Cable Pulling & Laying

Cable Pulling Calculation Example From Brugg Cables

June 11th, 2021

-

Special thanks to Damian Aegerter at Braavos GmbH / cableizer.com

for the kind permission to republish this article

Cable Pulling

In Part 1 of this Blog series we look at how Cableizer cable pulling calculation module has been much improved – today, we present you the application of the module in conjunction with Brugg Cables installation manual.

The following Cable Pulling Calculation example from Brugg Cables is an extract from their public document titled ‘Manual for Transportation and Cable Laying Maintenance’, published 2016. The calculation example is found on pages 12ff.

This example validates our cable pulling module and has been added to our test cases, ensuring that cable pulling calculations won’t unexpectedly and unnoticeably change.

Cable selection

In the Cable Tab of the cable pulling module the cable is selected, which in the example is of type XKDT 1×240/35 mm2, 20/12kV. Cableizer does display all relevant cable properties, which closely correspond to the values in the Brugg Cables manual (Cable weight m_tot per m of 3.36 kg, cable diameter D_e of 41 mm, minimum bending radius r_mbp of 615 mm, permissible pull force F_ppc of 9600 N).

Please be aware that Cableizer outputs all forces in [daN] (10 N = 1 daN). In addition it is shown if the cable is a single-core or a multi-core cable, and whether or not it is armoured (for armoured cables, it is possible to select pull on the armour in the cable editor as an alternative to pull on the conductor).

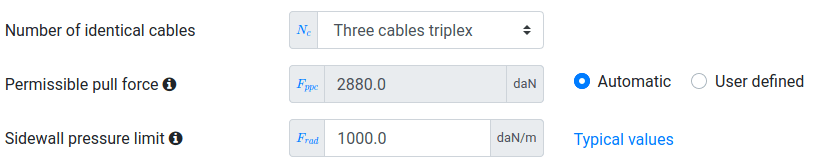

Once the cable has been selected, it is time to select the number of cables that are pulled in together, which in this case is 3. Brugg Cables does not mention whether or not the cables are bound together (Triplex), but from their admissible pull force which is 28800 N and thus thrice the permissible pull force of a single cable, it is concluded that the cables are assumed to be bound together.

For three unbound cables the total permissible pull force is normally assumed to be only twice the permissible pull force of a single cable, as the two cables on the bottom will take all the force (the cable laying on top is not exposed to any friction). If the automatically calculated limit is not suitable, it can be manually entered (e.g. if the pull is made with woven mesh pulling grips).

The admissible sidewall pressure has been selected as 10’000 N/m in accordance with the Brugg Cables manual. Both the permissible pull force and sidewall pressure limit values are optional. However, they should not be omitted as the program will clearly indicate if those limits are exceeded along your cable route.

Conduit selection

In the Conduit Tab of the cable pulling module a PE conduit with an inner diameter of 120 mm is selected in accordance with the Brugg Cables manual.

The conduit ratio CR_pull, the conduit fill CF_pull, and the conduit clearance CC_pull all show that the conduit dimensions are suitable for the intended cable pull. The conduit jamming ratio CJ_pull is not displayed since the three cables are bound together (triplex) and there is no risk for jamming.

💡 Conduit Ratio: this is the ratio between the diameter of a single cable to the inner diameter of the duct. The conduit ratio is a measure for the cable configuration in the duct and Cableizer uses the following ratio limits:

Three cables unbound have a triangular configuration for CRpull < 2.5 and a cradled configuration for CRpull ≥ 2.5.

Three cables triplex always have a triangular configuration.

Four cables unbound have a diamond configuration for CRpull < 3.0 and a cradled configuration for CRpull ≥ 3.0.

Three cables quadruplex always have a diamond configuration.

Please notice that the conduit preview is up to scale and helps to avoid possible input errors.

Brugg Cables calculates without weight correction factor f_wc and sidewall pressure factor f_rad, and so they have not been applied to our calculation. Please consult with your supplier whether or not to apply these factors to your calculations.

Route editor

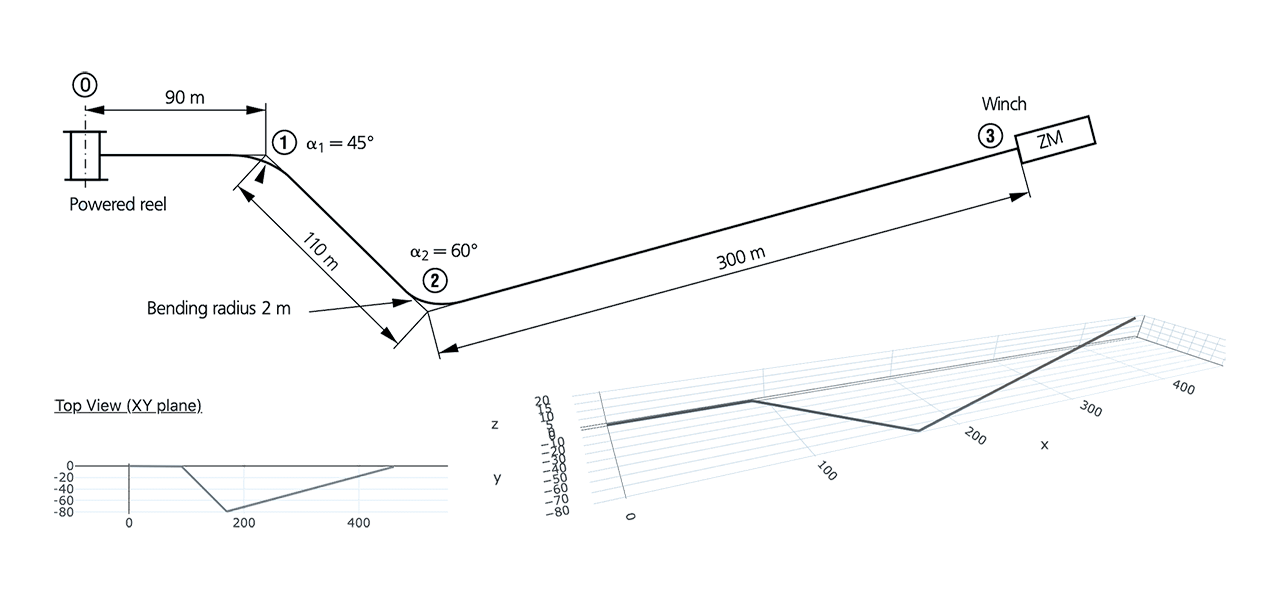

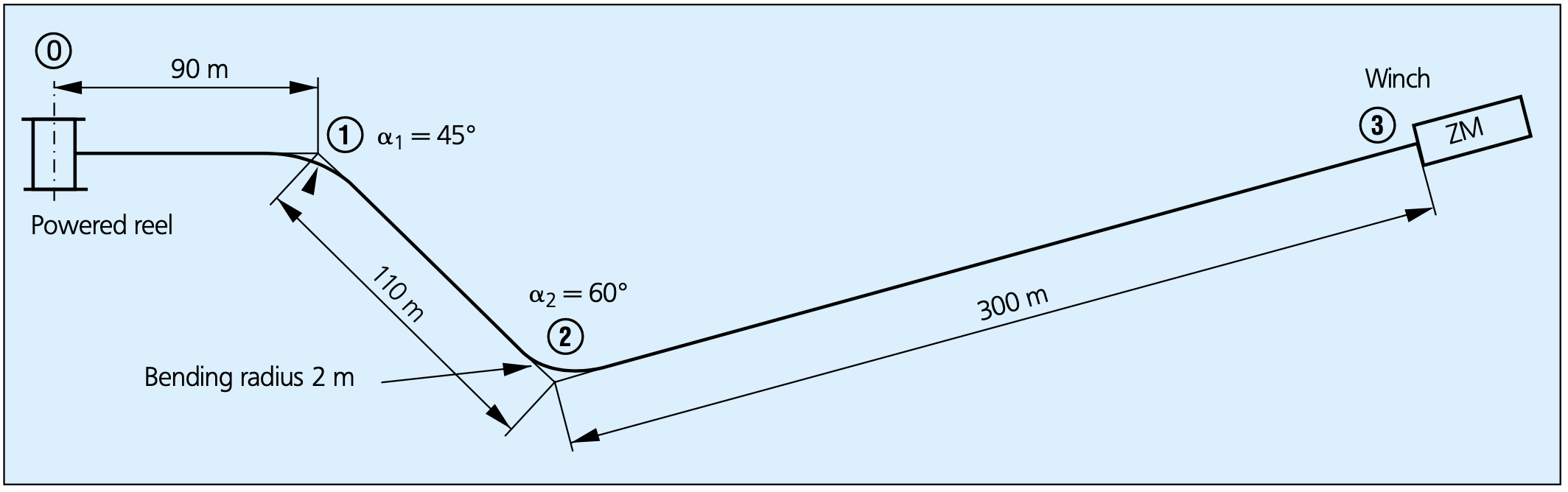

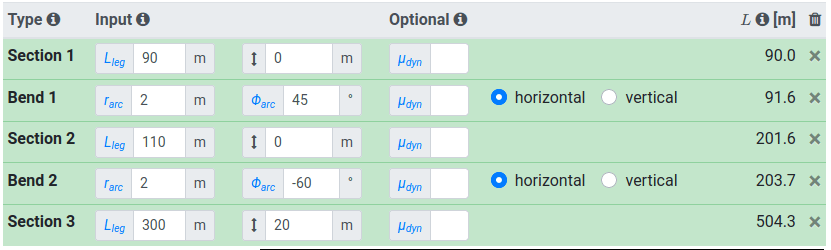

In the Routing Tab of the cable pulling module the example route is composed of sections and bends.

Please notice that the length of the cable route is slightly different between Cableizer and the Brugg Cables example due to the way the bends are handled. We have also focused on the alternative with an elevation of 20 m within the last section.

Our two- and three-dimensional preview help you to verify that the input is correct.

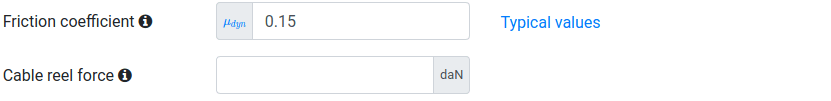

The friction coefficient μ_dyn is 0.15 all along the route (Cableizer does allow optional individual inputs for every section or bend). And since the reel is powered, there is no cable reel force.

💡 Dynamic Friction Coefficient: the coefficient of dynamic friction is a measure of the friction between a moving cable and the conduit. The coefficient of friction can have a large impact on the pulling force calculation. It can vary from 0.1 to 1.0 with lubrication and can exceed 1.0 for unlubricated pulls. Pulls should never be stopped and restarted because the coefficient of static friction will always be higher than the coefficient of dynamic friction. The coefficient of friction between a cable exterior (jacket/sheath) and conduit varies with the type of jacket or sheath, type and condition of conduit, type and amount of pulling lubricant used, cable temperature, and ambient temperature. High ambient temperatures can increase the coefficient of dynamic friction for cable having a non-metallic jacket.

Pulling lubricants must be compatible with cable components and be applied while the cable is being pulled. Pre-lubrication of the conduit is recommended by some lubricant manufacturers.

The coefficient of friction between a cable exterior (jacket/sheath) and conduit varies with the type of jacket or sheath, type and condition of conduit, type and amount of pulling lubricant used, cable temperature, and ambient temperature. High ambient temperatures can increase the coefficient of dynamic friction for cable having a nonmetallic jacket.

Pulling lubricants must be compatible with cable components and be applied while the cable is being pulled. Pre-lubrication of the conduit is recommended by some lubricant manufacturers.

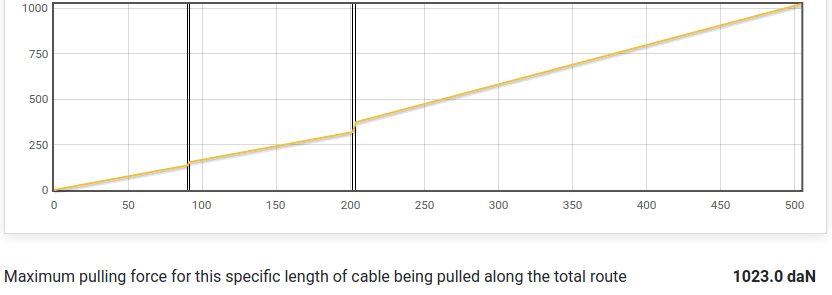

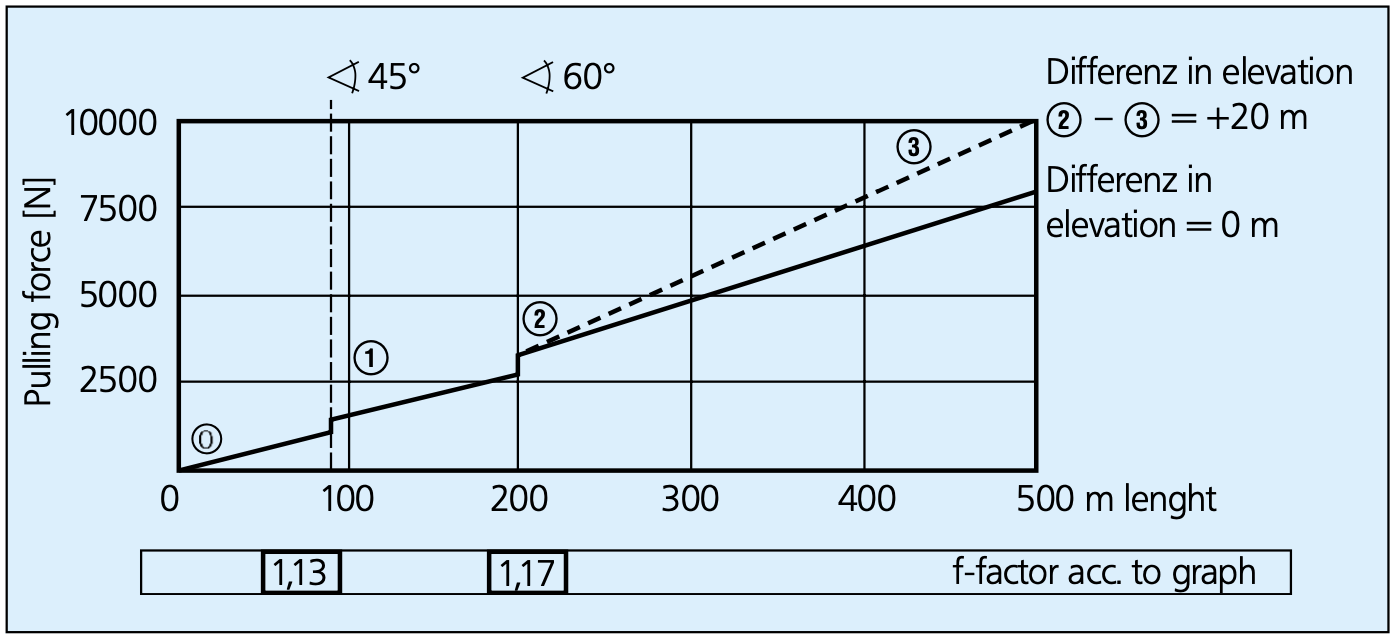

The approximate results show a good agreement with the Brugg Cables manual, which states a maximum pulling force F_pull of 10’215 N and a maximum sidewall pressure F_rad of 1’858 N/m.

The difference in the sidewall bearing pressure is due to the fact that Cableizer is calculating with the inside bending radius of the conduit, while Brugg Cables is considering the radius of the centerline of the bend r_arc (which is also used as input in Cableizer).

The results also show that it is beneficial to opt for a pull in the forward directions if possible, which has both lower pulling forces and sidewall bearing pressures than a pull in the backward direction.

➡ Cable Pulling Force & Tension: calculations of pulling forces or pulling tensions for cable trays are similar to those for pulling cable in conduit, adjusting the coefficient of friction to reflect using rollers and sheaves.

If the sheaves in the bends in cable trays are well-maintained, they will not have the multiplying effect on the force that bends in conduit have. The sheaves will turn with the cable, allowing the coefficient of friction to be assumed zero. This results in the commonly-used approximation for conduit bend equation becoming one. Even though cable tray bends produce no multiplying effect, it is essential for heavier cables to include the force required to bend the cable around the sheave. If the sheaves are not well-maintained, the bend will have a multiplying effect. The pulling force must then be calculated using the same equations used for installations in conduit.

Pulling lubricants must be compatible with cable components and be applied while the cable is being pulled. Pre-lubrication of the conduit is recommended by some lubricant manufacturers. The approximate results display only the pulling forces at the end of the respective sections, while the forward and backward direction tabs display the pulling forces all along the route. The approximate results also use a simplified equation for bends, which does not consider the gravitational forces or the vertical elevations.

Forward direction pulling forces

In the Forward Direction and Backward Direction tabs of the cable pulling module, the pull force curves and radial force curves can be calculate and displayed. As shown below, the forward pull force curve does correspond to the curve from the Brugg Cables manual.

Special feature

Pull a cable over a longer route

It is now possible to set a cable length that is shorter than the cable route and get corresponding pull force and sidewall bearing pressure curves.

The software calculates sequentially the pull force and sidewall bearing pressure of the cable being pulled over the whole route in steps of 10 cm. This leads to rising and falling values as the cable enters and leaves bends, slopes and cable pushers. The output provides the highest pulling force and sidewall pressure the cable experiences during the pull.

This feature has been added on customer request. Please let us know if you have any proposals for improvements or clarifications.

The original article can be found on LinkedIn here

Cableizer – The Online Cable Optimizer

Model power cables and calculate current rating, magnetic fields, electrical parameters, short-circuit currents, pulling forces… Experience the full potential of our browser-based simulation platform cableizer.com! Our 14-day free trial includes full access to all the simulation features of Cableizer.

View the other blogs in the Cable Pulling Blog Series below:

Cable Pulling & Laying Equipment

Suppliers & Distributors

Thorne & Derrick distribute the most extensive range of Low & High Voltage Cable Installation & Electrical Distribution Equipment to the Power Transmission & Distribution industry in the onshore and offshore wind, solar, rail, oil/gas, data centre, battery storage and utility sectors – this includes the most extensive range of Cable Pulling & Cable Laying Equipment to enable the installation of low, medium and high voltage power cables into underground trench or duct.

We service UK and international clients working on underground cables, overhead lines, substations and electrical construction at LV, 11kV/33kV and up to EHV transmission and distribution voltages.

Key Products: MV-HV Cable Joints & Terminations, Cable Cleats, Duct Seals, Cable Transits, Underground Cable Protection, Copper Earth Tapes, Cable Jointing Tools, Feeder Pillars, Cable Ducting, Earthing & Lightning Protection, Electrical Safety, Cable Glands, Arc Flash Protection & Fusegear.

Distributors for: 3M Electrical, ABB, Alroc, Band-It, Cembre, Centriforce, CMP, Elastimold, Ellis Patents, Emtelle, Furse, Lucy Zodion, Nexans Euromold, Pfisterer, Polypipe, ProGARM, Prysmian, and Roxtec.

- Scope –single-source supply of extensive range of products

- Stock – a multi-million pound stock holding provides complete global supply solutions

- Staff – technical support from a trained, proactive and friendly team

- Delivery – UK stock turnaround with express logistics to all international destinations

Further Reading | Handling Cable Drums & Laying Cables | A Guide from Nexans

Press Release | Thorne & Derrick Appointed Approved Stockist for UK Leading Cable Pulling Equipment Manufacturer

Cable Pulling & Laying | Technical Library

May 6th, 2021

Technical Library & Resources | Education & Learning with SEB International

Thorne & Derrick provide competitive prices and fast delivery as the main UK distributor of SEB Cable Pulling & Laying Products including handling and installation equipment for power (land and subsea), umbilicals, fibre and telecoms cables. SEB products are typically used to install transmission, distribution and medium/high voltage substation power cables into ducts or trenches, LV up to 400kV.

Thorne & Derrick International distribute the most extensive range of Cable Pulling & Laying Equipment to enable the installation of LV, MV HV Cables into underground trench or duct – products are also stocked for fibre optic blowing, OHL stringing, subsea trenching, offshore umbilical installations and pulling armoured cables onto cable tray.

Cable Pulling & Laying

TOP 20 BLOGS

See our collection of the Top 20 Cable Laying Blogs featuring SEB International, and their range of LV, MV & HV Cable Pulling and Cable Laying products:

- Cable Laying & Pulling – Installing LV-HV Cables Into Trench

- Cable Laying & Pulling – Installing LV-HV Cables Into Duct

- How Do Cable Socks React To Salt Water?

- Cable Pull Calculations – Installing & Pulling Heavy Cables

- Duct Rod Pushers | Installing Cables Into Conduits

- Cable Laying, Installation & Support Products | Offshore Oil & Gas Cables

- MV HV Cable Laying, Installation & Support Products | Offshore Windfarms

- Cable Pulling | Safe Pulling of Cables Using Manual Laying

- Lace Up Cable Socks – A Guide For Users When Pulling Cables

- Cable Socks – Technical Guide for Safe Cable Pulling Using Cable Socks

- What Is The Maximum Distance For Ease of HV Cable Pulling Between Manholes

- Cable Pulling Equipment – A Cable Duct Laying Guide From BT Openreach

- Stokbord®Drum | 33kV Cable Protection for Underground Medium Voltage Cables

- Stokbord Drum | Protection of High Voltage Electricity Cables

- Which Access Chamber Can Be Built Faster?

- Cable Winch | Customised & Refurbished 5 Tonne Cable Pulling Winch

- Cable Pulling | Safe Pulling of Cables Using Motorised Pullers

- Cable Laying | The Importance of Cable Installation Instructions

- Cable Drums | Recommended Transport & Storage

- How to Prepare Cables To Avoid Cable Damages & Faults

Further Reading | Cable Drum Handling & Laying Cables | A Guide from Nexans

T&D distribute the complete range of LV-HV Cable Pulling and Laying Equipment including cable rollers, cable socks, drum jacks, drum trailers, cable lubricant, underground cable protection and conduit duct rod.

THORNE & DERRICK are Specialist Distributors of LV HV Cable Jointing, Earthing, Substation & Electrical Eqpt up to 66kV – this includes the most extensive range of Ex Stock Innovation Tooling to facilitate safe and reliable preparation, termination and installation of cables.

MV HV High Voltage Cable Joints | Cable Terminations | Cable Connectors | Distributed from Stock | UK & Export Sales

Cable Pulling 1 x 70mm 2 Core FGT Aluminium (Water Blocked)

May 4th, 2021

Swapping a faulty power cable for a 1 x 70mm 2 core FGT Aluminium

1 x 70mm 2 core FGT Aluminium

Amaro Signalling Ltd | by Lee Fisher

A few weeks, our guys were getting some well-earned rest after a seriously tough shift in South East London…

A physically demanding job, they’d been tasked with pulling 300 metres of cable between two location cases at Plumstead Station, swapping out a faulty power cable with brand-new 70mm 2-cored FGT cable.

Lee Fisher Assistant Project Manager at Amaro Signalling Ltd commentated on Linkedin, ‘this was 1 x 70mm 2 core FGT Aluminium (water blocked). We have installed a wide range of FGT from 10mm up to 95mm.’

Part of the largest third rail network in the world, the bright yellow ‘third rail shrouds’ you see here proved essential, protecting our team from the 750v of DC power coursing through the conductor rail directly behind them.

Yet another cable installed and ready for commissioning. Keep up the good work!

About Amaro

A leading provider of specialist signalling, LV, HV, and OLE support to the UK’s rail sector, we work with some of nation’s most demanding clients, providing engineering and design support on many of their most critical projects.

Whilst we’re probably better known for our expertise in signalling, over the years we’ve forged an enviable reputation for excellence within the LV, HV, OLE, P-Way and civils sectors, offering a standard of engineering and a level of value rarely seen amongst our competitors.

RAIL CABLE ACCESSORIES, ELECTRIFICATION

& INSTALLATION EQUIPMENT

Thorne & Derrick supply an extensive range of 400V-33kV Rail Cable Accessories & Power Distribution Sytems including feeder pillars to contractors undertaking Low Voltage Power Distribution, HV Electrification & Substations, DC Traction & Networks, OLE and Track Feeder Cable Renewals – a complete range of Network Rail PADS approved track terminations, cable joints, cable repair and connection products up to 25kV, including 3M Cold Shrink, Pfisterer CONNEX and Nexans Euromold products.

Full range of Cable Pulling Equipment & Products to ensure safe and efficient of rail cables in to cable ducts and containment infrastructure including cable troughs.

Cable Cleats | Cable Hangers | Cable Joints | Cable Glands | Cable Lugs | Cable Transits | Arc Flash Clothing

Stokbord®Drum | 33kV Cable Protection for Underground Medium Voltage Cables

May 4th, 2021

Centriforce Stokbord® Drum has been installed as part of SSE’s improvement programme

Stokbord® Drum By Centriforce

Protection of High Voltage Electricity Cables

Centriforce, working through their distributor network including Thorne & Derrick, last year announced a new cable protection product that can help to improve working safety for High Voltage Electricity Cables applications – known as the Stokbord® Drum.

Centriforce are pleased to share that Stokbord® Drum has been installed as part of SSE’s improvement programme Petersfield – Fernhurst Network Upgrade.

The multinational energy company SSE has launched a network upgrade programme set to future-proof the local electricity infrastructure for homes and businesses of Petersfield, Fernhurst and the surrounding areas.

Through cable network upgrades and the refurbishment of an established substation, SSE’s work will prepare the network for future commercial and residential connections.

Born from our policy for innovation and continuous improvement, Stokbord® Drum is a faster and safer alternative to traditional buried cable and pipeline protection. Stokbord® Drum is a single material strip supplied on an industrial reel which, to install, is simply unwound into the trench removing the need for operatives to set foot below ground.

Suitable for high impact protection against heavy-duty tooling and machinery, Centriforce manufactures Stokbord® Drum to the same industry standards as our globally trusted Stokbord® Cover. The installation time and cost benefits gained through this innovation makes Stokbord® Drum the perfect partner for large scale utility projects.

An excellent example of Stokbord® Drum’s project versatility

Stokbord Drum | MV HV Cable Protection for Underground Utility Cables

Stokbord® Drum has also been installed on major infrastructure projects including: Triton Knoll, Hornsea 2, Dogger Bank

Key benefits of Stokbord Drum

Stokbord® Drum offers a range of key benefits to constructors and end-users including:

- Time and cost saving – Stokbord® Drum significantly reduces installation time in comparison to traditional cable protection, up to 5x faster than alternatives

- Reduced Risk – Helps to reduce potential risks posed to operatives by reducing the need to enter the trench

- Industry Specifications – Stokbord Drum complies with all UK and international industry specifications

- High impact resistance – Meets the same standards as Stokbord® Cable Cover – Stokbord® Drum does not shatter on impact from heavy-duty tooling and machinery

- Highly visible – Stokbord® Drum uses bright colours and bold text to provide a clear visual warning to workers and excavators on-site

- Long-lasting – Rot resistant and chemically inert to ensure the product’s long service life

Press Release | Thorne & Derrick Appointed Approved Stockist for UK Leading Cable Pulling Equipment Manufacturer

The below video shows Stokbord® Cable Covers from Centriforce and distributed by Thorne & Derrick that provide heavy duty, high impact, underground cable protection for fibre optic, low voltage, high voltage (11kV, 22kV, 33kV, 66kV) and extra high voltage (132kV-400kV) power cable networks.

Centriforce together with distributor UK Thorne & Derrick Tapetile and Stokbord underground cable protection tiles and covers are the market leading, heavy duty utility protection system for protecting underground cable and pipes – this includes low voltage, medium voltage and high voltage power networks working at 11kV and 33kV.

Stokbord Drum Cable Protection for Underground Utility Cables

FURTHER READING

- Stokbord Drum | Protection of High Voltage Electricity Cables

- Stokbord Drum | Cable Protection for Underground Utility Cables

- UKPN Cable Protection Tapes & Covers (LV MV HV)

- ENA-TS 12-23 : Cable Tiles & Cable Covers For Use With LV 11kV 33kV & HV Cables

- Stokbord Drum | Cable Protection for Underground Utility Cables

THORNE & DERRICK are national distributors of LV, MV & HV Cable Installation, Jointing, Duct Sealing, Substation & Electrical Equipment – we service UK and global businesses involved in cable installations, cable jointing, substation earthing, overhead line and electrical construction at LV, 11kV, 33kV and EHV.

Since 1985, T&D have established an international reputation based on SERVICE | INTEGRITY | TRUST.

Contact us for 3M Electrical, ABB, Alroc, AN Wallis, CATU Electrical, Cembre, Centriforce, CMP, CSD, Elastimold, Ellis Patents, Emtelle, Euromold, Filoform , Furse, Lucy Electric & Zodion, Nexans, Pfisterer, Polypipe, Prysmian, Roxtec, Sicame, WT Henley.

Cable Laying & Pulling – Installing LV-HV Cables Into Trench

April 29th, 2021

Thorne & Derrick | Cable Laying & Pulling Equipment Distributors | LV MV HV

-

Uploaded By Chris Dodds – Thorne & Derrick Sales & Marketing Manager

Thorne & Derrick | Specialist Distributors of Cable Pulling Equipment | LV MV HV up to 400kV

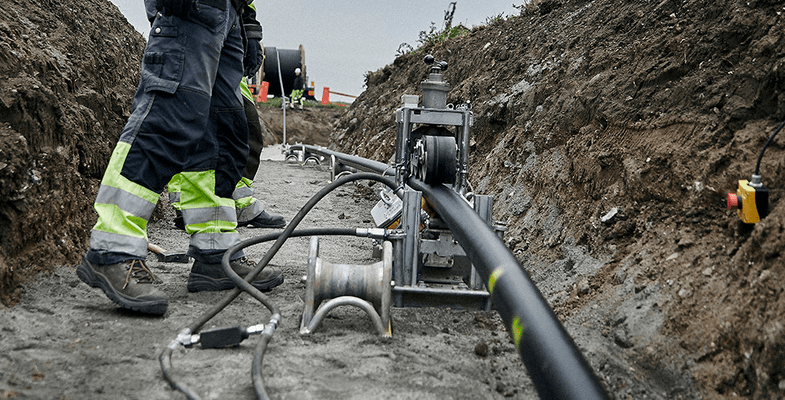

Today, in Part 2 of a 2 part series covering Cable Pulling & Laying Equipment, Thorne & Derrick look at the equipment requirements and preparation for cable pulling when installing cables into cable trench. In Part 1, we discussed the procedures and equipment requirements for cable pulling and laying into ducts.

Cable Pulling Equipment & Preparation

Trench

In Part 2 of our series of articles about Cable Laying & Pulling Equipment, we look at the equipment and process requirements for pulling and laying cables in an open trench.

Open trench cable laying is often used as opposed to laying cables directly into cable ducts. This method of laying cables into the ground tends to be used where the cables in use are of a higher voltage (MV HV Cables) and therefore have a greater outside cable diameter.

Press Release | Thorne & Derrick Appointed Approved Stockist for UK Leading Cable Pulling Equipment Manufacturer

The Preparation Of The Cable Trench

Prior to the cable being laid, the cable trench must be dug and prepared properly.

This means that the trench must be of adequate size to allow for the cables and ducting required.

Different cables will require different sized cable trenches – the higher the cable voltage, the bigger the cable and therefore the bigger the cable trench required.

The trench width and depth also depends on the where the cable trench is being dug. For instance, a cable being laid underneath a public footway will not be laid as deep as one under arable land that is to be ploughed.

When a trench is to be dug, it should be sufficient to allow the installer to install the cables and ducting at the correct depth for the cable being used.

It should also allow the cables to be installed within the bending radii specified.

The cable should be installed within the specified pulling dimensions and without damaging the cable sheaths.

When laying a cable into an open trench, there are 8 key components within the typical equipment layout used excluding the trench and the cable.

- Cable Winch – the cable winch is situated at the end of cable trench and is designed to be simple and robust. The winch provides smooth and controlled pulling of the cables through the trench. It is the cable pulling winch that provides the actual pulling of the cable. There is a number of different cable winches available dependant on the type of cable being pulled. Winches vary between telecommunications, power cables and lightweight cabling.

- Winch Wire Rope – the winch wire rope is attached to the cable in order for it to be pulled through. The wire rope gives extra strength and allows for heavier cables to be pulled through. In addition, the use of the winch wire prevents any potential damage being caused to the cable sheath.

- Swivel Link – the swivel link provides the connection between the cable and the winch wire rope. Each swivel link is designed and used to allow the wire to rotate when being pulled and avoid kinking or twisting. The extra layer of protection provided by the swivel link means damage to the cable sheath is reduced even further.

- Cable Socks – cable socks or stockings are available in either stainless steel or Kevlar but are traditionally constructed of high tensile, galvanised steel wire. Often called cable socks or grips, these are another level of protection between the cable and the cable winch. Fitted to the end of the cable, they are attached to the swivel link and avoid direct contact with the cable. All pilot and telephone, LV, 11kV, 20kV, 33kV, 66kV and 132kV cables should be normally pulled in using a correctly sized cable sock which is securely fixed to the LV-HV cable. More complex cable pulls may require the use of a cable pulling eye attached directly to the cable conductors.

- Straight Cable Rollers – the straight line rollers are, as the name suggests, for use in the straight part of the trench. Varying in size and weight, the straight rollers are selected by the size of the trench they are to be used in. The rollers enable to the cable to be pulled through without making contact with the base of the trench which would damage the cable outer sheath. Full range of cable trench rollers are available – cable pullers should check that cable rollers are in serviceable condition moving easily on their spindle and with rolling surfaces free from damage. Leading cable rollers are usually placed at the cable trench side at the cable pulling end with slide rollers on bends and “hoop” type rollers along straight cable section runs. Contractors can use inverted skid plates shall be used to prevent the cable or pulling wire rising into obstructions. At cable duct entries a bell mouth should be attached at end end with cable rollers positioned to give central access into the bell mouth.

- Corner Rollers – Angled corner rollers are to be used within the trench where there is a bend in the trench. Typically these incorporate a vertical and horizontal roller to allow for the pulling of the cable. Providing the same level or protection as the straight rollers they are both used alongside each other.

- Draw Off Roller – the draw off roller is the first piece of equipment the cable will come into contact with. When the cable is pulled through the open trench, the draw off roller leads the cable straight from the drum into the trench. The cable is then pulled through the trench with the draw roller acting as an initial guide for the cable.

- Cable Drum Trailer – the cable drum trailer is used to transport the cable drum. In addition the trailer is also used to stabilise the cable drum whilst the cable is being pulled through the trench.

Duct rods provide a strong, lightweight, labour saving solution for installing cables into ducts or pipes with or without draw ropes.

Cable Protection

Installation Of Cable Trench Covers & Cable Protection Tiles

All cables and ducts laid into cable trrench should be over-protected by a cable protection cover or tape depending upon the highest voltage cable to be protected within the cable duct – typically in the UK the following cable protection tapes and covers are used for LV, MV and HV cables.

Marker tile tapes or Stokbord covers are installed over the cable in the appropriate trench drawings – usually there is no requirement to install either above approved cable ducts installed using trenchless techniques (i.e. directional drill) but either may be installed if it is deemed that additional MV-HV cable protection is required. When Tile Tape is used it should be cut cleanly and installed so that the medium/high voltage cable is fully covered along the whole length of the installed cable duct.

- LV Service Cable 40m x 200mm x 2.5mm Tile Tape

- LV Mains Cable 40m x 200mm x 2.5mm Tile Tape

- 11kV MV Cables 40m x 200mm x 2.5mm Tile Tape

- 22kV MV Cables 40m x 200mm x 2.5mm Tile Tape

- 33kV MV Cables 1000mm x 244mm x 9mm Stokbord

- 66kV MV Cables 1000mm x 244mm x 9mm Stokbord

- 132kV MV Cables 1000mm x 244mm x 9mm Stokbord

More info ➡ Tile Tape | Stokbord

Duct Seals

Where electricity, pilot and telephone cables are installed into electricity cable ducts the utility engineering standard would normally recommend all cable ducts entering substations and buildings to be duct sealed to prevent the ingress of water and gas – this also applies to 33kV, 66kV and 132kV high voltage substation cables where cable transits are required.

Thorne & Derrick distribute an extensive range of Duct Sealing & Cable Transit Systems to protect utility assets and provide flood protection to substations from water entry via unsealed cable ducts and building penetrations.

Cable Pulling & Cable Laying Equipment Suppliers & Distributors

Thorne & Derrick International distribute the most extensive range of Cable Pulling & Cable Laying Equipment to enable the installation of low, medium and high voltage power cables into underground trench or duct – products also supplied for fibre optic blowing, subsea trenching, offshore umbilical installations and pulling armoured cables onto cable tray.

Cable Blowers | Cable Lubricant | Duct Rods | Cable Socks | Cable Jacks | Cable Rollers | Cable Protection Covers MV HV | Cable Joints MV HV | Duct Sealing