Blog

Facilitating Sensor Installation In Power Networks By Nexans MV Power Cable Accessories

October 22nd, 2019

The following Press Report has been developed by Nexans, to introduce the new Nexans Euromold Smart Adapter for Sensor Installation

-

Kind Permission: Volker Dobeck -

Marketing Communication Manager at Nexans Power Accessories Germany

Facilitating sensor installation

in power networks

The network distribution system is facing a rapid complexification on the once slow-paced LV grid.

To meet these new requirements, the distribution system operators will need to implement an accurate mesh of measurement of grid parameters as close as possible to the feeding points, enabling a real-time knowledge of network load and status.

Nexans believes, there is a way of meeting the need of enabling sensor installation closest to the feeding while keeping a simple interoperable approach irrelevant of switchgear, spacing and simplifying retrofitting.

As distribution networks move toward smart, the role of MV HV cable accessories suppliers, including separable connectors, becomes more and more crucial in ensuring a convenient/big-scale deployment of the smart grid.

IT’S EASY TO BE SMART WITH AN INTELLIGENT ADAPTER

The network distribution system is facing a rapid complexification pushed by the multiplication of connection of distributed production systems fueled by ever stronger national and international environmental objectives, causing additional and variable load on the once slow-paced LV Grid.

30/08/2019 – Facilitating Sensor Installation In Power Networks

These multiple connection points, be it delocalized generators such as photovoltaic clusters or punctual high-power rating consumers such as EV charging stations, have a local and adverse effect on grid stability, which renders a static load-managed grid design at best very costly, at worst very unreliable. Local authorities are not oblivious to the challenge that this new configuration will mean to the end consumer, as the requirements on quality of service and power feed-in control, as set out in the revised connection code of practice VDE-AR-N 4105. To meet these new requirements, the distribution system operators (DSO) will need to implement an accurate mesh of measurement of grid parameters as close as possible to the feeding points, enabling a real-time knowledge of network load and status.

Thankfully the recent years have seen a steady development of medium voltage low power sensors, which can be easily integrated into the network to supplement the traditional measurement transformers fixed in the substations. But is it really that easy?

A Headache in Perspective

Well, the answer is mitigated and can cause a lot of grey hairs to networks planners.

Indeed, the auxiliary plug-in voltage and current sensors offer a versatile solution to make almost any existing or new network smarter. But on the other hand, the grey areas in normalization have generated a wealth of solutions that are not always interoperable and can be troublesome to select.

Each link of the chain is well defined with regards to its own respective function – passive sensors have to comply to the instrument transformer standards IEC 61869, and power accessories have to comply to the HD 629 standard – but no standardization has been set forth to ensure that sensors and power accessories fit together. And so, planning of installation or retrofitting of equipment is very burdensome as each time every single parameter has to be fully checked in terms of:

- Type of Switchgear:

- AIS and GIS switchgears require different type of accessories, smart connector or termination, and thus different model of sensors

- Sensor Interface:

- Each accessory manufacturer can design its own interface for the piggyback connection, and thus a different model of sensorsSpace requirements:

- Each switchgear has its own design of connecting bay, thus not any type of sensor/connector assembly will fit

- Retrofitability:

- Adding sensors to existing installation will require different installation conditions which have to be verified beforehand

All these pitfalls combined are the sure promise for a lasting headache and “open-heart surgery” on each substation as can be guessed.

A welcome relief for sensor installation

So, is there no other solution than Aspirin?

Nexans believes there is a way of meeting the need of enabling sensor installation closest to the feeding while keeping a simple interoperable approach irrelevant of switchgear, spacing and simplifying retrofitting.

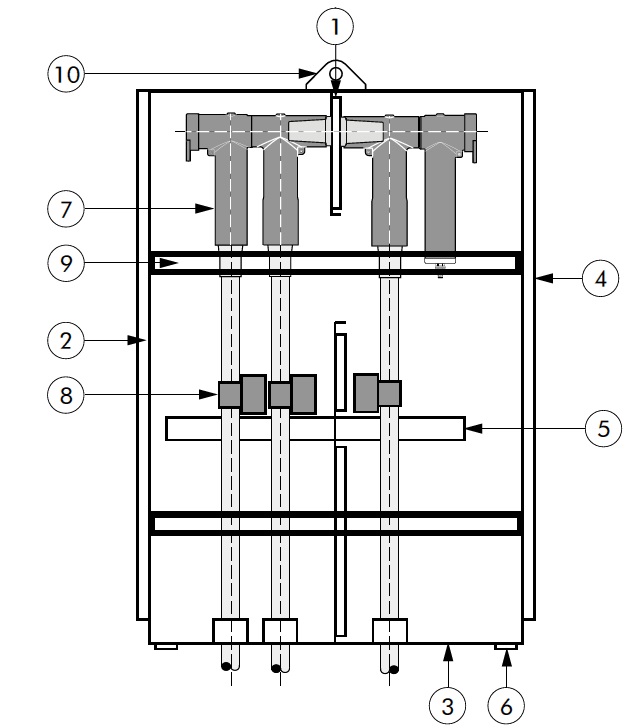

This is achieved by moving the low power transformer measuring point outside of the switchgear and onto the transformer bushing by using a Smart Adapter pre-fitted with the required sensors (fig. 1).

Fig. 1: Smart Adapter KAA4/8 by Nexans EUROMOLD®

In this configuration, most of the complexity is gone (fig. 2).

Fig. 2: Connector arrangement on transformer bushing with cable outlet

- One for all

- On top of the transformer spacing is less of a worry, and the bushing interface is well defined.

- The type of accessory or switchgear is no longer relevant.

- There are no reworks needed for retrofitting, the adapted simple comes plug & play in between the existing accessory and bushing.

- All for one

- Any brand of sensor can be pre-fitted inside the adapter in factory.

- The easy access to the interface allows for easy cabling and flexibility on site during installation.

Future Proof

Who knows what the future holds?

Although today the urgent needs call for network automation and power flow control, having an easy accessible and maintainable sensor array in the grid will enable for the digital revolution of the distribution nodes to come, with big data preventive maintenance applications, intelligent load management and other advanced network healing functions.

About Nexans

Nexans brings energy to life through an extensive range of advanced cabling systems, solutions and innovative services. For over 120 years, Nexans has been providing customers with cutting-edge cabling infrastructure for power and data transmission.

Today, beyond cables, the Group advises customers and designs solutions and services that maximize performance and efficiency of their projects in four main business areas: Building & Territories (including utilities, e-mobility), High Voltage & Projects (covering offshore wind farms, submarine interconnections, land high voltage), Telecom & Data (covering data transmission, telecom networks, hyperscale data centers, LAN) and Industry & Solutions (including renewables, transportation, Oil & Gas, automation and others).

Corporate Social Responsibility is a guiding principle of Nexans’ business activities and internal practices. In 2013 Nexans became the first cable provider to create a Foundation supporting sustainable initiatives bringing access to energy to disadvantaged communities worldwide. The Group’s commitment to developing ethical, sustainable and high-quality cables also drives its active involvement within leading industry associations, including Europacable, the NEMA, ICF or CIGRE to mention a few.

Nexans employs nearly 27,000 people with industrial footprint in 34 countries and commercial activities worldwide. In 2018, the Group generated 6.5 billion euros in sales. Nexans is listed on Euronext Paris, compartment A.

Nexans Power Accessories is the leading European specialised innovator, manufacturer and distributor of low, medium and high voltage accessories as well as connection technology for energy transmission and distribution networks. Longtime know-how and technological advance in cable connection systems was successfully transferred into high voltage applications.

Nexans Power Accessories provide a complete range of slip-on and cold-shrinkable accessories, e.g. premoulded EPDM rubber connectors and silicone terminations, epoxy bushings for transformers and switchgears and joints for power cables up to 170kV. For the international wind industry Nexans also develops and manufactures ready-to-install pre-assembled cable lengths and customized and factory tested cable bridges. An extensive range of additional equipment and a variety of dedicated installation trainings make Nexans a strong partner in the transmission and distribution of wind energy.

Two Times More Power. Jointers! Empower your CV and skill-set by grasping the 66kV Jointer Training opportunity. Jointers must currently be 33kV Competent and experienced to be ready to undertake the step-up to 66kV from 33kV.

Thorne & Derrick

Nexans Main UK Stockist & Distributor

Contact us for Competitive Prices & Fast Delivery from Stocks for Heat Shrink, Cold Shrink & EPDM Rubber Connectors, Joints & Terminations up to 66kV.

Thorne & Derrick International are specialist distributors of LV, MV & HV Cable Accessories, Jointing, Substation & Electrical Equipment – servicing UK and global businesses involved in cable installations, jointing, substation, overhead line and electrical construction at LV, 11kV, 33kV, 66kV and EHV.

Stocking & Supplying | Duct Seals | Cable Cleats | Cable Glands | Electrical Safety | Arc Flash Protection | Jointing Tools | Cable Pulling Eqpt | Earthing & Lightning Protection | Feeder Pillars | Cable Joints LV | Joints & Terminations MV HV

Euromold MV HV | Cable Terminations, Connectors, Elbows & Joints

3M Scotchcast Cable Splicing & Jointing Kits Supplied For Marine & Offshore Cables

October 22nd, 2019

-

uploaded by Chris Dodds | Thorne & Derrick Sales Marketing Manager

Cable Repair, Splicing & Jointing

Thornre & Derrick stock and supply marine salvage and shipwreck removal contractors with 3M Scotchcast 82F submersible cable splicing and jointing kits for connecting flexible marine cables onboard vessels.

The cable repair solution features seawater resistant and flexible 3M Scotchcast 2131 resin which provides stable performance in offshore seawater exposed locations without comprising the flexibility of cable circuit.

REPAIR & JOINT SUBMERSIBLE CABLES

Thorne & Derrick International, based in the UK, distribute an extensive range of Offshore Cable Joints to suit halogen free (zero halogen), flame retardant, MUD resistant, heat resistant and fire resistant offshore and shipboard power, control and instrumentation cables.

3M Scotchcast Flexible Power Cable Splicing Kits 82-F and 82-BF Series are flexible inline and tap splices for use on non-shielded portable power cables and cords. The cable splices are designed to be used on single or multiple conductor cables, depending on the voltage rating.

Submersible Cable Joints – 3M Scotchcast 82F 82BF Cable Splicing Kits – Dimensions

3M SCOTCHCAST 82-F2 FLEXIBLE POWER CABLE SPLICING KITS

- One-piece removable cable joint mold

- 3M Scotchcast 2131 resin compound in “Unipak” container

- 3M Scotch 23 tape for sealing cable joint mold ends

- Clear and comprehensive cable jointing instructions

Thorne & Derrick also supply marine contractors with 3M Scotchcast 2130 and 2131 resins to enable cable jacket repair using flame retardant electrical insulating resins

3M Scotchcast 2131 Resin Features

- Excellent adhesion to plastics and metals

- Bonds to itself as well as most modern cable jackets

- Tough, flexible and flame retardent

- Excellent hydrolytic stability

- Low exothermic reaction temperature

3M Scotchcast 2130 Resin Features

- Flame retardant

- Bonds to all modern cable jackets

- Bonds to itself

- Tough yet flexible

- Unipak container for mixing and pouring

- Excellent multipurpose moisture sealing resin

3M Scotchcast 2131 Resin – Offshore Application

Flame retardant mechanical protection and electrical insulation of flexible low voltage electrical joints installed for flame retardant indoor and outdoor, underground and submerged applications. 2131 resin can be used to replace or repair cable jackets for both single and multi core power cables. Suitable for sealing the crutch and/or sheath when terminating multi core cables.

T&D are 3M Electrical Products stockists for their complete range of cable accessories including Scotchcast resins, Scotchcast cable joints, Cold Shrink cable joints, Cold Shrink cable terminations and Scotch tapes.

LV Cable Joints (Low Voltage Cables)

Thorne & Derrick stock and distribute LV Joints in Cold Shrink, Heat Shrink or Resin Cast technologies – multicore and multi-pair cable joints are available for immediate backfill and energisation of Low Voltage power, control and instrumentation cables 600V/1000V 3.3kV.

Complete range of LV Cable Accessories ➡

Cable Breakouts | Cable Caps | Cable Lugs | Cable Cleats | Cable Trough | Cable Duct | Feeder Pillars | for 11kV/33kV/66kV networks see MV HV Joints & Terminations

Pfisterer | Nexans Euromold | Prysmian | Cable Joints & Terminations MV HV

Cold Shrink by 3M | Joints | Abandonment | Terminations | Low Voltage LV Cables

White Paper : Humidity Effects, Partial Discharge & Loss Of Substation Power By EA Technology

October 22nd, 2019White Paper : Humidity Effects in Substations By EA Technology (Download Here)

Author Tony Byrne, January 2013

Consequences For The Technical Specification of Cable Sealing Systems

Roxtec are global-market leaders in the innovation, design and manufacture of cable transits and pipe penetration sealing systems.

Roxtec solutions effectively seal cables, cable ducts and pipes against water and dust ingress into safety critical and sensitive electrical equipment and buildings.

Cable Transits

In this White Paper, Roxtec highlight the potential for electrical equipment failure resulting from high relative humidity within high voltage substations typically operating at 11kV, 33kV, 66kV and 132kV voltages.

Roxtec commissioned EA Technology to produce a report on the causes and effects of high relative humidity within indoor substation environments and methods of mitigation.

This influential report covers Relative Humidity and the effect it has on the inception or level of partial discharge (PD).

The White Paper discusses the factors affecting the environment within a high voltage substation and the best practice for the design of substations and internal environment control.

The findings in this White Paper have wide-reaching implications for the effective technical specification of cable and duct sealing systems.

Cable sealing systems can reduce the risk of high voltage electrical equipment failure caused by partial discharge as a result of inadequate specification of cable transit systems.

The report concludes, “cable entry points are one of the main sources of water ingress to substations and they should be effectively sealed.”

- Who Should Read This ?

We summarise several of the Key Points below, however a thorough and careful complete read is recommended to electrical industry professionals, substation design engineers, project managers and installers.

This White Paper should be mandatory reading for Lead Electrical Engineers, Electrical Project Engineers, Principal Electrical Engineers, Plant Engineers, LV HV EHV Cable Jointers, ATEX Inspectors, Substation Commissioning Managers, LV HV EHV Project Managers, Buyers & Procurement Managers, SAP’s.

- Environmental Conditions

Typical relative humidity (RH%) in the UK is between 65% – 95% in an internal substation environment.

Where there are cable trenches and basement ducts adequate cable sealing must be adopted to prevent water ingress in “normal” and “flood” conditions.

Even raised substations should seal all cable entries to prevent moisture ingress, the cause of high RH%.

- Operational Conditions

Loads/faults can cause considerable cable expansion and contraction – which may lead to traditional cable seal failure as mastic sealants are often not able to provide sufficient cable retention.

Due to lower ambient temperature and their location below ground, trenches and basements will experience a higher level of RH.

For below ground enclosures and external penetrations, a vermin proof seal would also be advantageous.

Pictured : Onshore Wind Power. Transformer Station & Shelter.

Using Roxtec R type cable transit frame and seals to provide a fireproof, watertight, gas-tight and anti-rodent seal.

- Partial Discharge

PD’s are electrical discharges occurring inside or on the surface of insulation materials, caused by HV electrical stressing of the insulation.

PD leads to progressive deterioration and plays a significant part in failures. Partial discharge affects all types of HV assets critical to network operation including high voltage switchgear, cables and transformers.

High RH% and particle contamination (typically dust ) cause and accelerate PD.

Large swings in RH% also have an adverse effect.

Partial discharge is hard to detect unless invasive maintenance is carried out or a failure occurs.

The most common cause of high RH in electricity substations is water ingress through the structure and below ground cable ducts.

Most common dust ingress points include below ground cable ducts and cable entries in walls and roofs.

- Partial Discharge Effects

PD can ultimately lead to a catastrophic equipment failure.

This typically cannot be rectified through cleaning or refurbishment and can incur significant costs through the need to replace substation equipment, maintenance downtime and loss of supply.

Pictured : Offshore Wind Power. Switchgear Sealing.

Using Roxtec RS round cable transit frames to seal large and rigid power cables with connectors in offshore substations.

Switchgear Specification & Design

- IEC 62271-1:2007 & BS EN62271-1: 2008 Ambient air not polluted with gas, smoke, corrosive / flammable gases, vapours

- Average RH% over 24hrs not to exceed 95%

- Average RH% over 1 month does not to exceed 90%

- Design notes – highlights the use of “control measures” to manage RH%

- All tests are short timescale, long term effects over several years are unknown

Environmental Requirements

Manufacturers Literature

Manufacturers recognise the design notes in the standards and use typical qualifying statements in equipment manuals.

Example 1 : “RH% must not exceed 80% and the combination of temp and humidity must be such that condensation, in or on the equipment, will not occur. Where RH% exceeds 80% take special precautions to prevent.”

Example 2 : “If the average air humidity exceeds 75% we recommend appropriate remedies are adopted.”

Example 3 : “Ideal conditions – Humidity below 40% and no dripping water. Standard conditions – Humidity below 60%”

Ideal conditions can be as low as 40% normal conditions less than 60%

Logical Conclusions

- RH% in UK between 65-95% as standard – manufacturers recommended operating levels may be below this

- Water / dust ingress – mainly below ground cable ducts – but also through walls

- Cable retention is a key factor as movement will occur in normal operation due to expansion and contraction of the cables, the natural weight of HV power cabling and the disturbance caused by routine maintenance and engineering works

- Beneficial to have vermin proof sealing

Many substations use costly control measures, such as sump pumps, heaters and de-humidifiers, to deal with the problem of RH without tackling the cause.

The sealing of service penetrations is not highlighted in many standards, although these are the number one ingress point for water and dust.

It makes sense to reduce operating costs and reliance on control measures to provide duct and service penetration sealing, which not only seals but remain tight under load and fault.

To repeat, “cable entry points are one of the main sources of water ingress to substations and they should be effectively sealed.”

Pictured : Sealing Cabinets, Panels & Electrical Equipment In Underground Substations.

Electrical substation cabinets for control and switching and any other cabinets used inside or outside the substation should be sealed against environmental hazards that may disturb the functionality of sensitive electrical and electronic equipment.

Roxtec Seals HV Electricity Substations, Transmission & Distribution

Roxtec have a track record in providing reliable Substation Cable Sealing to UK DNO’s and overseas electricity authorities.

Typical applications include sealing cables into control rooms, service rooms and control boxes at the high or medium voltage electricity substation.

Roxtec H3 Triplex Seals prevent water ingress generating increased humidity leading to partial discharge and eventual loss of power supply into 11kV, 33kV and 132kV substations.

Roxtec cable seals provide sealing solutions, with spare capacity for future cables, to prevent water ingress, gas migration and rodent infestation from damaging substation electrical equipment and causing loss of power supply.

Pictured : Roxtec H3 Cable Seal For Medium Voltage 11kV 33kV Trefoil Cables

Thorne & Derrick

Thorne & Derrick are national distributors of LV, MV & HV Cable Installation, Jointing, Substation & Electrical Equipment – servicing businesses involved in cabling, jointing, substation, earthing, overhead line and electrical construction at LV, 11kV, 33kV, 66kV and EHV. Supplying a complete range of power cable accessories to support the installation and maintenance of low/medium and high voltage voltage power systems:

- Slip-on Cable Terminations

- Cold-shrink Cable Terminations

- Heat-shrink Cable Terminations

- Cable Joints – Heat & Cold-shrink

- Separable Connectors (Euromold)

- Surge Arresters & Switchgear/Transformer Bushings

Key Product Categories: Duct Seals | Cable Cleats | Cable Glands | Electrical Safety | Arc Flash Protection | Cable Jointing Tools | Cable Pulling | Earthing | Feeder Pillars | Cable Joints LV | Joints & Terminations MV

How to Label Cables Safely In Zone 1 & Zone 2 Hazardous Areas

October 22nd, 2019-

uploaded by Chris Dodds (Sales & Marketing Manager - Thorne & Derrick International)

A Guest Blog from Michelle Michaelson (Silver Fox Limited Operations Director).

Cable Labels

Electrical, Instrumentation, Security, Data & Telecoms

Silver Fox are market leading manufacturers of Cable Labels and solutions worldwide.

Thorne & Derrick are Main Distributors for Silver Fox, the UK leading manufacturer of Wire & Cable Labelling Systems for the identification of LV MV HV in Zone 1 and Zone 2 hazardous areas and potentially explosive atmospheres.

Cables and wires must be contained and correctly labelled – safely.

Whether onshore or offshore, the oil and gas industry is exposed to the severe challenges of maintaining safe working practices in potentially  explosive atmospheres or hazardous areas.

explosive atmospheres or hazardous areas.

Basically, the classification of a hazardous area into Zone 1 or Zone 2 is determined by the time period a flammable atmosphere is likely to be present under international Directives, such as ATEX. See hazardous area zones for further guidance and technical information.

Silver Fox cable and wire making label systems are “cold-applied” (with the exception of heat shrink labels) and are therefore compatible for use within hazardous area locations posing no ignition source threat to the “Fire Triangle.”

Taking the Heat out of Hazardous Areas

Unlike traditional heat shrink wire and cable marking systems, Silver Fox can provide cold-installed cable labelling/ferruling for use in hazardous areas where working conditions preclude the application of naked flames or “hot-working”.

Advanced specification and performance wire marking and ferruling systems from Silver Fox provide safe and cost-efficient labelling of cables and wires located in hazardous areas and potentially explosive atmospheres

When it comes to labelling wires and cables in hazardous areas Silver Fox have found the answer with 2 safe solutions.

Labels for Cables

One of the most straightforward and easiest is the computer-generated Silver Fox Legend™ 2-Part cable labelling system.

Comprising of a clear plastic tube with two 2 recesses; one for the wire and one for the label. The recess for the cable label remains the same size while the size of the recess for the wire changes for different wire diameters.

Each sizing has tolerance for a range of different cable or wire diameters. Diameters from 2mm to 5mm are accommodated with just 3 different sizes covering diameters from 1.5 mm to 5mm.

Labels and tubing are available in 3 different lengths; uniquely there is a 50mm that can accommodate even the longest ID’s 25 to 30 characters and in some circumstances more.

The second solution is Legend™ Non-Shrink Tubing.

Durable PVC tubing that can be printed through the Silver Fox DTP1/300 thermal printer.

An alternative to heat shrink at 20% of the cost.

When fitted, the special oval design tube, stays exactly where it is placed.

Additionally, up against individual ferrules at approximately 30% of the cost, it represents a very powerful solution. Plus, there is no need to stock 0-9, A-Z as printing onto blank tubing means all characters are available.

A recent trial printed 25,000 25mm labels in 4 hours, that’s 100/minute.

BLOG ➡

Fox-in-a-Box® – The Most Efficient Cable Label Printer & System on The Market

Silver Fox Legend™ 2-Part Cable Labels

Benefits

- No hot gun permit is required – ideal for using in hazardous areas

- The idents are protected in the clear plastic tube mounting

- The special shape of mounting tube, maximises grip

- The idents can be turned in any direction for easy reading

- The idents can be changed after application without cutting the wire. This is particularly useful as a project progresses as idents can be easily changed and the wire does not need to be cut or re-terminated or the circuit re-tested

Available in 2 formats:

- Cable labels pre-cut in A4 sheets for use through an ordinary laser printer – no need for special equipment or

- Cable labels in a roll for printing through thermal Plug’N’Play thermal printer supplied as part of Fox-in-a-Box® starter kit

Are Silver Fox Cable Labels Easy to Install & Remove?

Yes, Silver Fox have a special flexible design so the installer can pull the label into a clear tube mounting. Silver Fox have developed this because rigid options can suffer from over tightness which in turn results in difficulties inserting/removing the label block from the clear tube. By using flexible plastics, Silver Fox addresses these issues, while still offering a fully durable wire and cable labelling solution.

➡ Silver Fox Tip – Leave the tail of the cable label on to the end of the project – this makes the cable label even easier to remove.

Further reading

Making Hazardous Area’s Safe

How We Can Help?

Thorne & Derrick, Specialist UK Distributors of LV MV HV Jointing, Earthing, Substation & Electrical Eqpt provide expert technical specification, customer support and product supply from stock of an extensive range of Hazardous Area Electrical Equipment including:

♦ Lighting – T&D can provide lighting designs to ensure lux levels are achieved in line with regulations, fittings are located correctly and meet certification requirements – we provide a comprehensive hazardous area lighting system design service.

♦ Heating – T&D can provide room heat loss calculations to ensure the correct heaters are specified and meet certification requirements.

Using heat tracing cables we can also provide competitive prices from stock for trace heating systems used to provide frost protection or process temperature maintenance to mechanical pipework services in substations.

- Raytec | ATEX Lighting (LED & Emergency Fittings)

- ATX Appleton | Lighting (LED & Emergency Fittings ) Flameproof Plugs & Sockets

- Abtech | Junction Boxes & Enclosures (EX Certified)

- Craig & Derricott | Isolators (Switch Disconnectors)

- EXHEAT | Space Heaters & Anti-Condensation Heaters

- Marechal | Plug & Sockets (EX Certified)

- Crowcon | Gas Detectors (Hydrogen & Oxygen)

- Technor | Enclosures & Control Equipment (EX Certified & Flameproof)

- Roxtec | Cable Transits & Sealing Systems

- CMP | Flameproof & Hazardous Area Cable Glands

- Safety Showers & Eyewash Stations

- Spill Bunds & Containment

- ATEX Fans

- Joints & Terminations | 3M Electrical, PFISTERER CONNEX, Nexans Euromold, Prysmian

Hazardous Area Substation Lighting ATEX Certified | Raytec

![]()

Blogs

- Jointing Cables In Hazardous Areas According To The ATEX Directive

- Sealing Cable Ducts In Hazardous Areas According To ATEX Directive

- The Temporary Hazardous Area Floodlight – Wolf LinkEx WF-300 XL LED Floodlite

- Confined Spaces – Powering, Lighting & Heating Explosive Atmospheres

Nexans OJC Offshore Medium Voltage Junction Cabinets For Wind Power Projects

October 22nd, 2019

Nexans Power Cable Accessories For Wind Energy Projects

-

by Chris Dodds T&D - estimated reading time 5 minutes

Nexans Offshore Junction Cabinet (OJC)

Offshore MV Junction Cabinets (Medium Voltage Up To 42kV)

T&D are UK Distributors for Nexans Power Accessories – this includes a range of medium and high voltage accessories including cable joints, terminations and connectors suitable for wind turbines on offshore and onshore energy projects.

Nexans Offshore Junction Cabinets (OJC) are designed to improve revenue streams for offshore wind power developments – the offshore junction cabinets are used as a disconnecting point for internal tower cable to external subsea array cables.

This can be used as a demarcation point between tower, transition piece and array cable related parties – Nexans OJC junction cable chambers are used as a connecting point for internal tower cable to external subsea arrays cables.

Nexans OJC can provide a convenient test point and can help with the earlier generation of power to help create revenue sooner.

The marine grade stainless steel cabinets is specifically suitable to be installed in severe offshore conditions.

The split cable gland plates allow to use pre-terminated and tested jumpers, reducing the installation time and increasing the quality of the cable installation.

- Up to 42 kV

- 1250 A

- Robust design with IP66 degree of protection (BS EN 60529:1992).

- Short circuit tested acc. to DIN VDE 0278-626-1(HD 629.1 S2:2006 + A1:2008): 2009-07: Thermal short-circuit 25kA/1s, Dynamic short-circuit 62.5 kA.

➡ There are also 33kV onshore junction cabinets known as Nexans ONJC-S that are designed, tested and manufactured for onshore renewable projects that can be used as a disconnecting point for branching between grid and applications – for applications with MV-HV separable connectors up to 42kV (630A) according to CENELEC HD 629.1 S2.

Also: 33kV Cabinets Onshore

Nexans OJC Benefits

Medium/High Voltage MV HV Cable Cabinets

- Suitable to be installed in the severe conditions of the transition piece prior to installation of the tower

- Simplified interface management, clear division of responsibility

- The chamber design is specifically suitable to be installed in the transition piece of the tower

- High accessibility for ease of installation

- Ideal test and demarcation point

- Possible use of pre-terminated and tested jumpers to tower equipment

- Time saving

- Distance involved between hang off and switchgear mean time/cost offshore for cable preparation

- Pre-terminated MV HV cable leads also saves space/complexity

- Prepared and tested onshore, ready to plug and play

- Project critical path activity, no delays for installer

- Efficiency of operation which can be highly beneficial for planning the installation of the collector cables from the array, thus creating additional potential cost benefit

- Accommodation offshore on the OSS maybe limited

- REDUCTION OF INSTALLATION TIME (30%)

Nexans OJC Offshore Cabinets/Junctions

Nexans Power Accessories have studied the installation of subsea array cables in the offshore towers and have developed a system that gives the developer and installer certain advantages over other medium/high voltage cable connection methods.

By employing pre-terminated cable leads that utilise less expensive flexible cables, a developer may save money and an installer can save time on the preparation and testing of the medium voltage cable link between the MV transformer to MV switchgear and/or MV switchgear to the array cable.

By using a cable termination point near to the hang-off rather than taking the array cable directly to the equipment, an installer may also save time on the preparation of the array cable and spend less time in the tower dealing with the inconvenience of stripping longer lengths of arrays.

This results in less reliance on the weather giving a cost saving to the developer due to the implications of the waiting on weather charges as more work can be done onshore preparing and testing the equipment.

By saving time on the installation offshore, this would in our opinion, give an earlier completion date and thereby earning the developer revenue sooner.

Nexans Offshore Junction Cabinets OJC – Design Specification

- Aluminium bushing support plate to feed through switchgear/transformer bushings

- Access panel for 2 array cable connections

- Split cable gland plate incorporating 9 feed through sealed glands

- Access panel for turbine connection

- Earth bar on insulated standoffs

- Cabinet secured by 4 x M16 internal base fixings

- Different cable connectors and surge arrester combinations are possible

- Cable cleats arrangement for 9 single core high voltage cables

- Channels for mounting external accessories

- Lifting eyes

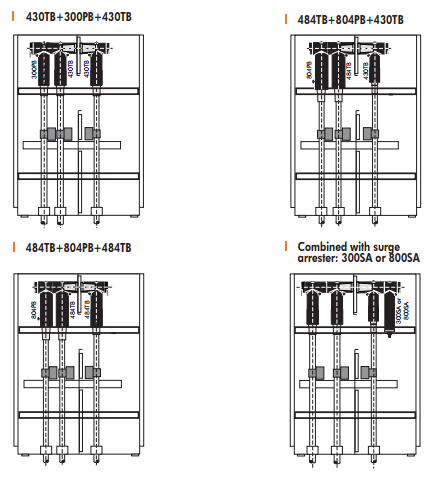

Nexans Junction Cabinets & Separable Connectors – Possible Arrangements

- Extension to larger cable sizes and additional array cables possible.

- Junction cabinet can be equipped with different connector combinations.

- Spare room at turbine connection to add surge arresters to protect tower equipment from high voltage surges.

- Pre-terminated and tested jumpers to connect junction cabinet with tower equipment.

| Offshore Junction Chamber Type | Voltage Um (kV) | Outer dimensions of chamber (w x d x h)(mm) | Fixing points | Conductor sizes (sqmm) | |

| min | max | ||||

| Nexans OJC1 | 42 | 600 x 800 x 1125 | 4 x M16 | 50 | 630 |

Thorne & Derrick

Thorne & Derrick are national distributors of LV, MV & HV Cable Installation, Jointing, Substation & Electrical Equipment – servicing businesses involved in cabling, jointing, substation, earthing, overhead line and electrical construction at LV, 11kV, 33kV, 66kV and EHV. Supplying a complete range of power cable accessories to support the installation and maintenance of low/medium and high voltage voltage power systems:

- Slip-on Cable Terminations

- Cold-shrink Cable Terminations

- Heat-shrink Cable Terminations

- Cable Joints – Heat & Cold-shrink

- Separable Connectors (Euromold)

- Surge Arresters & Switchgear/Transformer Bushings

Key Product Categories: Duct Seals | Cable Cleats | Cable Glands | Electrical Safety | Arc Flash Protection | Cable Jointing Tools | Cable Pulling | Earthing | Feeder Pillars | Cable Joints LV | Joints & Terminations MV