Blog

May 2022 VOLTS!

May 18th, 2022

THORNE & DERRICK LV HV Jointing, Earthing, Substation & Electrical Eqpt

Welcome to our industry bulletin – VOLTS.

So what is VOLTS?

VOLTS is our monthly round-up of industry news, projects, videos, technical tips, training information, promotions, webinars and career opportunities from Thorne & Derrick. Take a moment to Follow Us on LinkedIn to receive future VOLTS.

pROJECTS & NEWS

We Can Help

Thorne & Derrick are the Nexans Power Accessories stockist and UK Approved Distributor.

We offer the following 33kV ranges from stock at competitive prices – try us, we can help.

* JTS 33kV Joints – ex stock

* MONO 33kV Terminations – ex stock

* EUROMOLD 33kV Separable Connectors | T Boots – ex stock

To satisfy increasing market demand and our expanding customer base we are bolstering and extending all Nexans stocks. Should you require excellent customer service, supported by stock and underpinned by competitive prices, we can help.

Whether you are required to Connect 33kV cables using Separable Connectors into gas insulated equipment with inner cone (Size 3) or outer cone (Interface C) bushings or use conventional heat shrink technology to Terminate onto AIS, we can help.

If you require 33kV Joints or Jointer Competency Training, we can help.

Pictured | Picked & Packed & Shipping Out Today | Customer order despatched today to a UK wind farm project from our Bristol distribution centre which holds in excess of £1m stock of LV HV Jointing, Tooling, Earthing, Substation & Electrical Eqpt up to 66kV.

Read Press Release | Record Business Growth for T&D and Nexans Power Accessories

Sealing 132kV Cables

Thorne & Derrick distribute extensive cable sealing solutions for the effective flood defence and fire protection of medium and high voltage substations and LV power distribution ducting systems – we work closely with the UK DNO’s and their contractors to supply Approved Equipment from leading manufacturers. Here is a recent Case Application:

- Client: SSE (UK DNO)

- Product Category: Duct Seals

- Application: Sealing Extra High Voltage Cables & Ducts Against Water, Gas & Fire

- Voltage: High Voltage 132kV

- Sector: Renewable Energy (Wind)

- Product Installed: Filoseal+, Filoseal+HD and Filoseal+ HD Fire Cable Duct Sealing System

- Project Information: All 3 types of Filoseal cable duct seal systems were required; original Filoseal+ with foam backing, newer Filoseal+HD for heavier POWER cables and the newest seal type Filoseal+HD FIRE which adds BS EN1366 Part 3 with up to 4 hours of fire protection. All cable duct seals were installed according to instructions whilst special guidance and tips were given on site by the manufacturer.

Sealing Cables, Switch Hall & Grid Transformer Bases On 132kV Wind Farm

3M Electrical Stock Investment from Socket to Substation

T&D have distributed 3M Electrical Products & Cable Accessories since 1985 and this month we have committed to an additional £100K stock holding boost to support additional customer demand, project awards and mitigate supply chain bottle-necks in the marketplace.

From the humble roll of Scotch Tape to the lofty QTEN 66kV Termination, we can help.

LV MV HV Cable Abandonment Joints Terminations from 600v to 66kV Ex Stock.

Thorne & Derrick stock the most extensive range of LV Cable Joints from the Scotchcast Resin range of 3M Electrical for industrial and hazardous area cables including power, control and instrumentation.

Pictured: The QTEN 96-EP range of Cold Shrink Terminations stocked by Thorne & Derrick are suitable for the test, termination and connection of 66kV/72.5kV power networks

QTEN 66kV Features of the Termination

- The versatile design of the silicone Cold Shrink Termination body allows installation on a wide range of cable sizes and types and a fast and easy installation at temperatures ranging from -20°C to + 50°C

- No heat, flame, or special tools are needed during cable splice body installation

- Accommodates crimp or mechanical cable lugs up to 110mm in diameter

- Wide application range covering several cable cross sectional areas from 120sqmm –1500sqmm

- Solderless earth connection to copper screen wires or lead sheath

- Silicone rubber Cold Shrink outer rain sheds and sealing PST’s provide physical protection and moisture sealing of the completed cable termination

- Silicone outer rain sheds of the termination makes it ideal for zones with maximum environmental contamination, industrial or coastal

- Creepage path connection for additional protection in areas of high pollution

And The Winner Is……

Congratulations to Declan O Hara, your prize is in the post. Thanks PFISTERER for donating the copy of the Centenary Book.

PFISTERER meets future challenges with the knowledge that comes from one hundred years of experience. This expertise has developed continuously with advances in technology. Numerous innovations and patents continuously drive our growth with further investment in R&D planned for 2022 and beyond. Read more about our established relationship: Thorne & Derrick | Product Training With PFISTERER

Congratulations Harry

Just 10-years after joining Ellis Patents straight out of school as their very first trainee design engineer, Ellis the world-leading UK based manufacturer of cable cleats have promoted Chartered Engineer, Harry Taylor to the role of Technical Manager.

Talking about Harry’s promotion, Managing Director of Ellis Patents, Danny Macfarlane said: “We put a lot of focus on developing careers for young, local people and to see what Harry has already achieved is a source of great pride for us all.”

“He’s been a key member of the product development team since graduating with his first degree; and has been behind a variety of recent cable clamps innovations that have all had a big market impact – including an update to our 2 Hole Cable Clamp range that has seen the new product series sell three quarter of a million units since its re-launch.”

Tools | HV & FO

Pictured | A consolidated customer order, comprising over 100 Tools & Consumables prepared for despatch from Thorne & Derrick to a leading High Voltage Power & Jointing Contractor in the renewable energy sector – we can assist with an extensive range of Cable Accessories & Tooling to enable the installation, termination and test of both FO and HV cables up to 66kV. Find more info here about HV & FO Tools for Wind Farm Projects.

FO Tooling | Fibre Optic Strippers, Kevlar Cutting Tools, FO Cable Sheath Jacket Strippers, Spirit Level, Tweezers, Bent Nose Forceps, Angled Long Nose Pliers, Flare Nut Spanner, Jointers Knives, Flat Terminal Screwdrivers, Junior Hacksaw, Power Cutters, Worklights. Brands including Miller, Bahco & Knipex.

HV Tooling | Sheath Strippers, Semicon Screen Strippers, Insulation Removal Tools, Ratchet Spanners, Soldering Iron, Heat Shrink Gas Torch, Diameter Tape, Vernier Calipers, Nylon Hammer, Jointers Knife, Wire Brush. Brands including Alroc, Boddingtons & Sievert.

Tools for the Stripping & Preparation of FO & HV Cables

Staff Training

Thorne & Derrick are delighted to work with a supportive supply chain who provide training for our staff to aid their continued professional development.

Special thanks to Matt Page from Lucy Zodion for visiting our offices this month to provide training to our Sales Engineer Sarah Henderson on their EV & Pre-wired range of Feeder Pillars. Sarah has recently moved into her sales role and is progressing rapidly – she has become our Feeder Pillar specialist and is taking orders daily.

Sarah with Matt from Lucy Zodion

Industry event

Earthing Conference

Thorne & Derrick are Official Media Sponsors & Exhibitors at IDC Technologies, Inc. Earthing Conference UK which took place at the Park Regis Birmingham this month.

The aim of this conference was to demystify the subject of earthing and present the subject in a clear, straightforward manner. Earthing as a subject has been under-represented over the years and this event will attempt to remedy the gaps in technical knowledge and improve practices in the industry. The UK & Europe need a unified practical approach to earthing which can be commonly understood and widely applied.

Jonathan Hewitt (sales engineer) said: “It was great to be back to the face to face at the conference. Lots of people attended and there were some fantastic speakers.”

Special thanks to our partner AN Wallis for attending alongside Thorne & Derrick.

Sales Engineer Jonathan Hewitt with Jason Leatherland from A. N. Wallis

Top of The Posts

STRUTSLAYR

Clean, Consistent, Cuts – A Cutting Edge Innovation!

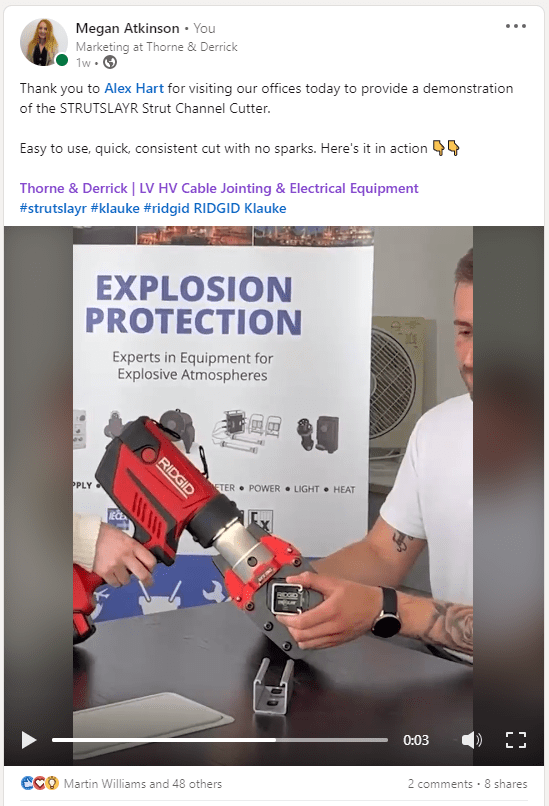

Alex Hart from Klauke visited our offices to provide an in-person demo to the team of the RIDGID® STRUTSLAYR™ Strut Channel Cutter. A short clip of the demonstration was shared on LinkedIn, which received fantastic engagement and several shares.

The StrutSlayr has been flying off the shelves since the start of the year and is said to be a ‘game changer’ for cutting strut in the industry. Time saving, burr-free and efficient ➡ Read more about the StrutSlayer.

Technical Tips

Cut & Crimp Cables with Total Safety

Insulated Cable Crimping & Cable Cutting Tools | ORANGE by Klauke

Klauke have launched the Klauke Orange range of fully insulated cable crimping & cable cutting tools that have set the standard within the global utility industry – working with underground cables and overhead lines presents a series of challenges: proximity to potentially live parts, limited space and time pressures.

The world‘s first battery hydraulic crimping and cutting tools with Tri-Insulation Barrier technology that provides users with 1000V protection against electrical shocks.

E-LEARNING

Here is a list of FREE Monthly Webinars created by Ian Griffiths from greymatters providing technically secure answers to your HV Earthing or Lightning Protection Design questions. The library of Webinars can be accessed from the link below. You can earn CPD units and receive a certificate for participating.

- Why Is The DNO Refusing To Energise – ‘Hot-Site’ Problems?

- Why Am I Getting A Hot Site?

- The Top 3 Most Useful Webinar Takeaways From 2021

- Are You Struggling To FoP Test An Earth In A City Environment? Try This

- Stop Struggling With Rolling Sphere Designs! Watch This And You Decide – XGSLabs 10

- Surge Protection – How To Find Out If Your SPD Is Working

- Earth Testing For Dummies – Common Mistakes To Avoid

- Earthing Design Series Part 2 – What Is A Touch/Step Voltage Hazard?

- Bringing Your Earthing Design To Life

- Earthing Design Series – Part 1

- Lightning Protection Myths Busted And Solutions For The DSEAR/COMAH Sites

- An Introduction To EMF And Why We Need To Understand It.

- Model Lightning Strikes Using XGS

- Soil Resistivity Part 3 – How The Seasonal Changes Affect The Electrode Performance/Behaviour

- Soil Resistivity Part 2 – How To Process The Data

- Using Earthing Software – It Should Be Childs Play.

- Hot Sites Or Transferred Potentials

- Split Or Reduction Factors

- Earthing In Difficult Geologies

- Soil Resistivity Part 1 – Testing, Avoid The Common Mistakes

- ➡ Go to all FREE Monthly Webinars here

Featured Contractor

Exemplary workmanship and Competency is demonstrated here by Heighway Ltd, a UK leading Power & Cabling Contractor, who recently completed a Civils and Electrical Package to enable grid connection of a 5MW solar farm. As well as 33kV Jointing & Connection services, Heighway Ltd provided the following services:

- HV Cable Diversion Works

- HV Cable Installation to New Customer Substation

- HV Park Feeder & VT Connections

- HV Current Transformer

- Installation of COP3 Metering Panel

All excavation works in and around DNO compound to include installation of new concrete bases was completed by Heighway Ltd.

Pictured: Nexans Euromold Type C Connectors Terminating 33kV Cables

Heighway Ltd | Supplying Electrical Services, Power Connection, Jointing & Termination Solutions to the Energy, Rail & Construction Sectors up to 33kV

33kV SAP’s | 33kV Jointers | 400v Live – Testing & Commissioning Engineers | Protection Engineers | Design Engineers | HV/LV Fitting Teams | Civils/Digging Teams | Skilled PTS Operatives (Rail) – Specialist Lifting Services

Jobs

Thorne & Derrick are privileged to partner with EDS HV Group and support career opportunities within the Wind Industry via their Talent Pool.

Are you an existing Senior Authorised Person (SAP) within the wind industry?

Are you an existing HV High Voltage SAP working in a similar industry looking to make a career move into renewables ?

Thorne & Derrick distribute the most extensive range of Low & High Voltage Cable Installation & Electrical Distribution Equipment to the Power Transmission & Distribution industry in the onshore and offshore wind, solar, rail, oil/gas, data centre, battery storage and utility sectors – this includes Joints, Terminations & Connectors to enable the installation of low, medium and high voltage power cables into underground trench or duct.

Key Product Categories: Connectors, Joints & Terminations MV HV | Cable Preparation & Jointing Tools | Duct Seals | Cable Transits | Cable Cleats | Cable Glands | Electrical Safety | Arc Flash Clothing & Protection | Cable Pulling | Earthing & Lightning Protection | Feeder Pillars

Main UK Stockists for: 3M Electrical, PFISTERER Connex, Nexans Power Cable Accessories (Euromold), Alroc, Ellis Patents, ABB, Roxtec, Cembre & CATU Electrical.

Volts! Archive

WITHDRAWN IEC 61914:2015 | Cable Cleats For Electrical Installations

May 11th, 2022

This article is intended to highlight IEC standard and specification updates in relation to short-circuit testing and purchasing of cable cleats.

The previous 2nd Edition of IEC 61914:2015 has now been withdrawn and replaced with IEC 61914:2021 – the 3rd Edition of the standard. This edition constitutes a technical revision of which we will detail below.

All cable cleats distributed by Thorne & Derrick are currently undergoing testing procedures to conform to the latest IEC 61914:2021 standards.

Certification will be in place before the deadline.

So What’s Changed?

IEC 61914:2015 Is Withdrawn

The new standard is available as IEC 61914:2021 CMV which contains the International Standard and its commented version, providing a quick and easy way to compare all of the changes between IEC 61914:2021 edition 3.0 and the previous IEC 61914:2015 edition 2.0.

View the document here.

IEC 61914:2021 specifies requirements and tests for cable cleats and intermediate restraints used for securing cable in electrical installations. Cable cleats provide resistance to electromechanical forces where declared. This document includes cable cleats that rely on a mounting surface specified by the manufacturer for axial and/or lateral retention of cables.

This third edition cancels and replaces the second edition published in 2015. This edition constitutes a technical revision. This edition includes the following significant technical changes with respect to the previous edition:

a) Requirements for mandrels used in testing rationalised and detailed in the general test requirements (Clause 5);

b) Definition of liner added and test requirements where liners and other optional parts are used;

c) Definitions for LV, MV and HV cables added and test requirements where MV & HV cable are used ;

d) New corrosion resistance classes for plated products added;

e) New requirements and test for durability and legibility of markings added;

f) New test requirements for axial load testing of cleats for more than one cable added;

g) Lateral load test requirements for intermediate restraints added

“Cable cleats are critical electrical safety products – in the event of a short circuit they can protect your people, not just plant. During a recent tender bid we were alerted to non-conformance of a competitor product during the technical qualification procedure for a major UK infrastructure project. Simply, their product was tested to the cancelled 2009, not superseding 2015 version. Thorne & Derrick distribute LV HV Cable Accessories & Electrical Equipment from market-leading manufacturers tested to the current range of international standards,” comments Chris Dodds (Sales Manager at Thorne & Derrick).

“The closest example I can think of for this is car seat belts. If you were on the market to purchase a car and were advised that the seatbelts on the car you had chosen were not compliant to the latest industry standards, you may decide against purchasing that car due to safety concerns. Moreover the car would not be safe for sale in UK or European markets and would not bear the required UK CA or CE mark. Cable cleats for cables can be viewed in a similar way to seatbelts in cars as they both perform safety functions, adds Noman Shabir (National Sales Manager at Ellis Patents).

All cable cleats stocked and supplied by Thorne & Derrick are short-circuit tested to the current updated version IEC61914:2015, and are undergoing testing to achieve IEC61914:2021.

Specialist Distributors of High Voltage Jointing & Electrical Safety Equipment

Thorne & Derrick International are Specialist Suppliers of products to provide safe and reliable LV HV Cable Termination, Jointing, Installation & Power Systems up to 66kV.

Key Product Categories: Connectors, Joints & Terminations MV HV | Cable Preparation & Jointing Tools | Duct Seals | Cable Transits | Cable Cleats | Cable Glands | Electrical Safety | Arc Flash Clothing & Protection | Cable Pulling | Earthing & Lightning Protection | Feeder Pillars

Thorne & Derrick distribute the most extensive range of MV HV Medium & High Voltage Cable Joints, Terminations & Connectors from manufacturers including 3M, Prysmian, Nexans Euromold, Elastimold, Pfisterer CONNEX & SEANEX.

Cable Cleats | Importance, How To Specify & International Standards

May 9th, 2022What Are Cable Cleats?

“A cable cleat is a device designed to secure electrical cables when installed at intervals along the length of the cables” – IEC 61914 Cable Cleats for Electrical Installations

“Cable cleats should:

Prevent excessive cable movement due to fault-current magnetic forces

Be rated for specific cable size and available current.”

The fifth edition of API Recommended Practice 14F (Design, Installation and Maintenance of Electrical Systems for Fixed and Floating Offshore Petroleum Facilities).

“Single core electric cables are to be firmly fixed, using supports of strength adequate to withstand forces corresponding to the values of the peak prospective short-circuit current.” – Lloyds Register. Rules and Regulations for the Classification of Ships, Part 6, Control, Electrical, Refrigeration and Fire.

“Cables are to be installed and supported in ways to avoid chafing and undue stress in the cable.” – ABS Steel Vessel Rules 4-8-4/21.9 Cable Support, 4-8-4/21.9.1 General and 4-8-4/21.9.3 Clips, Cable Saddles, Straps

“In order to guard against the effects of electro dynamic forces developing on the occurrence of a short-circuit or earth fault, single core cables shall be firmly fixed, using supports of strength adequate to withstand the dynamic forces corresponding to the prospective fault current at that point of the installation.” DNV Rules for Ships / High Speed Light Craft and Naval Surface Craft, Pt. 4 Ch. 8 Sec.10 – page 68, C50

ALWAYS REMEMBER: Any power cable system designer or installer has an obligation to consider the method of securing cables in order to restrain their movement whether caused by an electrical fault or any other reason – a job that can only be safely and securely done with correctly specified cable cleats.

HOW TO SPECIFY A CABLE CLEAT?

- Calculate the system peak fault current

- Identify the specification of the cable to be used including the nominal cable diameter and the manufacturing tolerance

- Identify the support structure type e.g. Ladder ( including rung spacing), basket, individual steel structure etc

- Consider support structure material type e.g. stainless steel, galvanised steel etc

- Consider the environmental conditions

- Consult with Ellis Patents who will provide you with the most cost effective solution for your needs

WHAT IS THE INTERNATIONAL STANDARD FOR CABLE CLEATS?

IEC 61914 Cable cleats for electrical installations outlines a series of tests that can be used to assess the performance of a cable cleat’s design.

Although the standard does not define pass or fail levels, it allows manufacturers to define the performance characteristics of their products, and specifiers to compare products from different manufacturers.

The aspects of construction and performance covered by the standard include:

- Material type – i.e. metallic, non-metallic or composite

- Minimum and maximum declared service temperatures

- Resistance to impact at the minimum declared operating temperature

- The ability of the cable cleat to withstand axial slippage forces

- Resistance to electro-mechanical forces – i.e. the ability of the cable cleat to withstand the forces between the cables in the event of a short-circuit

- Resistance to UV and corrosion

- Flame propagation

TRANSPORT FOR LONDON PROJECT

Working with Ellis Patents we completed the specification and have now moved into manufacturing for our largest contract to date to supply TfL (London Underground) approved cable hangers across several depot modernisation projects.

Thorne & Derrick in consultation with the Asset Manager at Transport for London and their appointed Telecoms & Power contractor secured formal Authorisation & Approval for the Pegasus range of non-metallic cable support hangers. The product will provide safe cable management of the cable route within the Bridges & Structures category – over 1000 hangers with proven lifecycle performance and utilising the standard J-type design for support of multiple cable runs including single, 3-way and 5-way configurations are now scheduled for delivery.

Thorne & Derrick are Approved Vendors to both Network Rail and Transport for London

THORNE & DERRICK

Thorne & Derrick are national distributors of LV, MV & HV Cable Installation, Jointing, Substation & Electrical Equipment – servicing businesses involved in cabling, jointing, substation, earthing, overhead line and electrical construction at LV, 11kV, 33kV, 66kV and EHV. Supplying a complete range of power cable accessories to support the installation and maintenance of low/medium and high voltage power systems:

- Slip-on Cable Terminations

- Cold-shrink Cable Terminations

- Heat-shrink Cable Terminations

- Cable Joints – Heat & Cold-shrink

- Separable Connectors (Euromold)

- Surge Arresters & Switchgear/Transformer Bushings

Key Product Categories: Duct Seals | Cable Cleats | Cable Glands | Electrical Safety | Arc Flash Protection | Cable Jointing Tools | Cable Pulling | Earthing | Feeder Pillars | Cable Joints LV | Joints & Terminations MV

Stokbord® Cable Covers | A Faster & Safer Solution For Cable Damage Prevention

May 9th, 2022

Stokbord® Cable Covers continues to be an industry leading innovation

Stokbord® Cable Covers

Cable Protection

Sustainability has been at the heart of Centriforce’s operation since its inception. One of the UK’s pioneers for recycling over 40 years ago, Centriforce continues to pave the way in sustainable material innovation for a range of applications – from damage prevention for underground utilities with Stokbord® Cover and Stokbord® Drum, to agricultural protection and maintenance.

➡ Thorne & Derrick provide competitive prices and fast delivery from stock for the complete range of Centriforce cable protection.

A UK manufacturer utilising UK waste, Centriforce reprocesses over 20,000 tonnes of discarded plastic material each year, such as plastic bottles, carrier bags and packaging film.

Saving plastic from landfill and extending its useful life, Centriforce supports various key industries by manufacturing over 9 million metres per annum of high-quality and 100% recyclable products – most notably Stokbord®. As such Centriforce is one of the largest independent recyclers of plastic waste into end use products.

Stokbord Cable Protection

Centriforce

Leading by example, Centriforce developed Stokbord® Cover as a faster and safer solution for cable damage prevention. Replacing traditional clayware and concrete with recycled polyethylene featuring brightly coloured warnings, Stokbord® Cover continues to be an industry leading innovation – globally recognised and DNO specified with compliancy including National Grid TS 3.05.07 and ENATS 12-23 Class 1 & 2 specifications.

Affirming Centriforce’s policy for continuous improvement, the company has developed Stokbord® Drum. Launched to acclaim in 2019, Stokbord® Drum supplies the internationally recognised Stokbord Cover on a single industrial reel.

Removing the need for workers in the trench and supporting installation efficiency, Stokbord® Drum is an incredible success in sustainable innovation. Stokbord® remains fully recyclable after use in application, extending the whole life of plastics and reducing the contribution to production waste.

Centriforce’s unremitting drive for innovation directs their entire operation and highlights their dedication to promoting sustainable manufacturing – supporting global efforts to secure our environmental future. Centriforce is therefore uniquely placed to help customers and suppliers improve recyclability and reusability of their products, and contribute to a sustainable and circular future for plastic.

Press Release | Thorne & Derrick Appointed Approved Stockist for UK Leading Cable Pulling Equipment Manufacturer

The below video shows Stokbord® Cable Covers from Centriforce and distributed by Thorne & Derrick that provide heavy duty, high impact, underground cable protection for fibre optic, low voltage, high voltage (11kV, 22kV, 33kV, 66kV) and extra high voltage (132kV-400kV) power cable networks.

Centriforce together with distributor UK Thorne & Derrick Tapetile and Stokbord underground cable protection tiles and covers are the market leading, heavy duty utility protection system for protecting underground cable and pipes – this includes low voltage, medium voltage and high voltage power networks working at 11kV and 33kV.

Stokbord Drum Cable Protection for Underground Utility Cables

FURTHER READING

- Stokbord Drum | Protection of High Voltage Electricity Cables

- Stokbord Drum | Cable Protection for Underground Utility Cables

- UKPN Cable Protection Tapes & Covers (LV MV HV)

- ENA-TS 12-23 : Cable Tiles & Cable Covers For Use With LV 11kV 33kV & HV Cables

- Stokbord Drum | Cable Protection for Underground Utility Cables

THORNE & DERRICK are national distributors of LV, MV & HV Cable Installation, Jointing, Duct Sealing, Substation & Electrical Equipment – we service UK and global businesses involved in cable installations, cable jointing, substation earthing, overhead line and electrical construction at LV, 11kV, 33kV and EHV.

Since 1985, T&D have established an international reputation based on SERVICE | INTEGRITY | TRUST.

Contact us for 3M Electrical, ABB, Alroc, AN Wallis, CATU Electrical, Cembre, Centriforce, CMP, CSD, Elastimold, Ellis Patents, Emtelle, Euromold, Filoform , Furse, Lucy Electric & Zodion, Nexans, Pfisterer, Polypipe, Prysmian, Roxtec, Sicame, WT Henley.

Stokbord® Drum Cable Protection Installation For Dogger Bank Wind Farm (A & B)

May 9th, 2022

Stokbord® Drum Cable Protection

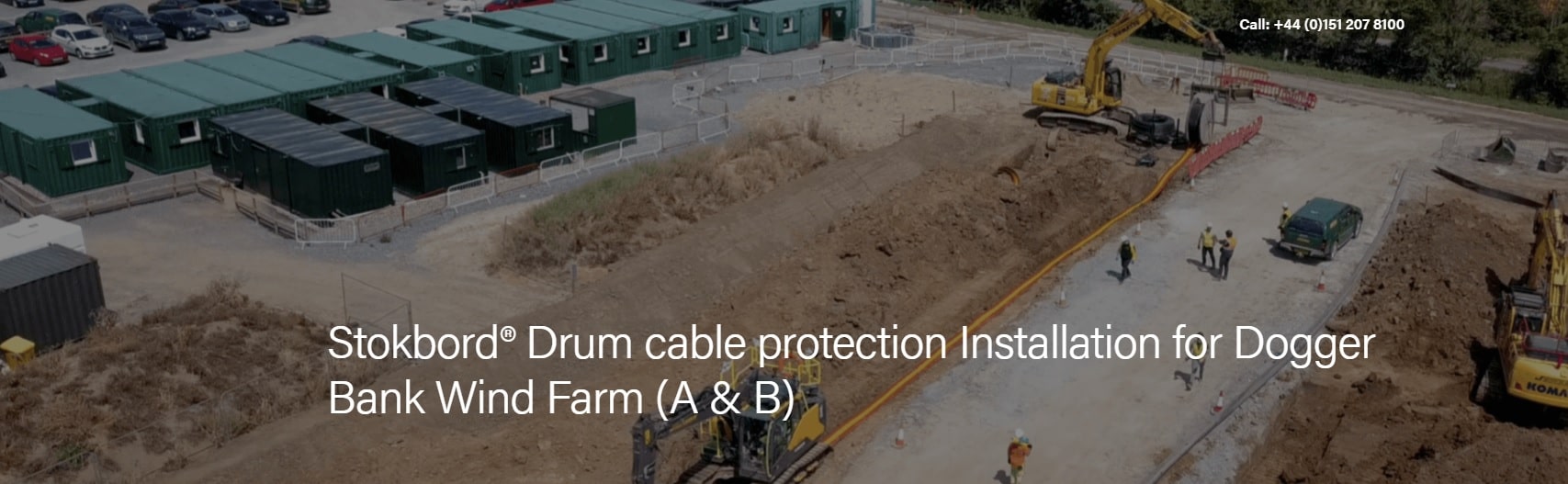

Stokbord® Drum has shown its strength once again on one of the world’s largest renewable energy projects – Dogger Bank Wind Farm. Funded by SSE Renewables, Equinor and ENI, Dogger Bank Wind Farm will be the largest wind farm in the world, and once complete it will be capable of powering over 6 million homes in Britain.

As always, great infrastructure needs great protection. Centriforce are proud to share that Stokbord® Drum has been installed as part of the cable protection system for Dogger Bank Wind Farm (A & B).

Stokbord® Drum delivers heavy-duty utility protection in a single material strip, allowing operatives to install cable protection directly into the trench without needing to set foot into it. Centriforce wind their protection material directly onto an industrial reel which allows users to unroll the material into application, providing significant health and safety benefits alongside major time and cost savings.

Stokbord® Drum has been developed to provide a mechanical installation option decreasing the need for any manual work

➡ Centriforce, working through their distributor network including Thorne & Derrick stock and supply Stokbord cable covers and Tapetile cable warning tapes that offer clear visual warning and excellent cable impact protection for 11kV-33kV high voltage cables including EHV circuits operating at 66kV, 132kV up to 400kV.

Cable Protection Installation

These specifications make Stokbord® Drum the perfect partner for large scale projects as heavy-duty cable protection can be installed in a matter of minutes without the need for individual peg connection as required by traditional protection tiles.

Centriforce met with Jones Bros Civil Engineering on the East Riding Cable Route for Dogger Bank Wind Farm (A & B) to see how Stokbord® Drum supported their team on this project.

Commenting on the speed of installation, James Lockwood – Project Manager for Jones Bros Civil Engineering says “It is estimated we can install 250 metres of Stokbord® Drum within 3 minutes, using 2 men. In comparison, it could take up to 90 minutes using 4 operatives and traditional plastic covers.”

On this project, Stokbord® Drum has allowed operatives to install cable protection up to 30x faster than traditional methods. This is an incredible advantage for contractors. With fewer operatives required to work on a single 250m stretch of cable, Stokbord® Drum saves time and costs by allowing more operatives to cover greater distances in a shorter space of time.

Key Benefits of Stokbord® Drum:

- Ease and speed of installation – up to 30x faster to install than traditional plastic covers

- Significant reduction in manual handling costs

- Supports health & safety on-site

- Removes the need for workers to set foot in the trench

- Reduced risk of injury and accidents in trenches

Centriforce’s CEO Simon Carroll comments “We are very proud to support Dogger Bank Wind Farm with one of our greatest innovations, Stokbord® Drum. Centriforce developed Stokbord® Drum through our policy for continuous improvement, working directly with our trusted customers and partners to overcome the challenges frequently faced when installing heavy duty cable protection.

Stokbord® Drum delivers an easy-to-install solution that greatly increases application speeds while reducing the risk of injury and accidents occurring on-site. This product capability is perfectly matched to large scale projects such as Dogger Bank Wind Farm – enabling significant time and cost savings in every kilometre.”

Centriforce Stokbord® Drum on the way to site

Stokbord® Drum MV HV Cable Protection for Underground Utility Cables

Stokbord® Drum Cable Protection Installation For Dogger Bank Wind Farm (A & B)

As well as Dogger Bank, Stokbord Drum has been installed on major infrastructure projects including Triton Knoll, Hornsea 2, Seagreen and Viking Link

CABLE PULLING & LAYING EQUIPMENT LV HV

T&D supply Utilities & Approved Contractors with cable pulling products including cable rollers, cable socks and cable jacks to enable the installation of low voltage and high voltage cables intro trench or duct: this includes single core, 3 core and Triplex 11kV/33kV power cables and LV waveform, mains and service cables.