Blog

Cable Fault Location & Detection On Live Power Distribution Systems (Network Rail Approved)

April 29th, 2019

Locating Cable Faults

-

uploaded by Chris Dodds - Thorne & Derrick Sales & Marketing Manager

CableGuardian by Viper Innovations allows for quick electrical fault location on rail signalling power systems and displays them clearly on a user-friendly interface.

The cable fault locator traces both insulation and conductor faults as multiple units can be connected can isolating insulation faults to a section of cable and pinpointing the location of the conductor fault.

CableGuardian has the ability to send notifications via e-mail, SMS, and even voice call for serious faults such as open circuits, short circuits and intermittent faults reducing the time spent trying to locate the fault due to Spread Spectrum Time Domain Reflectometry (SSTDR).

The modular nature of CableGuardian allows for remote compliance with the Network Rail M003 Maintenance and Testing requirements.

The cable fault detector is suitable for the following locations including rail industry signalling power systems, legacy system equipment upgrades and electrical power distribution systems with ungrounded (Isolation Terra) AC pairs at working low voltages of up to 750V on Network Rail infrastructure.

CableGuardian – Cable Fault Location & Detection

CableGuardian

Cable Fault Location & Detection

Features & Benefits

- Distributed and intelligent infrastructure for cable health monitoring

- Integrity alarms and fault information direct to asset stakeholders

- Helps to avoid injury and reduce downtime through early fault detection and cable location

- Analytics facilitate proactive, rather than reactive, maintenance

- Enables faster and more accurate repair, minimising service outage

- Permits a move from a frequency based inspection regime to one driven by actual asset condition and performance

- Immediately locates and alarms the first cut during cable theft

- Enables compliance with the requirements of the Network Rail standard for Insulation Monitoring NR/L2/SIGELP/27725

- Fault tolerance built in – each CableGuardian node is a “slave” to the “Supervisor and Analytics System” – no “Master” node required

- Automatic configuration of CableGuardian nodes added or removed from the system

- Inbuilt GPS for auto-location on installation (option)

- Provides “data hub” for interfacing with IOT nodes such as weather centres and IP enabled cameras

CABLEGUARDIAN – Product specification

| Electrical | |

| Input Power Supply (wiring options): | 110V AC 47/63Hz “domestic supply” 230V AC 47/63Hz “domestic supply” Direct from Line Supply being monitored |

| Line Supply Conditions: | Voltage: 300V to 750V 1 AC Frequency: 47Hz to 63Hz Capacitance: Up to 500μF |

| Power Consumption: | 25W typical 30W maximum |

| Earth Connections: | “Reference Earth” and “Protective Earth” wired connections via cable gland to internal Earth terminal |

| Interfaces | |

| Communications Options: | Ethernet 10/100 Base-Tx 3G/4G Cellular (SIM embedded) Fibre Optic 100Base-FX, LC Duplex, 1300nm Multimode |

| Service Port (setup & configuration): | USB 2.0 Type A |

| IR Current Loop (option): | Output: 4-20mA @ ±1% (various modes available) |

| Front Panel Indicators: | Input supply on Internal power on Line open / short circuit alarm IR pre-alarm (Warning) IR alarm (Fault) IC pre-alarm (Warning) IC alarm (Fault) Downstream IR alarm |

| GPS & Cellular Aerial (option): | External mounted, dual function (IP67) |

| Measurements | |

| Network Insulation Resistance (IR): | 1kΩto 1GΩ@ |

| Directional Insulation Resistance: (via External Coil) |

1kΩto 10MΩ@ Network IC dependent |

| Response Value (Alarms) 2: | 1kΩto 10MΩ |

| Network Insulation Capacitance (IC): | 0.1μF to 150μF @±25% ±0.05μF |

| Directional Insulation Capacitance: (via External Coil) |

0.1μF to 80μF @ Network IR dependent |

| Line Voltage (True RMS): | Up to 750V1 AC @±3% ±5V |

| Line Current (True RMS): (via External Coil) |

Up to 120A @±1% |

| Line Frequency: | 47Hz to 63Hz @±1% ±0.5Hz |

| Line Power (True RMS): | ±3% ±5W |

| Line Power Factor: | -1 to +1 |

| Polarisation Index (PI): | In accordance with IEEE-43-2000 |

| Dielectric Absorption Ratio (DAR): | In accordance with IEEE-43-2000 |

| Conductor Short/Open Circuit: | Located to 98% accuracy by distance |

| Intermittent Conductor Faults: | Duration >100mS |

| Environmental | |

| Operating Temperature Range: | -25 °C to +70 °C (-13 °F to 158 °F) |

| Storage Temperature Range: | -40 °C to +85 °C (-40 °F to 185 °F) |

| Relative Humidity: | Up to 100% |

| Design Life: | Minimum 15 years operation |

| Climatic Conditions: | ‘Category T1 environment’ as defined in BS EN 50125-3 |

| Solar Radiation: | 1120 W/m2 as defined in BS EN 50125-3 |

| Shock and Vibration: | ‘Outside the track’ as defined in BS EN 50125-3 |

| Dimensions: | See diagram below (in millimetres [inches]) |

| Weight: | <10kg |

| Mounting: | See diagram below (M6 fixings) |

| Construction and Assembly: | In accordance with BS EN 61439-2 and BS 7671 |

| Ingress Protection: | IP54 as defined in BS EN 60529 |

| Fire Protection: | Category F1 as defined in BS EN 50125-2 |

| Product Standards | |

| Safety: BS EN 61010-1: | Overvoltage Category III (110/230V Mains & 750V 1 Line) Pollution degree 2 |

| BS EN 61010-2-030: | Measurement Category III |

| Electro-Magnetic Compatibility: | In accordance with BS EN 50121-5 |

| Insulation Monitoring Device: | IEC 61557-1 IEC 61557-8 |

| Network Rail: | NR/L2/SIGELP/27725 NR/L2/SIGELP/27409 |

CableGuardian – Diagram

The CableGuardian system may consist of a single node or multiple nodes, depending on the system monitoring requirements and the level of fault location granularity desired.

Data Storage & Analytics System

Rail Cable Accessories, Electrification & Installation Equipment

Thorne & Derrick stock an extensive range of 400V-33kV Rail Cable Accessories & Power Distribution Sytems including feeder pillars to contractors undertaking Low Voltage Power Distribution, HV Electrification & Substations, DC Traction & Networks, OLE and Track Feeder Cable Renewals – complete range of Network Rail PADS approved track terminations, cable joints, cable repair and connection products up to 25kV, including 3M Cold Shrink, Pfisterer CONNEX and Nexans Euromold products.

Full range of Cable Pulling Equipment & Products to ensure safe and efficient of rail cables in to cable ducts and containment infrastructure including cable troughs.

Cable Cleats | Cable Hangers | Cable Joints | Cable Glands | Cable Lugs | Cable Transits | Arc Flash Clothing

Why Move To 3M Cold Shrink?

April 29th, 2019

Cold Shrink Cable Joints

-

uploaded by Chris Dodds - Thorne & Derrick Sales & Marketing Manager

3M Cold Shrink

Over 10 million 3M Cold Shrink products are installed worldwide ; this includes cable joints, cable terminations and cable abandonment kits.

Developed in the 1970’s by 3M, Cold Shrink technology has been found to be a safer, more reliable and easier to install technology for the jointing, terminating and abandoning of low voltage power cables.

Helping MV HV Contractors Make The Change

In order to help cable contractors, cable jointers and engineers make the change out of heat shrink and into 3M Cold Shrink, we feature a YouTube Video Playlist covering the installation of cable joints, terminations and abandonment kits using 3M Cold Shrink.

Cables must be jointed and terminated accurately, safely and quickly – T&D & 3M can provide cable jointer training to further reduce the risk of cable failure caused by poor workmanship.

5 Good Reasons To Switch From Heat Shrink To 3M Cold Shrink

- Reduced danger of damaging XLPE cable material – no scorching

- Less room for cable jointer error – no skill-sensitive multiple layer heat shrinking, single part construction

- No special site permits required – cold applied joints/terminations, no “hot-working”

- No cooling time needed before power energising – reduced outage periods and downtime

- Easier to use in enclosed areas – no need for heat shrink gas torches, bottles, cannisters

LV Cable Joints (Low Voltage Cables)

Thorne & Derrick stock and distribute LV Joints in Cold Shrink, Heat Shrink or Resin Cast technologies – multicore and multi-pair cable joints are available for immediate backfill and energisation of Low Voltage power, control and instrumentation cables 600V/1000V 3.3kV.

Complete range of LV Cable Accessories ➡

Cable Breakouts | Cable Caps | Cable Lugs | Cable Cleats | Cable Trough | Cable Duct | Feeder Pillars | for 11kV/33kV/66kV networks see MV HV Joints & Terminations

Pfisterer | Nexans Euromold | Prysmian | Cable Joints & Terminations MV HV

Cold Shrink by 3M | Joints | Abandonment | Terminations | Low Voltage LV Cables

SVL’s Sheath Voltage Limiters for Protection of MV HV Cables

April 29th, 2019

SVL’s Sheath Voltage Limiters for Protection of MV HV Cables

Protecting the Cable Sheath & Jacket from Switching Surge

Source: INMR

Over the past decade, demand for longer power lines and higher current capacities for HV High Voltage power cables has required new methods of loss prevention.

Sheath Voltage Limiters also known as SVL’s provide valuable protection to expensive cable installations. They are highly reliable and effective at managing cable sheath voltage rises and the associated power flows that can result under fault conditions.

At the same time, ensuring high reliability of these lines is progressively more important.

Together, these developments have sharply accelerated application of surge protection on underground cable networks.

This article from 2012 contributed by surge arrester expert and INMR Columnist, Jonathan Woodworth, explained the surge protection scheme offered by sheath voltage limiters (SVLs) – devices intended to protect the cable jacket or cable sheath from electrical stresses during transient events.

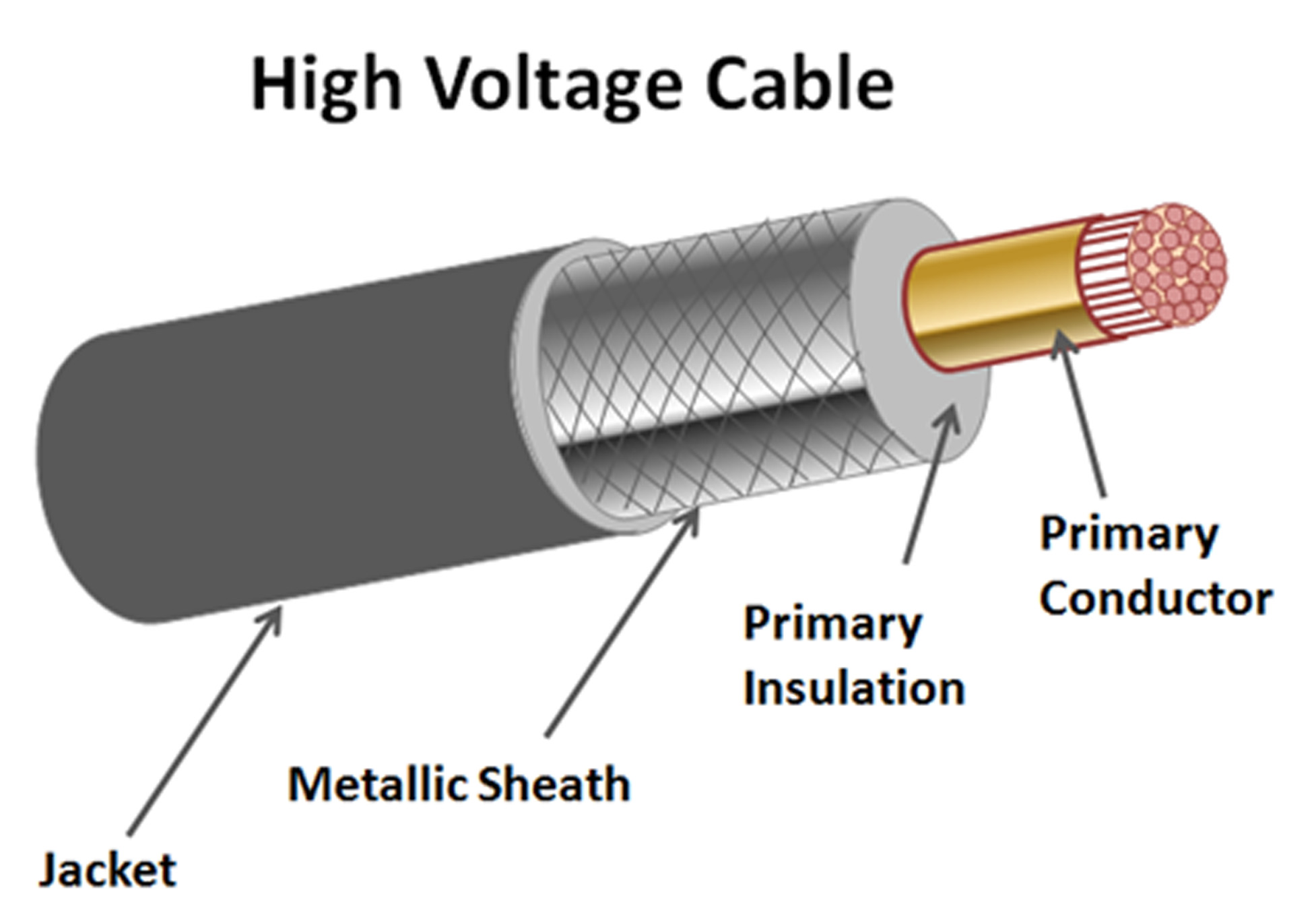

Since high voltage cables these days are available in an array of different types and designs, for the sake of simplicity the focus here was on a single core HV cable with metallic sheath and polymeric outer sheath jacket (as in Fig. 1).

Thorne & Derrick are Approved Suppliers for ENSTO‘s Sheath Voltage Limiters, which provide overvoltage protection of Power Transmission & Distribution underground cable sheaths – this includes MV HV Medium & High Voltage Cables according to the rated voltage of the SVL’s (Sheath Voltage Limiters). We can provide excellent customer support, product selection and competitive prices with next-day delivery from extensive stocks of electrical Link Boxes.

Fig. 1 Simple HV cable showing polymeric jacket that may require surge protection

Introduction

Sheath Voltage Limiters

Growth in installation of underground cables has focused more attention on some of their potentially negative environmental effects. Because cable is often installed with metallic sheaths, current is induced onto the sheath from the primary conductor and flows directly to earth, representing a 100% loss of energy. In the process it can also raise the temperature of the cable, which then becomes a limiting factor in the system’s overload capability.

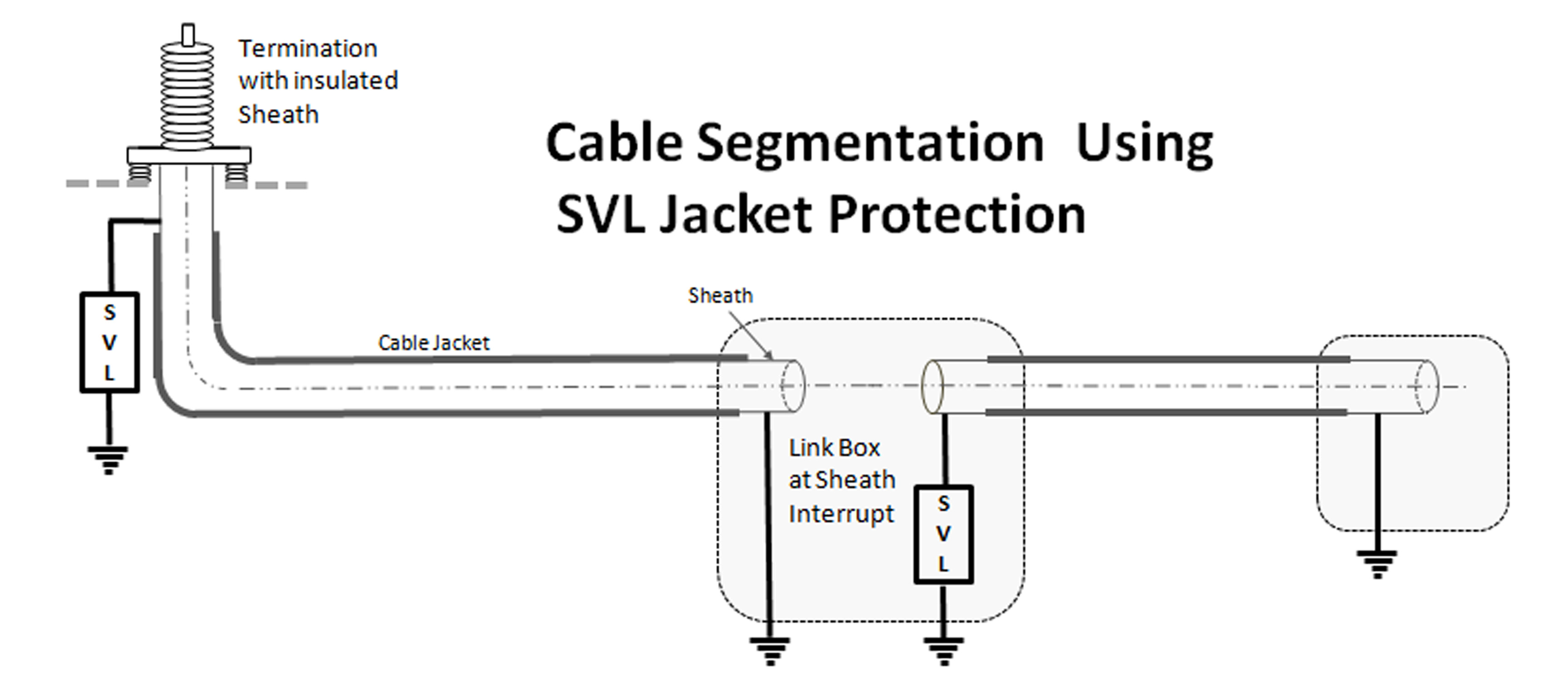

Fig. 2 Loss reduction in cable systems using segmentation and sheath voltage limiters

A common means to reduce such losses is to segment the cable sheath (as in Fig. 2). However, if segmentation is used to interrupt induced sheath current, measures must also be taken to limit voltage induced on the sheath during transient events.

Otherwise, the voltage differential between sheath and earth can exceed the cable jacket’s withstand, leading to puncture. This can become a point of moisture ingress, which can lead to long term dielectric and failure issues.

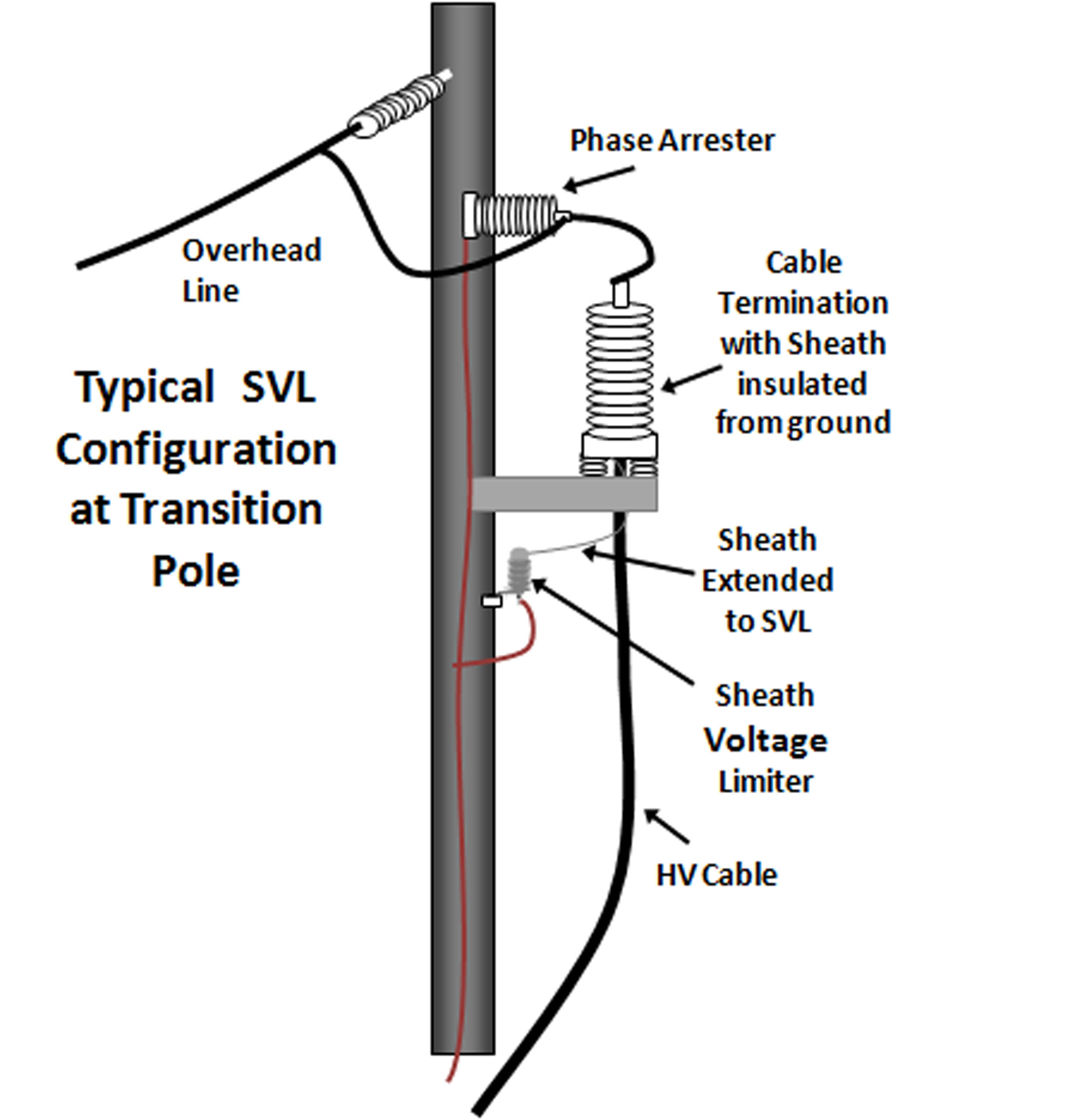

Fig. 3 Typical configuration of cable, SVL and phase arrester on transition pole with SVL mounted near bottom of cable termination

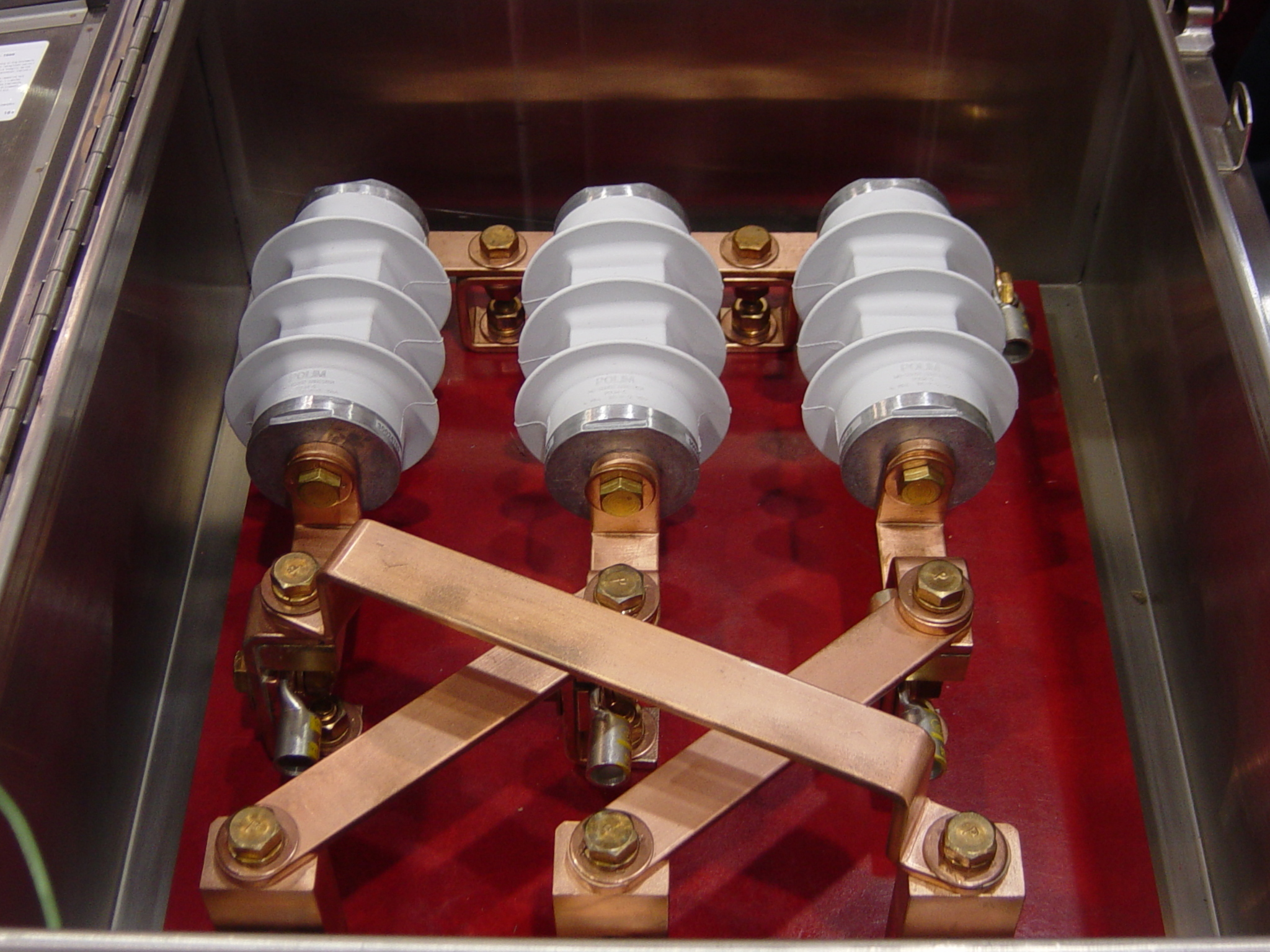

Fig. 4 Link box with 3 SVLs and cross-bonded sheaths

While a range of configurations is used to reduce losses in cable systems, (including cross-bonding of the sheaths and transposing phase conductors) segmentation along with surge protection of the cable jacket is considered the most effective.

The link box in this case is a universally used sealed junction box placed either in manholes or cabinets and that accommodates surge protectors as well as a point to cross-bond the sheaths.

Figure 4 shows a typical such link box setup that provides a location for the sheath voltage limiters as well as for cross bonding of the sheath. The phase conductors do not enter the link box, rather only the sheath or sheath extension.

The SVL

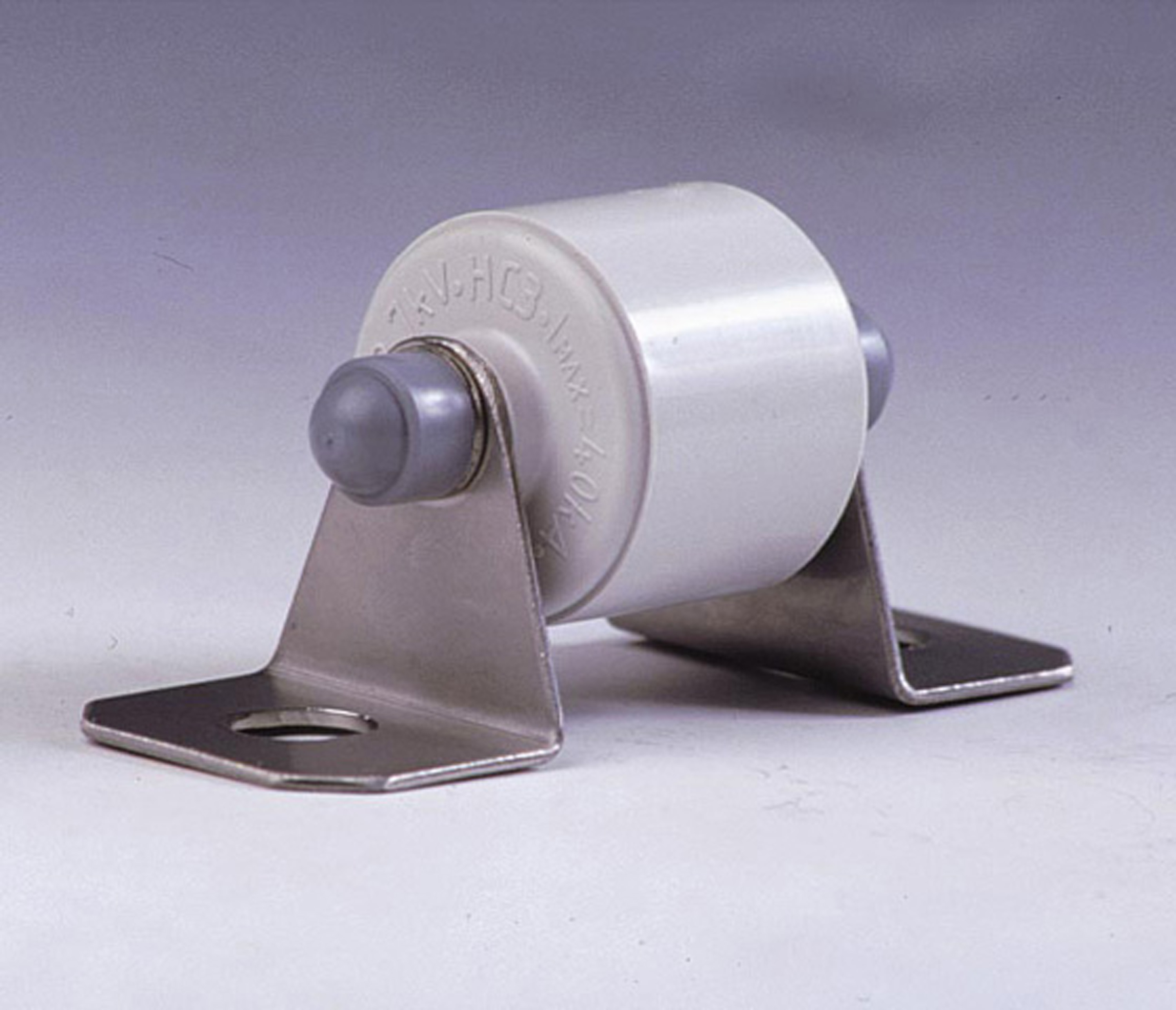

A sheath voltage limiter (SVL) is basically a surge arrester under a different terminology. It functions as surge arrester and, in most cases, is in fact a re-labelled distribution arrester.

Two examples of sheath voltage limiters are shown in Figures 5 and 6. In Figure 5, the arrester has no sheds because this particular design is intended only for use in the dry environment of a link box. By contrast, the SVL model shown in Figure 6 has sheds similar to an arrester because it is intended for outdoor application.

Fig. 5 Sheath voltage limiter with typical ratings 0.8 to 4.8 kV Uc (MCOV) used inside link boxes

Fig. 6 Sheath voltage limiter with typical ratings 4-14 kV Uc (MCOV) for use outdoors

Selecting an SVL

As stated earlier, the main purpose of the sheath voltage limiter is to clamp or limit the voltage stress across the cable jacket.

If the cable sheath is grounded at both ends, the voltage stress across the jacket is quite low during steady state and also relatively low during transients.

However, if the cable is segmented to reduce losses or if there are link boxes along the cable at locations of transposition or cross-bonding, it is important to install the SVLs here to eliminate any risk of insulation breakdown of the cable jacket or link box.

There is no standard method prescribed by IEC or IEEE for selecting the optimum rating for cable sheath/jacket protection. The following method is therefore proposed based on discussion with cable suppliers, arrester suppliers and with the aid of transient modeling of the system to determine the effects of a surge during transients.

This analysis assumes sheath segmentation is a single point bond (earthed at one end of the sheath) and an open point at the other end.

Sheath Voltage from Power Frequency Sources

Because the sheath of a cable is in such close proximity to the conductor, the voltage appearing on an open sheath can be substantial and is directly related to the current flowing through the phase conductor. This relationship applies during steady state as well as during faults.

Steps to Select the Optimum Sheath Voltage Limiter

- Determine the voltages that will appear on the sheath during transient events

- Select AC rating and TOV rating

- Check margin of protection of the selected rating

- Check the energy rating of the SVL is adequate

- Check mounting and failure mode for fit and function

Typical installation of an SVL

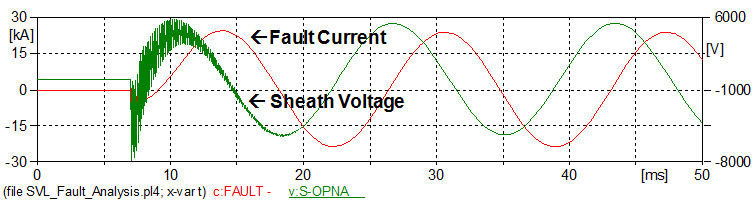

Figure 8 depicts an example where a 17 kA fault results in 3800 Vrms on the sheath. The most common rationale in selecting an arrester for protecting the sheath is to select an SVL with a turn-on level above the worst case induced power frequency voltage.

This means the SVL does not need to dissipate any energy during a temporary overvoltage (TOV) caused by faults. For overhead arresters, this is generally not the rule and, in those cases, the arresters are sized to conduct current during the TOV but not enough to cause it to fail. The overhead sizing rationale utilising an arrester’s TOV capability is not used for SVL selection unless it is necessary to achieve a better margin of protection.

Fig. 8 Example of sheath voltage during 27 kA fault on trefoil configured cable

Sheath Voltage Calculations

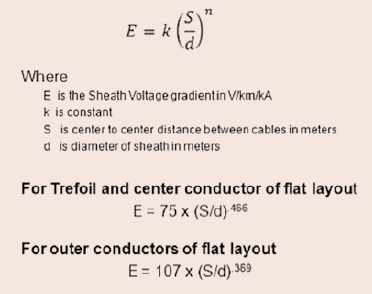

The steady state voltage gradient is the voltage that will appear along a 1 km length of sheath with 1000 amps flowing continuously and is a function of the configuration of the cable in the trench as well as its dimensions.

There are two basic trench configurations: the trefoil, comprised of three cables that are positioned equidistant from one another such that their cross-section forms an equilateral triangle; and the flat configuration whereby all cables are laid such that they are in the same plane and the same distance from one another.

If the voltage gradient is not supplied by the cable manufacturer for the configuration used, it can be calculated using relevant equations and methods derived from IEEE 575 “Guide for Bonding Sheaths and Shields of Single-Conductor Power Cables Rated 5 to 500 kV”:

Sheath Voltage Calculations

IEEE 575

The most common shield/sheath-bonding systems now in use on medium through extra high-voltage (5kV to 500kV) single-conductor shielded power cables and the methods of calculating the corresponding shield/sheath voltages and currents, when the cables are operated as part of a three-phase system, with the neutral grounded directly or through an impedance, are described in this guide.

Once the voltage gradient is known for 1 km at 1000 A, the voltage that will appear at the open end of a segment during a fault event can also be calculated. It is important to determine this voltage level because the SVL voltage rating (Uc) needs to be set just higher so that the arrester does not conduct during a fault event.

Should the surge arrester conduct in this instance, it would need a much higher energy handling capability than generally available for distribution type arresters. If it is found later in the sizing process that a lower level Uc is needed, a transient analysis will determine the SVL’s proper Uc and energy rating.

Assuming that the margin of protection will be adequate, then the Uc rating of the SVL will be greater than or equal to the voltage at the open point (Eopen), as follows:

Uc ≥ Eopen= voltage gradient x segment

length x max. expected fault current

where voltage gradient is V/km/1000A, length is in km and fault current is expressed in kA. For example, if a voltage gradient on a particular system is 200V/km/kA and the line is 2 km long with a potential of 17.5 kA, then the minimum acceptable Uc rating for the SVL would be 7000 V. Note that if the line were only 1 km long, the SVL’s minimum Uc would be half that of the 2 km long line and could be a minimum of 3500 V.

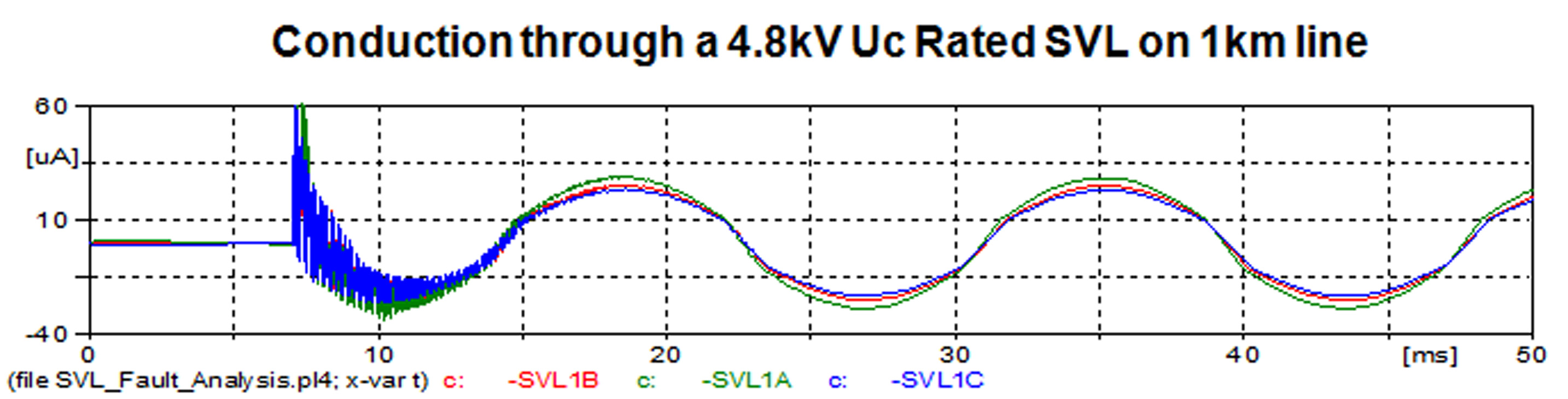

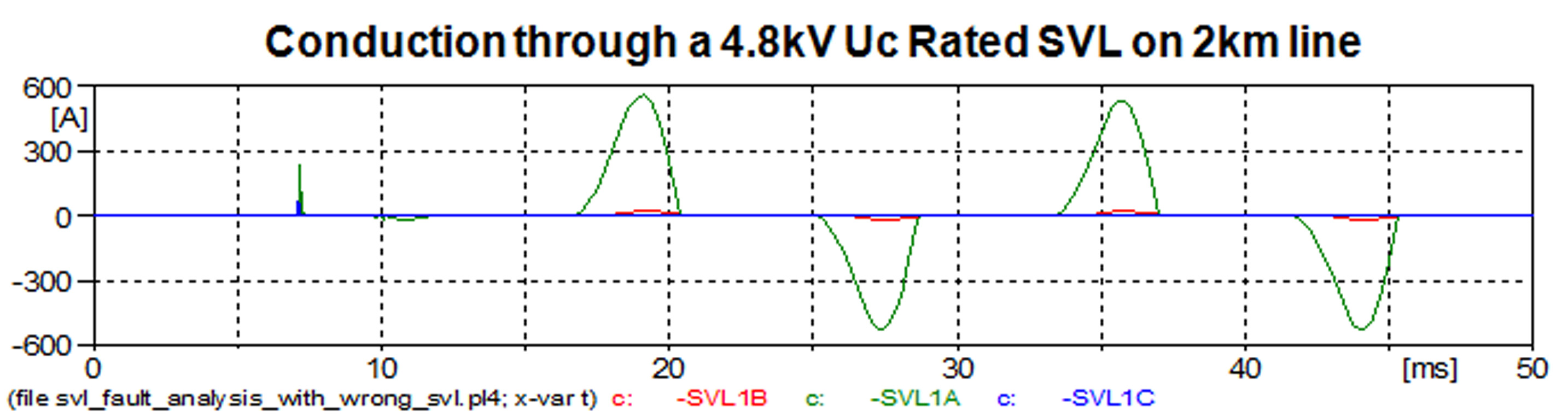

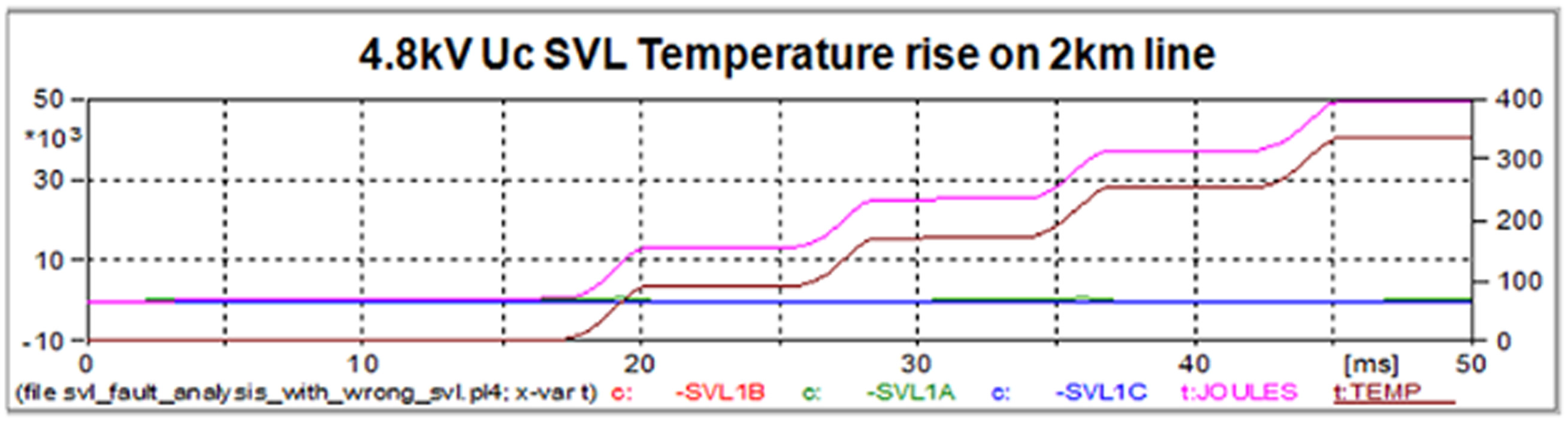

Figure 9 shows the current flow through an appropriately rated SVL on a 1 km line with the above-mentioned voltage gradient and fault current. It can be seen that only some microamps flow through the SVL, which is exactly what is desired. However if the same SVL is applied to a similar line of 2 km length, the current through the SVL would be significant (as in Figure 10) and the immediate temperature rise to failure is shown in Figure 11.

Fig. 9 Current conduction through properly sized SVL

Fig. 10 Current through improperly sized SVL with peak levels in 600 A range per half cycle.

Fig. 11 Temperature rise of improperly sized SVL showing imminent failure if breaker does not immediately interrupt fault

Therefore, when determining the proper Uc ratings for sheath voltage limiters SVLs, one cannot select one rating for all link boxes unless the lengths of all segments are equal.

Moreover, if the SVL is chosen correctly, it will not be required to absorb any significant level of energy during a system fault.

Protecting the Jacket from Switching Surge

The jacket and sheath interrupts are generally the weakest insulation in a HV power cable system. The below table shows their withstand levels as per IEEE 575.

Switching surge impulse withstand of the sheath interrupt and jacket are assumed to be similar to other insulator types and are 83% of the lightning impulse withstand rating (BIL).

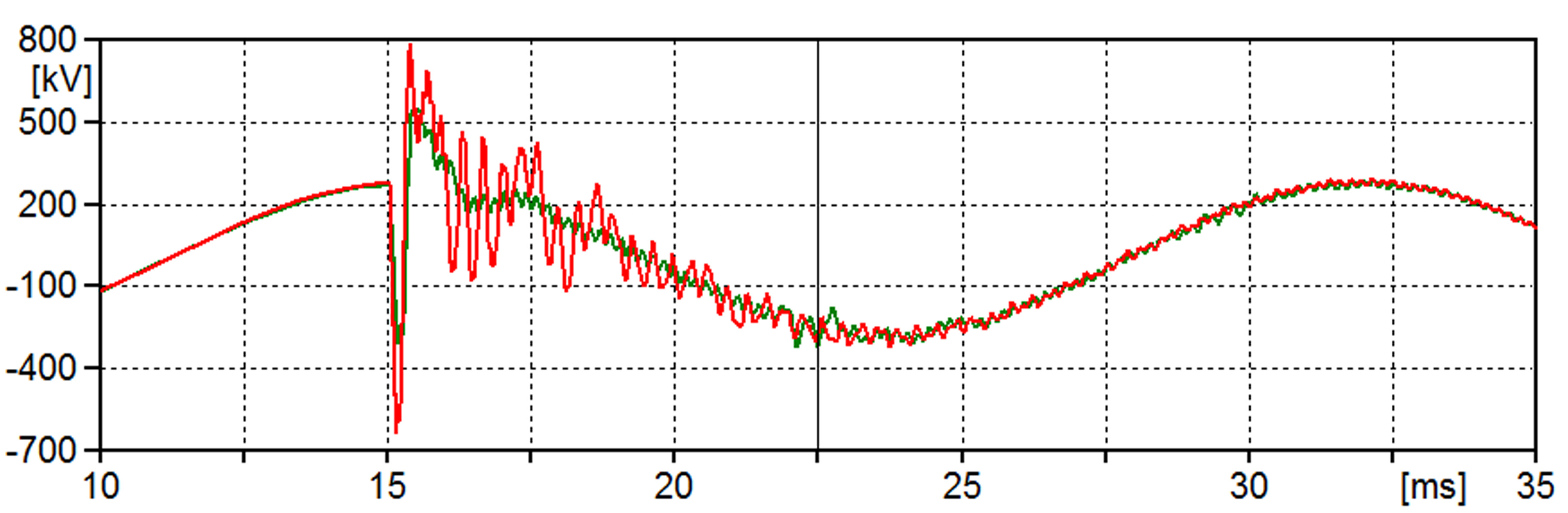

When there is a switching surge event on the phase conductor of a cable, the current through it will induce a voltage on the sheath in the same way it does at steady state or during fault events, even though the wave shape is significantly different. Since the voltage and current on the conductor during a switching surge are not sinusoidal or even a simple impulse (see Figure 13), it is not possible to accurately predict the resulting voltage and current on the sheath.

Lightning impulse withstand of sheath interrupts and cable jacket:

| Typical BIL withstand of sheath interrupt and jacket kV peak (1.2×50 us wave) | |||

| System KV | Across Halves | Each Half to Ground | Jacket |

| 69-138 | 60 | 30 | 30 |

| 161-240 | 80 | 40 | 40 |

| 345-500 | 120 | 60 | 60 |

Fig. 13 Switching surge on phase conductor of 345 kV cable with (green) and without (red) arrester protection on that phase.

The only ways to accurately determine the actual voltage and current on the sheath are through transient simulations or real field tests. Since tests are not practical, transient simulations are really the only option and some useful rules of thumb have emerged from running such simulations:

1. If the SVL is selected to ride through a fault event with minimal to no serious conduction, then the switching surge energy withstand capability of a 10 kA rated distribution type arrester is adequate. If the SVL is not dimensioned to ride through the fault, then station class arresters may be needed.

2. If the 1000 A switching surge residual voltage is not available, then the 1.5 kA 8/20 lightning impulse residual voltage can be used for the margin of protection calculation.

In the case study used to create Figure 14, the switching surge voltage on the sheath without SVL protection would rise to greater than 100 kV. According to the above table, this is more than 40 kV above what the jacket or interrupt insulation can withstand, representing certain failure of the cable jacket. In this case, with an SVL of 9.6 kV Uc, the voltage on the sheath is limited to a maximum of 33 kV.

To calculate margin of protection during a switching surge, it is recommended that the 1000 A switching surge residual voltage be used. Since switching surge residual voltage is not a mandated test for distribution type arresters, the 1000 A residual voltage may not be available. In this case, a reasonable substitute for the switching surge voltage is the 8×20 residual voltage at 1.5 kA. For the 9.6 kV SVL used in the above study, the V1000=1000 A 30/75μs residual voltage is 28.4 kV.

From the above table, it can be seen that the BIL withstand level of the jacket for a 345 kV line is 60 kV. This means that the switching surge margin of protection (MP2) for this case is: MP2=([( BIL x .83 )/V1000 ]-1) x 100 = 111%.

Fig. 14 Switching surge voltage inducted onto sheath of 345 kV cable with and without SVL protection. 3 pu switching surge on phase conductor without SVL (green) and with SVL (red)

Protecting the Jacket from Lightning Surge When lightning strikes an overhead line before the transition pole, the surge is clamped by the arrester that is universally mounted at this location and most of the surge current is diverted to earth.

However, a surge voltage of significant magnitude can travel into the cable with a moderate level of current as well. Figure 15, for example, depicts the voltage and current entering a 345 kV cable given a 100 kA lightning strike a few spans away.

Fig. 15 Voltage and current on phase conductor of 345 kV cable with 100 kA surge to phase several spans from transition pole.

Calculating margin of protection (MP1) for lightning is very similar to what is done in the case of switching surges. Here, 10 kA is used for the coordinating current and the full BIL is used for the withstand of the jacket and interrupt insulation. Using the same type of SVL as above for the switching surge calculation, the residual voltage at 10 kA is 35 kV and cable BIL is 60 kV.

Therefore, MP1=([BIL/V1000 ]-1)x100 = 71%. Again, a 9.6 kV Uc SVL will provide adequate insulation protection for the cable jacket.

➡ Further Reading

- 66kV Cable Jointer Training – A Question Of Competency Not Familiarisation

- PFISTERER CONNEX Size 4 | HV High Voltage Cable Jointer Training

- 66kV Connectors, Cables & Junctions Boxes – An Interview With Nexans

- Arc Flash Clothing & Protection For Safe Windfarm & Wind Turbine Working

LV, MV & HV Jointing, Earthing, Substation & Electrical Eqpt

Thorne & Derrick International are specialist distributors of LV, MV & HV Cable Installation, Jointing, Duct Sealing, Substation & Electrical Equipment – servicing UK and global businesses involved in cable installations, cable jointing, substation, overhead line and electrical construction at LV, 11kV, 33kV and EHV.

THORNE & DERRICK Product Categories: Duct Seals | Cable Cleats | Cable Glands | Electrical Safety | Arc Flash Protection | Cable Jointing Tools | Cable Pulling | Earthing | Feeder Pillars | Cable Joints LV | Joints & Terminations MV HV

Cable Cleats, Cable Glands & Cable Lugs For Prysmian FP600S Cables

April 26th, 2019

FP6000S

- uploaded by Chris Dodds – Thorne & Derrick Sales & Marketing Manager

The following article enables the correct specification of cable cleats, glands and lugs for the safe and reliable installation of Prysmian FP600S fire resistant cables without comprising the fire performance of the electrical circuit and integrity of the cable to survive and continue operation in fire conditions.

FP600S Cables

Prysmian FP600S is the ultimate fire resistant, armoured Low Voltage LV cable for power and control of emergency, life safety and fighting systems used in buildings.

Prysmian FP600S is the ultimate fire resistant cable for power and control of emergency, life safety and fighting systems used in buildings.

FP600S has been designed and developed for the most stringent British Standard fire test for cables, BS8491 F120 and meets or exceeds the fire resistance requirements of Category 1,2 and 3 which makes it suitable for power and control circuits as defined in BS8519:2010.

Prysmian fire resistant cable is featured on the LU – Approved Products Register approved by London Underground meeting the criteria for LU 1-085 and is suitable for use in Section 12 (underground and surface) applications.

BS 8519:2010

This British Standard and Code of Practice covers the selection and installation of fire-resistant power and control cable systems for life safety and fire-fighting applications.

BS 8519:2010 replaces BS 7346-6:2005, which is now withdrawn.

High-rise and complex buildings have developed in terms of increased size, height and complexity of active fire protection. This has allowed fire engineered solutions to be developed. These solutions require a high level of performance from the components of the building services, including the electrical supplies.

BS 8519 gives guidance and recommendations on the selection and installation of power and control cable systems. It covers systems that are required to maintain their cable circuit integrity for life safety and fire-fighting applications. It also gives recommendations for electrical system design for such applications, and recommended limits for survival times.

BS 8519 identifies those electrical loads defined as life safety and fire-fighting loads. It lists the factors to be considered by the engineer when selecting and specifying the performance requirements of the electrical distribution system needed to maintain integrity under defined fire conditions for a specified period, referred to as the fire survival time.

BS 8519 makes reference to the recommendations identified in BS 9999, with regard to the design and installation of the LV Low Voltage electrical distribution systems for life safety and fire-fighting equipment.

The British Standard also makes reference to 3 categories of circuits required to maintain their circuit integrity under defined fire conditions for varying fire survival times of 30 min, 60 min and 120 min. Appropriate cable tests are identified for each category derived from applicable British Standards that assess cable performance under conditions of fire as might be expected in an actual fire incident.

This standard aims to ensure that the level of circuit integrity is not compromised by other components of the whole electrical distribution system, including cable glands, terminations, joints and cable support and location systems including stainless steel cable ties.

BS 8519:2010 covers

- The source of supply

- The distribution voltage [high voltage (HV) or low voltage (LV)]

- The appropriate location of the main intake enclosures, HV switchrooms, LV switchrooms, transformer rooms, generator rooms, risers, fire life safety plant rooms and fire-fighting/evacuation lift motor rooms/shafts.

Prysmian FP600S also meets or exceeds low fire hazard requirements of LSOH cable.

Prysmian FP600S – The Ultimate Fire Resistant Armoured Power Cable

- 600/1000V Cable

- BS7846 F120

- BS8491 120 Minutes

- BS8519 Category 1,2 & 3 Power & Control Circuits

- BASEC Approved Cable

- LPCB Approved Cable

- London Underground Approved LU 1-085A (Previously ‘Section 12’)

Prysmian manufacture a range Fire Resistant cable accessories including cable cleats and cable glands to support the installation of FP600S cables.

Prysmian FP Cables – FP600S Fire Resistant Cables for Emergency & Essential Building Services

Why Degrade Cable Integrity By Installing Underspecified Cable Accessories?

Sub-standard cable accessories are often inadvertently installed forming weak links in many fire resistant cable installations. Plastic cable cleats and “budget” type cable glands only serve to introduce potential “flash-points” into cable circuits whose primary purpose is the safety and protection of people, assets and infrastracture in the event of a fire. For this reason Prysmian only recommend the installation of approved fire resistant glands, cleats and accessories.

The following tables should aid the contractor and specifier to selecting the correct FP cleats, glands and lugs.

PRYSMIAN FP600S FIRE RESISTANT CABLE – SINGLE CORE CABLES

The following selection table features the recommended cable accessories including claw cleats and cable glands LSF to support and terminate Prysmian FP600S cables – for the termination of the stranded copper conductors into control panels, enclosures, junction boxes and electrical equipment Cembre lugs can be used.

| Nominal Cross Sectional Area (sqmm) | Approximate Overall Diameter (mm) | Approximate Diameter Under Armour (mm) | Nominal Diameter of Armour Wires (mm) | Approximate Cable Weight (kg/km) | Maximum Conductor Resistance at 20ºC (Ω/km) | Short Circuit Rating (1 second) of Conductor kA | Current Rating Three Phase AC Clipped Direct (Amps) | Current Rating Three Phase AC Free Air or Perforated Tray (Amps) | Volt Drop Three Phase AC (mV/A/m) | Recommended Accessories | |

| Claw Cleat Ref Number | Brass Gland Ref Number | ||||||||||

| Three Core Cables | |||||||||||

| 4 | 21 | 15 | 1.25 | 800 | 4.61 | 0.57 | 42 | 44 | 10 | 370CG04 | LSF25CW |

| 6 | 21 | 15 | 1.25 | 820 | 3.08 | 0.86 | 53 | 56 | 6.8 | 370CG04 | LSF25CW |

| 10 | 23 | 17 | 1.25 | 1050 | 1.83 | 1.4 | 73 | 78 | 4.0 | 370CG05 | LSF25CW |

| 16 | 24 | 19 | 1.25 | 1400 | 1.15 | 2.2 | 94 | 99 | 2.5 | 370CG05 | LSF25CW |

| 25 | 29 | 22 | 1.6 | 2000 | 0.727 | 3.6 | 124 | 131 | 1.65 | 370CG06 | LSF32CW |

| 35 | 31 | 24 | 1.6 | 2300 | 0.524 | 5.0 | 154 | 162 | 1.15 | 370CG06 | LSF32CW |

| 50 | 32 | 25 | 1.6 | 2800 | 0.387 | 7.1 | 187 | 197 | 0.87 | 370CG07 | LSF32CW |

| 70 | 36 | 29 | 1.6 | 3600 | 0.268 | 10.0 | 238 | 251 | 0.60 | 370CG07 | LSF40CW |

| 95 | 40 | 32 | 2.0 | 4500 | 0.193 | 13.6 | 289 | 304 | 0.45 | 370CG08 | LSF50SCW |

| 120 | 43 | 35 | 2.0 | 5400 | 0.153 | 17.2 | 335 | 353 | 0.37 | 370CG08 | LSF50SCW |

| 150 | 48 | 39 | 2.5 | 6900 | 0.124 | 21.4 | 386 | 406 | 0.30 | 370CG09 | LSF50CW |

| 185 | 52 | 43 | 2.5 | 8200 | 0.0991 | 26.5 | 441 | 463 | 0.26 | 370CG09 | LSF63CW |

| 240 | 57 | 47 | 2.5 | 10100 | 0.0754 | 34.3 | 520 | 546 | 0.21 | 370CG09 | LSF63CW |

| 300 | 62 | 52 | 2.5 | 12200 | 0.0601 | 42.9 | 599 | 628 | 0.185 | 370CG12 | LSF63CW |

| 400 | 69 | 58 | 2.5 | 15000 | 0.0470 | 57.2 | 673 | 728 | 0.165 | 370CG13 | LSF75CW |

| Four Core Cables | |||||||||||

| 4 | 21 | 15 | 1.25 | 800 | 4.61 | 0.57 | 42 | 44 | 10 | 370CG04 | LSF25CW |

| 6 | 23 | 17 | 1.25 | 950 | 3.08 | 0.86 | 53 | 56 | 6.8 | 370CG05 | LSF25CW |

| 10 | 24 | 19 | 1.25 | 1200 | 1.83 | 1.4 | 73 | 78 | 4.0 | 370CG05 | LSF25CW |

| 16 | 27 | 20 | 1.25 | 1600 | 1.15 | 2.2 | 94 | 99 | 2.5 | 370CG06 | N/A |

| 25 | 32 | 24 | 1.6 | 2400 | 0.727 | 3.6 | 124 | 131 | 1.65 | 370CG07 | LSF32CW |

| 35 | 35 | 27 | 1.6 | 2800 | 0.524 | 5.0 | 154 | 162 | 1.15 | 370CG07 | LSF40CW |

| 50 | 36 | 29 | 1.6 | 3200 | 0.387 | 7.1 | 187 | 197 | 0.87 | 370CG07 | LSF40CW |

| 70 | 41 | 32 | 1.6 | 4500 | 0.268 | 10.0 | 238 | 251 | 0.60 | 370CG08 | LSF50SCW |

| 95 | 44 | 36 | 2.0 | 5700 | 0.193 | 13.6 | 289 | 304 | 0.45 | 370CG08 | LSF50SCW |

| 120 | 49 | 40 | 2.0 | 7300 | 0.153 | 17.2 | 335 | 353 | 0.37 | 370CG09 | LSF50CW |

| 150 | 55 | 44 | 2.5 | 8600 | 0.124 | 21.4 | 386 | 406 | 0.30 | 370CG10 | LSF63CW |

| 185 | 59 | 48 | 2.5 | 10500 | 0.0991 | 26.5 | 441 | 463 | 0.26 | 370CG11 | LSF63CW |

| 240 | 64 | 54 | 2.5 | 12900 | 0.0754 | 34.3 | 520 | 546 | 0.21 | 370CG12 | LSF63CW |

| 300 | 70 | 59 | 2.5 | 15500 | 0.0601 | 42.9 | 599 | 628 | 0.185 | 370CG14 | LSF75CW |

| 400 | 79 | 66 | 3.15 | 20100 | 0.0470 | 57.2 | 673 | 728 | 0.165 | 370CG15 | LSF85CW |

| Five Core Cables | |||||||||||

| 4 | 22 | 17 | 1.25 | 900 | 4.61 | 0.6 | 42 | 44 | 10 | 370CG05 | LSF25CW |

| 6 | 24 | 18 | 1.25 | 1070 | 3.08 | 0.9 | 53 | 56 | 6.8 | 370CG05 | LSF25CW |

| 10 | 27 | 21 | 1.25 | 1390 | 1.83 | 1.4 | 73 | 78 | 4.0 | 370CG06 | N/A |

| 16 | 30 | 23 | 1.6 | 1900 | 1.15 | 2.2 | 94 | 99 | 2.5 | 370CG06 | LSF32CW |

| 25 | 34 | 26 | 1.6 | 2500 | 0.727 | 3.6 | 124 | 131 | 1.65 | 370CG07 | LSF40CW |

| 35 | 37 | 29 | 1.6 | 3100 | 0.524 | 5.0 | 154 | 162 | 1.15 | 370CG07 | LSF40CW |

| Nominal Cross Sectional Area (sqmm) | Approximate Overall Diameter (mm) | Approximate Diameter Under Armour (mm) | Nominal Diameter of Armour Wires (mm) | Approximate Cable Weight (kg/km) | Maximum Conductor Resistance at 20ºC (Ω/km) | Current Rating DC or Single Phase AC Clipped Direct (Amps) | Current Rating DC or Single Phase AC Free Air (Amps) | Volt Drop DC (mV/A/m) | Volt Drop Single Phase AC (mV/A/m) | Recommended Accessories | |

| Claw Cleat Ref Number | Brass Gland Ref Number | ||||||||||

| Two Core Cables | |||||||||||

| 4 | 21 | 15 | 1.25 | 800 | 4.61 | 49 | 52 | 12 | 12 | 370CG04 | LSF25CW |

| 6 | 21 | 15 | 1.25 | 800 | 3.08 | 62 | 66 | 7.9 | 7.9 | 370CG04 | LSF25CW |

| 10 | 22 | 16 | 1.25 | 800 | 1.83 | 85 | 90 | 4.7 | 4.7 | 370CG05 | LSF25CW |

| 16 | 23 | 17 | 1.25 | 1000 | 1.15 | 110 | 115 | 2.9 | 2.9 | 370CG05 | LSF25CW |

| 25 | 26 | 20 | 1.25 | 1300 | 0.727 | 146 | 152 | 1.85 | 1.9 | 370CG06 | N/A |

| 35 | 30 | 23 | 1.6 | 1800 | 0.524 | 180 | 188 | 1.35 | 1.35 | 370CG06 | LSF32CW |

| 50 | 31 | 24 | 1.6 | 2200 | 0.387 | 219 | 228 | 0.98 | 1.00 | 370CG06 | LSF32CW |

| 70 | 33 | 26 | 1.6 | 2600 | 0.268 | 279 | 291 | 0.67 | 0.69 | 370CG07 | LSF32CW |

| 95 | 35 | 27 | 2.0 | 3400 | 0.193 | 338 | 354 | 0.49 | 0.52 | 370CG07 | LSF40CW |

| 120 | 39 | 30 | 2.0 | 4100 | 0.153 | 392 | 410 | 0.39 | 0.42 | 370CG08 | LSF50SCW |

| 150 | 42 | 33 | 2.0 | 4700 | 0.124 | 451 | 472 | 0.31 | 0.35 | 370CG08 | LSF50SCW |

| 185 | 46 | 36 | 2.5 | 6100 | 0.0991 | 515 | 539 | 0.25 | 0.29 | 370CG09 | LSF50CW |

| 240 | 51 | 41 | 2.5 | 7500 | 0.0754 | 607 | 636 | 0.195 | 0.24 | 370CG09 | LSF50CW |

| 300 | 56 | 45 | 2.5 | 9000 | 0.0601 | 698 | 732 | 0.155 | 0.21 | 370CG10 | LSF63CW |

| 400 | 61 | 50 | 2.5 | 11000 | 0.0470 | 787 | 847 | 0.120 | 0.19 | 370CG11 | LSF63CW |

LV Cable Joints (Low Voltage Cables)

Thorne & Derrick stock and distribute LV Joints in Cold Shrink, Heat Shrink or Resin Cast technologies – multicore and multi-pair cable joints are available for immediate backfill and energisation of Low Voltage power, control and instrumentation cables 600V/1000V 3.3kV.

Complete range of LV Cable Accessories ➡

Cable Breakouts | Cable Caps | Cable Lugs | Cable Cleats | Cable Trough | Cable Duct | Feeder Pillars | for 11kV/33kV/66kV networks see MV HV Joints & Terminations

Pfisterer | Nexans Euromold | Prysmian | Cable Joints & Terminations MV HV

Cold Shrink by 3M | Joints | Abandonment | Terminations | Low Voltage LV Cables

IEC 60903 Gloves | Class 1 Insulating Gloves – Compliance Notes

April 26th, 2019

Insulated Gloves | Class 1 IEC 60903 Compliant Gloves

- Article by SP Energy Networks

The following information is contained with SP Energy Networks document OPSAF-12-025 Issue No.6: Insulated Gloves for Electrical Purposes Other Than HV Rubber Glove Working.

IEC 60903

IEC60903 produced by the International Electrotechnical Commission is an internationally recognised electrical safety standard: Live Working – Electrical Insulating Gloves.

IEC 60903:2014 is applicable to electrical insulating gloves and mitts that provide protection of the worker against electric shock.

This standard also covers electrical insulating gloves with additional integrated mechanical protection referred to in this document as “composite gloves“. The third edition cancels and replaces the second edition of IEC 60903, published in 2002 and constitutes a technical revision which includes the following major changes:

- clarification of the requirements and tests for long gloves

- introduction of a new special property for gloves resistant to leakage current

- removal of the requirement for an area to mark the date of inspection

- the d.c. electric tests are no longer included in the normative part of the document but a proof test is suggested at the production level in a new informative Annex E

- preparation of the elements of evaluation of defects, and general application of IEC 61318:2007

- introduction of a new normative Annex H on classification of defects

- introduction of a new informative Annex I on the rationale for the classification of defects

INSULATED GLOVES FOR ELECTRICAL PURPOSEs

SCOPE

This section of the Energy Networks Live Working Manual (LWM) details the rubber gloves to be used by all persons who are required to work or test on, or in close proximity to, Live LV Conductors and for certain switching and testing activities on the Live HV System (up to 33kV). For Company employees it also describes the process for issue and replacement.

This document deals with gloves which comply with IEC 60903 (2014) Class 1.

The specification for the use and testing of rubber insulated gloves in connection with HV Rubber Glove Working is contained in OPSAF-13-001 (LWM 8.4) HV Rubber Glove Working techniques.

DEFINITIONS

Terms printed in bold type are as defined in the Scottish Power Safety Rules (Electrical and Mechanical) 4th Edition.

POLICY

Class 1 7.5kV insulated rubber gloves to the relevant IEC 60903 (2014) standard shall be issued to SP Energy Networks employees and its appointed contractors who are required to work or test on, or in close proximity to Live LV conductors. They are not meant to be the sole means of protecting those who work or test on Live LV conductors.

These IEC 60903 insulating gloves shall also be issued to personnel who are required to operate air-break switch disconnector handles, overhead Apparatus in substation outdoor compounds, link / fuse operating rods or to use moving-coil Approved voltage indicators on the HV System.

Pictured: Up to 36kV Air Break Switch Disconnectors

The Lucy Electric Rapier SAX Air Break Switch Disconnector range is compact and robust, providing a reliable, lightweight and flexible solution for network isolation and reinstatement. Incorporating a modular design switch that can be configured to suit a variety of applications, the range combines high performance and reliability and is particularly suited to rural environments.

Air-Break Switch DisconnectorS | 33kV 36kV Lucy Electric

Class 1 insulated gloves shall not be used for HV Rubber Glove Working on Live HV conductors.

Note: although Class 0 rubber gloves are rated for 1000V and would be appropriate for Live LV systems, experience has found them to be prone to damage when the gloves are not used with gauntlets. Class 1 gloves are thicker and more suitable to be worn without gauntlets if required.

Class 0 gloves shall not be used by SP Energy Networks employees or its appointed contractors on the SP Energy Networks System.

The SP Energy Networks specification TSE-03-044 for rubber gloves according to IEC 60903 require a high level of electrical arc flash protection. It is strongly recommended that insulating gloves provided by contractors provide an equivalent level of protection.

It is recommended that a leather protective outer gauntlet be used while operating on the HV System to prevent premature damage. Gauntlets shall be available for Persons with a preference to use them while working or testing on, or in close proximity to Live LV conductors.

Leather gauntlets also provide electrical arc protection which augments that provided by the rubber glove.

A protective wallet, to the relevant SP Energy Networks standard for the storage of rubber gloves shall be issued to all Persons issued with rubber gloves.

SP ENERGY NETWORKS GLOVE REPLACEMENT POLICY

This section describes the SP Energy Networks policy for replacement of damaged or time-expired insulating gloves to IEC 60903.

Contractors shall implement their own policy which may complement or differ from the Energy Networks policy.

The rubber insulating gloves shall be replaced before re-testing is required.

Class 1 7.5kV insulated rubber gloves shall be replaced twice per year, i.e. at 6 monthly intervals.

When the insulated gloves are first removed from the sealed bag in which they are delivered, the date of opening shall be written on each glove along the edge of the cuff using a ball-point pen or similar.

All IEC 60903 rubber gloves shall be replaced in pairs.

The leather gauntlets and protective wallet need not be replaced at the time of replacement of rubber gloves, but only as required.

At the time of replacement, all gloves shall be destroyed by having the fingers cut off. Gloves which exceed 12 months from the manufacturer’s test date shall be destroyed in the same manner.

Individual pairs of insulating gloves may be issued at other times as required.

Insulated gloves issued must have the manufacturers test date stamped on each individual glove. Insulated gloves shall only be in use within 12 months of the test date. Gloves shall not be in use for more than a 6 month period.

Insulated gloves remaining in the store, which have not been issued and have been stored appropriately, can be issued for the remaining duration of the 12 month period from the manufacturers test date as long as it does not exceed 6 months of use.

ORDERING

The quantities of IEC 60903 gloves required shall be determined far enough in advance of the period of issue to permit an order to be placed and delivery taken immediately prior to the period of issue.

If supply chain difficulties prevent delivery of adequate supplies of replacement gloves, the Operational Assurance Manager (or nominee) may approve a temporary extension of use.

STORAGE

IEC 60903 gloves shall be kept in store unfolded in the containers in which they are delivered. They shall be kept in dry conditions, away from strong light.

SAFETY REQUIREMENTS IN USE

When issued, but not in use, gloves shall be kept in the protective wallet, which shall be used only for storing the gloves. The wallet shall be kept away from moisture, strong light, and the risk of mechanical or chemical interference.

On each occasion before use, insulated gloves shall be examined by the user to ensure that they are safe for use. The examination shall include the following:

- Check that the manufacturer’s test date on the gloves is not more than 12 months old

- Check that gloves have not been in use for more than 6 months

- Check that gloves are clean and dry, both outside and in

- Check that the rubber does not show blisters or abrasions

- Stretch the gloves by hand and check for tears, cuts and punctures

- Complete an air test to confirm no punctures

- Replace immediately, if either of a pair of gloves shows signs of not being safe. Both gloves shall be replaced

If, as a result of the examination, either or both of the gloves is found to be unsafe, then the pair shall not be used.

PRECAUTIONS IN USE

Insulated gloves shall not be allowed to remain soiled or unnecessarily exposed to heat or light or allowed to come into prolonged contact with oil, grease, turpentine, motor spirit or strong acid.

Gloves shall be wiped clean on completion of work to remove any surface contamination.

When insulated gloves become heavily soiled, they should be thoroughly washed with soap and water then dried. If insulating compound such as tar or paint still adhere to insulating gloves, then those parts affected should be cleaned with approved cable cleaners or degreasant and then immediately washed and treated as described above.

Petrol, paraffin, or white spirit shall not be used to remove such compounds. Rinse the gloves with clean water after washing.

Any insulated glove, which becomes wet in use or through washing shall be thoroughly dried. Where heated air is blown into the glove, it shall not cause the temperature of the glove to exceed 55ºC.

IEC 60903

Insulated Gloves – Class & Category

The following gloves manufactured by CATU Electrical do not provide mechanical protection and must be used with silicon leather glove covers or over-gloves.

| Insulating Gloves Class | CATU Electrical Code | Category | Thickness | Length | Colour | AC | kV | DC |

| Class 00 | CATU CG-05 | AZC | 0.5mm | 360mm | Beige | ≤ 500V | 0.5kV | 750V |

| Class 0 | CATU CG-10 | AZC | 1mm | 360mm | Beige | ≤ 1000V | 1kV | 1500V |

| Class 1 | CATU CG-1 | RC | 1.5mm | 360mm | Bi-Colour | ≤ 7500V | 7.5kV | 11,250V |

| Class 2 | CATU CG-2 | RC | 2.3mm | 360mm | Bi-Colour | ≤ 17000V | 17.5kV | 25,500V |

| Class 3 | CATU CG-3 | RC | 2.9mm | 360mm | Bi-Colour | ≤ 26500V | 26.5kV | 39,750V |

| Class 4 | CATU CG-4 | RC | 3.6mm | 410mm | Bi-Colour | ≤ 36000V | 36kV | 54,000V |

Insulated Gloves

Specialist Distributors Of LV MV HV Electrical Equipment

We supply Product Categories: Duct Seals | Cable Cleats | Cable Glands | Electrical Safety | Arc Flash Protection | Cable Jointing Tools | Cable Pulling | Earthing | Feeder Pillars | Cable Joints LV | Joints & Terminations MV HV

Ellis Patents | Nexans Euromold | Pfisterer CONNEX | Prysmian – Distributors