UK DNO Approved Equipment

Cut Outs & Isolators | The Street Weapon In Street Lighting Safety by Lucy Zodion

August 4th, 2021

Street Lighting Safety

Cut Outs & Isolators

An industry leader in the design and development of street lighting control products, Lucy Zodion offers a range of solutions that span from the ground up; encompassing in-ground feeder pillars right through to cloud based IoT street lighting management. In the Highways industry, one of the key ranges Lucy Zodion offers is fused products.

Fused products or cut-outs and isolators have an important job that is often taken for granted – they terminate a supply cable and provide electrical protection for the light on the column, improving safety for those maintaining and upgrading lamp post infrastructure.

Greater awareness of safety & quality

Lucy Zodion understands that certain measures and standards should be met in order to ensure the safety of street lighting columns, where the independent testing of fused products contributes to their suitability in the field. From the materials such products are made with, to the way they are engineered to function, all are considerations before they can be used and installed.

The quality and manufacture of fused products contribute to their safety and reliability in the field. This is something that carries great impetus and should be understood by all in the industry. This paper explores what is currently known about fused products (from a manufacturing point of view) and the quality measures that are currently in place, to assure safety and quality.

What we know

British Standards

To comply with a British Standard indicates that a company/organisation takes its responsibilities seriously; compliance is often taken as evidence of due diligence.

By following the processes recommended in a Standard, it implies that impetus is made on doing things properly. It is important to highlight that standards aren’t the same as regulations; following a standard doesn’t guarantee that the relevant laws are met, due to the fact that legislation could change within the lifetime of the Standard. But, companies that follow the standard give customers and collaborators confidence that measures are being taken to provide a high level of quality in the products they produce.

In respect of the context of this paper, reference is made to the BS 7654 Standard, which is for single phase street lighting cut-out assemblies for low-voltage public electricity distribution systems – 25A rating for highway power supplies and street furniture. This is a standard which covers the whole of the product and not just parts. From constructional and performance requirements, normal service and mounting conditions over all sizes, the Standard requires the designed unit to pass the tests prescribed within it. This is to ensure firstly that the unit is safe.

A large part of the Standard is the type testing that the designed unit has to pass; these tests will prove that the unit will be fit for purpose in service.

Such tests include:

Terminal Torque Test

This is a test which proves that terminals have the strength to be tightened to a given torque onto a copper rod, for a period of one hour and to show no signs of cracking or distortion; thus proving its durability in the field.

In regards to the material /design of the terminal – it states which material cannot be used, to the minimum amount of threads (all screw holes with pinching screws shell contain at least three full threads conforming to BS 3643).

In reference to the design of the unit – a simple part of the Standard gives the layout of the terminals, stating that Phase Neutral and earth shall be positioned from left to right and viewed from the front, so that an operative will instinctively know their way around the cut out unit.

Where the standard does not cover the requirement in full, it will refer to other standards that will. This Standard also covers the IP levels required (IP22), again safeguarding the operative material choice is one area which is heavily scrutinized by the standard – this is covered by several tests:

Impact Test

This prescribes how the test is to be carried out. Impact energy of 0.25J, 2 Sets of units (6 in each); Test 1 at room temperature and Test 2 after the units have been at a temperature of -25°C for a period of not less than 18 hours, and is struck the amount of times as prescribed in the standard (three times).

This will prove the suitability of the given material and design; it proves both its durability and that the given materials will not shatter and expose dangerous parts. Clearances and creepage distances are also stated and are to be a minimum of 6mm.

The flammability test should be in accordance with BSEN 60695-11-10 test method A, which is a horizontal burn test.

Hot Ball Test

This is when a piece of apparatus with a 5mm diameter ball is pressed against the material surface with a force of 20N. and placed into a heating cabinet; this can be at different temperatures depending what the material is specified for:

- 125°C for insulating materials which retain current carrying parts,

- 70°C for other insulating material not necessary to retain current carrying parts in position

After a period of 1 hour, the test material is immersed in cold water at which point the diameter of the impression by the ball shall be measured.

Resistance to Tracking

This tests the material which in itself involves a series of tests, carried out in accordance to the Standard BS EN 60112.

In principle, this test requires the upper surface of the test specimen to be supported in an approximately horizontal plane and subjected to an electrical stress via two electrodes. The surface between the electrodes is subjected to a succession of drops of electrolyte, either until the overcurrent device operates, or until a persistent flame occurs, or until the test period has elapsed.

The individual tests are of short duration (less than 1 h) with up to 50 or 100 drops of about 20mg of electrolyte falling at 30 second intervals between platinum electrodes, 4mm apart on the test specimen surface. An AC voltage between 100 V and 600 V is applied to the electrodes during the test, where specimens may also erode or soften, thereby allowing the electrodes to penetrate them.

Resistance tracking is an important part of the testing process and pins down the characteristics of the materials used, as well as their ability to withstand environments similar to those in the field. Without such testing and the supporting certification, safety and performance cannot be assured.

Type Test

One of the main parts of the type test is the section on the performance side. These tests are designed to test the units in operation, temperature rise testing at maximum rating. Temperature rise test is when the unit is loaded to the maximum of 25A and is left on until it reaches a stable state; testing that the temperature limits stated for this test are not exceeded.

Cyclic loading of the unit puts the unit on test for 1h on/1h off, for a period 2000 cycles. At every 100 cycles a standard temperature rise test is carried out (this test alone can take approximately 6 months to carry out).

The BS 7654 Standard is extensive and the above information is not exhaustive of its entirety, however highlights the attention to detail that is required in certain aspects of the Standard.

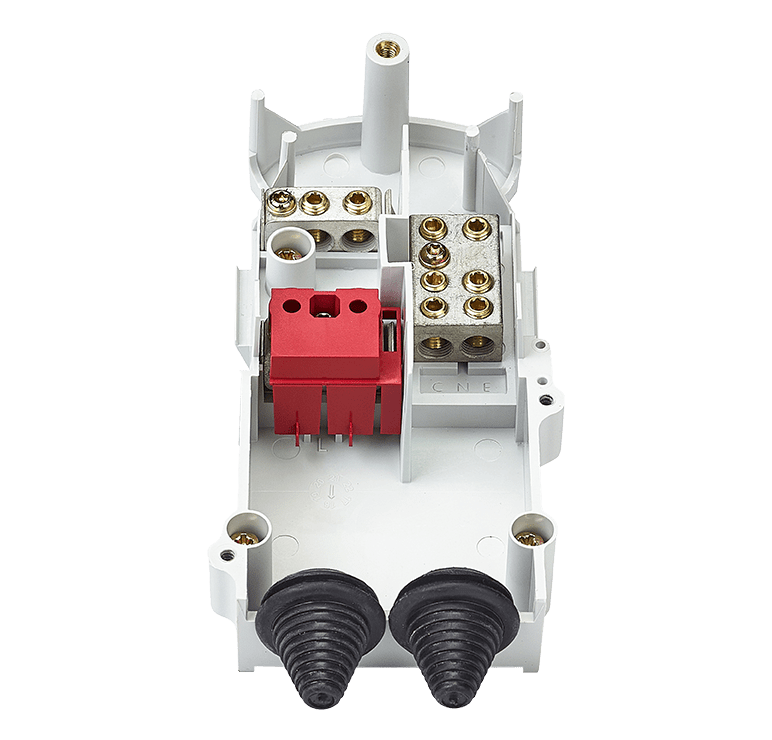

Cut outs

Cut outs are needed in every Distribution Network Operator (DNO) supplied streetlight in the UK. A cut out has its own British Standard, BS 7654 (as detailed above), which covers all aspects of the cut out from the materials it’s manufactured from to a series of tests relating to temperature, ingress protection, current, mechanical strength; it even states its physical size. Manufacturers must be able to prove this with an independent certification and this is something that those buying the product should always ask for.

The cut out comes with a set of terminal blocks, designed to accept cables up to 25mm² and has a suite of accessories that include extension pieces, brass and plastic cable entry plates, to suit different types of cable and to make installation as easy as possible.

The fuse in the cut out is contained within the cover of the unit, the action of removing this cover disconnects the fuse (so it can be replaced) which also isolates the load from the supply. Higher quality cut out designs (such as Lucy Zodion models) have a lever cam action handle on the cover, which improves operator access to cables. Although the terminals are isolated, removing a cover from a cut-out to change the fuse should be done in a safe and responsible manner that complies with the responsibilities under organisation and legislative policies.

Cut outs only come in either a single or twin fuse version; the option of using digital timers or RCCD’s to control or give additional protection aren’t covered by the Standard.

Lucy Zodion Electric Vehicle Power Supply Feeder Pillars for EV Charge Points

Isolators

Isolators are used for secondary isolation and add an extra layer of electrical safety; they are not required in all street lighting columns, unlike cut outs. The main body or casing of an isolator isn’t covered by the same BS as a cut out, however there are other British Standards that relate to them, which the switch and fuse carriers must meet (BS88). To assure quality, manufacturers should produce the body to the relevant BS for isolators (BS EN 60947-3:2009+A2:2015 and BS7671) and independent certification should be available.

The isolator provides a switch-disconnector which can be operated in order to isolate the load, allowing maintenance and for the fuse to be replaced. This makes changing fuses and isolating circuits simple and helps prevent risks of injury. Additionally, to increase safety, covers can be made lockable. Most isolators have an interlock device that automatically slides over the fuse carrier(s) when the isolator is moved to the ON position, ensuring that a fuse carrier cannot be opened with the circuit energised.

Both isolators and fuse carriers should be independently tested by a third party, in KEMA laboratories or the equivalent, to meet the relevant Standards. Factors like a high tracking index and self extinguishing plastics are vitally important when it comes to safety. Using robust and durable thermoplastic enclosures with high anti-tracking properties, well manufactured isolators often have a safe and transparent front access cover to offer clear visibility, reducing the need to open up the isolator.

Typically, the isolator comes with a 32 amp isolator and a fuse carrier, however, if the product has a DIN rail different arrangements and components can be used, e.g. digital timers, MCB’s, RCBO’s, RCCB’s, contactors, push buttons, etc. An isolator can form the basis of a unit used for Festive Decorations, for example.

The isolator usually has a DIN rail that can accept products like MCB’s and fuse carriers, which have a total of four modules in width, or less; however they are available with a capacity of more than four if required. Should the isolator include a DIN rail, a module with no more than 17.5mm width is to be used, almost like a mini distribution board.

The isolator typically has a suite of accessories that include extension pieces, brass and plastic cable entry plates to suit different types of cable and to make installation as easy as possible. Something the installer should consider is that terminal blocks sometimes need to be added to the final assembly to aid installation; this, in some instances, makes it quite long in length.

Street Lighting Isolators – Trojan Double Pole Cut Outs 32A – Lucy Zodion

Lucy Zodion Fused Products

The Lucy Zodion range of fused products follows the requirements under the respective Standards highlighted in this document. With an in-house Quality Team, it means that products can be tested at every stage of assembly – from initial design to completion – implying due diligence throughout each step of the manufacture process.

Additionally, each of Lucy Zodion’s products is independently tested by a third party, in KEMA laboratories, to ensure such measures meet industry Standards. As a responsible company Lucy Zodion has its own Quality Policy that covers operations throughout the whole company, as well as the manufacture of street lighting and power distribution products. It provides the approach necessary to ensure the requirements of ISO 9001:2015, and any regulatory/statutory requirements, are achieved in full and are improved where possible to ensure that customer requirements are met in full by the business.

Should Lucy Zodion customers wish view certification relevant to any aspect of the Standards and Policies stated above, Lucy Zodion is obliged to share and confirm the responsible steps have been taken to assure quality and safety.

Thorne & Derrick distribute an extensive range of products including MV & HV cables, cut outs and isolators and duct sealing products.

Further Reading

- Street Lighting Cut Outs – Lucy Zodion DNO Approved Cut Out Listing

- UKPN Cable Protection Tapes & Covers (LV MV HV)

- Cable Jointing Tools 11kV 33kV – Scottish Power Energy Networks

- Northern Powergrid Approved | Cable Joints, Terminations & Electrical Equipment

Lucy Zodion Feeder Pillars

LUCY ZODION – DISTRIBUTORS, STOCKISTS & SUPPLIERS

Thorne & Derrick provide competitive prices and fast delivery from stock for the complete range of Lucy Feeder Pillars, Isolators and Cut Outs.

LV MV HV Jointing, Earthing, Substation & Electrical Eqpt

UKPN Cable Protection Tapes & Covers (LV MV HV)

January 24th, 2019

UKPN LV MV HV 11kV 33kV | Tile Tape | Stokbord Covers

-

uploaded by Chris Dodds - Thorne & Derrick Sales & Marketing Manager

UKPN Tile Tape & Stokbord Covers

UK Power Networks, UKPN, are a UK Distribution Network Operator distributing low and high voltage electricity covering South East England, the East of England and London – we overview current UKPN recommendations and specifications for Cable Protection Tapes & Covers using Tile Tape and Stokbord cable protection products.

Note these are subject to change: check with Thorne & Derrick Sales.

This should assist LV-HV Cable Jointing, Installation & Civil Engineering Contractors installing the appropriate level of LV-HV Cable Protection for underground power cables.

T&D are Approved Vendors to UKPN and their contractors providing competitive prices and technical support for LV, MV & HV Cable Installation, Jointing, Substation & Electrical Equipment including low voltage electrical distribution feeder pillars manufactured by Lucy Zodion from the Fortress range.

All cables and cable ducts shall be protected by a cable protection tape or a Stokbord, the tape used depends upon the highest cable voltage to be protected:

- LV Service Cables – Tile Tape (40m x 200mm x 2.5mm) – UKPN Stores Code = 04040C

- LV Mains Cables – Tile Tape (40m x 200mm x 2.5mm) – UKPN Stores Code = 04040C

- 11kV MV Cables – Tile Tape (40m x 200mm x 2.5mm) – UKPN Stores Code = 04040C

- 22kV MV Cables – Tile Tape (40m x 200mm x 2.5mm) – UKPN Stores Code = 04040C

- 33kV MV Cables – Stokbord (1000mm x 244mm x 9mm) – UKPN Stores Code = 04041M

- 66kV HV Cables – Stokbord (1000mm x 244mm x 9mm) – UKPN Stores Code = 04041M

- 132kV HV Cables – Stokbord (1000mm x 244mm x 9mm) – UKPN Stores Code = 04041M

Cable protection tape or covers shall be installed so that they fully cover the width of the cable or cable duct installed below them.

- Excerpt from UKPN Engineering Construction Standard ECS 02-0019

- Installation of Underground Cables – LV to 132kV

- Document Number: ECS 02-0019

- Version: 10.0

- Date: 02/06/2015

Summary: The ECS 02-0019 Standard details the minimum requirements acceptable for the installation of new LV, 11kV, 20kV, 33kV, 66kV and 132kV cables plus associated pilot and telephone cables.

➡ View our complete range of LV-HV Cable Protection.

Cable Pulling & Laying Equipment LV HV

T&D supply Utilities & Approved Contractors with cable pulling products including cable rollers, cable socks and drum lifting jacks to enable the installation of low voltage and high voltage cables intro trench or duct: this includes single core, 3 core and Triplex 11kV/33kV power cables and LV waveform, mains and service cables.

Conduit & Duct Rods | Cable Lubricants | Cable Swivel Links | Cable Duct Bellmouths | Cable Cleaning & Cleaners | Jointers Tents | Cable Blowers

Street Lighting Cut Outs – Lucy Zodion DNO Approved Cut Out Listing

September 3rd, 2018

Street Lighting Cut Outs

-

uploaded by Chris Dodds - Thorne & Derrick Sales & Marketing Manager

Cut-outs

Lucy Zodion street lighting cut-outs are approved for use on every UK DNO Network.

Thorne & Derrick together with Lucy Zodion can offer a range of SLF street lighting cut-outs (SLCOs) which are now approved for use by every Distribution Network Operator (DNO) in the UK.

The high level of specification status of their cut-outs for street lighting applications on both the UKPN and WPD networks is a clear demonstration of Lucy Group’s commitment to keeping LV electrical connections safe and reliable.

The Lucy Zodion SLF range of street lighting cut outs use high quality materials and provide a wide range of features that help ensure robust and reliable protection and isolation across a number of street lighting network types and applications.

Additionally, the Lucy Zodion brand of Fortress type feeder pillars are extensively specified and installed throughout the UK DNO LV Electricity Distribution network.

➡ For further information about how Lucy Zodion provide control and power distribution products for street lighting applications, please review the Lucy Titan (Cut-outs) and Lucy Trojan (Isolators) ranges of products.

Cut Outs

Here is the current street lighting cut out approval listing according to UK DNO designation:

| DNO Approved Products | DNO Area | ||

| DNO | Lucy Zodion Code |

Cut Out Description | |

| WPD* | THM0048847 | SLF IPC Type 1 HEX Drive Clear Cover (SNE) |

|

| THM0041767 | SLF IPC Type 2 HEX Drive Clear Cover (CNE) |

||

| ENW | 0260009009 | SLF 25A SLCO Type 1 (SNE) |  |

| 0260010009 | SLF 25A SLCO Type 2 (CNE) | ||

| NPG | THM0001978 | SLF 25A SLCO TYPE 2(CNE) POLYCARBONATE |  |

| THM0001979 | SL DNO DP 25A SLCO (CNE) POLYCARBONATE | ||

| THM0001970 | SLF 25A Single Pole SNE | ||

| SPEN | 0260009009 | SLF 25A SLCO Type 1 (SNE) |  |

| 0260010009 | SLF 25A SLCO Type 2 (CNE) | ||

| SSE | 0260009009 | SLF 25A SLCO TYPE 1 (SNE) |  |

| 0260010009 | SLF 25A SLCO TYPE 2 (CNE) | ||

| 0260026007 | SL DNO DP 25A SLCO (CNE) | ||

| UKPN* | 0260011007 | SLF 25A SLCO TYPE 1 (SNE)3mm HEXDRIVE |  |

| 0260012009 | SLF 25A SLCO TYPE 2 (CNE)3mm HEXDRIVE | ||

*sole supplier status

Street Lighting | House Service | DNO | Heavy Duty – complete range of Cut Outs

THORNE & DERRICK SPECIALIST ELECTRICAL DISTRIBUTOR

LV ♦ MV ♦ HV

T&D distribute the most extensive range of LV, MV & HV Cable Jointing, Terminating, Cable Pulling & Installation Equipment – we service UK and international clients working on underground cables, overhead lines, substations and electrical construction at LV, 11kV, 33kV and EHV transmission and distribution voltages.

- Key Products: MV-HV Cable Joints & Terminations, Cable Cleats, Duct Seals, Cable Transits, Underground Cable Protection, Cable Jointing Tools, Feeder Pillars, Cable Ducting, Earthing & Lightning Protection, Electrical Safety, Cable Glands, Arc Flash Clothing & Fusegear.

- Distributors for: 3M, ABB, Alroc, Band-It, Catu, Cembre, Centriforce, CMP, Elastimold, Ellis Patents, Emtelle, Furse, Lucy Zodion, Nexans Euromold, Pfisterer, Polypipe, Prysmian, Roxtec.

T&D, CATU Electrical Safety & Arc Flash Protection Specialists for SAP’s, Linesmen, Jointers & Electrical Engineers – Largest UK Stockist

Cable Terminations 11kV Polymeric Indoor & Outdoor | ENWL Approved

April 30th, 2018

Cable Terminations 11kV ENWL Approved

-

by Chris Dodds T&D - estimated reading time 5 minutes

11kV Cable Terminations

The following 11kV Terminations are currently approved by ENWL for use on their medium/high voltage cable network when jointing, connecting and terminating 11kV polymeric cables to indoor electrical equipment in substations or buildings and pole-mounted overhead line applications. All cables and conductors should be thoroughly prepared and cleaned using approved cable cleaning wipes prior to the installation of terminations, joints or connectors.

For private network installations the Nexans FB1 bushing boots are suitable for either straight or angled connections to switchgear or transformers without need for heat-shrinking. The boots are cold applied and type tested to 15kV for use with Cold shrink or heat shrink cable terminations. Also, the bushing boot can be peeled back for routine medium/high voltage equipment maintenance and testing by voltage detectors without need to be cut-off and re-terminated as with heat shrink types.

| Termination Location | 11kV Cable Size sqmm | Cable Termination Kit | ENWL Commodity Code |

| Indoor | 95-185 | EH1029/ENWL | 144516 |

| 300 | EH1031/ENWL | 144518 | |

| 400 | BM9364/ENWL | 144519 | |

| 500/630 | BM9352/ENWL | 144520 | |

| Outdoor | 95-185 | EH1030/ENWL | 144521 |

| 300 | BM9353/ENWL | 144523 | |

| 400 | BM9363/ENWL | 144524 | |

| 500/630 | BM9350/ENWL | 144525 |

11kV Cable Termination Accessories

| Cable Size sqmm | Reference | ENWL Commodity Code | |

| Mechanical Shearbolt Cable Lugs – Offset Palm Lugs (Pack of 3) | 95-240 | 144534 | |

| 185/400 | 144535 | ||

| 500/630 | 144536 | ||

| Insulating Bushing Boot Kit | 95/300 | 144517 | |

| Bushing Boot Build Up Collar | – | 144533 | |

| Bushing Boot Grease | – | 144522 |

Read Our Blog: The Next Generation Of 11kV Transformers For MV HV Networks

Termination Of Cable Conductors

Cable jointer preferences and installation conditions of cable joints and terminations determine whether compression or shearbolt technology is used to terminate cable conductors. For instance, 11kV and 33kV single and multi-core medium/high voltage power cables with stranded copper conductors (Class 1) according to BS6622 are commonly crimped or terminated using hydraulic crimping tools (Cembre HT131-C) or battery operated crimping tools (Cembre B1350-CE) – these Cembre tools accommodate cable lugs up to 400sqmm. To install MV HV cable lugs with cross sectional areas 500sqmm and up to 630sqmm we can recommend the Cembre ECW-H3D crimphead coupled with the hydraulic PO7000 foot pump or B70M-P24 portable 24v electro-hydraulic pump.

The Pfisterer Sicon range of mechanical shearbolt cable lugs, terminals and connectors are suitable for the connection and termination of MV HV cables up to 66kV with copper or aluminium conductors (stranded circular, solid, sectoral shaped) without requirement for crimping tools – installed using no specialist jointing tools. The stepless shearbolt cable lugs have no predetermined breaking points in the thread ensuring the optimum thread load is achieved without protusions or need for conductor filing by the MV HV jointer.

T&D are Approved Vendors of Electricity North West Approved Materials List & Assessed Products to enable the cable jointing, termination, distribution and installation of LV, MV (11kV-33kV) & HV cables onto ENW cable network from manufacturers including:

| 3M | CATU Electrical |

| Pfisterer | Nexans Euromold |

| Prysmian | Ellis Patents |

| AN Wallis | Furse |

| Lucy Zodion & Electric | WT Henley |

| Sicame | Cembre |

| Polypipe | Emtelle |

| Tyco TE Connectivity | NKT |

| Roxtec | Alroc |

| Centriforce | MV HV Cables |

➡ Further Reading: Electricity North West Approved | Cable Joints, Terminations & Electrical Equipment LV HV

JOINT ♦ TERMINATE ♦ CONNECT ♦ GLAND ♦ CLEAT ♦ CRIMP ♦ DUCT ♦ SEAL ♦ REPAIR ♦ CABLE ♦ SPLICE ♦ INSULATE

Thorne & Derrick – Stickists & Suppliers of MV HV Joints, Terminations & Connectors

Cable Jointing Tools 11kV 33kV – Scottish Power Energy Networks

March 6th, 2018

-

uploaded by Chris Dodds - reading time 2 minutes

The following Cable Jointing Tools are approved and used by Jointers working for or on behalf of Scottish Power Energy Networks (SPEN) for the preparation of 11kV/33kV power cables prior to the installation of MV HV Joints, Terminations & Connectors.

| Cable Jointing Application | Tool Type | Comments | Manufacturer |

| MDPE Cable Sheath Stripper | KMS-S | na | |

| Cable Stripping Pliers | Alroc PG3 | Width 2.8mm cutting wheels, for cable diameter 30-55mm PICAS | Alroc |

| Cable Stripping Pliers | Alroc PG4 | Width 3.0mm cutting wheels, for cable diameter 45-75mm PICAS | Alroc |

| XLPE Screen Stripping Tool (Easy strip/Peelable) | Alroc LHM1R | Adjustable screen scoring tool 14-40mm diameter cables | Alroc |

| XLPE Screen Scoring Tool | Prysmian TT2352/1 | 0.4mm (for use on 33kV cables) | Prysmian |

| XLPE Screen Scoring Tool | Prysmian TT2352/2 | 0.6mm (for use on 11kV cables) | Prysmian |

| XLPE Screen Stripping Tool (Fully Bonded Screen) | INT.BZ Mod. 1714 | 10-52mm | Boddingtons |

| XLPE Screen Stripping Tool (Fully Bonded Screen) | NKT 500 30 | 16-40mm | NKT |

| XLPE Screen Stripping Tool (Fully Bonded Screen) | Alroc ASC40R2 | 38-60mm diameter cables (630sqmm cables) | Alroc |

| XLPE Adjustable XLPE Insulation Stripping Tool | Alroc BRMrd1 | 14-40mm | Alroc |

| XLPE Adjustable XLPE Insulation Stripping Tool | Alroc BRMrd2 | 38-60mm | Alroc |

Alroc Tools | Remove Sheath | Remove Screen | Remove Insulation

♦ See also: Scottish Power Energy Networks Approved | Cable Joints, Terminations & Electrical Equipment LV HV

➡ Visit Alroc to view the complete range of Jointers Tools for stripping and preparing 11kV/33kV power cables – cable tools also available for 66kV-132kV cable jointing and preparation.

Insulation | Screen | Sheath | Cable Preparation Tools 11kV 33kV

JOINT ♦ TERMINATE ♦ CONNECT ♦ GLAND ♦ CLEAT ♦ CRIMP ♦ DUCT ♦ SEAL ♦ REPAIR ♦ CABLE ♦ SPLICE ♦ INSULATE