reliable power supply.

ubitricity is a market leading supplier of on-street EV charging solutions, integrating them within existing street furniture to make on-street charging available and simple to use.

The EV charging specialist recently carried out work as part of the (GULCS) by transforming existing street lighting columns into on-street charge points, throughout London and surrounding boroughs. As the UK’s market leader in the provision of connection equipment for external lighting infrastructure, including the sole supply of street lighting cut-outs and isolators in to the UKPN electrical network, ubitricity selected Lucy Zodion as its solution partner for the project.

Challenge

The main challenge of the project was to support the transition of the use of the streetlight.

From being solely used to illuminate the street, it is now required to become a multipurpose piece of street furniture, providing both illumination and EV charging facilities simultaneously, while ensuring power and protection to both equipment and people, in-line with electrical regulations.

EV charge points fall into four main categories according to the charge speed – Slow, Fast, Rapid and Super.

Objectives

Lucy Zodion worked with ubitricity’s UK Operations Director to provide a certified and approved solution that works alongside existing street lighting infrastructure. The key objectives for the EV project included feeder pillar design to satisfy the following criteria:

• Reliable Power – The solution had to meet all relevant industry standards, as well as those outlining the safety of users. It also had to demonstrate a proven track record.

• Safe – As the lamppost is being transformed from street furniture to a point of public access, the solution needed to consider not only electrical safety within the street lighting column, but the safety of the end-user while accessing EV charging equipment.

• Readily Available – As the project was on a short-lead time, Lucy Zodion was required to provide a distribution pillar solution that was immediately available.

• Multi-purpose – The power distribution solution was required to provide appropriate protection of both the EV charging equipment and to protect the user from electric shock in line with industry standards. The solution had to provide a separate feed to the luminaire to ensure continual operation in the event of electrical issues.

Project Summary

- Project Name: Taking charge of safe and reliable on-street EV infrastructure using Lucy Zodion feeder pillars manufactured for EV sector

- Location: Greater London, UK

- Completed: 2019

- Pillar Installed: Lucy Zodion single phase secondary isolators

Collaborator: ubitricity

Solution

Lucy Zodion’s solution was to manufacture and supply several thousand secondary isolators to provide 32A supply protection and lockable isolation for the street lighting column. They provide 25A residual protection for the 5.8kW EV charging equipment,plus 6A protection for theluminaires. The product installed is:

• Product Specification: Lucy Zodion Trojan Midi with 32A switch disconnector

Lucy Zodion Results

Lucy Zodion’s isolation solution met all objectives successfully, resulting in a certified and approved installation. As a result of the project, various London Boroughs are closer to meeting their Ultra-Low Emissions targets with a capable infrastructure to support EV drivers. The objectives were met in the following ways:

Safe | Lucy Zodion included in the design a 25A residual current protection for the 5.8kW ubitricity EV chargers. Additionally 6A protection for the luminaires was included so that in the event of a fault on the charging equipment, the luminaire will continue to operate as normal.

Reliable | Lucy Zodion isolators are manufactured considering current British and Industry standards. Components are also tested by third party, KEMA, for further compliance and accreditation. The 32A isolator is KEMA tested to IEC/EN 60947-3 and the fuse carrier is KEMA tested to IEC/EN60269-1. Additionally the isolators’ 25A residual current protection and 6A protection, were integrated in line with the IET Code of Practice for Electrical Vehicle Charging Equipment Installation (BS7671:2008+A3: 2015).

Delivery Time | Due to the number of units required, these were shipped weekly to support a wide-scale roll out over a relatively short period, which suitably matched the installation schedule.

Versatile | The isolators provide 25A residual current and overload protection for ubitricity’s 5.8kW EV chargers, which are mounted into existing streetlights. In addition, 6A protection is included for the luminaires to provide dedicated supply and protection in order to minimise outages. The isolators were used in conjunction with the Network Operators (UKPN) approved Lucy Zodion Street Lighting Cut-Out.

Thorne & Derrick | Distributor & Supplier of Feeder Pillars

Cable Fault Location Equipment | Power Cable Testing Post Installation

March 21st, 2022

-

By Damon Mount | Head of Business Development at Megger

Power Cable Testing

Cable Fault Location Equipment

An essential stage in the commissioning of any power cable is testing prior to energisation.

Properly performed, this test will provide the information needed to ensure that any problems that have occurred during the manufacture or installation can be corrected before they lead to costly and disruptive faults.

But what is the best way to approach post-installation cable testing?

Without any shadow of doubt, the first step is to get the cable preparation right and, if you are using a contractor to carry out the work, this means choosing one that can unequivocally demonstrate that they know what they are doing.

This may seem obvious but there are good reasons to be wary and, although this sounds paradoxical, one of the main underlying reasons is that modern cable test sets, such as those in the Megger range, are very easy to use.

This is undoubtedly a good thing overall, but a possibly unexpected side effect is that contractors with little or no cable test experience may believe that if they hire one of these test sets and quickly peruse the manual, they’re ready to offer cable testing services. They are not. There is much more to cable testing than simply knowing how to operate the test set, especially if the work is to be carried out safely and to deliver accurate results.

An experienced contractor will first formulate a safe method of work, and will manage the test area effectively and efficiently. It is important to keep anyone who is not involved with the testing away from the area, remembering particularly that there’s no visual difference between an energised cable and a de-energised cable.

This doesn’t just mean keeping members of the public away as colleagues acting as onlookers can be even more hazardous – they are the ones who are most likely to poke at the test set in an attempt to be helpful, and to offer distracting comments and suggestions.

The next step is to prepare the cable for test and, in particular, to prepare the cable ends so that, when carrying out a cable sheath test, there will be no flashover between the metallic sheath or screen and the semiconducting oversheath. Checking that the semiconducting material has been properly removed by carrying out a quick and simple test using an ordinary handheld insulation tester is always worthwhile.

TDR1000/3P Handheld TDR by Megger

It is now necessary to remove any cross-bonding links that are used in the cable system and it is essential to allow sufficient time for this. It is by no means unusual for a single link box to contain 30 or even 45 links. Removing these prior to testing and refitting them after testing will involve hours of work, something that those setting deadlines for testing often fail to realise.

Cable Fault Location Equipment

With preparations complete, testing can commence, but there is another essential factor that needs to be considered – the right test equipment must be available on site.

This doesn’t just mean the test set that will be used for carrying out basic sheath testing, but also the additional equipment that will be needed to diagnose and locate the cable fault, if one should be found.

Few cable operators will be happy about the delays involved in returning to base to fetch more test equipment – it needs to be on site already, so that cable faults can be dealt with quickly and effectively.

This is another area where experienced cable testing contractors score. Since they carry out cable testing regularly, it is worth their while investing in a full range of test equipment and, just as important, in training their staff to use it safely and effectively. Companies that carry out cable testing relatively infrequently are unlikely to be able to match this level of investment and commitment.

The test voltage should, of course, be applied in line with the appropriate standards and specifications, and a good suggestion is that the test results should be written down on paper, even if they are stored in the instrument. The paper records may hardly ever be needed, but they are a simple and inexpensive precaution against stored results being accidentally erased or overwritten.

If all has gone well, it only remains to discharge the cable, issue the test certificate and, in the case of a contractor, send the client an invoice. Never rely on the test set alone, however, to discharge the cable! Even if the test set is indicating zero volts it takes only a few seconds to make sure the cable really is discharged by using a discharge stick. Failing to do so could, in the worst case, lead to a fatality.

What about those cases where a fault is found? The first thing to do is to STOP and assess the situation. Turn off the test equipment, discharge the cable and check that all connections at the local and distant ends of the cable have been made correctly. Re-test and, if the fault persists, decide on a testing strategy that will allow the fault to be diagnosed and located with the minimum risk of causing further damage to the cable.

This will typically involve the use of TDR to pre-locate the fault, and then a pin-pointer to find its exact location. Once again, it’s important to keep the crowds away, especially when using an acoustic pin-pointer, as footsteps in the vicinity can make it much more difficult to determine the precise fault location.

Pictured: Megger TDR1000/3P Cable Fault Location Equipment showing an LV underground mains cable fault. Fault location from substation at 104 metres. The images show an open circuit and then an issue 13 metres from point of electricity supply – this cable fault was caused by incorrect cable laying.

Accurate, dependable results are essential because, for the fault to be remedied, the cable will need to be excavated. This is a costly and time consuming task, so the risk of digging in the wrong place must be eliminated as far as possible.

It is always worth bearing in mind that post-installation sheath tests are relatively inexpensive to carry out and they are an excellent way of guarding against potentially costly future problems. A vital point, however, is to resist the temptation of opting for cheap solutions.

If you carry out the work yourself, make sure that you have the right equipment, that it’s calibrated and in full working order and that your staff are properly trained. Allow plenty of time for the work to be carried out – rushing work significantly increases the risk of making mistakes and, in cable testing mistakes can be fatal.

Megger TDR1000/3P Handheld TDR For Power Application

If you subcontract the work, choose your contractor with care – opting for the lowest price may well turn out to be false economy. Ensure that your chosen contractor has a proven track record in cable test and, bearing in mind the points discussed in this article, check that they will be able to cope efficiently and safely, even if the work turns out not to be straightforward.

Post-installation cable testing, properly carried out, is an excellent and very affordable form of insurance. But as with any other form of insurance it pays to check the details carefully and to avoid automatically opting for the cheapest option, unless you’re really sure that it meets your needs.

-

Electrical Test Equipment LV MV HV

JOINTING, EARTHING, SUBSTATION ELECTRICAL & SAFETY EQUIPMENT DISTRIBUTORS

Thorne & Derrick International are specialist distributors of LV, MV & HV Cable Installation, Jointing, Duct Sealing, Substation & Electrical Equipment – servicing UK and global businesses involved in cable installations, cable jointing, substation, overhead line and electrical construction at LV, 11kV, 33kV and EHV.

THORNE & DERRICK Product Categories: Duct Seals | Cable Cleats | Cable Glands | Electrical Safety | Arc Flash Protection | Cable Jointing Tools | Cable Pulling | Earthing | Feeder Pillars | Cable Joints LV | Joints & Terminations MV HV

Distributors for 3M Cold Shrink & Scotchcast | Nexans Euromold | Pfisterer Connex

Working Loads & Break Strength | The Key is Your Factor of Safety

March 21st, 2022

Line Pulling Swivels By Slingco

Line Pulling Swivels By Slingco

Working Loads & Break Strength

Safety is critical when dealing with utility, construction or maintenance projects.

One of the main ways to ensure safety is by working within the load limits of crucial equipment. Slingco promote the safety critical role of cable support grips and the need for independent break load testing to safeguard project, people and reputations.

Swivels designed for use in stringing high tension wires for electrical transmission and distribution. Line Pulling Swivels are important in pulling when the lines develop torsion during the installation. This torsion must be released.

Use of a swivel will release torque and prevent it from reaching dangerous levels, which can cause damage to the cable or cable socks.

Slingco also offers a ‘bull nose’ style swivel designed for underground and overhead applications. All swivels are stringently quality tested and inspected to ensure optimum performance and reliability with working Loads from 10 to 134 kN.

What is Factor of Safety?

This is the factor used to ensure sufficient break load to handle working load spikes. It is critically important that all devices and tools used for pulling conductor are rated for the working loads expected on each job.

Factor of Safety (FOS) is often notated as X to 1 or X:1. It is the ‘extra’ coverage of the breaking load over the working load expected. When pulling conductor or cable, many factors impact how much load your equipment must handle.

Sometimes the conductor can get hung up on something which will cause the load tension to spike. The factor of safety helps accommodate a normal spike without dropping wire or experiencing equipment failure.

How do you determine Break Load?

Break Load must equal or exceed the Working Load x Factor Of Safety.

To help explain this, imagine the tension for a pull is calculated to be 1,800kg – this is Working Load of the pull. If the equipment used is only rated to a Break Load of 1,800kg, any variation in the load tension over the standard can cause failure. So, project designers assign a factor of safety (FOS).

- A FOS of 3 to 1 is commonly accepted in the UK for overhead line pulls. Different countries may have a different standard.

This means that the Break Load of any tool used must be 3 times the expected load tension. In this example:

Working Load of 1,800kg x FOS of 3 = Break Load of 5,400kg.

Grips and swivels would need to be selected with a break load of 5,400kg or more.

When selecting equipment for a pull, be sure you know whether items are rated at BREAK LOAD or WORKING LOAD. If rated at working load, you must know the Factor of Safety this working load is based upon to ensure it matches your project’s working load. If rated at break load be sure it meets your project’s break load including the Factor of Safety.

Here are a few common rules of thumb for the Utility industry:

Pulling & Support Grips – usually rated at approximate BREAK load. This means a factor of safety for your project must be applied. To determine the working load, divide the break strength by your project’s Factor of Safety. For example, a grip with an approximate break load of 5,400kg to be used on a project with a FOS of 3:1 has a safe working load of 1,800kgs.

Swivels – This is where it gets tricky (or trickier). Most (but not all) manufacturers will label swivels at a 3:1 FOS working load. Slingco (along with two other prominent manufacturers of swivels) go ahead and CONVERT THE BREAK LOAD INTO THE WORKING LOAD. Our 2,240kg swivel is rated for a 6,720kg Break Load – we have already built in the Factor of Safety of 3:1.

Connectors – (90 degree, Rope to Rope, Rope to Swivel): Similar to swivels these are typically listed at their rated 3:1 WORKING LOAD. Connectors are used to connect grips when pulling though a tensioner or around an angle greater than 50 degrees. Swivels should not be pulled around a tensioner. Swivels are not designed to handle the side loads experienced when going around a tensioner wheel. This can cause damage to the bearing structure within a swivel.

These are only a few of the tools used. Remember to make sure you understand how each tool is rated (Working Load at what FOS or Break Strength). The key to ensuring a safe project is making sure all tools meet or exceed your project’s Working Load.

➡ Contact Thorne & Derrick for technical support on your cable pulling, laying and installation projects.

Cable socks and support grips are available to enable the installation of 33kV 66kV array cables prior to MV HV Jointing & Terminating in windfarm towers, turbines and offshore substations.

Further Reading

- Slingco Take A Firm Grip on The Future With Cable Socks

- How To Lace Up Cable Socks By Slingco

- Cable Grips | Supporting Inter-array, Export, Umbilical & Subsea Cable Installations

- How Do Cable Socks React To Salt Water?

- Cable Laying, Installation & Support Products | Offshore Oil & Gas Cables

- MV HV Cable Laying, Installation & Support Products | Offshore Windfarms

Supplying Cable Termination, Jointing, Pull-in & Electrical Equipment up to 66kV

Specialist Distributors to the UK and international Offshore Wind & Renewable industry to provide safe and reliable LV HV Electrical Cable & Power Distribution Systems up to 66kV – we are highly customer responsive and absolutely committed to providing a world-class service. Contact our UK Power Team for competitive quotations, fast delivery from stock and technical support or training on all LV-HV products.