Blog

Substation Earthing

December 5th, 2017

Images: ABB

by Chris Dodds T&D - estimated reading time 6 minutes

Earthing Substations

Thorne & Derrick International are distributors for the ABB Furse and AN Wallis range of Earthing & Lightning Protection Systems – this includes earth rods, earth bars, earth tapes and a full supporting range of accessories to comprise the complete earthing system for electricity transmission and distribution systems.

The copper products are used typically to provide electricity substation earthing to medium/high voltage grids containing electrical infrastructure, cables, switchgear and transformers. Furthermore, it is usual for all exposed and normally un-energised metalwork inside the substation perimeter, including doors, staircases, ventilation ducts, cable supports etc to be be bonded to the main earth grid to avoid any potential differences between different items of metalwork.

Guidelines and policies vary according to the Distribution Network Operator – specialist contractors using modern earthing techniques compliant with relevant British and international standards, including BS 7430:2011+A1:2015 Code of Practice For Earthing and IEEE80-2000 Guide for Safety in AC Substation Grounding should be employed to calculate specific substation earthing requirements.

A final design of the earthing system can only be undertaken when sufficient knowledge is available of the proposed physical and electrical requirements of the substation – as an absolute minimum the earthing system desginer must have knowledge of:

- value of fault current and supply arrangements (overhead and/or underground cable)

- fault duration (or protection settings)

- soil resistivity

- substation dimensions

The specification for fixed earthing systems within EHV, HV, HV/MV and LV substations also applied to terminal towers adjacent to substations and cable sealing end compounds, pole mounted transformer or air-break switch disconnector installations and pole mounted reclosers with ground level control.

➡ View our complete range of Substation Earthing products including substation and overhead line earth clamps, telescopic sticks and portable earthing kits – see also Exothermic Welding.

Full range of bare copper, printed and covered earth tapes are available

Copper Earthing Products

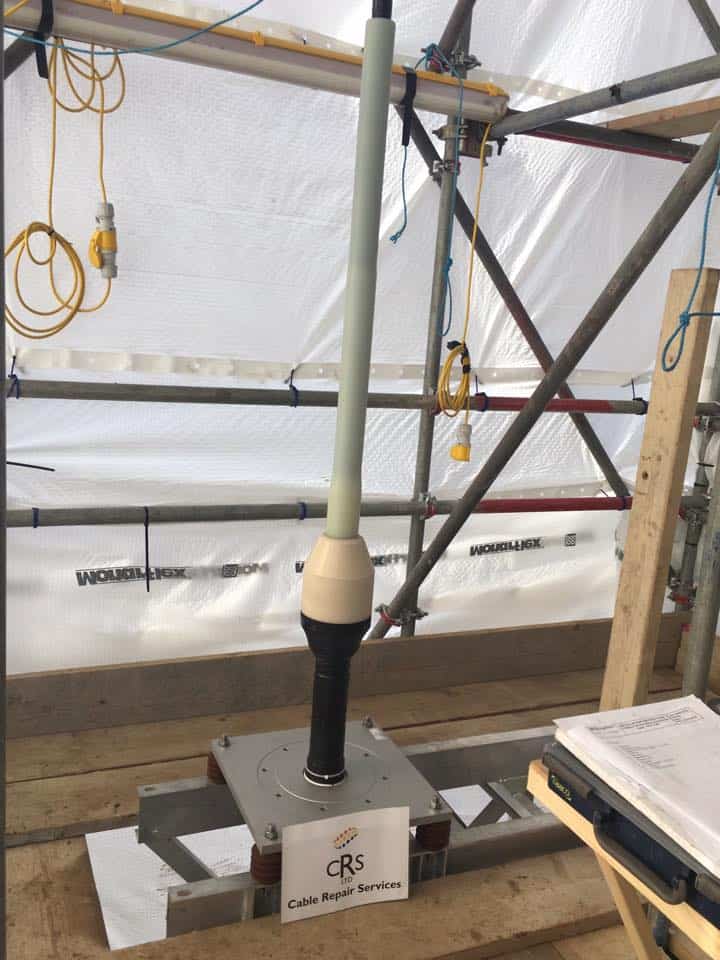

Example – Substation Earthing 11kV. Image: SPE Electrical Ltd

For MV & HV Substations

Earthing products and systems can be supplied by T&D for all substation voltages:

- MV Medium Voltage 11kV 33kV

- High Voltage 66kV 132kV

- Extra High Voltage EHV 275kV 400kV

T&D provide expert technical support, competitive prices and delivery from stock for substation earthing projects – all earthing products are available to meet the design criteria and construction specification of the earthing systems for substations and equipment for 33kV and 132kV substations.

This include copper earth tapes with typical dimensions 32mm x 4, 40mm x 6mm, 50mm x 4mm and 50mm x 6mm.

With respect to high voltage earthing applications in the power utility sector the following items would normally be earthed or bonded to the main earth grid:

- Overhead line termination structures including towers, gantries and earthed wood pole structures adjacent to the substation

- Power cable sheaths and armours

- Transformer and reactor banks, cooler and radiators, tap changers, earthing resistors, earthing reactors, high voltage transformer neutral connections

- Metal clad switchgear assemblies and cases, isolators and earth switch bases

- Metal gantries and structures and metalwork mounted on wood structures

- Metallic structures including steel frames (bonded at each corner) rebars and piles

- Panels, cubicles, kiosks, LV AC equipment, lighting and security masts

It is usual for critical items such as medium/high voltage transformer tanks and terminal towers to have duplicate connections to the main earth grid.

11kV Substations

Pictured above is a diagram showing the typical layout of a high voltage GRP electricity substation distributing 11kV power – an outer ring of 70sqmm copper earthing conductor plus 4 earth rods of standard depth are shown with a 10 metre tail in the HV cable trench accompanied by a layout for the concrete rebar. Here, the HV substation is contained within a GRP enclosure with potential touch and step voltage risks.

Earth tapes are available stamped with the UK DNO ownership details to discourage copper metal theft – earth tapes printed “National Grid Property” are also available.

Full range of copperbond earth rods, couplings and driving studs are available for grid and primary substation earthing depending upon the calculated fault level.

- E – Earth electrode (copper earth rod)

- UE – Earth potential rise (EPR)

- S1, S2, S3 – Potential grading earth electrodes connected to the earth electrode E

- US Touch – Source voltage for touching (Touch Voltage)

- US Step – Source voltage for stepping (Step Voltage)

Touch Voltage

The potential on the surface of the soil near a copper earth rod during the time that fault current flows. If a person were to touch a rod (or any exposed metalwork connected to it), then the potential difference experienced between hands and feet is termed the touch voltage. Touch voltages are calculated assuming that the feet of the person are 1 metre away from the metalwork being touched. Touch voltages are normally reduced by using potential grading electrodes.

Step Voltage

Potential differences are established on the surface of the soil whilst fault current is flowing. Step voltage in a particular direction is defined as the potential difference between two points a metre part. Step potentials can be reduced by using potential grading copper electrodes or installation electrodes, such as copper earth rods, at a greater soil depth.

Transfer Potential

A potential rise of an earthing system caused by a current flowing to earth, transferred by means of a connected conductor (eg metallic sheath or pipe), which enters a substation area, with little or no potential rise relative to reference earth, and which is not connected to earth in that area. This results in a potential difference occurring between the conductor and its surroundings at the remote position.

Electrical Safety – Maintaining & Repair Of Earthing Systems

Substation earthing systems are the victim of operational and intentional damage – copper theft is rife and earthing maintenance work is often identified during routine site checks and inspection. Earth faults can be weekly occurrences on primary substations supplying extended high voltage rural overhead line networks. During these maintenance tasks there is serious risk of injury or even fatal electric shock when working on depleted or damaged earthing systems – specialist electrical safety equipment including insulated sticks, poles or rods, portable earth shorting leads, earthing clamps (substation or line-end), insulating footwear (shoes or boots) and insulating gloves depending on the voltage class of the substation earthing system.

T&D distribute a full range CATU Electrical Safety equipment including Arc Flash Kits, Insulating Boots & Safety Shoes and Voltage Detectors

High Voltage Substation Earthing 275kV

All images courtesy: Ian Forster (EHV Site Manager)

More Substation Earthing Applications

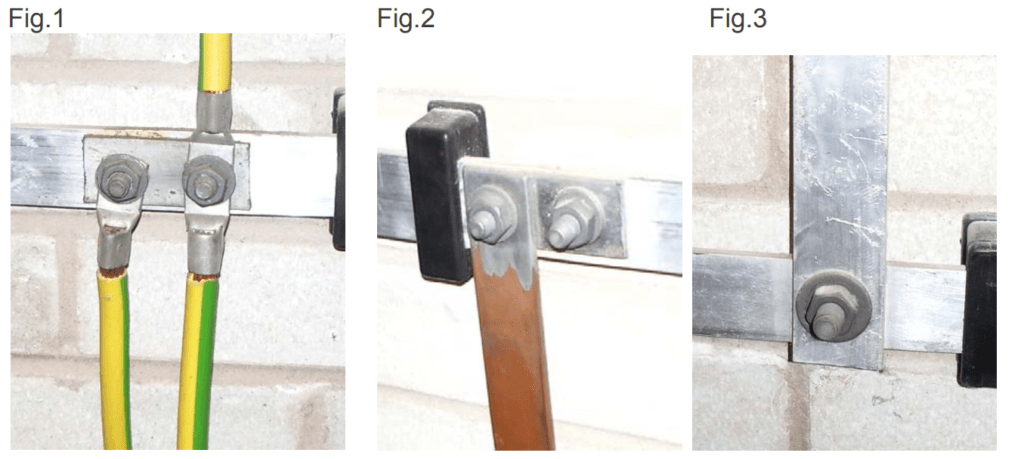

Fig.1 3 x Copper earth cables connected to main aluminium substation earth tape

Fig.2 Copper earth tape connected to main aluminium earth tape

Fig.3 Aluminium to aluminium tape connection

View the Earthing Products below for further information and technical details.

3M Scotchcast Cable Joint – Resin & Taped Manhole Cable Splice 600/1000V

December 4th, 2017

- Application: Resin & Taped Manhole Cable Joint / Splice 600/1000V

- Cable Joint: 3M Scotchcast Cable Joints

- Cable Jointer: Andy O’Malley (IBEW 258 EHV Cable Jointer / Cable Splicer)

- Featured Manufacturer: 3M Electrical

Cable Jointing In Confined Spaces

-

by Chris Dodds - Sales & Marketing Manager Thorne & Derrick

Prior to jointing cables in confined spaces control measures and risk assessment must be undertaken. This picture was taken from outside the manhole once the cable joint was complete – the looped cables were spliced using 3M Scotchcast cable joints to effect a repair to damaged cables in a confined space.

Initially the cable jointers bump test their gas detectors then gas sample the manhole with the lid on for the presence of harmful, flammable or toxic gas.

If all is safe to proceed the jointers remove the lid. Next the working space is vented with forced air while the jointers constantly monitor the confined space with their gas detectors. Access to the manhole is via a wooden ladder with the cable jointers wearing a rescue harness – a tripod and winch are positioned and a gate guard around the manhole is erected to prevent trips, falls or accidents.

The cable is jointed within the manhole to prevent overbending strains on the low voltage cable when fed back into the manhole if jointed at ground level – cable duct seals can be used to prevent the migration of flammable gas or flood waters into the manhole.

The 500kcmil 100 volt rated DC cable circuit is operating at 600 volt – the cable joint/splice utilises 3M Scotch Electrical Tapes with no heat shrink or cold shrink tubing.

3M Scotchcast Cable Joint – Resin & Taped Manhole Cable Splice 600/1000V

3M Scotchcast Cable Joint

3M cable joints use Scotchcast resins for the low voltage jointing of cables with XLPE, EPR, PVC or PILC insulation up to 3.3kV. Resin cable joints specially modified with high performance hydrocarbon resistant, low smoke zero halogen, fire resistant and flame retardant resins are available to withstand harsh operating and environmental conditions in industrial and hazardous area locations. The 3M cable joints are specified throughout ther oil, petrochemical, gas, mines, telecoms, rail and industrial cables are available – suitable for direct burial (underground) or exposed onto cable containment.

3M SCOTCHCAST LV RESIN CABLE JOINTS – Benefits

Resin Cable Joints – Features & Benefits Of 3M Scotchcast Cable Jointing Systems

Contact Thorne & Derrick to discuss your application for jointing LV cables – we can provide expert technical support, training and specification advice to ensure the correct supply of electrical LV cable joints to suit industrial and hazardous area location cables.

T&D – Main Distributors For 3M Electrical

Should you require any assistance with the selection or specification of cable joints or terminations using 3M Cold Shrink on MV-HV cables please do not hesitate to contact us.

Thorne & Derrick Specialist Electrical Distributor

LV ♦ MV ♦ HV

T&D distribute the most extensive range of LV, MV & HV Cable Jointing, Terminating, Installation & Cable Pulling Equipment – we service UK and international clients working on underground cables, overhead lines, substations and electrical construction at LV, 11kV, 33kV and EHV transmission and distribution voltages.

- Key Products: MV-HV Cable Joints & Terminations, Cable Cleats, Duct Seals, Cable Transits, Underground Cable Protection, Cable Jointing Tools, Feeder Pillars, Cable Ducting, Earth Tapes, Electrical Safety, Cable Glands, Arc Flash Protection & Fusegear.

- Distributors for: 3M, ABB, Alroc, Band-It, Catu Electrical, Cembre, Centriforce, CMP, Elastimold, Ellis Patents, Emtelle, Furse, Lucy Zodion, Nexans Euromold, Pfisterer, Polypipe, Prysmian, Roxtec.

LV – Low Voltage Cable Joints, Glands, Cleats, Lugs & Accessories (1000 Volts)

MV HV – Medium & High Voltage Cable Joints, Terminations & Connectors (11kV 33kV EHV)

Cable Laying – Underground Cable Covers, Ducting, Seals & Cable Pulling Equipment

More…

T&D’s Power Blog covers: LV MV HV & EHV Transmission & Distribution, Substations, Switchgear, Cable Jointing & Termination, Cable Fault & Repair, Underground Cables.

➡ Visit Power Blog

11kV Switchgear Cable Terminations, Jointing & Spiking In High Voltage Substations

December 4th, 2017

Jointing, Terminating & Installation of 11kV Substation Cables

Guest Post from Mick Beeby - Technical & Operations Manager at UK Power Solutions Ltd

Uploaded by Chris Dodds - Thorne & Derrick Sales & Marketing Manager

“I spent a couple of days on site this week with one of our team of Operations Engineers, connecting 4 new ESP adopted 11kV high voltage substations on Phase 2B of the Ballymore Royal Wharf Development in London.

UKPS have provided the electrical infrastructure for Phase 1, 2A and now 2B to date.

This includes 1 x UKPN 11kV boundary substation with 2 RMUs, 1 x SSE 11kV boundary substation with 2 RMUs, 11 x ESP 11kV permanent distribution substations and 1 x ESP 11kV TBS installed and disconnected again, 1 x UKPN 11kV metered TBS to private high voltage transformer.

There are more ESP 11kV distribution substations to install in Q1 2018. This now takes us to 10 of a final 12 total on this ESP 11kV ring.

An IEC was received from SSE for the DNO/iDNO boundary end of the ESP 11kV circuit, which was made Dead, Isolated and Earthed before the 11kV cables were identified and cables spiked under a Sanction-for-Test. A Permit-to-Work was then issued for the 11kV cable jointing, followed by pressure testing under another Sanction-for-Test and final energisation and 11kV phase checks to bring 4 new 11kV high voltagew substations onto the system.”

1 of 4 new ESP 11kV high voltage substations connected on this visit, taking the total on this ESP 11kV ring to 4 substations, and 11 on the Ballymore Royal Wharf development so far.

2 x 3c 11kV polymeric SSE specification straight cable joints of TE Connectivity MXSU series, to loop 4 high voltage substations into the existing ring of 4, making 8 total.

5 Way Transformer Mounted Cabinet post energisation testing. 5 outgoing LV circuits to the multi-occupancy buildings on Phase 2b of the Royal Wharf development.

1 of the 4 new ESP adopted substation internally, comprising Schneider RN2C SF6 Ring Main Unit, Schneider 11000V/400V transformer and Schneider 5 Way Transformer Mounted Fuse Cabinet with incoming high voltage 3c 11kV XLPE polymeric cables.

About Mick Beeby

With over 25 years of experience in the UK Electricity Distribution sector, coming from an apprentice electrician, through Electrical Fitter, Project Manager and Senior Authorised Person roles. Familiar with many types of low voltage, medium voltage and high voltage switchgear, transformers and cables. In depth familiarity of Schneider Genie Evo 11kV switchgear, switchgear cable terminations including complete stripping, re-build and testing.

In depth theoretical and practical knowledge of MV-HV testing and commissioning, cable fault location and cable repair, including test equipment application and limitation.

Experience of all aspects of medium voltage distribution substation testing and commissioning; cable sheath testing, cable/switchgear IR testing, over voltage testing (DC/AC/VLF), primary and secondary injection testing, transformer testing, CT mag curves, CT polarity, soil resistivity and earth electrode systems testing.

Unlike the Distribution Network Operator, we can design & install your private High Voltage network downstream of your HV metering point, providing a more complete package of works to save you time & money. pic.twitter.com/7GtXGzSefH

— UKPS (@ukpowersolution) November 29, 2017

Schneider

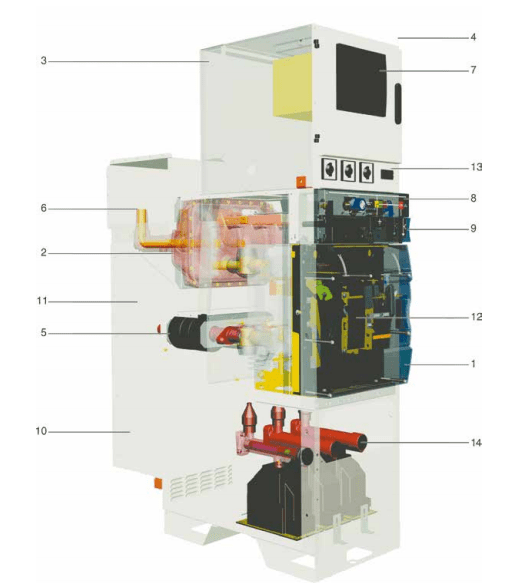

Schneider Genie Evo Air Insulated

MV HV Switchgear 3.3kV 13.8kV

The Schneider GenieEvo concept is an evolution from the extremely successful Genie philosophy which offers increased levels of flexibility and greater choice for the distribution of medium/high voltage power – this is achieved by allowing separate selection of the MV-HV switchgear and protection and control modules. GenieEvo extends the concept of Genie by offering a gas free circuit breaker to the MV-HV product portfolio.

- Schneider GenieEvo comprises

Cast resin encapsulated MV medium voltage system

Demountable vacuum circuit breaker

Controlled air, resin encapsulated series disconnector

Flexible pre-engineered protection and control modules

1. Vacuum circuit breaker 2. Controlled air disconnector 3. Top entry pilot box 4. Internal arc protection 5. CT chamber 6. Cast resin insulated busbar system with optional earth shielding 7. Multi functional protection and control unit 8. Unit fascia with active operating mimic display 9. Front access cable and vacuum test facility 10. Rear entry MV medium voltage cable box 11. Internal arc vented via dedicated cable trunking for operator safety 12. Mechanical operations counter 13. Circuit potential indicator as standard 14. VT chamber

Medium & High Voltage Switchgear

Thorne & Derrick International

T&D distribute the most extensive range of MV & HV Jointing & Terminating, Installation & Cable Pulling Equipment – we service UK and international clients working on underground cables, overhead lines, substations and electrical construction at LV, 11kV, 33kV and EHV transmission and distribution voltages.

- Key Products: MV-HV Cable Joints & Terminations, Cable Cleats, Sealing Cable Ducts, Cable Transits, Underground Cable Protection, Cable Jointing Tools, Feeder Pillars, Cable Ducting, Copper Earthing, Electrical Safety, Cable Glands, Arc Flash Protection & Fusegear.

- Distributors for: 3M, ABB, Alroc, Band-It, Catu, Cembre, Centriforce, CMP, Elastimold, Ellis Patents, Emtelle, Furse, Lucy Zodion, Nexans Euromold, Pfisterer, Polypipe, Prysmian, Roxtec.

Switchgear Cable Terminations

T&D distribute MV-HV Switchgear Cable Terminations to suit 11kV/33kV connections into air, oil and gas insulated switchgear or transformers including heat shrink, cold shrink and separable connectors for both inner cone and outer cone bushings from leading manufacturers including Nexans Euromold, 3M and Pfisterer.

♦ See more: Heat Shrink Cable Terminations 11kV 33kV | Cold Shrink Cable Terminations 11kV 33KV

MV HV – Medium & High Voltage Cable Joints, Terminations & Connectors (11kV 33kV EHV)

More…

T&D’s Power Blog covers: LV MV HV & EHV Transmission & Distribution, Substations, Switchgear, Cable Jointing & Termination, Cable Fault & Repair, Underground Cables.

➡ Visit Power Blog.

Drum Heating & Cable Straightening Jackets For 132kV Extra High Voltage Cable Terminations

November 30th, 2017

- Application: Drum Heating & Cable Heating HV EHV

- Drum Heater Type: Heating Jacket For Silicone Oil Drums

- Contractor: Matthew Taffs (CRS Ltd) – EHV Cable Jointer & Director

- Featured Manufacturer: Prysmian 132kV Click Fit Cable Terminations XLPE

- Featured Product: Thorne & Derrick Drum Heater HF5-D

- Extra High Voltage Cable Type: 132kV Prysmian Single Core XLPE 800sqmm

Terminating 132kV Cables

Cable Oil & Drum Heating

Drum Heaters

Cable heating jackets are initially used to heat the EHV cable to enable relaxing and straightening of the high voltage power cable prior to cable preparation and stripping using cable jointing tools – typically the cable heaters provide a stable temperature of 85 degrees Celsius (185F) for at least 12 hours to the XLPE cable to improve cable manipulation for the HV jointer.

Straightening tubes are then applied to the heated cable and allowed to cool.

The following day cable jointing commences.

The drum heating jacket is applied around the oil drum (silicone oil) and heated to a temperature between 105 – 115 degrees Celsius.

This is done firstly and most importantly to ensure there is no moisture in the oil and secondly to make the oil thinner so it can be pumped into the high voltage cable termination. Once the oil has reached a temperature exceeding 105 degrees Celsius the cable jointer can check with a flash light the condition of the oil.

The heated oil should remain clear with no signs of bubbles, white clouds or foaming.

The oil is then pumped from the drum into the cable terminations insulator to a measurement given on the drawing/ cable jointing instruction. Once the insulator is full to the required measurements, the top is then bolted on and then the cable jointer must press crimp the connector using hexagonal process (HEX) at the correct positions.

T&D supply an extensive range of High Voltage Jointing & Electrical Equipment to enable cable lubrication, cable pulling and installation of 66kV/132kV power cable systems – this includes 132kV surge arresters for electrical protection against overvoltages caused by lightning strike and switching operations.

♦ View complete range of 132kV Terminations, Joints & Sealing Ends

Pictured: T&D drum heater providing consistent and stable electric surface heating to oil drums for EHV cable termination installations.

In order to achieve the required drum heating temperature of 100+ degrees Celsius the heater jacket was used in conjunction with a base drum heater to accelerate the high temperature heating requirement of the oil – you can see the plate of the base drum heater in the photo below.

Cable Repair Services Ltd

CRS are predominately a reactive cable faults and services team specialising in repairing high voltage fluid filled cables.

CRS have a wealth of experience maintaining, repairing, jointing, terminating and fault-finding on all types of HV fluid filled cable systems ranging from 33kV to 400kV.

All CRS operatives have been trained to the highest standards by companies such as BICC, Prysmian and Balfour Beatty and are able to undertake jobs safely and efficiently while remaining cost effective. Their highly skilled Cable Jointing and Oil Technicians have the capability to joint both polymeric (XLPE) and fluid filled cables up to and including 400kV.

Additional cable services include PILC cable jointing (11kV-66kV), HP gas jointing (66kV-132kV), pilot cable jointing, joint bay refurbishment, cable sheath repairs, serving faults, cable fluid leak locating, gauge calibration and circuit fluid pressurisation.

CRS Cable Repair Services Ltd (CRS Ltd) – trained staff have completed course training to comply with UK Power Network (UKPN) types A,B & C confined spaces.

Prysmian | Cable Joints | Terminations | Cleats | Connectors Distributor

- Thorne & Derrick Distributors for: 3M, ABB, Alroc, Band-It, Catu, Cembre, Centriforce, CMP, Elastimold, Ellis Patents, Emtelle, Furse, Lucy Zodion, Nexans Euromold, Pfisterer, Polypipe, Prysmian, Roxtec.

MV HV – Medium & High Voltage Cable Joints, Terminations & Connectors (11kV 33kV)

More…

T&D’s Power Blog covers: LV MV HV & EHV Transmission & Distribution, Cable Duct Sealing, Substations, Switchgear, Cable Jointing & Termination, Cable Fault & Repair.

➡ Visit Power Blog.

Do Insulating Gloves Provide Arc Flash Protection?

November 30th, 2017

Electrical Safety Equipment | Insulating Gloves | Arc Flash Gloves

-

uploaded by Chris Dodds - Thorne & Derrick Sales & Marketing Manager

There are a lot of misconceptions about arc flash clothing and protection levels required including what actually is a flash of light or an arc of fire. Similar to an electric shock but not the same as usually there is not direct contact with electricity.

Arc flash is a serious issue with more than 30,000 incidents that result in 400 fatalities every year. So how can you protect your hands from this deadly killer and do insulating gloves provide arc flash protection? Or are special application arc flash gloves required?

The below Blog from Scanwear delves deeper into the issue.

One question that comes up all the time during electrical safety training is whether or not an electrician’s rubber insulating gloves offer any protection from Arc Flash?

Interestingly enough, even though you probably won’t find a label on the insulating glove that says so, rubber insulating gloves used in conjunction with leather protectors do offer sufficient protection from arc flash burns.

Now we are talking about arc flash protection but don’t forget why you are wearing the gloves in the first place. That needs to be your primary concern when it comes to protecting your hands. Once you’ve got that taken care of you can worry about arc flash.

Is This Legitimate?

The industry standard for electrical safety, NFPA70E, does not offer much information about how to size your gloves for arc flash protection or how to determine the incident energy rating for your gloves but we are led to believe that they have done some testing and feel comfortable saying that the rubber insulating gloves with leather protectors will protect you from an arc flash.

Here is what it says in the standard:

“If rubber insulating gloves with leather protectors are used, additional leather or arc-rated gloves shall not be required. The combination of rubber insulating gloves with leather protectors satisfies the arc flash protection requirement.”

That note applies to an arc flash PPE category of 4 which requires a minimum of 40 cal/cm2 protection. So that gives the user a good level of comfort that the gloves offer great protection from arc flash.

How Can You Prove It?

Up until June 2013, the amount of arc flash protection was determined by the thickness of the leather protectors. That year though a new standard for testing gloves was approved and testing started immediately. Because thickness of the gloves was not part of the criteria for meeting the standard manufacturers are now coming out with thinner leather gloves that still offer the maximum protection against arc flash.

Something you might want to look into with your supplier of arc flash clothing, garments and protection including helmets and gloves.

Also, traditional rubber insulating gloves with leather protectors were tested alongside some of the arc flash gloves which you may now see on the market and it was proven that they offer fantastic protection from arc flash. In case you are curious, the standard for testing gloves for arc flash is ASTM F2675-13.

Just remember, the main reason you are wearing the rubber insulating gloves is to protect against shock hazards. Fortunately, your regular rubber insulating gloves with leather protectors offer an excellent protection from an arc flash hazard and should always be worn, when there is a risk of a shock or an arc flash event.

Further Information ➡

Arc Flash Gloves | 25 40 60 Cal Arc Flash Protection Gloves PPE

Arc Flash Gloves | 50 Cal Arc Flash Protection Gloves PPE

INSULATING GLOVES

Selection Of Correct Gloves

Insulating gloves should be selected according to their class which corresponds to the voltage level used – additionally the gloves are classified into categories according to environmental resistance properties detailed below.

- Class

- Voltage

- Product colour

- Size – between 7-12 for either male of female use

- Classifications and standards

When selecting the correct insulating gloves all of the above factors are vital to consider in order to achieve the adequate level of protection required.

In addition, some gloves will also require an under-glove for comfort or a leather over-glove to maintain product longevity.

Inspection and storage of insulating gloves is also a vital factor to consider as all gloves must be visibly inspected after each inflation and before each use.

This is to make sure there are no tears or abrasion to the gloves prior to use, maintaining their dielectric properties.

Insulating rubber gloves are also categorised by environmental resistance properties for protection against acid, oil, o-zone and very low temperatures.

- A – Acid

- H – Oil

- Z – O-Zone

- R – Acid, Oil and O-Zone

- C – Very Low Temperatures

INSULATING GLOVES – CLASS & CATEGORY

The following gloves manufactured by CATU Electrical and T&D would normally recommend for mechanical protection they be used with silicon leather glove covers or over-gloves but in light of the above this might all change.

| Insulating Gloves Class | CATU Electrical Code | Category | Thickness | Length | Colour | AC | kV | DC |

| Class 00 | CATU CG-05 | AZC | 0.5mm | 360mm | Beige | ≤ 500V | 0.5kV | 750V |

| Class 0 | CATU CG-10 | AZC | 1mm | 360mm | Beige | ≤ 1000V | 1kV | 1500V |

| Class 1 | CATU CG-1 | RC | 1.5mm | 360mm | Bi-Colour | ≤ 7500V | 7.5kV | 11,250V |

| Class 2 | CATU CG-2 | RC | 2.3mm | 360mm | Bi-Colour | ≤ 17000V | 17.5kV | 25,500V |

| Class 3 | CATU CG-3 | RC | 2.9mm | 360mm | Bi-Colour | ≤ 26500V | 26.5kV | 39,750V |

| Class 4 | CATU CG-4 | RC | 3.6mm | 410mm | Bi-Colour | ≤ 36000V | 36kV | 54,000V |

Arc Flash Learning & Resources

Thorne and Derrick are proud to be distributors of ProGARM arc flash coveralls and protection.

We can help – should you require arc flash calculators or advice on the type of clothing and protection available please do not hesitate to contact us.

We supply Product Categories: Duct Seals | Cable Cleats | Cable Glands | Electrical Safety | Arc Flash Protection | Cable Jointing Tools | Cable Pulling | Earthing | Feeder Pillars | Cable Joints LV | Joints & Terminations MV HV