Blog

Exothermic Welding – 5 Benefits of the Exothermic Weld Connection

November 29th, 2018

Exothermic Welding

-

uploaded by Chris Dodds - Thorne & Derrick Sales & Marketing Manager

The following table highlights 5 Benefits of using Exothermic Welding systems for Earthing & Lightning Protection when permanently joining copper conductors.

| Mechanical Connection | Exothermic Welding |

| Connection is made by pressing and tightening. Contact connection. | Connection is made by fusion – welding is more reliable and durable. Irreversible molecular bond. |

| Lower conductivity than the copper conductors involved. | Conductivity equal to or greater than the copper conductors involved. |

| Transient connection. Electrical degradation over time. | Permanent connection. Lifetime equal to that of the earthing system. |

| Suffers with the flow of current, faults or repetitive discharges. | Able to withstand repeated current flow without degrading. Minimum maintenance. |

| Connection depends on the tightening torque applied by the installer. | Once the exothermic welding mould is closed the process is autonomous, reproducible and uniform. |

Exothermic Welding

AT3W & Thorne & Derrick

Thorne & Derrick are working with AT3W to introduce and develop specifications and business for the Apliweld Secure+ exothermic welding system.

Jason Leatherland (UK Manager AT3W) comments, “having worked successfully together with Thorne & Derrick in the past, I was keen to demonstrate and discuss this product system with them as I knew they would be best suited to showcase the system, and in particular, its increased health and safety benefits, to the most relevant sectors in order to increase the users efficiency and reduce the potential of site accidents from exothermic welding.”

Jonny Hewitt (T&D UK Power Team) added, “working with the UK DNO’s and their preferred ICP’s we look forward to further developing relationships and presenting the exothermic welding system to existing and new clients. We will be working closely with AT3W to introduce the product to market and improve worker and site safety in the utility industry.”

Pictured: Jonny Hewitt (T&D) with Jason Leatherland and Chris Dodds (T&D).

💡 HV Earthing & Lightning Protection Training Courses go to ➡ Online Training Resource provided by Ian Griffiths, Principal Engineer at GreyMatters. Ian is an Earthing & Lightning Consultant of 27 years, one of the top 1% UKAS accredited CDEGS consultants and professional advisor to international utility companies, data centre and infrastructure developers. See our Blog to learn more about GreyMatters and High Voltage Earthing.

LV MV HV Cable Accessories & Substation Electrical Equipment

Thorne & Derrick are Specialist Distributors of leading manufacturers of Cable Accessories, Substation Earthing, Jointing & Installation Equipment.

LV MV HV cable accessories from stock used to joint, terminate, connect, cleat and gland power cables to air and gas insulated substations, transformers, switchgear and overhead line networks.

LV 600/1000V ◊ MV 11kV 33kV ◊ HV 66kV 132kV

|

|

|

|

|

|

|

|

|

|

G81 ENA Engineering Recommendation – 11kV 33kV 66kV Joints, Terminations & Connectors WPD

November 27th, 2018-

uploaded by Chris Dodds - Thorne & Derrick Sales & Marketing Manager

G81

The following materials framework according to ENA Engineering Recommendation G81 Part 5 “Framework for Materials Specification for Industrial & Commercial Underground Connected Loads Up To & Including 11kV” includes the approved Cable Joints, Terminations & Connectors approved for use with HV Switchgear, HV/LV Transformers & Substations on the Western Power Distribution (WPD) network.

Should you require any technical support or have any commercial requirements about G81 Approved 11kV/33kV Cables & Accessories please do not hesitate to contact Thorne & Derrick Sales Team.

WPD

List Of Approved Materials & Suppliers 11kV 33kV 66kV

| Component | National Specification | Manufacturer | Size Type |

| Earth Rods | ENATS 43-94 | W Furse CBS Products ERICO (GB) |

|

| Cable Marker Tape | ENATS 12-23 and BS EN12613 | Fiberweb Geosynthetics Ltd | 150mm x 0.1mm x 365m |

| Fuses (LV) | BS88 Part 5 | Cooper Bussmann Ltd Lawson Fuses Ltd |

100A Slot 92mm 160A Slot 92mm 200A Slot 92mm 250A Slot 92mm 315A Slot 92mm 355A Slot 92mm 400A Slot 92mm 500A Slot 92mm 630A Slot 92mm |

| Link Boxes | Prysmian (2 or 4 way) Sicame (2 or 4 way) |

Insulated Resin Filled 2W Sicame Mk3 4W Sicame Mk 3 |

|

| Cut-Outs (100A) | BS7657 | WT Henley | Single Phase 100A Three Phase 100A SNE Link/Earth Terminal |

| Cut-Outs (Heavy Duty) | Lucy Switchgear | 400A Cut Out 600A Cut Out |

|

| Street Lighting Cut-Outs | Lucy Zodion | CNE 1 Pole CNE 2 Pole SNE 1 Pole |

|

| Connectors LV Mains Joints | IEC 61238-1 | TE Connectivity (B&H) | MSIP – Service UST – Straight USBT1 – Straight UBR – Branch UBRD – Cut Main BCNE-3UTB – Neutrals TAI, TA II & TAIII Consac Neutral VETA-33P-UTB |

| Connectors LV Service | IEC 61238-1 | TE Connectivity (B&H) | BTC – Straight BTCL 6-130W – Straight & Branch SSIPC |

| Connectors LV Terminations | IEC 61238-1 | TE Connectivity (B&H) | LVET Cable Lugs BET Cable Lugs ML Cable Lugs |

| LV Cable Joints | NAT ER C81/3 or BS EN50393 | TE Connectivity | Various depending on cable being jointed |

| 11kV Jointing Compounds | HD 628 & 629 | Lovink | Lovisil |

| 11kV EPR Single Core Cable | BS7870 Part 4.10 | Prysmian Cables, Tratos Cables, Nexans Cables, Quintas & Quintas Cables |

630sqmm |

| 11kV EPR Triplex Cable Cu | BS7870 Part 4.10 | Prysmian Cables, Tratos Cables, Nexans Cables, Quintas & Quintas Cables |

300sqmm | 400sqmm |

| 11kV EPR Triplex Cable Al | BS7870 Part 4.10 | Prysmian Cables, Tratos Cables, Nexans Cables, Quintas & Quintas Cables |

95sqmm | 185sqmm | 300sqmm |

| 11kV Terminations Indoor & Outdoor | HD 628 & HD 629 | TE Connectivity | 70-95sqmm Indoor CSTI3121-GB01, 185-300sqmm Indoor CSTI-3131-GB01, 400-630sqmm CSTI-3141-GB01 & Outdoor 70-95sqmm Outdoor CSTO-3121-GB01, 185-300sqmm Outdoor CSTO-3131-GB01 400-630sqmm CSTO-3141-GB01 |

| 11kV Straight Joints | HD 628 & HD 629 | Lovink | K85 – 95-185 sqmm K95 – 185-400 sqmm |

| 11kV Stop Ends | HD 628 & HD 629 | Lovink | K85 – 95-185 sqmm K95 – 185-400 sqmm |

| 11kV Live Break Elbows & Bushing Well Insert | HD 628 | Nexans (Euromold) | 11kV 95sqmm |

| 11kV Separable Connectors | HD 629.1 S1 | Nexans (Euromold) | 630sqmm Single – K440TB/G32- TMBC400-630 MWS 630sqmm Double – K440TB/G- P2-32 TMBC 400-630MWS; 300sqmm – K400TB/G-25-TMBC120-300 MWS |

| HD 629.1 S1 | Nexans (Euromold) Lucy Sabre Mk2 RMU | K430TB/G | |

| 33kV EPR Single Core Cable | HD 7870 Part 4 | Prysmian Cables, Tratos Cables, Nexans Cables, Quintas & Quintas Cables |

185, 300, 400, 630 and 800sqmm Single Core EPR |

| 33kV Joints | HD 629 | Lovink | Single Core Poly / Poly 185 to 1000sqmm Single Core Trif Joint 185 to 400sqmm Stop Ends 185 to 1000sqmm |

| 33kV Terminations | HD 629 | Ensto | 185 Through to 1000sqmm EPR Indoor & Outdoor Partially Insulated Terminations |

| 33kV Inner Cone Type Size 3 CONNEX Terminations | HD 629 | Pfisterer | 185sqmm to 800sqmm EPR Size 3 CONNEX Cable Terminations |

| 33kV Outer Cone Terminations | HD 629 | Euromold | 185sqmm to 800sqmm EPR (M)430 TB/G and (M)440TB/G Outer Cone Terminations |

| 66kV Joints | HD 629 | 3M | Single Core Poly / Poly 185 to 1000sqmm Single Core Stop Ends 185 to 1000sqmm |

| 66kV Terminations | HD 629 | 3M | 185 Through to 1000sqmm EPR Outdoor Partially Insulated Terminations |

| 66kV Inner Cone Type Size 4 CONNEX Terminations | HD 629 | 3M | 185 Through to 1000sqmm EPR Outdoor Partially Insulated Terminations |

| 66kV Outer Cone Terminations | HD 629 | Pfisterer | 185sqmm to 1000sqmm EPR Size 4 CONNEX Terminations |

| 66kV Connectors | HD 629 | Euromold | 185sqmm to 1000sqmm EPR (P)430 TB/G and (P)440TB/G Outer Cone Terminations |

Thorne & Derrick International

T&D distribute the most extensive range of MV & HV Jointing & Terminating, Installation & Cable Pulling Equipment – we service UK and international clients working on underground cables, overhead lines, substations and electrical construction at LV, 11kV, 33kV and EHV transmission and distribution voltages.

- Key Products: MV-HV Cable Joints & Terminations, Cable Cleats, Sealing Cable Ducts, Cable Transits, Underground Cable Protection, Cable Jointing Tools, Feeder Pillars, Cable Ducting, Copper Earthing, Electrical Safety, Cable Glands, Arc Flash Protection & Fusegear.

- Distributors for: 3M, ABB, Alroc, Band-It, Catu, Cembre, Centriforce, CMP, Elastimold, Ellis Patents, Emtelle, Furse, Lucy Zodion, Nexans Euromold, Pfisterer, Polypipe, Prysmian, Roxtec.

Read Our Blog: The Next Generation Of 11kV Transformers For MV HV Networks

Switchgear Cable Terminations

T&D distribute MV-HV Switchgear Cable Terminations to suit 11kV/33kV connections into air, oil and gas insulated switchgear or transformers including heat shrink, cold shrink and separable connectors for both inner cone and outer cone bushings from leading manufacturers including Nexans Euromold, 3M and Pfisterer.

♦ See more: Heat Shrink Cable Terminations 11kV 33kV | Cold Shrink Cable Terminations 11kV 33KV

MV HV – Medium & High Voltage Cable Joints, Terminations & Connectors (11kV 33kV EHV)

More…

T&D’s Power Blog covers: LV MV HV & EHV Transmission & Distribution, Substations, Switchgear, Cable Jointing & Termination, Cable Fault & Repair, Underground Cables.

➡ Visit Power Blog.

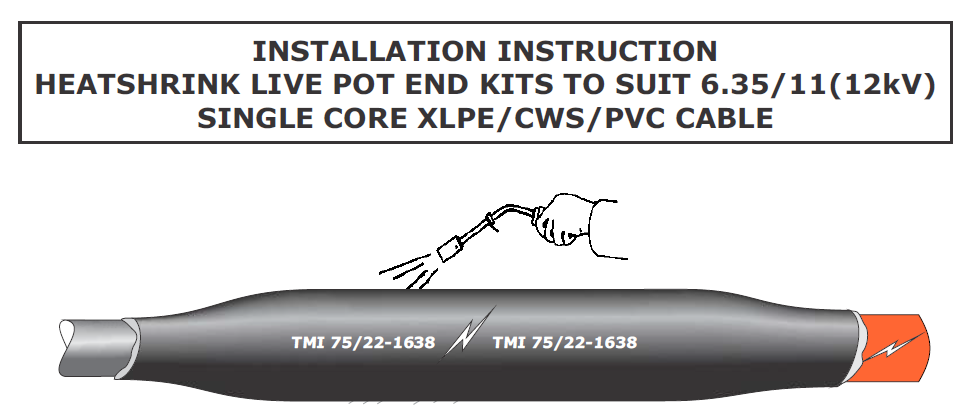

11kV Pot End Live Cable End Seal | 11kV Cables Single Core XLPE CWS

November 26th, 2018Complete range of cable abandonment kits and live pot end sealing kits for : 11kV HV High Voltage Cables Single Core XLPE CWS.

Kits also available for: 11kV HV High Voltage Cables 3 Core XLPE EPR Cables.

For 600/100V power cable systems see Live Pot End Kits for LV power systems.

➡ Joints | Terminations 11kV 33kV Heat Shrink

11kV

Installation Video: High Voltage Pot End Live Cable End Seals

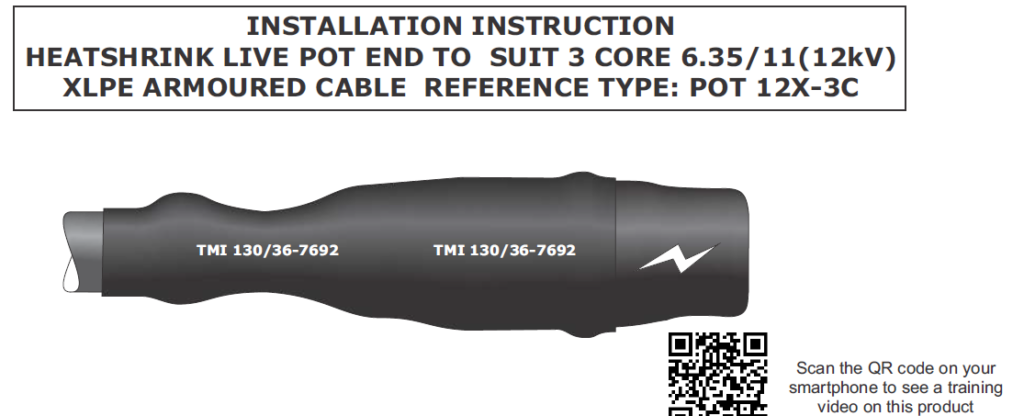

11kV Pot End Live Cable End Seal | 11kV Cables 3 Core XLPE EPR

November 26th, 2018Complete range of cable abandonment kits and live pot end sealing kits for : 11kV HV High Voltage Cables 3 Core XLPE EPR.

Suitable to provide 11kV Pot End Sealing of all types of 3 core polymeric insulated cables XLPE/EPR with copper tape screen and wire braid (PSWB GSWB) or wire armour (SWA).

For 600/100V power cable systems see Live Pot End Kits for LV power systems.

Kits also available for: 11kV HV High Voltage Cables Single Core XLPE CWS (Copper Wire Screened).

➡ Joints | Terminations 11kV 33kV Heat Shrink

11kV

Installation Video: High Voltage Pot End Live Cable End Seals

Arc Flash Clothing & Protection For Safe Windfarm & Wind Turbine Working

November 22nd, 2018

Arc Flash Clothing & Protection

-

uploaded by Chris Dodds - Thorne & Derrick Sales & Marketing Manager

Arc flash

Arc flash accidents are not nearly as rare as you would think and the hazards they create are severe. In wind turbines, these hazards are magnified.

Installing and maintaining wind turbines can be a tricky job and it is important to understand the importance of staying safe and Protecting Lives by wearing arc flash clothing including an arc flash helmet, insulating boots and arc flash gloves.

In fact, most employers wouldn’t dream of permitting their teams on site without adequate protection and workers themselves are more than clued up when it comes to the latest electrical safety equipment requirements.

However, the same can’t be said when it comes to the potentially fatal risk posed by an Arc Flash – a relatively misunderstood, but extremely common type of electrical explosion facing those working on onshore or offshore, private or commercial wind turbine projects.

Arc Myth Busted: Did you know most arc flash accidents occur in LV systems?

Especially legacy switchgear and switchboards undergoing the The Three R’s – retrofit, refurbishment or repair. Modern technology Low, Medium & High Voltage Electrical Equipment with integral insulated arc-free busbar assemblies, arc flash relays and arc quenching switchgear, such as manufactured by Eaton, minimises but does not eliminate the risk of arc flash completely.

Of course, the best way to avoid arc flash is to de-energise – nevertheless, Arc Flash can occur on power systems inadvertently made live while undergoing maintenance under planned isolation procedures.

Image: Safety Management Services, Inc.

A Wind Turbine Arc Flash Incident

The Clear & Present Danger

Although no injuries were reported – thankfully – the devastation inflicted to the wind turbine pictured below is extreme, to the point of destruction. That turbine is beyond repair.

Now imagine just for a moment if the wind turbine had been manned or the incident had involved manpower – the feasibility of providing urgent medical treatment to an injured worker in a nacelle at high level is complicated. Often, the physical workplace location of the wind turbine prevents rapid rescue and emergency intervention due to remoteness and accessibility – quite often offshore. By September 2018, the UK wind power sector consisted of 9,088 wind turbines with a total installed capacity of over 20.1 gigawatts: 12,222 megawatts of onshore capacity and 7,907 megawatts of offshore capacity.

Technicians from Vestas, the company that oversees the maintenance of the turbine, attended site in April 2018 to complete a damage assessment. An expert from the company, who specialises in examining wind turbines that have experienced major malfunctions and fires, began an investigation into how the fire occurred.

An engineer hired as part of the insurance claim eligibility process was able to look at the wind turbine and investigate the cause of the fire. According to the engineer’s findings, the turbine experienced an arc flash that caused an electrical fire.

Officials with Vestas have declared the nacelle a total loss, though the tower and foundation are reusable, and will be providing the client with the costs for options ranging from decommissioning of the wind turbine to replacement of the unit.

Clean-up at the site to remove the damaged nacelle occured over the summer but is not expected to be completed before the end of the year.

So don’t ignore The Arc – a few attributable costs of arc flash induced outages and downtime:

- Revenue loss incurred from inability to generate electricity. £100K’s-ish. Minimum.

- Outage period until repairs are complete. Weeks? Months??

- Replacement of damaged or destroyed equipment. Financially, don’t think about it.

- Consequential reputation damage. Immeasurable.

Image: Crown Estates

What Is An Arc Flash?

Hotter than the sun (around 20,000°C) and louder than a bullet, an Arc Flash is when an arcing fault releases dangerous levels of radiant energy, which vaporises metal that spews from the arc. The air is super-heated causing pressure waves that can propel individuals across rooms and create a deadly molten shrapnel.

It goes without saying; the extreme temperatures of an Arc Flash can burn clothing and human skin within fractions of a second, even if the operative is situated five or six metres away from the Arc Flash event. It can also result in an explosive pressure wave that can throw workers across the room and a sound blast that can rupture eardrums.

An Arc Flash event is also accompanied by a bright flash which can cause temporary or even permanent blindness.

Treatment for those that survive an incident can require years of skin grafts, hospital stays and rehabilitation – they may never recover sufficiently to regain their lifestyle, so it’s safe to say that choosing the appropriate PPE is key when it comes to Arc Flash safety.

Posing A Risk

Electrical in nature, Arc Flash poses a substantial risk to those working in the wind industry which is constantly growing in importance due to its potential to contribute significantly to our national energy needs.

When working on wind turbines or windfarms, Arc Flash incidents can occur in both low voltage environments as well as high voltage, with particular reference to the following incidents…

- Opening energised electrical cabinets and verifying zero energy (testing dead)

- Securing and removing lock out and tag out (LOTO) devices

- Conducting trouble shooting on energised equipment and parts

- Working on near or exposed live conductors

- Breaking ground to install turbines

It is worth noting that the above incidents are of broadly the same severity whether the turbine is part of a large commercial windfarm or one of the growing number of small scale turbines installed by businesses.

How To Protect Yourself Against Arc Flash

Arc Flash protection is found in specialist clothing and garments for “head-to-toe” protection – everything from arc flash coveralls to arc flash trousers.

Enhanced and effective arc flash protection is safely achieved by wearing layers of protective clothing and garments manufactured from inherent fibres and which feature specific Arc Flash resilient components. Without the correct high-quality garments, arc protection levels will be compromised.

In addition to quality, it’s important to consider the longevity of the garment – depending on how it’s manufactured it may lose its effectiveness. Always look for products that feature Arc Flash protective qualities in the thread, as opposed to just a sprayed material, which will lose its impact over time.

Arc Flash Risks & How To Prevent Them – Wind Turbines & Windfarms

Overview of Arc Flash Clothing | Contact us to discuss your garment and PPE requirements, we can mitigate risk with guidance on safe working practices and by providing appropriate worker clothing that offers advanced Arc Flash Protection that saves lives every day. Whether working on underground cables or overhead lines, here is a selection of workwear clothing – contact us to discuss your requirements;

>> Download Your Guide To Here <<