Blog

Repairing Cables In Industrial & Hazardous Area Onshore & Offshore Locations

September 7th, 2020

Repairing Damaged Cable Sheath

Repairing Cables

Guest Article | Carl Pike from Filoform UK

Industrial & Hazardous Area Onshore & Offshore Locations

Thorne & Derrick International are UK distributors for Filoform, a leading manufacturer of cable joints, duct seals and special resins for installation in the utilities, telecom, traffic, rail, fibre optic, street lighting and construction industries.

Have a damaged cable sheath or jacket?

Look no further – Filoform have innovated and made repairing a cable sheath simpler, stronger and hassle free.

Introducing

FiloSlim Cable Sheath Repair System

Whilst repairing damage to the outer sheath of a cable may seem like a formality, it is often subject to unforeseen conditions. Particularly if the cable is to be buried or subject to severe environmental elements.

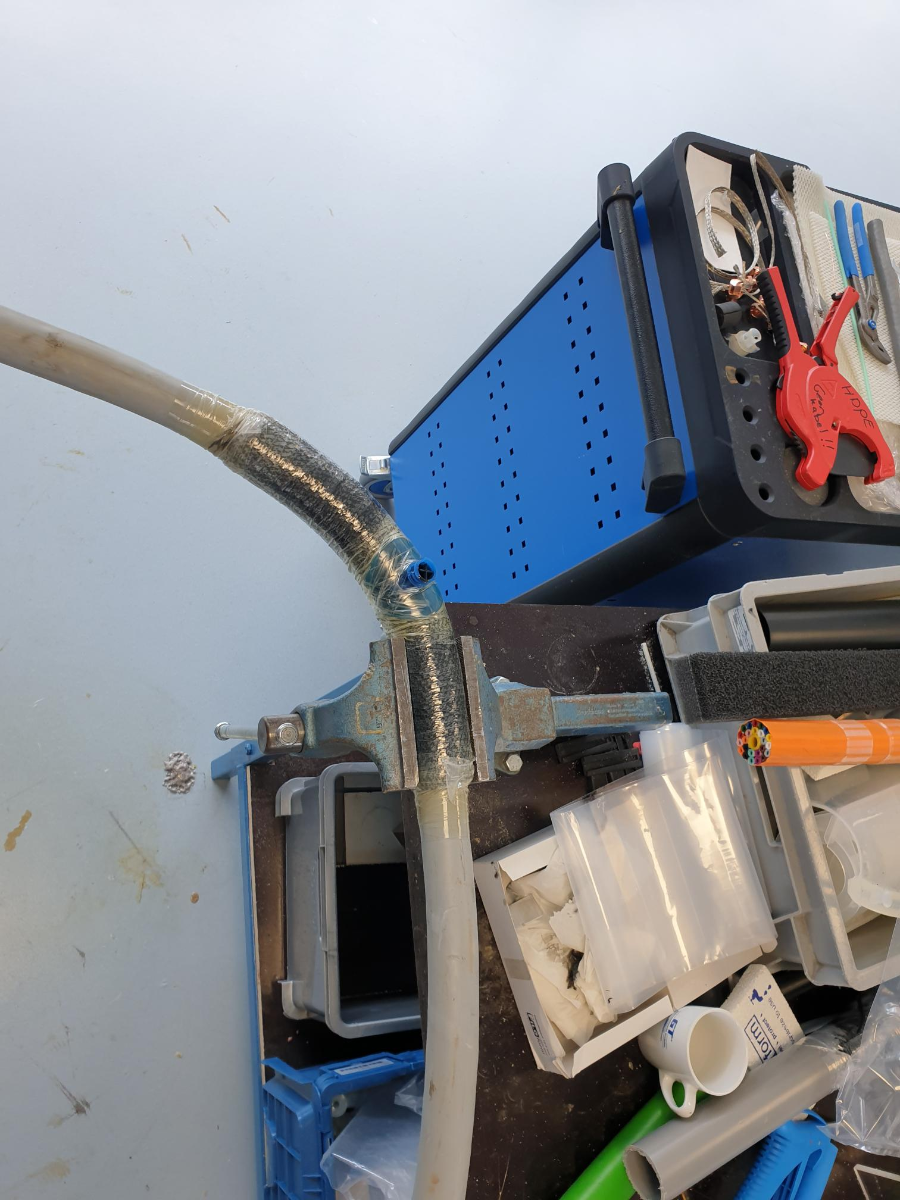

Recognising these situations – FiloSlim Cable Sheath Repair Kit can repair them quick & easily with NO heat or special tools.

Repair Damaged Cable Sheaths

The FiloSlim Cable Repair kit has been designed to accommodate all types of cable sheath, and to withstand the rigors of many applications.

EPR, XLPE, PVC, PILC LV, MV & HV cable sheaths

The unique Polyurethane Resin has been manufactured to offer protection in the harshest of conditions. Subsea, exposed to UV, wound onto cable drums and subject to attack by hydrocarbons within the petrochemical industry.

The FiloSlim Repair Kit is designed to offer a multi-functional, single solution, suitable to all markets. Onshore, Offshore, Hazardous Area, Direct Buried, Subsea: all remedied by a single product.

No heat source > total mechanical protection, suitable for low, medium and high voltage cables.

FiloSlim is a simple and effective method of repairing a damaged cable sheath and cable jacket. The flexibility of a quick and easy installation, coupled with the security of a long term seal against moisture, and the insurance of full mechanical protection.

Filoslim offers a welcome alternative to the historical heat shrink repair sleeves from TE Connectivity/Raychem CRSM, Hellermann RMS and DSG-Canusa CRDW.

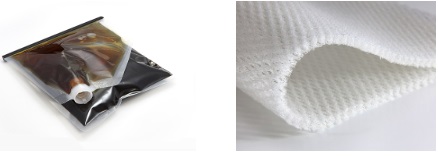

The totally enclosed mixing and pouring of the resin via the nozzle and non return valve.

Both the valve and outer tape wrap is removed easily at the end of the installation – offers a secure and safe method of work; even in the harshest of environments. From a pitching deck to a frozen landscape, Filoslim is quick, safe and easy to apply.

No specialist tools. NO HEAT source or naked flame.

One kit to suit all cable diameters up to 170mm, and the ability to offer bespoke solutions beyond that. Sheath repair made simple.

Questions & Answers

1, Can the blue injection valve be removed?

Yes, the tape and valve can be de-laminted after 1 hour of dispensing the resin.

2, Is the resin flexible?

Yes, the resin will flex but does require a little force.(Example below shows a 95sqmm 4 core un-armoured cable)

3, Will the FiloSlim cable sheath system repair work if the damage is through to the conductor?

If we are talking about an LV cable, unarmoured, and with no damage to the conductor; we would say its fine. The conductor insulation being intact has retained the original integrity of the primary insulation within the cable;

However, if the insulation around the conductor has been damaged, we would propose stripping back a section of the cable and exposing the damaged area but not cutting the cable.

Over-taping this with self-amalgamating tape will restore the original integrity, and then the kit can be used from there.

filoslim Features:

- No heat source required

- No specialist tools

- Enclosed mixing and pouring

- Suitable for cables up to 170mm diameter as standard

- Suitable for use as a moisture seal

- Suitable for direct buried and vertical application cable repairs

- Suitable as an outer seal on EPR, XLPE, PVC and PILC LV and MV cable sheaths

- Void filling properties of the resin, negate the requirement for additional mastic tapes or gap fillers

- Seawater resistant repairs to cables

- Hydrocarbon resistant repairs to cables

- Kit contains all components required; including the resin, tape, nozzles and gloves

- Can be de-laminated (tape and blue injection valve can be removed, when cured)

LV Cable Joints (Low Voltage Cables)

Thorne & Derrick stock and distribute LV Joints in Cold Shrink, Heat Shrink or Resin Cast technologies – multicore and multi-pair cable joints are available for immediate backfill and energisation of Low Voltage power, control and instrumentation cables 600V/1000V 3.3kV.

Complete range of LV Cable Accessories ➡

Cable Breakouts | Cable Caps | Cable Lugs | Cable Cleats | Cable Trough | Cable Duct | Feeder Pillars | for 11kV/33kV/66kV networks see MV HV Joints & Terminations

MV Cable Jointing & Some Jointers Tips Using 3M Scotch Tapes

September 7th, 2020Today Levingston George, Lead Specialist Electrical Engineer at AM/NS Calvert in Alabama shares some cable jointing tips using 3M Scotch Tapes.

Levingston George has over 40 years of experience within the construction, maintenance and utilities industries – a Certified High Voltage Cable Splicer/Lineman and industrial electrician having worked in more than 26 countries on multi-million dollar projects.

Scotch

Levingston kindly shares some “tips n tricks” using 3M Scotch Electrical Tapes in the medium voltage power industry.

“In cable splicing and jointing all cable insulation needs to be sanded, be it XLPE or EPR insulation.”

“A good rule of thumb is “cleanliness is the rule and the cleaner the cable joint the better it will operate and test.”

“Many jointers do not understand the requirement of the semi-con screen being square and perfectly cut. SRM (stress relief material) in many of the splicing kits is often disregarded – and then the cable fails. I have also noted that many cable jointers use indenter crimp tools and they forget to fill the voids left by the crimping tool.”

“Then the butt splice has air voids and this leads to cable failure. If using an indenter type crimp tool always fill the voids created by the tool with mastic. I have found Scotch 2229 Mastic Tape to be effective for the application. Also 600 volt butt splices should never be used on medium voltage cable – the cable should be chamfered at the butt splice and the butt splice itself (MV and HV butt splices) are tapered for a reason.

“I also use Scotch 13 Semi Con Tape to go over the butt splice to place the strand shield back on to the medium voltage cable. This prevents air voids at the conductor entering the butt splice and returns the cable to its configuration prior to making the cable splice. PILC is still around here in the USA and there are few splicers who are actually trained to repair it professionally,” informs Levingston.

Here a lineman/cable splicer is using 3M Scotch 33tape to provide electrical insulation layers to a medium voltage cable– taping up the neutral tails.

Further Reading

- 6.6kV 3 Core Cable Breakout Using 3M Scotch Tapes

- 3M Electrical Tapes – Scotch Brand Electrical Tapes From 3M

- Some 3M Scotch Electrical Tapes Tips & Skills….

LV, MV & HV Jointing, Earthing, Substation & Electrical Eqpt

Thorne & Derrick International are specialist distributors of LV, MV & HV Cable Installation, Jointing, Duct Sealing, Substation & Electrical Equipment – servicing UK and global businesses involved in cable installations, cable jointing, substation, overhead line and electrical construction at LV, 11kV, 33kV and EHV.

THORNE & DERRICK Product Categories: Duct Seals | Cable Cleats | Cable Glands | Electrical Safety | Arc Flash Protection | Cable Jointing Tools | Cable Pulling | Earthing | Feeder Pillars | Cable Joints LV | Joints & Terminations MV HV

Access Chambers for LV HV Power & Trackside Rail Cables | HS2 Case Study

September 7th, 2020

Access Chambers for LV HV Power & Trackside Rail Cables

Access Chambers

LV HV Power & Trackside Rail Cables

HS2 Case Study

The vast scope of redevelopment by Cubis to transform London Euston Station into the first modern, intercity transport hub for high-speed rail services is well underway. Euston Station is one of 4 stations that will be transformed ahead of the new High Speed 2 (HS2) rail line connecting London to the Midlands, the north of England and Scotland.

Network Rail and Skanska, on behalf of HS2 are delivering enabling works at the station and surrounding area, with the groundworks being subcontracted to Kilnbridge. This will see the eventual construction of a 25,260m² terminus, new high-speed platforms and improvements to the surrounding open public areas.

To enable the new Euston station development to take place, works have begun on constructing a new electrical substation that will assist in powering the station and its facilities.

Cubis Modular Access Chamber Range STAKKAbox

The new substation, located just off the main London Euston line at Barnby, has been erected to distribute both HV and LV power cables into the substation and onward to the track and station. The substation, like many new buildings in London, is located within a restricted area with limited access, storage and mobility.

The project had a requirement for cable draw pits with easy accessibility for new power cables and in the future-proofing of the development for any new HS2 station and track cabling requirements. However, site conditions would not allow for a traditional concrete access chamber construction due weight and access restrictions. Cubis were approached to provide advice on our innovative, lightweight and modular access chamber range, STAKKAbox™.

ULTIMA Access Chamber

The team at Skanska worked with the Cubis Technical team to design and specify STAKKAbox™ ULTIMA Connect due to its lightweight and flexible onsite capabilities with the capacity to be installed manually without the need for skilled wet trades.

The individual 150mm deep sections of twin-wall GRP that make up the ULTIMA Connect chamber system provided a lightweight, modular solution with components falling under 25kg making them suitable for a single person lift under manual handling regulations.

With the added flexibility of being delivered to site with pre-drilled duct entries and the need only to reassemble the chamber components, the overall installation was significantly faster in comparison to conventional alternatives.

STAKKAbox™ ULTIMA Connect was designed and supplied to seamlessly integrate with Cubis’ B125 composite AX-S™ recessed access covers, providing a complete site chamber access and cover solution, while offering an improved aesthetic finish to the open public space, situated alongside the new substation. This integrated system offered a complete solution for the customer, reducing both time, health and safety risks and resulting in a significant overall cost saving.

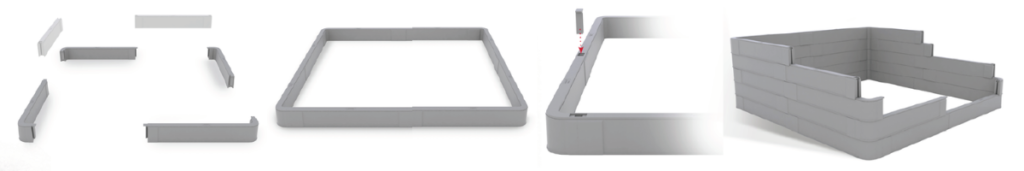

Access Chamber Step By Step Installation Guide

CUBIS ACCESS CHAMBERS

STAKKAbox™ chambers are significantly faster to install than conventional alternatives, with complete installations typically taking under one hour. This results in reduced costs for the installer and significant time saving. No specialist equipment or plant is required in order to install an access chamber and there is no need for specialist box builders. With flexible installation, Cubis access chambers can be adapted to suit on-site conditions with standard tools to build over existing networks.

Cubis | Access Chambers, Access Covers, Cable Protection & Cable Accessories

LV, MV & HV Jointing, Earthing, Substation & Electrical Eqpt

Thorne & Derrick International are specialist distributors of LV, MV & HV Cable Installation, Jointing, Duct Sealing, Substation & Electrical Equipment – servicing UK and global businesses involved in cable installations, cable jointing, substation, overhead line and electrical construction at LV, 11kV, 33kV and EHV.

THORNE & DERRICK Product Categories: Duct Seals | Cable Cleats | Cable Glands | Electrical Safety | Arc Flash Protection | Cable Jointing Tools | Cable Pulling | Earthing | Feeder Pillars | Cable Joints LV | Joints & Terminations MV HV

Protect Your Electrical Equipment From Electromagnetic Threats | Roxtec ES Sealing System

September 7th, 2020

Roxtec Sealing Systems: Electromagnetic Shielding

Roxtec Cable Seals

Electromagnetic Shielding

Roxtec cable seals are used in cable vaults, duct banks, electrical substations, trenches and M&E building services protecting low, medium and high voltage power systems against numerous external risk factors including fire, gas, water, cables, pressure, electrical, particles and blast.

Electromagnetic shielding

Why do you have to protect critical LV MV HV infrastructure equipment against EMI, IEMI, EMP and HEMP? How can you both seal and secure the electromagnetic shield? There are many questions regarding electromagnetic threats.

Roxtec are happy to be able to provide answers – and cable transit solutions.

Their skills and expertise enable the correct solution to be chosen that has electromagnetic shielding alongside fire, gas and water ingress certification.

What is EMI, IEMI, EMP and HEMP?

EMC refers to good electromagnetic compatibility.

Disturbances can be attributed to electronics like computers and mobile phones.as well as war or acts of terror. They can majorly affect electrical equipment and critical power supply to hospitals, banks and server halls, and a blackout can be very expensive.

- EMI – electromagnetic interference

- IEMI – intentional electromagnetic interference

- EMP – electromagnetic pulse

- HEMP – high altitude electromagnetic pulse

The Roxtec ES sealing system

The Roxtec ES sealing system provides an effective protection when used in shielded environments. It diverts conducted disturbances, shields against radiated disturbances and provides a mechanical and environmental protection against fire, gas, water, dust, dirt and rodents.

HEMP protection

Some 3M Scotch Electrical Tapes Tips & Skills….

September 6th, 2020

3M Scotch Electrical Tapes

-

uploaded by Chris Dodds - Thorne & Derrick Sales Marketing Manager

3M Scotch Electrical Tapes

Once upon a time, 3M introduced a revolutionary electrical tape.

That was in 1946 when the vinyl electrical tape patent was issued and since then 3M Electrical have pioneered the role of electrical tapes for maintenance and repair jobs.

So the humble PVC insulation tape was born and named Scotch 33 – this tape evolved into the mass-market over the proceeding decades to become established as the Number 1 PVC Electrical Tape.

And the rest as they say is history…

- 1951 Improved aging, higher temperature performance and wet dielectric

- 1952 Improved cold weather handling characteristics

- 1953 Improved slitting and telescoping performance

- 1957 Flame retardant properties developed

- 1961 Improved adhesive anchorage to cables, joints and splices

Quickly No. 33 Tape manufactured by 3M and branded Scotch became the new standard for insulating electrical connections and cables.

In 1966, when England were winning World Cups, the standard Scotch 33 tape became “Super” – the introduction by 3M of this new and improved electrical tape commonly called “Super 33” had a new operating temperature rating up to 176º F and was coloured black for UV resistance.

All Scotch electrical tapes exhibit smooth unwind and excellent handling characteristics.

Essentially, 3 basic qualities must be carefully evaluated when choosing your tape:

Essentially, 3 basic qualities must be carefully evaluated when choosing your tape:

- Shear Adhesion or “Holding Power”

- Peel Back or “Pull-off Strength

- Thumb Appeal or “Quick Stick”

Peel Back measures the adhesive resistance of the electrical tape to be peeled away from the surface to which it is adhered – the thumb appeal measures the quality of the adhesive to actually feel sticky and retain the bond strength without suffering departure from the surface.

This tendency for adhesive “creep” can lead to the need to remove and re-tape the application to maintain the electrical insulation and mechanical protection.

Additionally, consider the following factors when choosing an electrical tape: backing construction, tape thickness, and dielectric strength.

High tensile strength, excellent elastic memory and stable recovery – specify 3M Scotch

Taping Skills & Tips

Overtime the use of conventional electrical tapes has declined as modern product advances, such as 3M Cold Shrink Tubes, have replaced traditional taped solutions for effecting cable repairs, jointing and termination. Even though electricians are unlikely to consider “old-school” taping skills to be an important element in the engineers skill-set of today the importance of cable splice and termination taping skills for electricians, jointers and linesmen remain a focal element of training courses.

Watch the electrical taping techniques of an experienced cable jointer using 3M Scotch 33 tape to provide electrical insulation layers to the cable – neutral tails are taped up here with the cable splicer demonstrating the slick pass, stretch and apply method to the Scotch tape.

Here are several good reasons to master the craft of electrical taping.

When quick “on the spot” electrical and cable repairs are required and other products are simply not available, 3M Scotch Electrical Tapes can be real “day-savers”.

3M Electrical Tapes offer long-term performance, excellent adhesion, chemical resistance and temperature performance – their smooth unwind from the roll can provide “quick-fix” and simple solutions to electrical insulation tasks straight out the engineers pocket.

The primary 3M Scotch tapes used in electrical applications are vinyl, rubber, mastic, varnished cambric and corrosion protection.

Thorne & Derrick Stockists & Suppliers | 3M Scotch Tapes

Weatherproof & Watertight Taping

The function of moisture-sealing tapes such as vinyl, rubber, and mastic products is to exclude moisture from the insulation assembly and provide electrical insulation to cable, splices and terminations. One of these Scotch tapes — or alternatively a 3M mastic pad — generally forms the second layer of the insulation assembly. Rubber, mastic, and filler tapes are also used to pad the underlying surface by covering sharp edges.

LV Tapes

3M rubber tapes are generally non-adhesive and are either equipped with a liner (Scotch 23) or are linerless (Scotch 130C). Stretched and overlapped layers of the tape will fuse or bond together – “self amalgamating“ – to form an effective electrical insulation and moisture barrier. For low-voltage (1000V or less) applications, rubber tapes should be stretched during wrapping so that tape width is reduced to approximately 75%.

linerless (Scotch 130C). Stretched and overlapped layers of the tape will fuse or bond together – “self amalgamating“ – to form an effective electrical insulation and moisture barrier. For low-voltage (1000V or less) applications, rubber tapes should be stretched during wrapping so that tape width is reduced to approximately 75%.

Similarly, low voltage inline splices, connectors and joints can be protected using Scotch tape by wrapping the installed connector with four half-lapped layers of rubber mastic tape or rubber splicing tape, and then over-wrapping it with two half lapped layers of premium vinyl electrical tape, such as Scotch 33.

MV & HV Tapes

For high voltage (HV) and medium voltage (MV) applications — where the electrical stresses are high (e.g. connector areas, cable lug areas and cable shield semicon cut-back areas) — electrical tape should be stretched just short of its breaking point.

3M Vinyl Tape forms the final outer layer and serves several important functions in addition to electrical insulation, including abrasion protection, corrosion resistance, UV resistance and protection from chemicals including alkalis and acids.

insulation, including abrasion protection, corrosion resistance, UV resistance and protection from chemicals including alkalis and acids.

Conformable vinyl tape is tougher than the softer, stickier surfaces of rubber, mastic, and putty tapes it protects. Several grades of vinyl electrical tape are available — all of which differ in conformability, ease of unwinding, resistance of the adhesive to heat and cold, and loosening (flagging).

Brandname Scotch

The Scotch brand is a registered trademark of 3M Electrical and is synonymous with the highest levesl of quality, performance and reliability. So much so, Scotch has became a language term for the entirety of the market niche that the respective brand dominates. But unlike some lapsed and generic trademarks such as Lollipop, Trampoline or Aspirin, the Scotch brand which recognises problem-solving as the ultimate creative act continues to pervade and guide customer choice and preference.

Insulating Cables

While general-use vinyl tapes are appropriate for bundling, wire pulling and other ancillary tasks, Scotch 35 premium-grade vinyl tape is the best choice for permanent insulation work as it handles the broadest range of environmental factors and functions, such as chemical resistance – available in a rainbow rich choice of colours.

The combination of elastic backing and aggressive adhesive provides moisture-tight electrical and mechanical protection with minimum bulk. For cold weather applications down to – 18°C, Scotch 88 tape is recommended.

3M Scotch 35 and Scotch Super 88 available ex stock

Electricians should use a minimum of two half-lapped layers of 3M vinyl tape to insulate and jacket low-voltage cables, cable sheaths and electrical components. A half-lap consists of overlaying each turn by one-half the width of the tape. The general rule of thumb calls for a tape thickness of 1.5 times the thickness of existing wire or cable insulation.

Two half-lapped layers of 3M vinyl tape

In every case, tension on the electrical tape should be sufficient to conform the 3M Scotch tape evenly to the surface. A slight reduction in tension is encouraged for the final wrap. Trim the Scotch tape end and allow it to return to shape before pressing down with the thumb to avoid lifting or flagging.

Further Reading

How To Repair A Damaged Cable Jacket With 3M Mining Cable Splice Kits 3100 Series

3M Scotch Tapes – PVC Vinyl Electrical Tapes

3M Scotch Tapes

Further details on the complete range of 3M Scotch Electrical Tapes can be found here:

- 3M Scotch Insulation Tapes

- 3M Scotch Self Amalgamating Tapes

- 3M Scotch Mastic Tapes

- 3M Scotch Corrosion & Fire Protection Tapes

- 3M Scotch Glass Cloth Tapes

- 3M Scotch 24 Tape – Electrical Shielding Earthing Tape

- 3M Scotch 25 Tape – Electrical Shielding Earthing Tape

➡ The following tape application table provides an overview of the standard uses of Scotch Electrical tapes:

| Scotch Electrical Uses | Vinyl Tapes | Rubber Tapes | Varnished Fabric Tapes | Mastic & Filler Putty Tapes |

| Protective Cable Jacketing | X | X | ||

| Electrical Insulation | X | X | X | X |

| Moisture Sealing | X | X | ||

| ID & Colour Coding | X | |||

| Cable Harness Bundling | X | |||

| Mechanical Padding | X | X | X | |

| Shaping | X | X | X | |

| Re-entry | X | X |

➡ Visit 3M Electrical for further information about joints, terminations, tapes and insulation to seal, repair, splice and connect LV MV HV cables.

Cold Shrink | Joint | Terminate | Seal | Repair | Splice | LV MV HV Cables | 3M

- 3M Electrical Products Stocked By Thorne & Derrick International

LV, MV & HV Jointing, Earthing, Substation & Electrical Eqpt

Thorne & Derrick International are specialist distributors of LV, MV & HV Cable Installation, Jointing, Duct Sealing, Substation & Electrical Equipment – servicing UK and global businesses involved in cable installations, cable jointing, substation, overhead line and electrical construction at LV, 11kV, 33kV and EHV.

THORNE & DERRICK Product Categories: Duct Seals | Cable Cleats | Cable Glands | Electrical Safety | Arc Flash Protection | Cable Jointing Tools | Cable Pulling | Earthing | Feeder Pillars | Cable Joints LV | Joints & Terminations MV HV