Blog

Filoform Cast Resin Cable Joints For Cathodic Protection

February 5th, 2019

-

uploaded by Chris Dodds - Thorne & Derrick Sales & Marketing Manager

Cathodic Protection Cable Joints

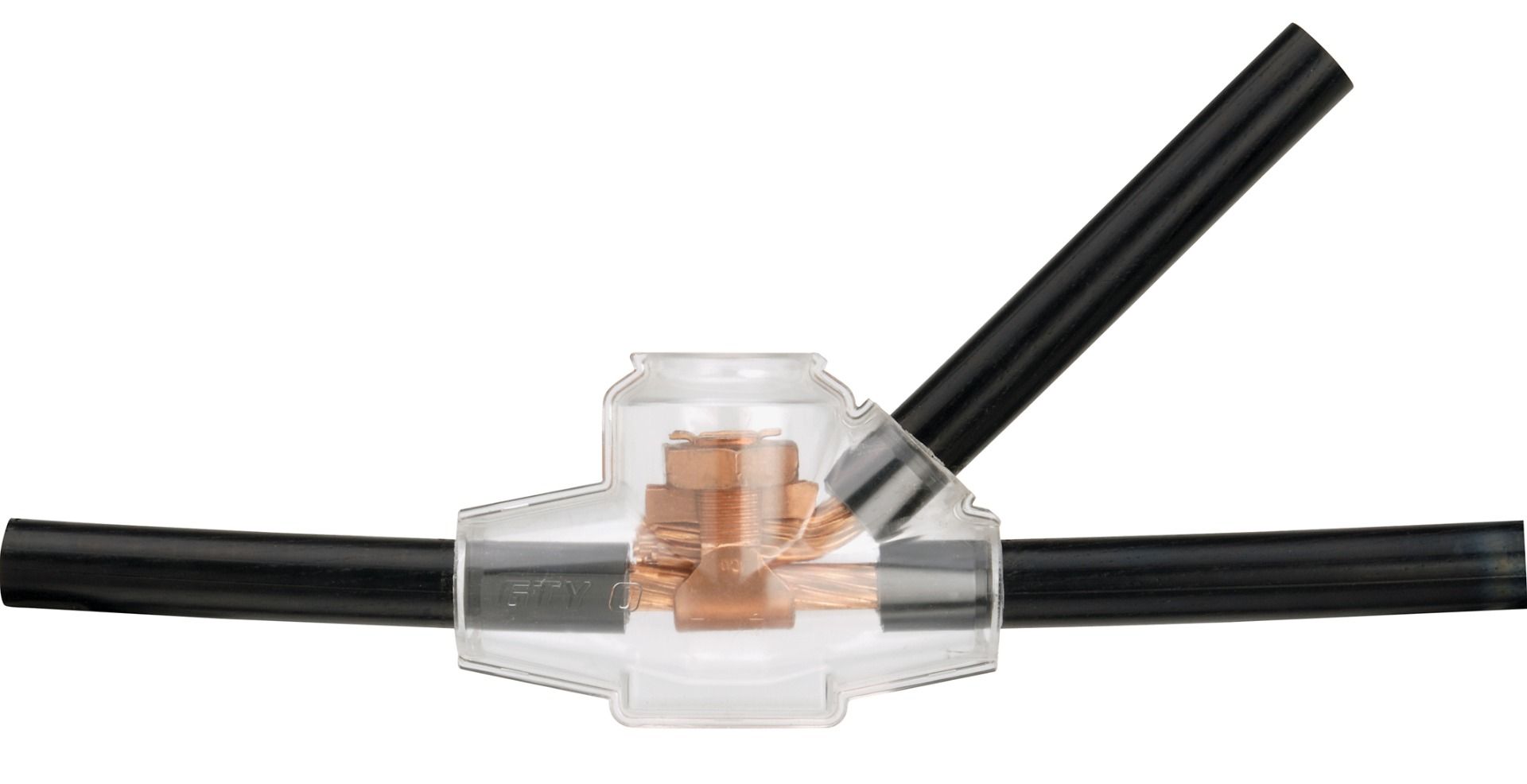

Cathodic protection is a technique that is used to protect a metal structure from corrosion under water by acting like an electrical cathode. A simple method of protection connects the metal to be protected to a more easily corroded “sacrificial metal” to act as the anode.

Thorne & Derrick, a leading distributor for Filoform cable joints, have this week supplied 300 off Filoform CPJ95 Cathodic Protection Joints to the oil and gas industry.

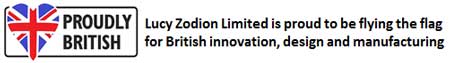

Filoform CPJ cable jointing kits are used on cathodic protection applications including pipelines, tanks and buried structures. The CPJ joints can be supplied with or without brass line taps as standard – this range of cable joints suit mains cable single core maximum size up to 120sqmm and branch single core cables up to 35sqmm.

Two variants of Filoform CP cable joints are offered:

CPJ – The classic cathodic protection joint for use when upright branch joints are required

CB0 – A “Y” shaped joint for horizontal branch jointing applications

| Max Cable Size single core (sqmm) | Max Branch single core (sqmm) | Basic Kit- NO CONNECTOR | Kit with Split bolt line tap | |

| Cable Joint Part Number | Part Number | Joint Kit Includes | ||

| 120 | 95 | Filoform CPJ120 | CPJ120+C | Joint + line tap |

| 95 | 95 | Filoform CPJ95 | CPJ95+C | Joint + line tap |

| 95 | 95 | Filoform CB0 | CB0+C | Joint + line tap |

Image: Hubbell

Filoform Cast Resin Cable Joints

Features & Benefits

- Strong clear plastic mould body with Snaplock connection for tight seal

- Stepped cable entry cut off points for all cable diameters

- Large mould shell enables crimp or split bolt / line tap connectors to be used

- High quality resin sealing compound has a high resistance to moisture absorption, is mixed in a clear pack and stored in an aluminium protective bag.

- The long term electrical properties of the resin sealing compound result in a more reliable connection without any associated maintenance costs

- Resin sealing compound is suitable for all climate conditions

- Designed to meet the requirements of BS 7888:1998

- Specified by leading oil, gas and water companies and consulting engineers

- Used extensively on rail projects

Filoform CPJ95 cable joint is designed to suit mains cable single core maximum size up to 95sqmm and branch single core cable up to 35sqmm.

Typical applications include for cathodic protection cables and cable joints :

- Pipelines – oil, gas, product, water

- Above ground and underground storage tanks

- Well casings

- Sheet and cylindrical piling – land and marine

- In plant pipe work

- Compressor stations

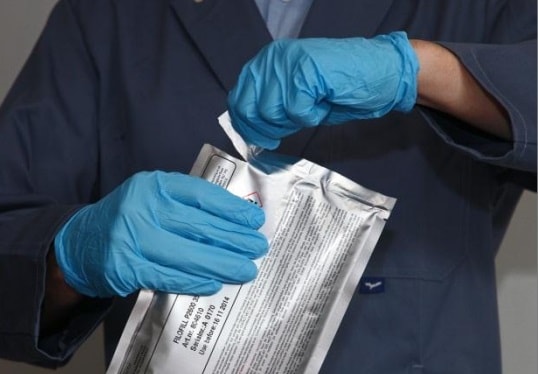

Pictured : Filoform Cable Joint (Cathodic Protection) – cable joint kit includes mould, jointing resin, sealing tapes and mechanical connector for conductor connecting.

Filoform CPJ Cable Joints – Mixing Instructions

Care should be taken by the Jointer to ensure the cable jointing resin is mixed thoroughly and in accordance with the manufacturers guidelines:

|

| 1. Remove the aluminium outer bag taking care not to damage the clear inner bag. Immediately use the cable jointing resin after opening the aluminium outer bag |

|

| 2. Remove the separator from the centre of the resin bag |

|

| 3. Mix contents by kneading vigorously for at least two minutes. Make certain all the resin cable compound is squeezed from the corners and edges of the bag. |

|

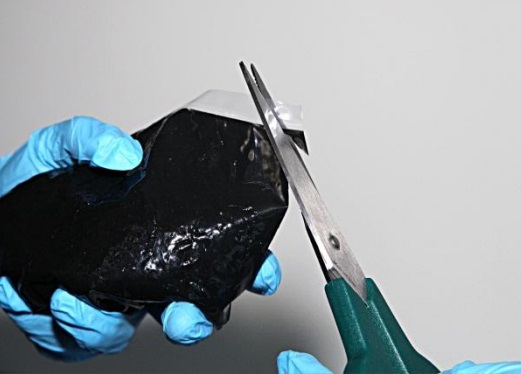

| 4. Pouring of the resin: Cut a small edge from the bag. Carefully pour the resin into the joint shell. Empty (hardened) resin packs can be disposed as regular waste material. |

Attention:

- Do not mix different types or brands of cable resins

- Take steps to prevent damage as a result of spilling resin

- Wear disposable gloves and process only in a well ventilated room

Typical Applications for

Cathodic Protection Cable Joints

- N2XY XLPE/PVC 600/1000v

- XLPE/XLPE

- N2XRY XLPE/SWA/PVC

- HMWPE

- KYNAR/HMWPE

- HALAR/HMWPE

LV Cable Joints (Low Voltage Cables)

Thorne & Derrick stock and distribute LV Joints in Cold Shrink, Heat Shrink or Resin Cast technologies – multicore and multi-pair cable joints are available for immediate backfill and energisation of Low Voltage power, control and instrumentation cables 600V/1000V 3.3kV.

Complete range of LV Cable Accessories ➡

Cable Breakouts | Cable Caps | Cable Lugs | Cable Cleats | Cable Trough | Cable Duct | Feeder Pillars | for 11kV/33kV/66kV networks see MV HV Joints & Terminations

Cold Shrink by 3M | Joints | Abandonment | Terminations | Low Voltage LV Cables

3M Scotchcast Cable Joints For Type 11 Flexible & Trailing Mining Cables

February 5th, 2019

-

uploaded by Chris Dodds - Thorne & Derrick Sales & Marketing Manager

Jointing Mining Cables

3M 82-F2 Flexible Cable Jointing Kits are specified for inline (straight) and tap (branch) jointing of Type 11 Trailing Cables used in underground coal mines to power coal-cutters and face equipment – Thorne & Derrick distribute a complete of cable joints for mining cables using resin cast, heat shrink or Cold Shrink technology for LV (Low Voltage), MV (Medium Voltage) and HV (High Voltage) networks.

Type 11 0.64/1.1kV BS6708 Trailing Cable features an EPR rubber insulation which allows cable flexibility on site for frequent coiling and diverting to support the coal mining extraction process. 3M Scotchcast 82-F2 cable joints feature Scotchcast 2131 resin which is flexible, flame retardant and moisture sealing for damp working environments experienced in deep underground coal mines.

3M 82-F2 flexible cable joints allow trailing cable to maintain cable bend radius for handling, installation and reeling applications – compatible with most types of flexible cables including EPR types used in both onshore and offshore locations.

3M 82-F2 submersible cable joints are suitable also for both indoor and outdoor cable installations – this includes weather exposed, direct burial underground, submerged and cable reels.

3M Scotchcast 82-F2 Flexible Power Cable Splicing Kits

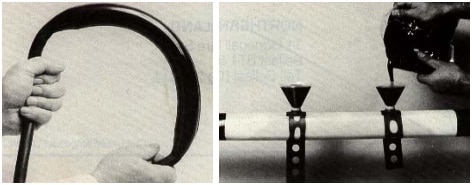

- One-piece removable cable joint mold

- 3M Scotchcast 2131 resin compound in “Unipak” container

- 3M Scotch 23 tape for sealing cable joint mold ends

- Clear and comprehensive cable jointing instructions

Pictured: The first automated drill for the small-face drilling segment, the Boomer S2’s COP from Atlas Copco. Johan Halling, President of Atlas Copco’s Mining and Rock Excavation Business Area, said he is optimistic about the future of coal mining. “The global mining industry has experienced downtrends before, and each time it has managed to bounce back and become even stronger, largely thanks to the development of innovative products and new thinking,” Halling said. “I am certain that the current downtrend is no exception.”

3M Scotchcast 82-F2 cable splices are assigned by the Mine Safety & Health Administration (P-142-5 MSHA).

Mining Cable Joints – MHSA Approved

T&D stock both the 3M 82-F range of Scotchcast Inline and Tape cable joints utilising Scotch Electrical tapes for the jointing, repair and re-jacketing of damaged mining cables, including flexible and trailing cables.

3M 82-F Scotchcast cable joints accommodate outside cable diameters up to 30mm. For jointing or repairing flexible and trailing above 30mm diameter, T&D stock and recommend the 3M Resin Flexible Cable Repair & Jointing Kits which suit up to 152mm outside diameter cables.

3M Flexible Cable Jointing & Repair System

Flexible mining trailing cables are for use with shuttle cars, coal cutters and similar face equipment.

Type 11 Trailing Cable (Mining) – 3M Scotchcast 3M 82-F2 Cable Joints

3M Scotchcast resin cable joints are available to suit :

- Type 7 Trailing Cable

- Type 7M Trailing Cable

- Type 7S Trailing Cable

- Type 11 Trailing Cable

- Type 62, 63 & 64 Flexible Trailing Cable (Galvanised Steel Wire Armouring)

- Type 201 & 211 Flexible Trailing Cable (Galvanised Steel Wire Armouring)

- Type 307 Trailing Cable

- Type 307S Trailing Cable

- Type 331 and 321 Flexible Trailing Cables with Galvanised Steel Wire Armouring

- Type 631 Flexible Trailing Cables with Galvanised Steel Wire Armouring

- PVC Insulated, Wire Armoured and PVC Sheathed Power Cable

- PVC Insulated Wire Armoured Telephone Cables

- XLPE Insulated, Wire Armoured and PVC Sheathed Power Cables

- See Complete Range of Mining Cables

Some Mining Cable Jointing Tips

- Cut out all kinks, twists and crushed spots – if several cable joints are located close together, remove them all and install a single cable joint to eliminate possible multiple weak spots

- Take care not to nick or cut the cable construction (conductor, insulation, shield) – use correct jointing tools

- When preparing mine power feeder cable make square, even cable cuts. Leave no loose threads or sharp points protruding as corona could be initiated within the cable joint

- Stagger connections (crimped or mechanical) on conductors to reduce bulkiness in the cable joint and promote cable flexibility

When The Going Gets Tough…..

3M Scotchcast resins are highly modified to resist degradation and contamination by acidic and alkaline dusts experienced in the global mining and quarrying industrial sectors such as coal, clay, china clay, chalk, gypsum and limestone.

Mining & Quarrying Conveyors

Electrical plant, equipment and machinery in the mining industry is designed and manufactured to withstand harsh environmental conditions. Naturally, cables and cable accessories such as cable joints should be carefully specified to avoid downtime caused by installation of underspecified equipment.

3M Scotchcast Cable Joints – Mining Quarrying

Global economic growth and infrastructure development depends heavily on mined and quarried natural resources such as minerals, metal ores and coal. Open-cut and underground mining operations require powerful electric machines and cabling to enable extraction. Electrical equipment and cable systems are routinely exposed to heavy dust pollution, high machinery vibration and G-forces. Large scale digging and excavation equipment for open-cut mines, such as electric power shovels and large scale conveyors, require trailing, level-wind cable reels. Drill and blast equipment used for hard rock and underground mining require rugged, compact cable management systems. Mobile power is also needed for shotcrete machines, blast-hole drills, ceiling bolters, and other underground equipment.

Open Cut Mining At Glencore Bulga Coal

Underground Shuttle Car Loading Coal

Hydraulic Face Shovel Loading Coal In Dump Truck

Mining Cable Accessories

Complete range of LV HV Cable Accessories to support the installation of mining cables.

Cable Glands | Cable Cleats | Cable Joints LV | Cable Joints MV HV | Cutting Tools | Crimping Tools | Cable Labels

➡ Contact T&D for 3M, CATU, Cembre, CMP, Ellis Patents, Emtelle, Euromold, Filoform, Furse, Nexans, Pfisterer, Prysmian and Roxtec.

Cable Jointing Copper To Aluminium Conductors Correctly Using Resin Cable Joints

February 4th, 2019-

uploaded by Chris Dodds - Thorne & Derrick Sales & Marketing Manager

What To Consider When Jointing Cables With Various Types Of Conductor

A common question posed by LV cable jointers concerns the conductor jointing of dissimilar metals or core construction in underground cable joints.

Thorne & Derrick can make recommendations to overcome the potential problems encountered when cable jointing aluminium to copper cables and provide guidance on best practice to avoid potential corrosion problems within resin cable joints up to 3.3kV.

Typical applications could involve the transition cable jointing of BS5467 XLPE SWA copper conductor to existing imperial PILC SWA aluminium conductor cables in an underground application (or direct burial) in a cable trench.

3.3kV cable joints utilising heat shrink technology and mechanical shearbolt connectors are available for the jointing of power cables up to 3.3kV in accordance with IEC 60228 and IEC 60502 – this includes the cable jointing of circular to sectoral conductors.

Similarly mechanical style conductor connectors are commonly used to joint conductors with divergent cross section areas – often called “reducer connectors” the shearbolt type connectors permits the “step-down” jointing of cables within the range accommodation of the connector.

Where crimp connectors from manufacturers such as Cembre are “dead-sized” and specified to connect “like-for-like” sized metric conductors the mechanical connector allows improved cable application ranges.

Mechanical shearbolt connections, such as Pfisterer, provide quick to install options for jointing dissimilar conductor types and constructions, whether circular, sectoral, stranded or solid – suitable for power systems at 3.3kV, 11kV, 33kV and up to 66kV.

Pfisterer Sicon connectors are used by Jointers to provide immediate and reliable connection of all types of cable conductors.

![]()

➡ Video. Pfisterer Sicon Connectors – Safe & Reliable Cable Conductor Jointing.

The range-taking nature of mechanical connectors allow the jointing of different cross section area conductors together without resort to crimp tooling.

➡ Read Blog: Overcoming Cable Corrosion On Steel Wire Armoured & Braided Cables

2 Factors Associated With Conductor Corrosion

1. Atmospheric action

2. Galvanic action

For atmospheric action to result in cable corrosion both moisture and oxygen must be present within the cable joint.

Galvanic action results in corrosion when 2 dissimilar metals in an electrolytic series, such as copper and aluminium, are in physical contact.

This contact could be caused by the compression or crimping of aluminium and copper conductors together causing any moisture present to act as an electrolyte. In this situation, the copper becomes a cathode and receives the positive charge and the aluminium becomes the anode receiving a negative charge.

The resultant current flow attacks the aluminium leaving the copper unharmed.

Cable joints utilising Scotchcast Resins are trusted to provide uninterrupted power supply to electrical infrastructure in industrial and hazardous area locations – specialist application and chemical formula resins are available including hydrocarbon resistant, flame retardant, submersible and zero halogen types.

Cable Jointing For Industrial & Hazardous Areas Up To 3.3kV

To avoid bi-metallic corrosion caused by the connecting of the copper to aluminium conductors, 3M Scotchcast LVI resin cable joints can be used – 3M cable joints are fully encapsulated with either 3M Scotchcast 470W Resin for industrial cable installations or 3M Scotchast 1402FR Resin for cables being jointed in hazardous areas.

The pouring of the cable jointing resin into the shell eliminates air voids driving out moisture eliminating the basic requirements for galvanic reaction and cable corrosion to occur.

3M Scotchcast Resin LVI-1 Type Cable Joints For Low Voltage Power Cables

LV Cable Joints (Low Voltage Cables)

Thorne & Derrick stock and distribute LV Joints in Cold Shrink, Heat Shrink or Resin Cast technologies – multicore and multi-pair cable joints are available for immediate backfill and energisation of Low Voltage power, control and instrumentation cables 600V/1000V 3.3kV.

Complete range of LV Cable Accessories ➡

Cable Breakouts | Cable Caps | Cable Lugs | Cable Cleats | Cable Trough | Cable Duct | Feeder Pillars | for 11kV/33kV/66kV networks see MV HV Joints & Terminations

Pfisterer | Nexans Euromold | Prysmian | Cable Joints & Terminations MV HV

Cold Shrink by 3M | Joints | Abandonment | Terminations | Low Voltage LV Cables

Cable Abandonment Kits – Using 3M Cold Shrink CSCAK Kits (Installation Guide + Video Demo)

February 4th, 2019

-

uploaded by Chris Dodds - Thorne & Derrick Sales & Marketing Manager

Cable Abandonment Kits

Onshore & Offshore Power Cables

3M Cold Shrink Cable Abandonment Kits are suitable to abandon onshore and offshore polymeric (XLPE and EPR) insulated cables with lead sheath and steel wire armour or wire braid (galvanised steel, phosphur bronze or stainless steel) – this includes both single and multi-core unscreened power cables, 600/1000 volts up to 3.3kV.

3M Cold Shrink Cable Abandonment Kits (CSCAK) CSCAK1 – CSCAK5 accommodate cables 12 – 81mm outside diameter.

Cable abandonment kits are generally employed to abandon cables in the offshore, marine, petrochem, nuclear and power industries on decommissioning projects. Decommissioning projects in the oil and gas sector include a requirement to safely abandon offshore power, control and instrumentation cables – 3M CSCAK kits effectively “ground” the abandoned (redundant) cable circuit thereby avoiding potential electrocution shock to engineers caused by inadvertent future energisation.

3M CSCAK kits are specified for routine offshore cable maintenance and final platform cable decommissioning where topside, subsea and drill site cables must be abandoned.

Between now and the mid-2050s, around 470 platforms, 5,000 wells, 10,000km of pipelines and 40,000 concrete blocks will have to be removed from the North Sea. Source: FT.com.

Using Cable Abandonment Kits

3M Cable Abandonment Kits require no heat source to install – “cold-applied” – and are therefore suitable for use in Zone 1 and Zone 2 hazardous areas with potential explosive atmospheres according to the ATEX Directive. No “hot-working” permits, no naked flames required.

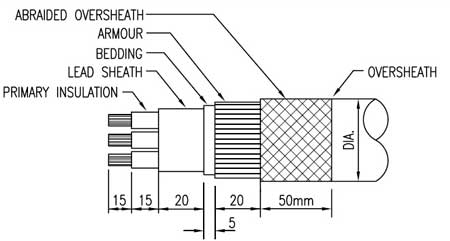

Fig 1 : Prepare the cable as indicated below exposing the primary insulation, lead sheath, bedding, armour and cable oversheath – abraid the cable sheath and clean using suitable cable cleaning wipes for 50mm.

Fig 1 : Prepare the cable as indicated below exposing the primary insulation, lead sheath, bedding, armour and cable oversheath – abraid the cable sheath and clean using suitable cable cleaning wipes for 50mm.

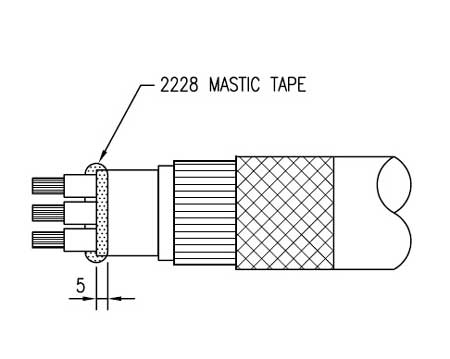

Fig 2 : Apply 3M 2228 Mastic Tape to seal the cable crutch over lead sheath and between the cable cores – 3M 2228 Scotch tape should overlap 5mm on to cable bedding or lead sheath (if applicable).

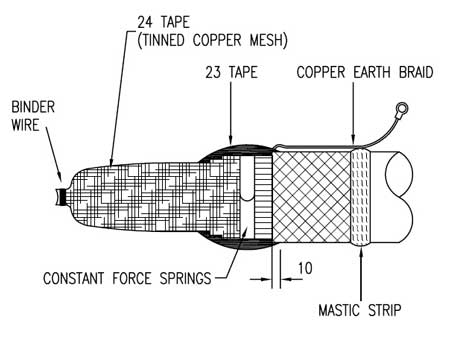

Fig 3 : Wrap 2 half lapped layers of 3M Scotch 24 Tape over the cable to be abandoned starting at the conductors up on to the cable armour – use binder wire over the conductors and lead sheath (where applicable) to ensure contact. Fit 3M Constant Force Spring over the Scotch 24 Tape and cable armour – if an earth is required this should be fixed between the Scotch 24 Tape and cable armour. Over tape the 3M Constant Force Spring with 2 layers of highly stretched 3M Scotch 23 Self Amalgamating Tape applied in the same direction as the spring. Continue up over the cable oversheath for 10mm.

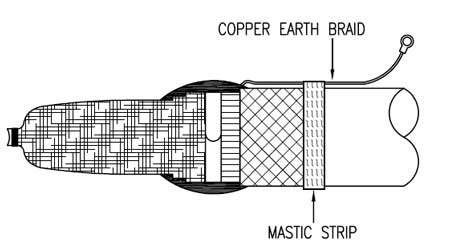

Fig 4 : Where an earth braid is being used apply 1 layer of mastic strip around the cable sheath at given dimension, push braid into mastic and apply a second layer over the braid.

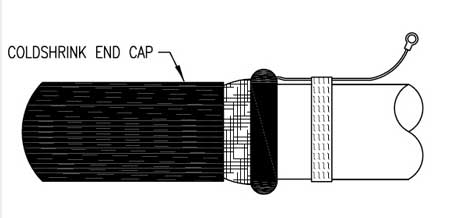

Fig 5 : Position the 3M Cold Shrink End Cap over the end of the cable as shown – shrink onto the cable by unwinding the core.

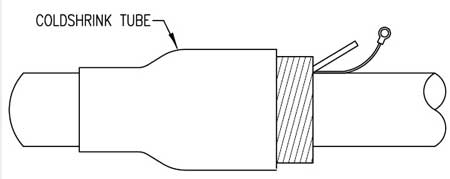

Fig 6 : Position the 3M Cold Shrink PST (Pre-Stretched Tube) over the cable to be abandoned – commencing 15mm on end of end cap shrink down the 3M Cold Shrink PST by unwinding core in an anti-clockwise direction.

Cable Abandonment Kit Selection Table

The following 3M CSCAK selection table is based upon low voltage power cable type according to BS5467 – XLPE insulated cables including aluminium wire armoured (AWA) single core cables and steel wire armoured (SWA) multicore cables, 600/1000 volts.

➡ Offshore Cables. Cable abandonment kits are available to suit halogen free (zero halogen), flame retardant, MUD resistant, heat resistant and fire resistant offshore and ship board power, control, instrumentation and lighting cables – including NEK606 (RFOU BFOU EPR TCWB) and BS6883/BS7917 (UKOOA) Cables.

| Cable Abandonment Kit | XLPE AWA Single Core | XLPE SWA 2 Core | XLPE SWA 3 Core | XLPE SWA 4 Core | 3.3kV XLPE SWA Lead 3 Core |

| 3M CSCAK/1 | – | 1.5-6sqmm | 1.5-6sqmm | 1.5-4sqmm | – |

| 3M CSCAK/2 | 70-120sqmm | 10-35sqmm | 10-16sqmm | 6-16sqmm | – |

| 3M CSCAK/3 | 150-500sqmm | 50-150sqmm | 25-120sqmm | 25-95sqmm | 25-95sqmm |

| 3M CSCAK/4 | 500-630sqmm | 185-400sqmm | 150-185sqmm | 120-150sqmm | 120-185sqmm |

| 3M CSCAK/5 | 800-1000sqmm | – | 240-400sqmm | 185-400sqmm | 240-400sqmm |

3M Cold Shrink Cable Abandonment Kits CSCAK

➡ Watch the Video Demonstration produced by 3M Electrical:

LV Cable Joints (Low Voltage Cables)

Thorne & Derrick stock and distribute LV Joints in Cold Shrink, Heat Shrink or Resin Cast technologies – multicore and multi-pair cable joints are available for immediate backfill and energisation of Low Voltage power, control and instrumentation cables 600V/1000V 3.3kV.

Complete range of LV Cable Accessories ➡

Cable Breakouts | Cable Caps | Cable Lugs | Cable Cleats | Cable Trough | Cable Duct | Feeder Pillars | for 11kV/33kV/66kV networks see MV HV Joints & Terminations

Pfisterer | Nexans Euromold | Prysmian | Cable Joints & Terminations MV HV

Cold Shrink by 3M | Joints | Abandonment | Terminations | Low Voltage LV Cables

Cut Outs & Isolators – Lucy Zodion Explain The Differences

February 4th, 2019

Cut Outs or Isolators

What’s The Difference?

Thorne & Derrick invited Giles Davidson (Area Sales Manager at Lucy Zodion Ltd) and Robert Ashworth (Export Sales Manager – Lucy Zodion Ltd) to guide us through the technical and terminological differences between using cut outs and isolators for roadway, tunnel, urban, industrial and street lighting applications.

Lucy Zodion is a leader in the design and manufacture of Street Lighting Equipment in the UK – this includes feeder pillars and appropriately cut outs and isolators for industrial power, street lighting and house service applications.

➡ Let’s let Lucy Zodion educate and inform us on the key differences.

“Confusingly, some people refer to cut outs as isolators and isolators as cut outs, that’s probably not what you want to hear, and to be honest as a manufacturer neither does Lucy Zodion. Although the descriptive terms are loosely treated as interchangeable there are clear distinctions between the two product types.

Let’s get back to basics, in essence both cut outs and isolator products set out to do the same thing, they are both primarily used in the street lighting market.

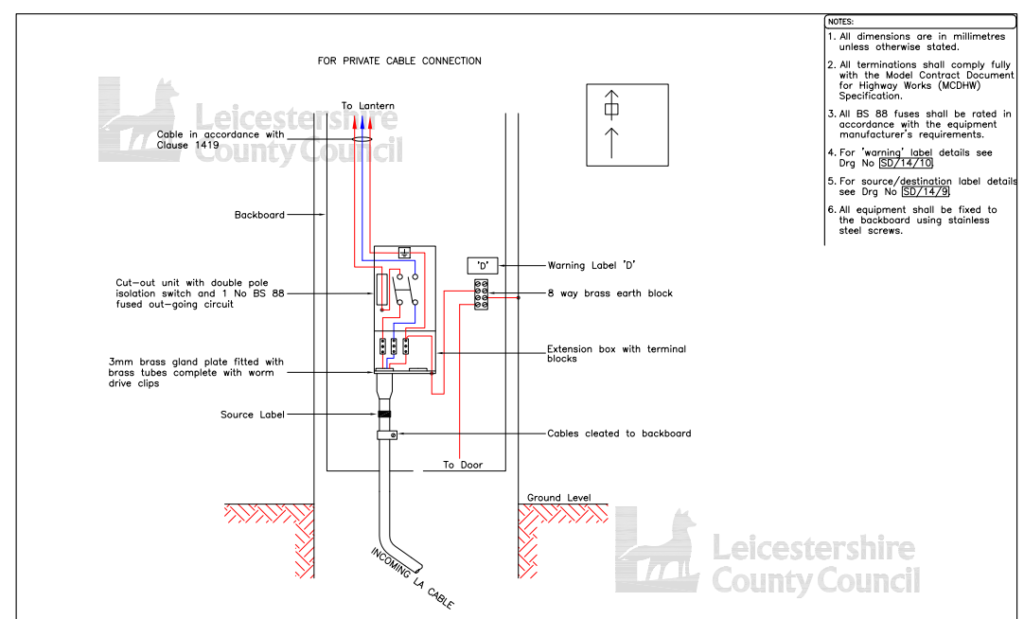

Cut outs and isolators are installed behind the column door at the base of a lamp post (or street lighting column to give it its correct title) – both comprise of an enclosure which is used to terminate a low voltage supply cable (typically with SWA armour and XLPE insulation according to BS5467) and provide electrical protection and a means of isolating the light on the street lighting column.

If it’s the installers choice on what to install, both products would be suitable, however the choice isn’t always down to the installer, so they should consult with their client to see if they have a specification they need to comply with.

So, if both products do the same thing, what is the difference between a cut out and an isolator?

Titans & Trojans…………

Cut Outs

OK, a cut out has its own British Standard – BS7654, there’s a nice easy number to remember!

BS7654 is the specification for single-phase street lighting cut-out assemblies for low voltage public electricity distribution systems.

This BS standard covers all aspects of the cut out from the materials it’s manufactured from to a series of tests relating to temperature, ingress protection, current, mechanical strength; it even states its physical size.

You should ask if the manufacturer has independent certification, good ones will and should be happy to send you a copy without hesitation.

The cut out will come with a set of terminal blocks designed to accept cables up to 25sqmm and will have a suite of accessories that include extension pieces and brass and plastic cable entry plates to suit different types of cable and to make installation and cable glanding as easy as possible.

➡ Pictured Opposite: Brass or insulated gland plates are available in one, two or three entry formats – the cable gland plates are able to receive 20mm, 25mm or 32mm brass tubes for the termination of SWA cables or alternatively grommets and cable glands of the sizes indicated in the Selection charts.

The fuse in the cut out is contained within the cover of the unit, the action of removing this cover disconnects the fuse (so it can be replaced) which also isolates the load from the supply.

Better cut out designs (such as Lucy Zodion of course) have a lever cam action handle on the cover which saves greatly on grazed knuckles or falling backwards into the road when removing the cover.

It’s worth pointing out that although the terminals are isolated removing a lid from a cut-out to change the fuse should only be performed by a qualified electrician.

Cut outs only come in either a single or twin fuse version with the option of using digital timers or RCCD’s to control or give additional protection aren’t available – see the reliable and durable MC040SLF single phase cut out from the Lucy Zodion range of Titan cut outs available with Type 1 Separate Neutral & Earth ( SNE) and Type 2 Combined Neutral / Earth (CNE) for PME applications, 25A maximum fuse rating.

Cut outs only come in either a single or twin fuse version and it isn’t possible to use digital timers or RCCD’s to control or give additional protection.

♦ BS7654 : This British Standard specification is for single-phase street lighting cut-out assemblies for LV low voltage public electricity distribution systems. 25A rating for highway power supplies and street furniture applications and installations.

Street Lighting Cut Outs – See the Lucy Zodion range of Titan Cutouts

Isolators

So how does an isolator differ?

Firstly the main body or enclosure of the isolator is not covered by a BS, however reputable manufacturers will still produce the body in the same material as the cut out, and again independent certification should be available.

Factors like a high tracking index and self-extinguishing plastics are vitally important when it comes to safety.

The isolator is in essence an enclosure with a DIN rail that typically can accept products like MCB’s and fuse carriers which are in total no more than four modules in width (a module is a product 17.5mm in width). Think of an isolator as a mini distribution board if you will.

The isolator provides a “switch” which can be operated in order to isolate the load circuit, therefore compared with a cut out changing fuse(s) and isolating the load circuit is relatively simple.

Typically the isolator comes with a 32 amp isolator, hence the name, and a fuse carrier, however as the product has a DIN rail different arrangements and components can be use e.g. digital timers, MCB’s, RCBO’s, RCCB’s, contactors, push buttons etc.

An isolator can form the basis of a unit used for Festive Decorations for example.

One thing that doesn’t come as standard with a street lighting isolator is a set of terminal blocks for the incoming cable (unlike the cut out); so the engineer or installer needs to take this into serious consideration and add in terminal blocks to the final assembly to ensure safe and reliable installation is possible.

The isolator range will also have a suite of accessories that include extension pieces and brass and plastic cable entry plates to suit different types of cable and to make installation as easy as possible for all types of armoured (SWA) and unarmoured cables.

Note that the addition of extension troughs does of course add length to the assembly of the isolator so it is important to ensure that sufficient room is available in the lighting column to accommodate the isolator.

Street Lighting Isolators – See the Lucy Zodion range of Trojan Isolators

Power Management & Control Equipment For Street Lighting

Summary

So in summary, the cut out is a great work horse providing a method of terminating cables in straightforward situations where no more than two load circuits are needing protection.

The isolator can offer greater flexibility of protection and control but can be more complex in some scenarios.

Unless there is a local authority specification or similar, in most cases the choice of cut-out or isolator will be determined by the type of installation and the functions required.

If you know the size and type of incoming cable, whether it is looping in and out or not, if it is single or three-phase, plus the number of outgoing circuits required (often the number of lights on the column), then this is 95% of the information needed to work out what is needed. Beyond this the checks are mostly physical size etc.

The cable termination specification and engineering standards vary according to the street lighting engineer and the local authority system requirements – a comprehensive range of standard and customised cut outs and isolators are available from stock with short delivery lead times. Our design and build service enables the configuration of isolators with various DIN rail mounting modules.

The Lucy Zodion Range

Lucy Zodion and T&D are pleased to offer advice and assistance – Lucy Zodion fused Titan and Trojan cutouts and isolators provide DNO primary and secondary isolation with extension boxes suitable for SWA armoured cable tails and concentric cables.

- Street Lighting Isolators – Lucy Trojan Double Pole Cut Outs 32A

- Street Lighting Cut Outs – Lucy Titan Single & Double Pole Cut Outs

- DNO Cut Outs – Lucy Zodion

- Pole Mounted Cut Outs CNE & SNE – Lucy Electric

- House Service Cut Outs HSCO Three Phase SNE & CNE 60/80A or 100A – Lucy Electric

- House Service Cut Outs HSCO Single Phase SNE & CNE 60/80A or 100A – Lucy Electric

- Heavy Duty Cut Outs HDCO 200A, 400A, 600A – Lucy Electric