Blog

3M Cold Shrink Tubes For Electric Submersible Pump (ESP) Cable Repair

February 1st, 2019

3M Cold Shrink Tubes – EPDM Rubber

-

uploaded by Chris Dodds - Thorne & Derrick Sales & Marketing Manager

Electrical Submersible Pump (ESP)

Cable Repairs

Electrical Submersible Pumps (ESP) are used to lift oil from a production well, so it is important that the supply cables are reliable and operate safely for an extended service life in the harshest offshore downhole environments.

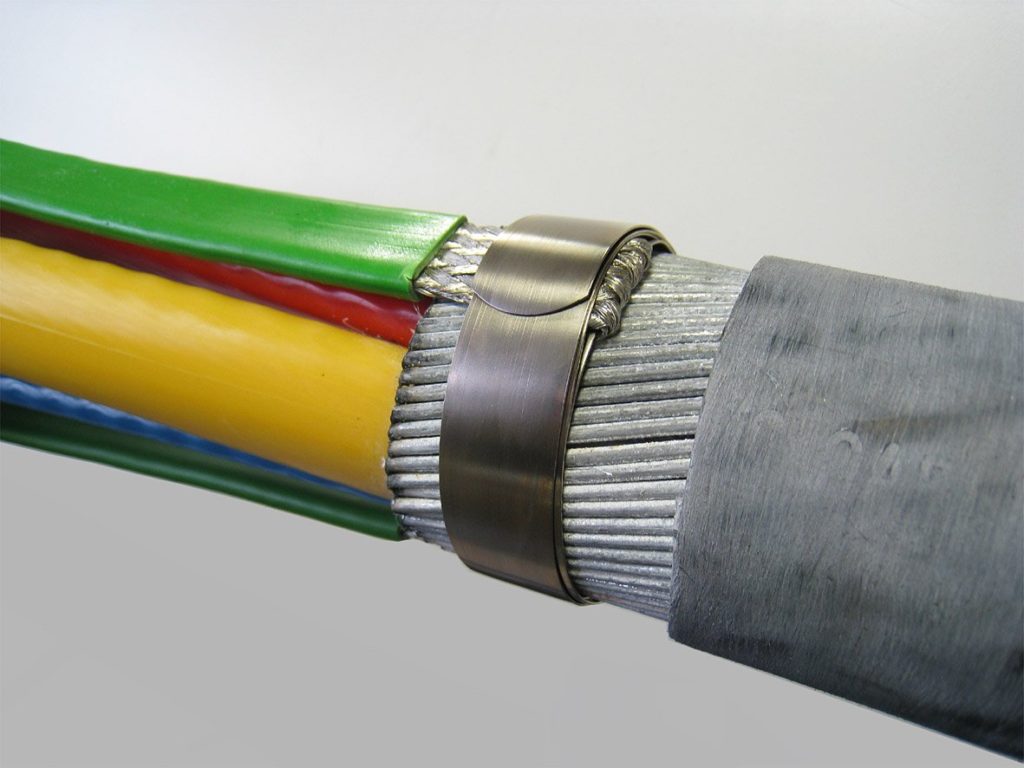

The ESP cable used to transmit power and sensor outputs to and from the surface is a key component in an ESP installation. The cable must withstand mechanical abrasion, corrosion, high temperature and pressure and should be available in a variety of cross-sections and configurations so the space the cable takes in the well bore is optimized and it can be installed or retrieved easily.

Schlumberger RedaMAX 400 is a 5kV-8kV high voltage cable designed specifically for use with electrical submersible pumps, however the cable can also be used within onshore and offshore gassy wells and other high temperature applications in the oil and gas industry with ESP systems installed.

The benefits associated with the RedaMAX 400 ESP submersible pump cable include lower life cycle cost, long insulation life and longer ESP system life – with EPDM insulation-jacket compounds, galvanised steel armor and lead barrier the power cables temperature rating up to 232°C provides consistent delivery of electrical power to downhole equipment.

The ESP cable is available in three options including the common round profile option but also a flat cable version – in this post we provide information about cold shrink tubes for use with ESP cable repair applications.

RedaMAX 400 ESP Cable Specifications

The 3 versions of the Schlumberger RedaMAX 400 cables are available in different voltages :

- 4kV Flat Cable | Lead Barrier | Galvanised Steel Armor | EPDM Cable Jacket

- 4kV Round Cable | Lead Barrier | Galvanised Steel Armor | EPDM Cable Jacket

- 5kV Flat Cable | Lead Barrier | Galvanised Steel Armor | EPDM Cable Jacket

- 5kV Round Cable | Lead Barrier | Galvanised Steel Armor | EPDM Cable Jacket

- 8kV Round Cable | Lead Barrier | Galvanised Steel Armor | EPDM Cable Jacket

Cables Nomenclature Guide ➡

Cold Shrink Cable Repair Tubes

Power Cables Portfolio for REDA ESP Systems

| Cable Family | Cable Application | Cable Construction |

| REDA MAX 250 | Low temperature, low gas | PPEO, PP, PTB, POTB |

| REDA MAX 400 | High temperature, moderate gas | EE, ETBE |

| REDA Lead | High temperature, gassy, corrosive | ELBE, ELB, EHLTB |

| READ Lead 8kV | Deep water, subsea, high temperature, high horsepower | ELBE, ELB, EHLTB, SESLTBE |

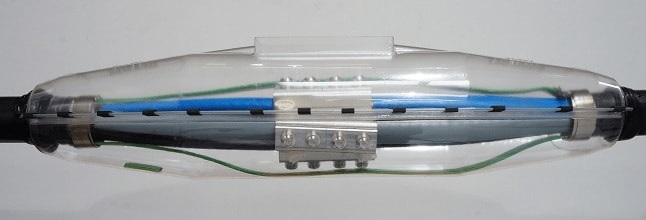

3M EPDM Rubber Cold Shrink Tubes

When repairing Schlumberger RedaMAX ESP Power Cables it is advisable to use the 3M EPDM Connector Insulators 8420 Series Cold Shrink Tubes.

This insulating tube forms part of the wider range of cold shrink tubes available from 3M Electrical and distributed by Thorne & Derrick.

There are many benefits of using cold shrink technology :

- Simple installation, requiring no tools or heat shrink torches – ideal for “explosive atmospheres” and hazardous area locations

- Can accommodate a wide range of LV HV cables – Cold Shrink is a versatile cable repair solution

- Good thermal stability and tight seal around the cable sheath jacket profile

- Fungus, acid and alkali resistant for onshore and offshore aggressive applications

- Excellent wet electrical properties for offshore installations

3M EPDM cold shrink tube forms a cable sheath repair when it is applied around the electrical connector and the cable itself.

3M Connector Insulators 8420 Series Cold Shrink Application

Insulation of inline conductor transition connectors

The insulating cold shrink tube is made from EDPM rubber containing no chlorides and six diameter sizes will cover a full range of 1000 volt cables.

In addition to ESP cables, the 3M 8420 Series EPDM tubes can be used in other applications including dig-in and cable sheath repairs, insulation of secondary cable splices and primary electrical insulation for all solid dielectric (rubber and plastic) insulated wire and cable splices rated to 1000 volts.

3M Cold Shrink EPDM Tubes

Connector Insulator 8420 Series

Selection Table

| 3M Cold Shrink Tubes Part No | Suit Conductor Sizes AWG & Kcmil | Min Diameter (mm) | Max Diameter (mm) | Length (mm) |

| 8423-6 | 6 – 4 | 7.8 | 14.3 | 152 |

| 8425-7 | 2 – 1/0 | 9.9 | 17.8 | 178 |

| 8425-8 | 2 – 1/0 | 10.2 | 20.8 | 203 |

| 8426-11 | 2/0 – 250 | 13.0 | 25.4 | 279 |

| 8426-9 | 2/0 – 250 | 13.0 | 25.4 | 229 |

| 8427-12 | 250 – 400 | 17.5 | 33.0 | 305 |

| 8427-16 | 250 – 400 | 17.5 | 33.0 | 406 |

| 8427-6 | +++ | 17.5 | 33.0 | 152 |

| 8428-12 | 450 – 800 | 24.0 | 49.3 | 305 |

| 8428-18 | 450 – 800 | 24.0 | 49.3 | 457 |

| 8428-24 | 450 – 800 | 24.0 | 49.3 | 609 |

| 8428-6 | +++ | 24.0 | 49.3 | 152 |

| 8429-12 | 900 -1000 | 32.2 | 67.8 | 305 |

| 8429-18 | 900 – 1000 | 32.2 | 67.8 | 457 |

| 8429-6 | +++ | 32.2 | 67.8 | 229 |

| 8429-9 | +++ | 32.2 | 67.8 | 152 |

| 8430-18 | 1250-2000 | 42.6 | 93.7 | 457 |

| 8430-9 | +++ | 42.6 | 93.7 | 229 |

| 8430-18 | 1250-2000 | 42.6 | 93.7 | 457 |

| 8430-24 | 1250-2000 | 42.6 | 93.7 | 610 |

+++ Primary Cold Shrink Use: Sealing cable lugs and terminal barrels, conduit couplings and conduit-to cable breakouts

LV Cable Joints (Low Voltage Cables)

Thorne & Derrick stock and distribute LV Joints in Cold Shrink, Heat Shrink or Resin Cast technologies – multicore and multi-pair cable joints are available for immediate backfill and energisation of Low Voltage power, control and instrumentation cables 600V/1000V 3.3kV.

Complete range of LV Cable Accessories ➡

Cable Breakouts | Cable Caps | Cable Lugs | Cable Cleats | Cable Trough | Cable Duct | Feeder Pillars | for 11kV/33kV/66kV networks see MV HV Joints & Terminations

Pfisterer | Nexans Euromold | Prysmian | Cable Joints & Terminations MV HV

Cold Shrink by 3M | Joints | Abandonment | Terminations | Low Voltage LV Cables

Heat Shrink Cable Joints & Terminations Manufactured By Nexans – Reference List

February 1st, 2019

Heat Shrink Cable Joints & Terminations

The range of Heat Shrinkable Products manufactured by Nexans have been in service on LV & MV Cables and Networks for over 20 years and are approved by the following international electric power utilities:

- ENEL – Italy, Spain & Romania

- ACEA ROMA – Italy

- A2A MILANO & BRESCIA – Italy

- ELECTRICITY AUTHORITY OF CYPRUS

- ENERGIAS DE PORTUGAL (E.D.P)

- RWE — Germany

- EON — Germany, Romania and Czech Republic

- ENDESA — Spain

- DONG ENERGY — Denmark

- CARUNA – Finland

- PPC / DEDDIE – Greece

- ELECTRICA — Romania

- EDESUR — Argentina

- SONELGAZ / CAMEG — Algeria

- SOCIETE TUNISIENNE DE L’ELECTRICITE ET DU GAZ (STEG) — Tunisia

- CENTRAL ELECTRICITY BOARD (C.E.B.) — Mauritius

- ZESCO — Zambia

- ELECTRICITE DU LIBAN (EDL) – Lebanon

- GENERAL ELECTRICITY COMPANY of LIBYA (G:E.CO.L)

- DUBAI ELECTRICITY and WATER (D.E.W.A) — U.A.E.

- FEDERAL ELECTRICITY and WATER (F.E.W.A.) — U.A.E

- JORDANIAN ELECTRIC POWER COMPANY (J.E.P.C.O.) — Jordan

- ELECTRICITY DISTRIBUTION COMPANY (E.D.CO.) – Jordan

- NATIONAL ELECTRIC POWER COMPANY (N.E.P.CO.) — Jordan

- KUWAIT CONTROL COMPANY (KCC) — Kuwait

- PERUSAHAAN LISTRIK NEGARA (PLN) — Indonesia

- CEYLON ELECTRICITY BOARD (C.E.B.) — Sri Lanka

- SARAWAK ENERGY BERHAD – Malaysia

- TENAGA NATIONAL – Malaysia

- METROPOLITAN ELECTRICITY AUTHORITY (M.E.A.) — Thailand

- PROVINCIAL ELECTRICITY AUTHORITY (P.E.A.) – Thailand

Thorne & Derrick, Specialist Distributors of MV HV Power Cable Products, welcome the opportunity to tender and submit competitive prices for UK and international projects requiring LV MV HV Joints, Terminations & Connectors manufactured by Nexans – this includes the Euromold brand of screened separable connectors.

THORNE & DERRICK SPECIALIST ELECTRICAL DISTRIBUTOR

The MV HV Specialists

Thorne & Derrick distribute the most extensive range of MV HV Cable Jointing, Terminating, Pulling & Installation Equipment – we service UK and international clients working on underground cables, overhead lines, substations and electrical construction at 11kV and up to and EHV transmission and distribution voltages.

- Key 11kV Products: MV-HV Cable Joints & Terminations, Cable Cleats, Duct Seals, Cable Transits, Underground Cable Protection, Copper Earth Tapes, Cable Jointing Tools, Feeder Pillars, Cable Ducting, Earthing & Lightning Protection, Electrical Safety, Cable Glands, Arc Flash Protection & Fusegear.

- Distributors for: 3M Cold Shrink, ABB, Alroc, Band-It, Catu, Cembre, Centriforce, CMP, Elastimold, Ellis Patents, Emtelle, Furse, Lucy Zodion, Nexans Euromold, Pfisterer, Polypipe, Prysmian, Roxtec.

LV – Low Voltage Cable Joints, Glands, Cleats, Lugs & Accessories (1000 Volts)

MV HV – Medium & High Voltage Cable Joints, Terminations & Connectors (11kV 33kV EHV)

Cable Laying – Underground Cable Covers, Ducting, Seals & Cable Pulling Equipment

T&D, CATU Electrical Safety & Arc Flash Protection Specialists for SAP’s, Linesmen, Jointers & Electrical Engineers – Largest UK Stockist

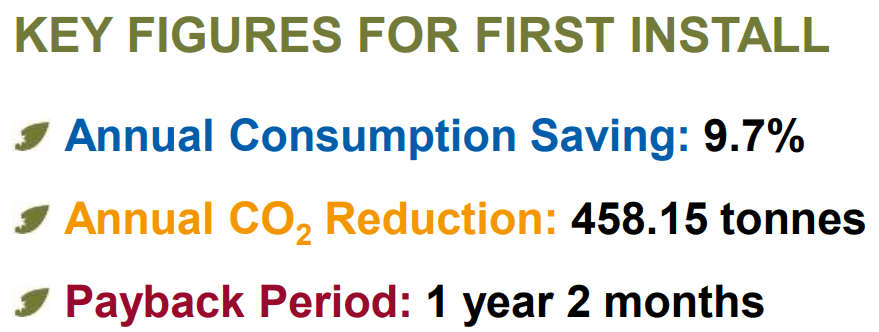

11kV Transformers | Introducing Amorphous Core HV Transformers

February 1st, 2019

Manufactured & Designed In UK | Short Lead Time | Transformers LV 11kV

♦ Guest Post from Richard Kerr & Lindsay Brownless from Powerstar

11kV Transformers

The Next Generation Of Distribution Transformers (LV HV Up To 11kV)

Powerstar SO-LO range of super low loss transformers are the only amorphous core transformers designed and manufactured in the UK and provide a cost-effective way of reducing energy consumption by upgrading high voltage (HV) infrastructure up to 11kV.

Distribution transformers have been at the heart of the energy network, and for many large businesses, their sites, for years. However, as technology has advanced it has been an area that has been left in the dark and somehow avoided the wider revolution known as Industry 4.0, referred to as the fourth industrial revolution. Industry 4.0 champions the connectivity of machines to transfer data and give insights into optimising operations.

To change this, there has been a concerted effort from major players in the LV HV power industry to modernise distribution transformers with the introduction of smart distribution transformers. These LV-HV transformers up to 11kV have inherent connective capabilities which allow for remote monitoring and enable the transformer to be compatible with the wider digitisation of industry.

One company dedicated to the production of smart distribution transformers is Powerstar, leading provider of smart energy solutions, which launched Powerstar SO-LO, an 11kV/415V super low loss amorphous core, smart distribution transformer with remote monitoring capabilities, in September 2018.

Super Low Loss Transformers Up To 11kV By Powerstar SO-LO

Powerstar SO-LO was developed in response to the requirement for greater efficiencies as well as greater insights into energy use.

Regarding efficiency, Powerstar realises that traditional cold rolled grain-oriented silicon steel (CRGO) transformers, suffer from higher load losses than transformers manufactured with the more efficient materials such as amorphous alloy. This is particularly true when you compare the current deployed ageing CRGO transformers which may have been in place for over 30 years to contemporary equivalents.

Excellence In LV-HV Transformer Efficiency

To produce a more efficient LV or 11kV transformer, Powerstar had to first identify a material to replace the traditionally used CRGO. The new material selected was an amorphous alloy core. The amorphous alloy core has a more flexible internal structure than CRGO, which enables easy magnetisation and demagnetisation to take place. This allows for lower losses to be achieved than in CRGO transformers, therefore enabling the achievement of higher efficiencies.

These increased efficiencies are perhaps best displayed by the fact that amorphous core transformers can provide up to 75% lower core losses than CRGO transformers. This results in a reduction to energy wasted through load and no-load losses, providing energy consumption savings of up to 3% when replacing ageing transformers.

Bespoke Transformer Offerings Up To 11kV

As a manufacturer, Powerstar understands that every customer has different requirements when it comes to 11kV high voltage (HV) infrastructure and can therefore provide a number of fittings and accessories to maximise the impact of an amorphous core transformer for each site. This is a necessity, with popular sectors for Powerstar SO-LO ranging from manufacturing and industrial, to retail and healthcare.

The most popular fittings that have been applied to Powerstar SO-LO are radiator valves, bi-directional rollers, dehydrating breathers, AVR relays and control panels, winding temperature indicators, close coupled MV switchgears, close coupled LV cabinets/feeder pillars, pressure relief devices, marshalling boxes, forced air cooling systems, and oil temperature indicators.

Additionally, whilst Powerstar SO-LO is an 11kV to 415V amorphous core smart distribution transformer by standard, as a specialist transformer manufacturer with over 20 years’ experience, Powerstar can provide a variety of bespoke solutions including dual voltages, single phase transformers, and three phase transformers.

The solution can also be integrated with Powerstar’s patented voltage management technology to address issues caused by an unnecessarily high voltage profile on the LV side, if applicable, providing additional savings to energy consumption and costs.

Transformers Designed To Connect Power

From LV To 11kV

Due to its remote monitoring capabilities, included as standard, the Powerstar SO-LO 11kV transformer offers 24/7 visibility and understanding of how the equipment is operating, enabling issues to be identified before an event occurs, reducing the risk of operational downtime caused by equipment breakdown or repair.

This is done via a secure platform, accessible by the user from anywhere with an internet connection, which provides comprehensive data in real time. This data can also be used to identify where efficiencies can be made to make further optimisations and enhance the solution’s return on investment.

It is clear that with solutions such as Powerstar SO-LO, the aim to modernise distribution transformers for an age of increased connectivity has been enabled. Through the ability to gain greater efficiencies, amorphous core smart distribution transformers provide a way of ensuring your site’s HV infrastructure is as efficient as possible whilst reducing the risk of downtime in a single, effective solution that is fit for the demands of modern sites.

➡ Case Study 11kV

➡ 11kV Case Study Download: Vassiliko Cement Works Public Company Ltd is the largest heavy industry company in Cyprus – learn how Powerstar MAX Transformers achieved significant LV/11kV power and energy consumption savings by reading the Case Study.

11kV & LV Transformers

Powerstar SO-LO is the The Super Low Loss, Smart Transformer – amorphous core distribution transformers with remote monitoring capabilities.

Dr Alex Mardpittas unveils Powerstar SO-LO

THORNE & DERRICK SPECIALIST ELECTRICAL DISTRIBUTOR

The 11kV Specialists

Thorne & Derrick distribute the most extensive range of 11kV Cable Jointing, Terminating, Pulling & Installation Equipment – we service UK and international clients working on underground cables, overhead lines, substations and electrical construction at 11kV and up to and EHV transmission and distribution voltages.

THORNE & DERRICK today welcomed Lindsay Brownless from @PowerstarVO today – look out for a series of online articles from us about their UK manufactured, online, smart #Transformers with amorphous core and remote monitoring capabilities, 415/11kV.#POWER pic.twitter.com/KfmIZoBuPJ

— Thorne & Derrick (@ThorneanDerrick) January 16, 2019

- Key 11kV Products: MV-HV Cable Joints & Terminations, Cable Cleats, Duct Seals, Cable Transits, Underground Cable Protection, Copper Earth Tapes, Cable Jointing Tools, Feeder Pillars, Cable Ducting, Earthing & Lightning Protection, Electrical Safety, Cable Glands, Arc Flash Protection & Fusegear.

- Distributors for: 3M Cold Shrink, ABB, Alroc, Band-It, Catu, Cembre, Centriforce, CMP, Elastimold, Ellis Patents, Emtelle, Furse, Lucy Zodion, Nexans Euromold, Pfisterer, Polypipe, Prysmian, Roxtec.

LV – Low Voltage Cable Joints, Glands, Cleats, Lugs & Accessories (1000 Volts)

MV HV – Medium & High Voltage Cable Joints, Terminations & Connectors (11kV 33kV EHV)

Cable Laying – Underground Cable Covers, Ducting, Seals & Cable Pulling Equipment

T&D, CATU Electrical Safety & Arc Flash Protection Specialists for SAP’s, Linesmen, Jointers & Electrical Engineers – Largest UK Stockist

NOFIRNO Sealant | Sealing For Cable & Pipes 2 Hour Jet Fire Tested

January 31st, 2019

NOFIRNO Sealant For Cable & Pipes

NOFIRNO Sealant For Cables & Pipes

The CSD NOFIRNO is a Single & Multi Pipe Penetration Sealing System – one of the most adaptive systems for sealing straight and angled pipe penetrations and can even accommodate multiple pipe runs, significantly saving in space and weight.

The offshore sealing system for pipework maintains the integrity of vessels providing fire protection and ensuring bulkheads and decks remain gas and watertight when pipes need to pass through them – the CSD NOFIRNO pipe penetration sealing system provides fire protection seals to A60 H120 for offshore and marine ships bulkheads and decks.

An uncontrolled discharge of combustible gas under pressure poses a serious fire hazard in areas such as petrochemical plants, offshore petroleum rigs and other hazardous area locations and environments that are sensitive to extreme fires.

NOFIRNO is manufactured by Beele Engineering.

What Are Jet Fires?

A jet or spray fire is a turbulent diffusion flame resulting from the combustion of a fuel continuously released with some significant momentum in a particular direction or directions. Jet fires can arise from releases of gaseous, flashing liquid (two phase) and pure liquid inventories.

Jet fires represent a significant element of the risk associated with major accidents on offshore installations. The high heat fluxes to impinged or engulfed objects can lead to structural failure or vessel/pipework failure and possible further escalation. The rapid development of a jet fire has important consequences for control and isolation strategies.

The properties of jet fires depend on the fuel composition, release conditions, release rate, release geometry, direction and ambient wind conditions. Low velocity two-phase releases of condensate material can produce lazy, wind affected buoyant, sooty and highly radiative flames similar to pool fires. Sonic releases of natural gas can produce relatively high velocity fires that are much less buoyant, less sooty and hence less radiative.

Source: UK HSE.

Jet Fire Testing

If high pressure flammable gas, pressure liquefied gas or flashing liquid fuels are emitted at high velocity and ignited, the result will be a jet fire. Withstanding these jet fires is most demanding for a pipe sealing system.

BEELE Engineering’s NOFIRNO sealing system for multi-cable and pipe transits has successfully completed a jet fire test, in accordance with ISO 22899-1:2007 and ISO/CD 22899-2 for two hours at the Health & Safety Laboratory at Buxton in England. The jet fire test was recorded on DVD; copies of the DVD can be ordered via BEELE Engineering.

From a time/temperature perspective, jet fire tests are similar to hydrocarbon (H-Class) fire tests.

During the hydrocarbon test, an instantaneous temperature rise up to 800°C (1472°F) takes place, with the overall exposure temperature rising to 1150°C (2102°F).

However, during the hydrocarbon test, there are no extreme conditions imparted to the penetration seal, such as thermal and mechanical loads or severe erosive forces, as is the cases with the Jet Fire Test.

Jet fire tests simulate the most onerous conditions of a hydrocarbon fuelled fire on an offshore oil rig, or a missile strike on a military warship.

Jet fires give rise to high convective and radioactive heat fluxes as well as high erosive forces.

To generate both types of heat flux in sufficient quantity, a 0.3 kg/second sonic release of gas is aimed into a hollow chamber, producing a fire ball with an extended tail.

The flame thickness is thereby increased and hence so is the heat radiated to the test specimen. Propane is used as the fuel since it has a greater propensity to form soot than natural gas and can therefore produce a flame of higher luminosity. Strong erosive forces are generated by the release of sonic velocity gas jet, 1 meter from specimen (bulkhead) surface. The jet velocity is ca. 100 meter/second at 0.25 meter from the back of the recirculation chamber (e.g. the front of the web of a structural steel specimen) and ca. 60 meter/second at the back of the chamber.

For the Jet Fire test, a cable penetration with dimensions 600x300mm with armoured and non-armoured cables up to 3x400mm² (102mm OD) and bundled LAN cables, representing a shipboard cable installation, was tested. The conduit sleeve for the NOFIRNO pipe transit was 406.4 mm ID and a steel pipe with an OD of 273mm was passed through. Both penetrations maintained their integrity for the full two hours.

Despite the jet speed of about 360 km/hour, causing high erosive forces, and the flame temperatures of about 1200°C, the temperature rise measured on the surface of the NOFIRNO sealant at the unexposed side was only max; 160°C. This proves the high thermal insulation values under fire load of the NOFIRNO sealing system. After dismantling it was noticed that the NOFIRNO filler sleeves were not consumed by the fire and were even hardly affected by the fire. Based on the positive outcome of this harsh fire tests, BEELE Engineering will apply for Jet Fire Certificates.

➡ NOFIRNO – Jet Fire Testing For Cable Duct & Pipe Penetration Sealing Systems

Sealing Pipes, Cables & Ducts Using NOFIRNO

NOFIRNO is one of BEELE Engineering’s ‘rapid cable and pipe sealing systems’ for use on board ships, on offshore pipework installations, in building and construction and other environments where the safety of people and installations has to be guaranteed.

NOFIRNO offers the ultimate fire safe sealing solution for metallic and plastic pipes. Even combined penetrations for metal and plastic pipes and cables can be sealed effectively. That means that one sealing system can be used for all types of pipe penetrations.

NOFIRNO is also tested on full scale bulkheads and decks in accordance with IMO Res. A.754 (18). An EC (MED) certificate according to the European Union Council Directive 96/98 EC on Marine Equipment has been issued by Det Norske Veritas.

The system has also been tested for H-class partitions and has obtained a Type Approval Certificate of Det Norske Veritas as well. Important is that both for A-0 and H-0 class the system has been tested without any insulation. For building and construction applications RISE/NOFIRNO has been tested according to EN1366-3:2004 and classified according to EN 13501-2:2003 for a fire rating of two hours (fire class E120 (flame resistance) and EI120 (flame resistance and thermal insulation) and lately in-house for a four hours fire rating.

Contact us for duct sealing systems for onshore and offshore sealing of medium/high voltage (MV-HV) substation cables.

NOFIRNO – A Brand of CSD Sealing Systems | Distributed by Thorne & Derrick

NOFIRNO has been developed for a service life of over 20 years and offers the best Total Cost of Ownership on the market of pipe and cable sealing systems in both onshore and offshore locations. The sealing system is resistant to weathering, UV and ozone resistant and is capable of absorbing temperature changes. The system is shock and vibration resistant and can be used in wide range of temperatures (-50°C up to +180°C).

Fire-safe NOFIRNO is also watertight. The system has no metal parts thus avoiding corrosion on the pipe work. The perfect sealing of the NOFIRNO sealant also avoids (invisible) corrosion within the penetration.

BEELE Engineering

BEELE Engineering is market leader in the field of passive fire safety. This position is based on the company’s ongoing R&D and innovation, advanced manufacturing technology and first class service. All the cable and pipe sealing products are developed and manufactured on the basis of an integrated approach to fire safety. All components are made in the company’s own factory under stringent ISO quality system.

Further Reading ➡

- A60 H120 Pipework Fire Protection For Offshore Bulkheads & Decks

- NOFIRNO – Cable & Pipe Sealing Systems

THORNE & DERRICK SPECIALIST ELECTRICAL DISTRIBUTOR

LV ♦ MV ♦ HV

Thorne & Derrick distribute the most extensive range of LV, MV & HV Cable Jointing, Terminating, Pulling & Installation Equipment – we service UK and international clients working on underground cables, overhead lines, substations and electrical construction at LV, 11kV, 33kV and EHV transmission and distribution voltages.

- Key Products: MV-HV Cable Joints & Terminations, Cable Cleats, Duct Seals, Cable Transits, Underground Cable Protection, Copper Earth Tapes, Cable Jointing Tools, Feeder Pillars, Cable Ducting, Earthing & Lightning Protection, Electrical Safety, Cable Glands, Arc Flash Protection & Fusegear.

- Distributors for: 3M Cold Shrink, ABB, Alroc, Band-It, Catu, Cembre, Centriforce, CMP, CSD Sealing Systems, Elastimold, Ellis Patents, Emtelle, Furse, Lucy Zodion, Nexans Euromold, Pfisterer, Polypipe, Prysmian, Roxtec.

LV – Low Voltage Cable Joints, Glands, Cleats, Lugs & Accessories (1000 Volts)

MV HV – Medium & High Voltage Cable Joints, Terminations & Connectors (11kV 33kV EHV)

Cable Laying – Underground Cable Covers, Ducting, Seals & Cable Pulling Equipment

T&D, CATU Electrical Safety & Arc Flash Protection Specialists for SAP’s, Linesmen, Jointers & Electrical Engineers – Largest UK Stockist

INVITATION

Thorne & Derrick invite you to join LinkedIn’s largest LV-HV Electrical Discussion Group : Low & High Voltage Power, Cabling, Jointing & Electricals. Discussion subjects include cable installations, cable jointing, substation, overhead line and electrical construction at LV, 11kV, 33kV and EHV. Network, engage and promote your profile, company or products with over 10,000 influencers.

What Makes Filoform The Best Low Voltage Resin Cable Joint?

January 30th, 2019

Low Voltage Resin Cable Joint

-

uploaded by Chris Dodds Sales & Marketing Manager | Thorne & Derrick

Cable Joints

Thorne & Derrick International are the UK distributors for Filoform, a leading manufacturer of cable joints, duct seals and special resins for installation in the utilities, telecom, traffic, rail, fibre optic, street lighting and construction industries.

In the following overview we explain what makes a good cable joint and via video demonstrate how to install Filoform resin cable joints.

Firstly, lets examine the kit contents of Filoform resin cable joints.

Joints Tested & Certified

Cable Joints

To European Standard

Filoform cable joints are approved in accordance with the standard DIN EN 50393 VDE 0278-393:2015-10 – test methods and requirements for accessories for use on distribution cables of rated voltage 0,6/1,0 (1,2) kV. This European Standard details the performance requirements and the test methods for type testing of cable joints for use with power distribution cables of rated voltage 0,6/1,0 (1,2) kV as defined in HD 603 or other relevant cable standards.

Injection Moulded Cable Joint Shells

Rigid and very strong snap-lock design forms an excellent seal and prevents resin leakage from the cable joint. Filform cable joints are designed and sized around UK manufactured steel wire armour cables (SWA) to BS5467 ensuring ample working-space for the jointer within the cable joint shell.

Transitions from PILC to XLPE, cross-core jointing and jointing of 3.3kV power cables can also be achieved with minor kit modifications.

Mechanical Connectors

Brass Tunnel Connectors

Brass tunnel connectors provide straight connections on stranded or solid circular conductors (both copper and aluminium). The range-taking tunnel connectors permit the jointing imperial to metric and step-down transitions where dissimilar size conductors preclude the use of conventional crimp connectors.

No specialist jointing tools – fast and simplified jointing of cable conductors without resort to crimping tools and associated die sets is achieved by Filoform brass tunnel connectors.

Two Allen screws for each core ensure a sound electrical performance and an Allen key is also provided with each resin joint kit to ensure that everything needed to joint a cable is included in the one box.

Earth Braid Armour Continuity

Armour Continuity Earth Braids

Wire Armour & Braided Cables

Tinned copper earth braid offers significant advantages over “single wire type” earth continuity systems in resin cable joint kits, which can fail if poorly positioned within wire armour cores that have “spread”. The flat, soft braid ensures good electrical contact and is insulated for extra protection – suitable for both wire braided and wire armoured cables.

Constant Force Springs

Cable joints move and expand due to earth shift and heat from electrical current. Constant force springs react to this movement and maintain a sound electrical connection between the steel wire armouring and the earth continuity braid.

Constant Force Springs

Core Separators

Provide safe separation of cores and connectors within the resin joint.

Two-Part Cable Jointing Resin

Filoform cable joint resin formula is equally suitable for both LV and HV jointing applications and provides excellent adhesion to PVC, XLPE, polythene and paper cables. Supplied in “easy-mix” transparent 2 component bag.

Cable Joint Resins

Cable Jointers Instructions

Detailed, clear and concise cable jointing instruction sheets ensure there is no ambiguity about safe jointing procedures – less cable jointer error.

Cable Joints – prior to resin pour with steel wire armour continuity across the cable by flexible copper earth braid, conductors jointed with mechanical range-take connectors

Thorne & Derrick International distribute the complete range of Filoform Resin Cable Joints for low voltage power, control, pilot and telecoms cable jointing.

LV Cable Joints (Low Voltage Cables)

Thorne & Derrick stock and distribute LV Joints in Cold Shrink, Heat Shrink or Resin Cast technologies – multicore and multi-pair cable joints are available for immediate backfill and energisation of Low Voltage power, control and instrumentation cables 600V/1000V 3.3kV.

Complete range of LV Cable Accessories ➡

Cable Breakouts | Cable Caps | Cable Lugs | Cable Cleats | Cable Trough | Cable Duct | Feeder Pillars | for 11kV/33kV/66kV networks see MV HV Joints & Terminations

Pfisterer | Nexans Euromold | Prysmian | Cable Joints & Terminations MV HV

Cold Shrink by 3M | Joints | Abandonment | Terminations | Low Voltage LV Cables