Blog

3M Scotch Tapes – PVC Vinyl Electrical Tapes

July 26th, 2018

A series of How-To videos for repairing, jointing and terminating cables using 3M Cold Shrink & Scotchcast products.

-

uploaded by Chris Dodds - Thorne & Derrick Sales & Marketing Manager

Scotch Tapes

This video by 3M Electrical shows the benefits of 3M Scotch Electrical Tapes.

3M Scotch tapes are used to cable joint, splice, repair damaged cables, seal and protect cables against abrasion, fire and corrosion – this includes protection of LV-HV (11kV-33kV) cables and connections.

Please contact T&D should you require assistance with selecting the correct 3M Scotch tape.

The 3M video explains the benefits of using Scotch electrical tape over alternative tapes.

Extreme Heat or Cold Applications For Scotch Tapes

Watch the video to see how Scotch tapes perform and endure installation and service conditions at temperatures down to 0°F and up to 220°F temperatures with cracking or unwinding. Scotch tapes will not degrade overtime when subject to temperature extremes, weathering, moisture or chemicals.

3M Scotch tapes demonstrate strong adhesion and excellent durability ensuring they are ideal for permanent jobs such as insulating and protecting electrical cable connections – once wound properly it remains wound.

3M Scotch tapes can also be used in zero degree temperatures and withstands high temperature up to 220ºF unlike other vinyl electrical tapes which would crack and unwind.

A greater stretch and tape elasticity provides a smooth, professional wrap and the coloured coded and fade resistant design ensures permanent and clear cable identification using 3M Scotch vinyl electrical tapes.

Scotch Tapes Manufactured By 3M Electrical For Professionals

The Scotch brand of PVC vinyl electrical tapes, manufactured by 3M Electrical, provide distinct competitive advantages over unbranded poor quality tapes which may have a superficial low price but actual high cost associations – since plastic vinyl tapes hit the mass-market in the 1940’s 3M Scotch has been the choice brand of the professional electrician for tapes with excellent electrical and mechanical properties.

For instance, 3M Scotch Super 33+ is the market-leading “fit and forget” vinyl electrical tape for providing cable protection, insulation and repair in industrial and hazardous area installations – this includes chemical (resists acids and alkalies), offshore (resists abrasion and corrosion) and industrial outdoor (resists UV ultraviolet light) applications.

As standard Scotch 33+ is coloured black so for colour-coding, phase marking and identification applications go with 3M Scotch 35 – same product specification as Scotch 33+ but with a colour spectrum of red, yellow, blue, brown, grey, white, green, orange and violet.

For cold weather and extreme low temperature applications select 3M Scotch 88 for continuous service down to 0 Degrees Celsius – Scotch 88 by 3M features excellent pliability and adhesion.

A varnished cambric tape is “off-the-shelf” for high puncture and cut-through resistance with Class A thermal stability – contact sales and ask about 3M Scotch 2510 for further information.

The protection of medium/high voltage cables and joints demands heavy-duty electrical tapes – substandard and under specified tapes pose risk and danger to power systems and life. Here, upgrade your tape choice to 3M Scotch 22, recommended by 3M Electrical for outer sheath and cable jacket protection or repairs to high voltage power cables and joints with rubber or polymeric cables. That’s XLPE and EPR in “cables-speak”.

Where cost is King but a good quality and general purpose PVC electrical tape is required contact us to place an order for 3M Temflex 1500.

All 3M Electrical Tapes are super stretch and strong for holding power in place without fail.

Due to the physical properties of 3M Scotch the tapes provide moisture-tight, chemical resistant electrical sealing of cables, connections and cable joints.

So overall, Thorne & Derrick distribute an extensive range of electrical tapes including fire proofing tapes with arc protection, see 3M Scotch 77 and high specification fire resistant tapes manufactured by Nexans.

Further details on the complete range of 3M Scotch Electrical Tapes can be found here:

- 3M Scotch Insulation Tapes

- 3M Scotch Self Amalgamating Tapes

- 3M Scotch Mastic Tapes

- 3M Scotch Corrosion & Fire Protection Tapes

- 3M Scotch Glass Cloth Tapes

- 3M Scotch 24 Tape – Electrical Shielding Earthing Tape

- 3M Scotch 25 Tape – Electrical Shielding Earthing Tape

Cold Shrink – invented by 3M over 40 years ago and now the preferred technology for heat-free jointing, terminating, sealing and abandonment of LV HV cables

We hope you find this video informative and educational, contact T&D for technical support, quotations and stock availability for 3M Scotch Electrical Tape.

➡ Visit 3M Electrical for further information about joints, terminations, tapes and insulation to seal, repair, splice and connect LV MV HV cables.

Cold Shrink | Joint | Terminate | Seal | Repair | Splice | LV MV HV Cables | 3M

-

-

- 3M Electrical Products Stocked By Thorne & Derrick International

-

Consac Cable Joints – Mains Fault Located, Excavated, Jointed & Supply Restored

July 26th, 2018

- Application: Jointing Low Voltage LV Consac Utility Cables

- Cable Joint: 95sqmm Consac to 95sqmm 3 Core Wavecon Repair Straight Joint

- Cable Jointer: Grant Butler – 33kV/11kV HV & LV Cable Faults Jointer (SSE)

- Featured Manufacturer: Tyco Electronics

Consac Cable Joints

These type of cable joints must only be installed by Trained & Competent Jointers using the approved and correct Consac cable jointing tools.

.1 x 5 Core Cu PILC STA Mains Cable to 3 Core 95sqmm Wavecon Transitional Straight Joints

Consac Live Cut & Test Whilst Fault Finding To Locate Underground Fault

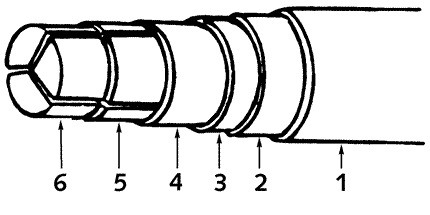

Consac Cable Construction

- Extruded PVC or polythene oversheath cable jacket

- Layer of bitumen containing corrosion inhibitor

- Extruded smooth aluminium sheath

- Paper belt insulation

- Paper core insulation

- Solid aluminium conductors

—-

How To Remove The Aluminium Sheath From Consac Cable

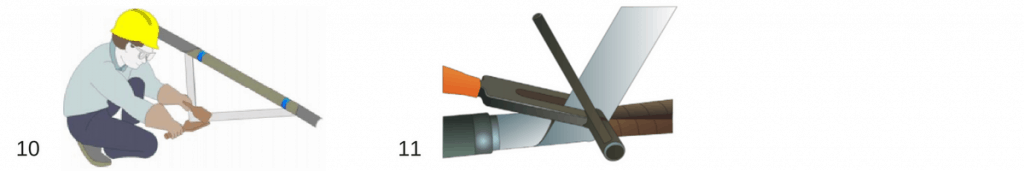

- Mark the aluminium sheath at the cable joint centre and make an additional two extra marks at 60 degrees to form an arrow – this arrow MUST point to the cable jointer

- Select the correct cutting wheel for the Consac sheath stripping tool according to the cable cross sectional area. The 45 thousands of an inch cutter is used for 70mm to 120mm cable, the 70 thousands of an inch cutter is used for 150 to 240mm cable

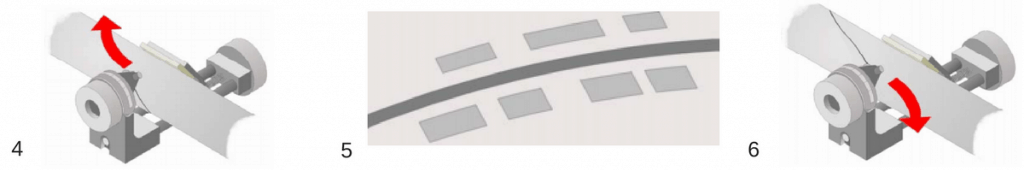

- Set the angle of the Consac sheath cutting tool to 60 degrees, using the front control wheel and scale

- Using the rear pressure control wheel, open then close the tool onto the first of the 60 degrees marks. Apply the light pressure then rotate the tool outward along the cable until it butts up to the PVC sheath edge, this should occur at tool bottom dead centre

- Repeat this operation, moving the cable jointing tool forward and backward along the cable, gradually increasing the pressure using the rear wheel. Continue this process until scuff marks from the shoulders of the cutting wheel appear along the edges of the cut, then stop

- Remove the cable cutting tool and re-set the cutter angle to 60 degrees on the opposite hand. Re-fit the tool and repeat operations 4 & 5. Remove the tool on completion

- At the point where the two tool cuts join, use the edge of a six inch half round file to deepen the cut until the underlying papers begin to appear. The flat side of the file must point towards the inside of the arrow

- Using a hammer and pliers lift the point of the arrow – wearing insulating gloves unpeel the aluminium sheath from the cable until the ends of the cut are reached. The sheath should now appear as shown in the illustration pointing away from the cable jointer

- Fit PVC binders at the points where the underlying papers are to be terminated

- Bear the cut part of the sheath flat with a pair of wooden beaters

- Holes can be punched in the aluminium sheath where required using a special purpose hole punching tool

Note: Using approved cable cleaning wipes ensure that the prepared Consac cables are cleaned thoroughly and all dirt, debris or contaminants are removed.

Should you require any assistance with the selection or specification of LV cable joints, connectors or terminations please do not hesitate to contact us.

Thorne & Derrick Specialist Electrical Distributor

LV ♦ MV ♦ HV

T&D distribute the most extensive range of LV, MV & HV Cable Jointing, Terminating, Pulling & Installation Equipment – we service UK and international clients working on underground cables, overhead lines, substation earthing and electrical construction at LV, 11kV, 33kV and EHV transmission and distribution voltages.

- Key Products: MV-HV Cable Joints & Terminations, Cable Cleats, Duct Seals, Cable Transits, Underground Cable Protection, Cable Jointing Tools, Feeder Pillars, Cable Ducting, Earthing & Lightning Protection, Electrical Safety, Cable Glands, Arc Flash Protection & Fusegear.

- Distributors for: 3M, ABB, Alroc, Band-It, Catu, Cembre, Centriforce, CMP, Elastimold, Ellis Patents, Emtelle, Furse, Lucy Zodion, Nexans Euromold, Pfisterer, Polypipe, Prysmian, Roxtec.

LV – Low Voltage Cable Joints, Glands, Cleats, Lugs & Accessories (1000 Volts)

MV HV – Medium & High Voltage Cable Joints, Terminations & Connectors (11kV 33kV EHV)

Cable Laying – Underground Cable Covers, Ducting, Seals & Cable Pulling Equipment

T&D, CATU Electrical Safety & Arc Flash Protection Specialists for SAP’s, Linesmen, Jointers & Electrical Engineers – Largest UK Stockist

Invitation

Thorne & Derrick invite you to join LinkedIn’s largest LV-HV Electrical Discussion Group : Low & High Voltage Power, Cabling, Jointing & Electricals. Discussion subjects include cable installations, cable jointing, substation, overhead line and electrical construction at LV, 11kV, 33kV and EHV. Network, engage and promote your profile, company or products with over 10,000 influencers.

Triplex Cleats – Selection Guide for Cleating 11kV BS7870 Part 4.10 Cables

July 25th, 2018

Distributors for Ellis Patents Cable Cleats

- uploaded by Chis Dodds – Thorne & Derrick Sales & Marketing Manager

The following post is provided to enable the selection of cable cleats to suit a standard UK DNO utility cable for medium/high voltage power systems – this type of MV HV cable commonly referred to as “Triplex” cable has increasingly replaced conventional BS6622 11kV 3 core XLPE insulated cable.

Triplex cable consists of 3 x single cores in a “twisted” spiral formation – this non linear cable orientation must be recreated into a circular formation using Triplex cable surrounds.

It is essential to effectively cable cleat Triplex cables to containment to ensure safe and reliable cable restraint in the event of a short-circuit situation – to simplify the cable cleat selection process it is a basic requirement to consider the calculated short-circuit fault current rating, installation environment and overall outside diameter of the 3 x single core cables when combined in Triplex formation.

The short circuit calculation would normally be the responsibility of the Electrical Design Engineer and can be calculated using a formula as recommended by IEC61914 the international standard which specifies requirements and tests for cable cleats and intermediate restraints used for securing cable in electrical installations.

Triplex Cables 11kV BS7870 4.10

Specification: 11kV Triplex, Solid Aluminium Conductor, Triplex Extruded Conductor Screen, XLPE Insulation, Fully Bonded Semi-con Screen, Copper Wire Screen, Longitudinal Water Blocking Tape, MDPE Cable Sheath, 6350/11000V to BS7870 Part 4. Sheath colour: Red.

Based on the following 11kV Triplex specification we can recommend and supply 3 types of cable cleat

- Ellis Patents 2F Cable Cleat (Plastic)

- Ellis Patents Vulcan+ Cable Cleat (Stainless Steel)

- Ellis Patents Emperor Cable Cleat (Stainless Steel)

| Voltage | Conductor Type | Conductor Sqmm | Nominal Conductor Diameter | Dia Over Insulation mm | Dia Over Semi-con Screen | Dia Over Cable Sheath | Diameter In Triplex Formation | Triplex Liner | 2F Cleat | Vulcan Cleat | Emperor Cleat |

| 11kV | Solid Aluminium | 95sqmm | 10.65mm | 18.95mm | 23.03mm | 27.17mm | 58.24mm | SFT26 | 2F+10 | VRT+04 | ES58-66 |

| 11kV | Solid Aluminium | 185sqmm | 14.9mm | 23.25mm | 27.33mm | 31.67mm | 68.24mm | SFT31 | 2F+1200 | VRT+06 | ES65-73 |

| 11kV | Solid Aluminium | 300sqmm | 19.0mm | 27.3mm | 31.38mm | 36.12mm | 77.83mm | SFT36 | 2F+1201 | VRT+07 | ES73-85 |

♦ Important: Manufacturers cable dimensional data and tolerances can vary by significant % factors hence critical measurements can be inconsistent – always provide manufacturers cable specification complete with construction information to ensure supply of correct cable cleats. Above is provided for guideline purposes only – check with Thorne & Derrick.

Based on the above cable dimensions we can supply the range of cable cleats listed below.

Triplex Liner & Cable Surrounds

Ellis Patents Triplex cable surrounds are manufactured from LSF Zero Halogen Polymeric material and used within single cable cleats to secure triplex cables – the cable liner surrounds have a maximum short circuit test level of 76kA when used with Ellis Patents 2F cable clamps and 600mm cleat spacings.

Triplex Cleats

The following table provides an overview of the Ellis Patents range of Triplex cable cleats depending on levels of short circuit fault protection required by the clamps.

More Cable Cleats Reading

Ellis Patents Cable Cleats

Correctly Sealed Cable Ducts Will Protect From Ingress Into Potable Drinking Water

July 16th, 2018

-

uploaded by Chris Dodds - Thorne & Derrick Sales & Marketing Manager

The following information is provided courtesy of Severn Trent Water as part of their series of Lessons Learn Bulletins which highlight the potential use or adoption of products to ensure cleaner, safer and more reliable distribution of water supply – specifically this short update is focussed on duct sealing to prevent pollution of potable drinking water.

Brief Description

The Whitacre / Warwickshire team identified a shortfall in the way cable ducts are sealed following installation of new and the maintenance of existing assets.

This was identified as part of coliform investigations where there is a potential for water ingress into injection chambers, reservoirs and back wash tanks. Lack of correct duct sealing in this instance resulted in water entering a level probe chamber with the potential to pollute potable drinking water.

Sealing Cable Ducts

Several options to securely seal cable ducts have been investigated with support from Water R&D. As a result of findings Asset Creation updated the STW design manual for E&M Plant Electrical Design (DM0106-03) and issued a technical bulletin informing key departments, ensuring that the new minimum standard is adhered to.

Two duct sealing kits were used and approved by PH&S, both provided similar results.

PLEASE NOTE: These kits are not DWI Reg 31 approved and must not be used where direct contact with potable water occurs. Any proprietary seal kit used must be of the type listed in the Water Industry Mechanical & Electrical Specification 3.02 (SPC 0302-W302).

Lessons Learnt

Share at your Comm Cells with your operational and maintenance teams.

• During routine inspections check for any cable ducts which could possibly allow ingress into reservoirs or injection chambers which could lead to a water quality failure?

• Contact either of the above for any assistance for procuring and advice on installing the sealing kits.

• Track any next steps via your Comm Cell, raise WQ U/C and sign off when complete.

Sealed Cable Ducts

Examples of installed duct sealing systems

More info: Filoform Filoseal Seals | CSD RISE Seals

Cable Duct & Cable Protection

Thorne & Derrick supply an extensive range of underground cable duct and protection covers suitable for LV MV HV cable installations – this includes Tape Tile 11kV and Stokbord Covers 33kV used to protect underground power cables pulled and laid into trenches.

To promote the installation of cable into duct a labour-saving range of cable lubricants is available to facilitate friction-free cable pulling and reduce damage to cables. See our range of cable ducts suitable for low, medium and high voltage power and utility cables.

Key Product Categories: Duct Seals | Cable Cleats | Cable Glands | Electrical Safety | Arc Flash Protection | Cable Jointing Tools | Cable Pulling | Earthing | Feeder Pillars | Cable Joints LV | Joints & Terminations MV HV

Lightning Protection Earthing Systems – Type A,B & Foundation Earth Electrodes

July 10th, 2018

-

uploaded by - Chris Dodds (Sales & Marketing Manager Thorne & Derrick)

The following information has been provided courtesy of AN Wallis, leading UK manufacturers of Earthing & Lightning Protection Systems.

In general the Lightning Protection System (LPS) system should:

- Be an integrated system for lightning protection, power systems and telecoms systems

- Have a low overall resistance of 10 ohm’s or less

- Have an even spread of readings across all the individual earth electrode terminations to ensure as far as possible the current is evenly distributed

- Have a high resistance to corrosion

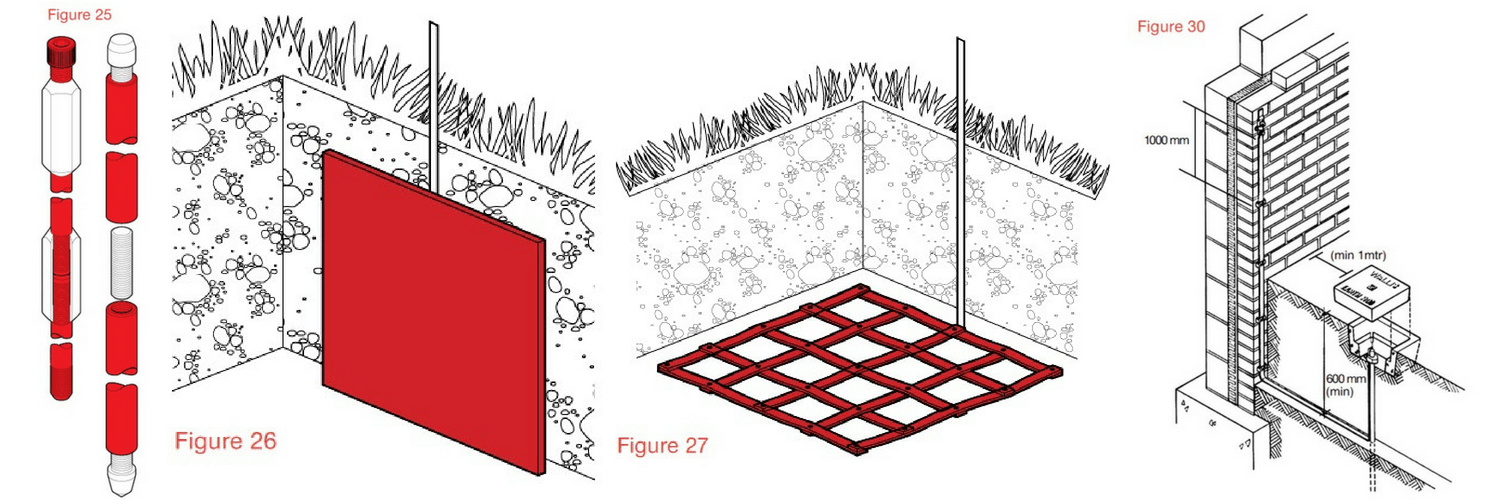

Lightning protection and earthing equipment is usually made up of earth rods either copperbonded, solid copper or stainless steel (figure 25) – also forming the earthing system are copper earth plates (figure 26), copper lattice earth mats (figure 27) or 25 x 3mm copper earth tapes.

Driven earth rods manufactured from solid copper and bonded with copper are available from stock – contact Thorne & Derrick

There are three types of LPS Earthing systems types A, B and Foundation Earth Electrodes

Type A – The conventional LPS Earthing system using

vertical or horizontal electrodes such as

copperbond Earth rods or copper tape

Type B – The ring electrode sited around the periphery of the structure

Foundation Earth Electrodes

The foundation electrode system installing the conductors in the concrete foundations of the structure.

Type A Earthing Arrangement

This is the conventional type of LPS Earthing System where earthing rods are used to form the earth electrode and usually each down conductor, such as copper earthing tapes, are connected to an earth rod.

The type A earth termination arrangement is suitable for low structures (below 20 metres in height) or an LPS with rods or stretched wires. For an isolated LPS the British Standard BS EN 62305 recommends a type B earthing arrangement where the structure is housing extensive electronic systems.

The type A arrangement uses vertical or horizontal earth electrodes. Practically it uses both connected to each down conductor, installed outside the structure (below the foundation) to be protected and housed in a plastic or concrete pit for ease of inspection (figure 30).

Lightning Protection – Copper Earthing Equipment

The minimum number of electrodes is 2.5 metres, regardless of the perimeter of the structure/class of LPS.

The minimum length of each earth electrode at the base of each down-conductor is specified in BS EN 62305 and the table below.

Minimum length l¹ of each earth electrode according to class of LPS

It is 11 for horizontal electrodes – usually copper tapes.

Or

0.511 for vertical copperbonded rods or solid copper rods. Or

>11 in the case of a lattice mat measuring the total length of the conductor in the earth mat.

Or

If copper plates are to be used the surface area of the plate should be at least equal to either.

The surface area of the length of earthing conductor that would need to be used to satisfy the requirement for a vertical electrode 0.511.

Or

The surface area of the length of earthing conductor that would need to be used to satisfy the requirement for a lattice mat electrode 11.

Or

If using vertical and horizontal electrodes, the individual earthing electrode lengths should follow the 0.511 and 11 principle respectively.

Type A earth electrodes should be installed so that the top of the earth rod is 0.5 m below the surface, this distance is to reduce the effects of step potential at ground level.

The earth rod should be housed in an inspection pit, commonly concrete or plastic for ease of inspection and registering the location during and after installation figure 30.

Full range of copper earth tapes available from stock in range of widths and thicknesses.

Type B Earthing Arrangement

The type B Earthing arrangement is most suitable for:

- Structures built on rocky ground

- Structures housing sensitive electronics/equipment

- Large structures

The type B earthing is recommended as either a ring conductor outside the perimeter of the structure which it’s recommended should be in contact with the soil for at least 80% of its total length.

The alternative is to use a foundation earth electrode which can be in a mesh form.

It is recommended that the type B earthing network whichever method is chosen should be integrated as a meshed network buried to a minimum depth of 5 rats.

The reinforced concrete floor slab can be used around the structure.

If the required resistance cannot be achieved by this method the vertical or radial earthing electrodes can be added to the network.

For ease of testing after installation an inspection pit with an earth bar should be installed where the legs of the ring and conductor routing onto the ring from the each test clamps join (figure 31).

Any internal down conductors should be connected to the internal foundation using a test clamp for ease of maintenance.

Foundation Earth Electrodes

Once all the services are connected its unlikely the installer will be able to measure the earthing resistance of the foundation earth in isolation.

The use of the foundation as an earth electrode is allowable only where the reinforcement network is below any insulating or waterproof membrane.

Where a foundation is used as an earth-termination the reinforcing bars must be clamped or welded together to ensure electrical continuity.

Alternatively an additional meshed network of conductors can be installed to ensure continuity. The additional network should be connected to the reinforcing bars by clamps or welded joints every 20 m throughout the system.

The earthing system whether using reinforcing bars or additional conductors or a combination of both must be connected to every down conductor and internal steelwork.

Internal Lightning Protection System

The internal LPS is important to fully complete the installation to fulfil the requirements of BS EN 62305.

The main reason for installing an internal LPS is to avoid any dangerous sparking within the building.

The sparking is caused by current flow and the difference in potential between internal conductive components such as steelwork and the external LPS on the outside of the building or from the use of the internal steelwork as part of the LPS.

The earthing system whether using reinforcing bars or additional conductors or a combination of both must be connected to every down conductor and internal steelwork.

THORNE & DERRICK

T&D are Specialist Distributors to UK Distribution Network Operators (DNO’s), NERS Registered Service Providers, ICP’s and HV Jointing Contractors of an extensive range of LV, MV & HV Jointing, Earthing, Substation & Electrical Eqpt – this includes 11kV/33kV/66kV cable joints, terminations and connectors for both DNO and private network applications.

Contact our UK Power Team for competitive quotations, fast delivery from stock and technical support or training on all LV-HV products.

Key Product Categories: Duct Seals | Cable Cleats | Cable Glands | Electrical Safety | Arc Flash Protection | Cable Jointing Tools | Cable Pulling | Earthing | Feeder Pillars | Cable Joints LV | Joints & Terminations MV HV