Blog

UKPN Polylam Cable Jointers Tool Kit – Alroc CPM-GB1

May 10th, 2018-

uploaded by Chris Dodds - Thorne & Derrick, Sales & Marketing Manager

Cable Jointing Tools For LV MV HV Cables

Thorne & Derrick are Specialist Distributors of LV, MV & HV Jointing, Earthing, Substation & Electrical Eqpt approved for use by UKPN on their medium/high voltage underground cables and overhead lines network – including complete range of cable jointing tools approved by UKPN available from stock for the removal of sheath, screen and insulation from UKPN Polylam specification cables.

Customised for UKPN the jointers tool sets are used to prepare Polylam medium/high voltage cables prior to the installation of heat shrink joints, terminations or connectors.

Order Code From Thorne & Derrick: ALROC CPM-GB1

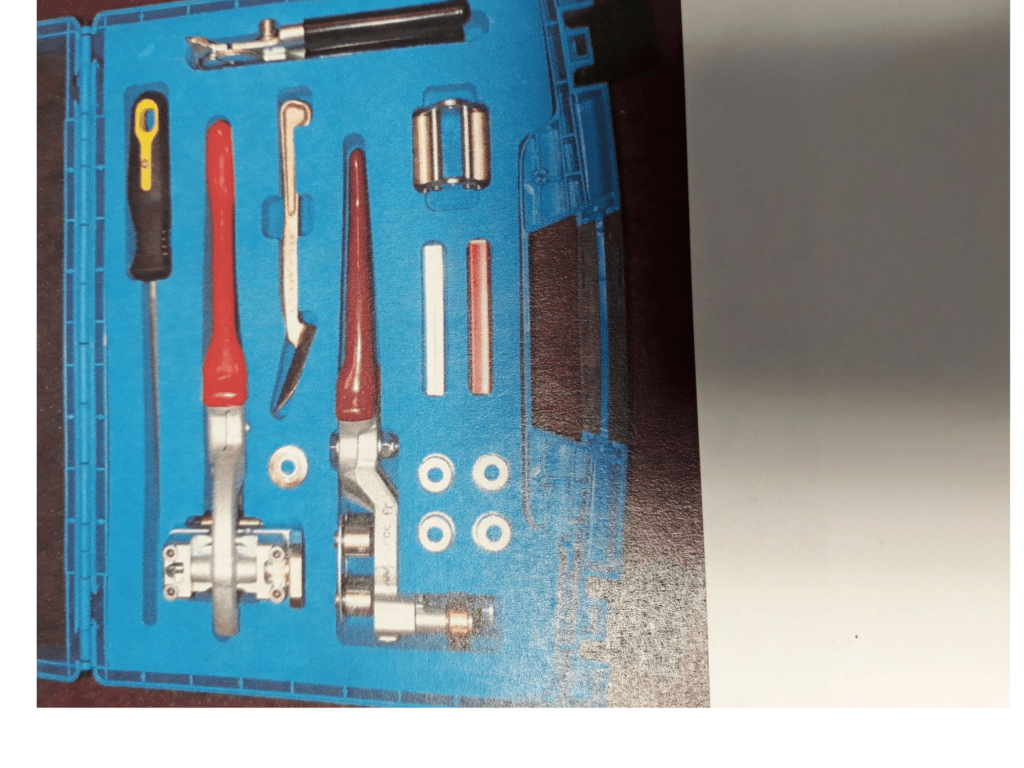

The jointers tool set includes:

1 X Alroc CPM-1GB Empty Plastic Tool Case

1 X Alroc Cable Sheath Pliers PG3HTA/2833

4 X Circular Cable Cutting Blade For PG3

1 X Longitudinal Cable Cutting Spare Blade PG3

1 X Spreader For Sheath Aluminium Screen 150sqmmm | 240sqmm

1 X Ligarex Pliers

1 X Alrocan Tightening Pliers For Cables 50sqmm 50-240sqmm 12kV 20kV

Jointing tools are also available to strip and prepare waveform cables prior to termination or jointing.

NOTE – The header image also shows depth cutters and a jointers rasp file – these are supplied as additional items and prices are available from Thorne & Derrick on request.

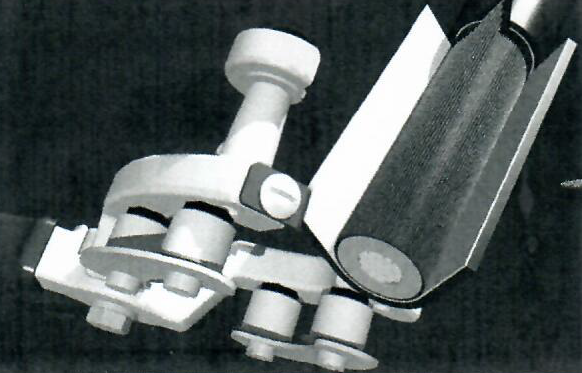

Using Alroc PG HTA Cable Sheath Pliers

- Longitudinal Cut. Position the Alroc PG HTA cable cutting pliers to remove the cable sheath to the desired length – tighten the stripping pliers until the cable cutting wheel penetrates onto the stop rollers. Pull the stripping pliers along the length to be stripped.

- Circular Cut. Position the Alroc PG HTA cable cutting pliers at the end of the longitudinal cut. Close the pliers onto the cables pressing slightly to ensure penetration of the cutting wheels – rotate the pliers back and forth by a third of revolution.

- Sheath Removal. Use the two end blades to separate the cable sheath as show opposite.

LV Jointing Tools UKPN Approved

| Jointing Tools Description | UKPN Stores Code | Number Required |

| 100A Cut-Out Safety Shield | 11757V | 3 |

| 13mm Magnetic Nut Holder | 33589P | 1 |

| 150mm Core Wedge | 33598N | 4 |

| 185mm Waveform Core Twister | 33156D | 2 |

| 2-Way Earth Continuity Strap | 03543Q | 2 |

| 200 & 400A Cut-Out Safety Shield | 11759Q | 3 |

| 225mm Core Wedge | 33599X | 4 |

| 240mm Waveform Core Twister | 31608J | 2 |

| 300mm Waveform Core Twister | 33175N | 2 |

| 600A Cut-Out Safety Shield | 11766U | 3 |

| 7mm Insulated Nut Spinner | 33704L | 1 |

| 8mm Insulated Nut Spinner | 33705V | 1 |

| 95mm Waveform Core Twister | 31607Y | 2 |

| Cable Armour Saw | 33528C | 1 |

| Core Guard for Cable Ratchet Cropper | 33601Y | 1 |

| Fire Blanket | 03527M | 1 |

| First Aid Kit | 38537X | 1 |

| IIPC Holding Tool | 32047S | 1 |

| Insulated Core Knife | 31400Q | 1 |

| Insulated Ratchet Cable Cutter | 01134C | 1 |

| Insulated Universal Connector Holding Tool | 31046D | 1 |

| Insulated Waveform Neutral Connector Holder | 33163H | 1 |

| Insulated 13/17mm Ratchet Spanner | 31045T | 1 |

| Jointer Shrouding Kit | 03522N | 1 |

| Jokari Knife | 33358N | 1 |

| Metal Hack Knife | 31399Y | 1 |

| Plastic Core Seperator | 33600P | 2 |

| Plastic Hack Knife | 31981H | 2 |

| Plastic Lead Belling Tool | 19415D | 1 |

| Plastic Medium Wedge | 32266Q | 2 |

| Plastic Mini Wedge | 32265F | 2 |

| Plastic Mini-Hepnyf | 31401A | 1 |

| Insulating Rubber Matting | 33411S | 1 |

| Shroud for Waveform Neutral Connector | 03521D | 6 |

| Sicame Insulated Universal Screw Ratchet Tool | 31547B | 1 |

| Spirit Level | 33380L | 1 |

| Straight Tin Snips | 33447C | 1 |

| Temporary Core Shroud – Size 0 | 03533G | 8 |

| Temporary Core Shroud – Size 1 | 03534T | 8 |

| Temporary Core Shroud – Size 2 | 03535B | 8 |

| Temporary Core Shroud – Size 3 | 03536L | 8 |

| Test Lamp – Long Probes | 19440F | 2 |

| Un-insulated Ratchet Cutters | 33170M | 1 |

| Voltstick Tester | 32255W | 1 |

Alroc – Cable Tools (LV MV HV EHV Cable Jointers Tools)

♦ Further Reading: Removing Bonded Screen 11kV 33kV Cables – Alroc CWB18-60

Substation Safety Equipment From CATU Electrical

May 9th, 2018-

Uploaded by Chris Dodds - Thorne & Derrick Sales & Marketing Manager

CATU Electrical is the world leading manufacturer of Electrical Safety Equipment for working on opower systems including cables, switchgear, substations and electrical equipment operating at LV (Low Voltage), MV (Medium Voltage) and HV (High Voltage).

Thorne & Derrick International, based in the UK, are the largest stockist and supplier of CATU Electrical products in Europe.

Together, we make the world a safer place. Here’s how.

Once Upon A Time…..

CATU Electrical was created in 1919 and since the beginning it has dedicated its activity to the manufacture of safety material, PPE and equipment for LV MV HV electricity networks and installations – whether underground or overhead, onshore or offshore, CATU Electrical protects utility workers from the workplace hazards of the amp and volt.

Since 1936, CATU’s activity has been concentrated on equipment for personal protection against electrical hazards such as arc flash clothing and accordingly has now more than 60 years experience in this field.

After the end of World War II, many French companies involved in Production, Transmission and Distribution of  electrical energy were amalgamated into one national company, called “Electricité de France” (EDF).

electrical energy were amalgamated into one national company, called “Electricité de France” (EDF).

Poster : Le Bon D’Electricite by Mario, an original vintage poster from 1926 France. This original antique poster features a plug and contact nest in the shape of the map of France.

A short time later, a central department for Safety and Prevention of Accidents was created within EDF.

Because of experience that CATU already had in this field, a close cooperation was forged between EDF and CATU which resulted in joint development of all the important Safety Material and Equipment now used in France.

The international recognition gained by EDF in this field has contributed to giving CATU Electrical a foremost position as international suppliers of LV MV HV Electrical Safety Equipment from Argentina to Zambia.

Today, CATU Safety Equipment including all the ranges of short-circuiting and portable earthing systems, voltage detectors and testers, the live working tools and the electrical safety equipment for Cable Jointers and Linesmen is used by the main power utilities and electrical contractors in over 100 countries spread across 5 continents.

CATU’s experience and level of investment and research is unmatched and unrivalled – they are members of the main national and international technical committees (such as UTE, CENELEC, IEC and ASTM).

CATU Electrical is contributing to the development and application of the latest technologies – this quest for continuous improvement and innovation is now reinforced with their ISO 9001:2000 Quality Insurance Certification.

No surprises then that CATU Electrical is the preferred brand of choice and most specified manufacturer by the world’s leading oil and gas EPC companies.

Insulating Gloves

Insulating gloves conform to international IEC-60903 standard – to satisfy the requirements of this standard CATU Electrical gloves are subjected to dielectrical, mechanical resistance and ageing tests.

* CATU part references to be completed by size A, B, C, D. **References to be completed by size C, D. Correspondence with standard sizes: A = 8, B = 9, C = 10, D = 11

| CATU Electrical Glove Reference | Insulating Level | Voltage (V) | Thickness | Weight (g) |

| CG-02* (1) | Class 00 Gloves | 500V | 0.9mm | 220g |

| CG-05* | Class 00 Gloves | 500V | 0.5mm | 90g |

| CG-10* | Class 0 Gloves | 1000V | 1.0mm | 200g |

| CG-15** | Class 1 Gloves | 7500V | 1.5mm | 270g |

| CG-20** | Class 2 Gloves | 17000V | 2.3mm | 450g |

| CG-30** | Class 3 Gloves | 26500V | 2.9mm | 560g |

| CG-40** | Class 4 Gloves | 36000V | 3.6mm | 800g |

Insulating Boots

CATU MV-135*

CATU Electrical manufacture insulating boots made from elastomer canvas support, very flexible and slip resistant for offshore electrical engineers and substation workers. Anti-perforation stainless steel sole and shell the electrical insulating footwear is in accordance with EN 345.

Insulating Matting

The insulating matting is manufactured of elastomer compounds with slip-resistant surface. High quality dielectrical rubber matting conforming to international IEC 61111 standard for LV MV HV offshore electrical switchgear and switchboard applications including 11kV and 33kV operating voltages.

| CATU Electrical Matting Reference | Tension (kV) | Thickness | Dimensions (m) |

| MP-42/11 | ≤26.5kV | 3mm | 1m x 1m |

| MP-42/16 | ≤26.5kV | 3mm | 0.6m x 1m |

| MP-42/66 | ≤26.5kV | 3mm | 0.6m x 0.6m |

| MP-60/03-10 | ≤26.5kV | 3mm | 0.6m x 10m |

| MP-100/03-5 | ≤26.5kV | 3mm | 1m x 5m |

| MP-60/05-5 | ≤26.5kV | 5mm | 0.6m x 5m |

| MP-100/05-5 | ≤36 | 5mm | 1m x 5m |

| MP-60/10-10 | >80kV | 10mm | 0.6m x 10m |

IEC6111 Insulating Matting

| Class Of Insulating Matting According To IEC61111 | Proof Test | AC Maximum Working Voltage | Withstand Test Of Insulating Matting |

| Class 0 Insulating Matting | 5kV | 1000V – LV Low Voltage | 10kV |

| Class 1 Insulating Matting | 10kV | 7500V – MV Medium Voltage | 20kV |

| Class 2 Insulating Matting | 20kV | 17000V – MV Medium Voltage | 30kV |

| Class 3 Insulating Matting | 30kV | 26500V – MV Medium Voltage | 40kV |

| Class 4 Insulating Matting | 40kV | 36000V – HV High Voltage | 50kV |

Insulated Tools

➡ Further information about insulated tools manufactured by CATU Electrical.

| CATU Part Number | MO-510-03 (Delivered without tool bag) |

| Personal Equipment | |

| MO-11001 | 1 Safety Glasses |

| CG-98 | 1 Working Gloves |

| Voltage Detector | |

| MS-911-EX | 1 Voltage Multitester |

| Insulating Equipment | |

| CG-05-B | 1 Rubber Gloves Size B |

| CG-36 | 1 Carrying Bag for Rubber Gloves |

| MP-42/16 | 1 Insulating Mat 3mm |

| MP-26-A | 10 Insulating Caps |

| MP-35/12 | 1 Insulating Blanket |

| MP-39 | 10 Wood Clamps for Insulating Blanket |

| MP-32/15 | 6 Line Protectors 1.50m |

| MP-19 | 5 Insulating Adhesive Tapes |

| Insulating Tools | |

| MO-61001 | 1 Stripping Knife |

| MO-67502 | 1 Cable Cutter 230mm |

| MO-68008/19 | 1 Open End Spanners Set With 8 / 10 / 11 / 12 / 13 / 14 / 19mm |

| MO-69903 | 1 Right Angle Hexagonal Key Wrench 3mm |

| MO-69904 | 1 Right Angle Hexagonal Key Wrench 4mm |

| MO-69906 | 1 Right Angle Hexagonal Key Wrench 6mm |

| MO-751 | 1 Insulating Folding Rule |

| MO-69003 | 1 Adjustable Spanner 250mm |

| MO-66002 | 1 Universal Pliers 180mm |

| MO-66202 | 1 Round Nose Pliers 160mm |

| MO-66502 | 1 Water Pump Pliers 250mm |

| MO-67102 | 1 Side Cutter 160mm |

| MO-69308/23 | 1 Sockets 3/8″ Wrench Set with 10 Sockets: 8, 10, 12, 13, 14, 17, 19, 21, 22, 23 |

| MO-65205 | 1 Flat Blade Screwdriver 4 x 100 |

| MO-65207 | 1 Flat Blade Screwdriver 6.5 x 150 |

| MO-65209 | 1 Flat Blade Screwdriver 8 x 175 |

| MO-65232 | 1 Phillips Screwdriver No.1 |

| MO-65234 | 1 Phillips Screwdriver No.2 |

| MO-65236 | 1 Phillips Screwdriver No.3 |

Arc Flash Clothing & Protection

➡ Further information about arc flash clothing and protection manufactured by CATU Electrical.

Arc Flash Face Shield Kit – 10cal/sqcm

CATU KIT-ARC-01 arc flash face shield kit comprises of:

- 1 Face shield with chin cup 10cal/sqcm, absorbs> 99.9% of harmful UV radiation, 70% light transmission, tested to ASTM F2178 specifications

- 1 ABS helmet electrically insulated EN397, EN 50365, ANSI Z89.1, 20kV.

- 1 carrying bag for face shield and helmet

KIT-ARC-01 – Arc Flash Face Shield Kit

Arc Flash Jacket Kit – 11cal/sqcm

CATU KIT-ARC-02 arc flash jacket kit comprises of:

- 1 Face shield with chin cup 10cal/sqcm, absorbs> 99.9% of harmful UV radiation, tested to ASTM F2178 specifications

- 1 ABS helmet electrically insulated EN397, EN 50365, ANSI Z89.1, 20kV.

- 1 safety glasses EN 166/EN 170

- 1 arc flash protective jacket 11cal/sqcm (size XL – other sizes on request),ASTM F1506 and NFPA 70E Standards

- 1 carrying bag for face shield and helmet

- 1 all kit carrying bag

KIT-ARC-02 Arc Flash Jacket Kit

Arc Flash Protective Coverall Kit – 11cal/sqcm

CATU KIT-ARC-03 arc flash protective coverall kit comprises of:

- 1 Face shield with chin cup 10cal/sqcm, absorbs> 99.9% of harmful UV radiation, tested to ASTM F2178 specifications

- 1 ABS helmet electrically insulated EN397, EN 50365, 20kV.

- 1 safety glasses EN 166/EN 170

- 1 arc flash protective hood

- 1 protective coverall 11cal/sqcm (size L- other sizes on request),ASTM F1506 and NFPA 70E Standards

- 1 carrying bag for face shield and helmet

- 1 all kit carrying bag

Arc Flash Protective Hood Kit – 40cal/sqcm

CATU KIT-ARC-04 arc flash protective hood kit comprises of:

- 1 arc flash protective hood 40cal/sqcm, ASTM F2178 and NFPA 70E Standards

- 1 arc flash protective coat 40cal/sqcm, (size L), ASTM F1506 and NFPA 70E Standards

- 1 arc flash protective bib overall 40cal/sqcm,(size XL*), ASTM F1506 and NFPA 70E Standards

- 1ABS helmet electrically insulated EN397, EN 50365, ANSI Z89.1, 20kV.

- 1 safety glasses EN 166/EN 170

- 1 carrying bag for face shield and helmet

- 1 all kit carrying bag

Substation Life Saving Kits

➡ Further information about substation and life saving kits manufactured by CATU Electrical.

Wall Mounted Life Saving Kit

In case of an electrical accident, quick response is essential: seconds gained or lost can decide the life or death of a victim.

Our life saving equipment is designed to make all necessary materials immediately available to rescue personnel.

CATU Wall Mounted Life Saving Kit

Composition of the kit:

- 1 moulded plastic support with translucid high resistance plastic door.

- 1 rescue telescopic stick

- 1 voltage detector with flexible antenna contact (with autotest)

- 1 cable cutter with insulated handles Forged steel blades maximum opening: 30 mm

- 1 insulating platform 24 or 36 kV high voltage

- 1 insulating gloves

- 1 insulating boots

- 1 Safety instructions on the plastic door

- 1 talcum powder can.

| CATU Part Ref | Description | Maximum Voltage | Dimensions | Weight |

| CATU CZ-54-R | Wall mounted life saving kit with instructions in English | 24kV | 840mm x 754mm x 270mm | 21kg |

| CATU CZ-54-RM | Wall mounted life saving kit with instructions in English / Arabic | 24kV | 840mm x 754mm x 270mm | 21kg |

| CATU CZ-55-R | Wall mounted life saving kit with instructions in English | 36kV | 840mm x 754mm x 270mm | 21kg |

| CATU CZ-55-RM | Wall mounted life saving kit with instructions in English / Arabic | 36kV | 840mm x 754mm x 270mm | 21kg |

Compact Carrying Life Saving Kit

This compact kit is designed especially to be carried in a vehicle for safety electrical intervention (up to 24 kV). Made in two part (of moulded material: PEHD), the case is also on its red part, an insulating platform.

CATU Substation Life Saving Kits

Composition of the kit:

- 1 insulating platform 24 or 36 kV

- 1 telescopic insulating stick

- 1 voltage detector with autotest

- 1 rescue hook

- 1 insulated cable cutter

- 1 pair of insulating gloves

- 1 pair of insulating boots

- 1 talcum powder can

- 1 safety instructions and safety first aid posters

- 1 adhesive tape (black and yellow).

| CATU Part Ref | Description | Maximum Voltage | Dimensions | Weight |

| CATU CZ-53-R | Life saving kit with instructions in English | 25kV | 710mm x 510mm x 240mm | 21kg |

| CATU CZ-53-MR | Life saving kit with instructions in English / Arabic | 25kV | 710mm x 510mm x 240mm | 21kg |

| CATU CZ-53-R/2 | Life saving kit with instructions in English | 36kV | 710mm x 510mm x 240mm | 21kg |

| CATU CZ-53-MR/2 | Life saving kit with instructions in English / Arabic | 36kV | 710mm x 510mm x 240mm | 21kg |

Voltage Detectors

➡ Further information about voltage detectors manufactured by CATU Electrical.

The DETEX voltage detector HBL is designed to offer users maximum safety on MV installations with explosive atmosphere.

- Voltage presence is indicated by both extremely bright red flashing LED’s and powerful rated audible signal > 60 dB/2 m.

- High reliability

- Tropicalized: -25 / +55 °C.

- housing made from polycarbonate with high mechanical properties and dielectric strength.

CATU CC-365-(*)-HBL-(**)

**End fitting C or K, recommend stick: CE-4-21

*Range of voltage 3/10 kV, 10/30 kV, 30/45 kV

Phase Comparators

➡ Further information about phase comparators manufactured by CATU Electrical.

Detect differences in voltage between any two points of an installation indicated by LED’s. It also enables assessment of the order of magnitude of the residual voltage induced by nearby live lines or circuits, and thus differentiates it from the one provided directly from a high voltage source.

Range of voltage: 2/36 kV

CATU CL-8-36

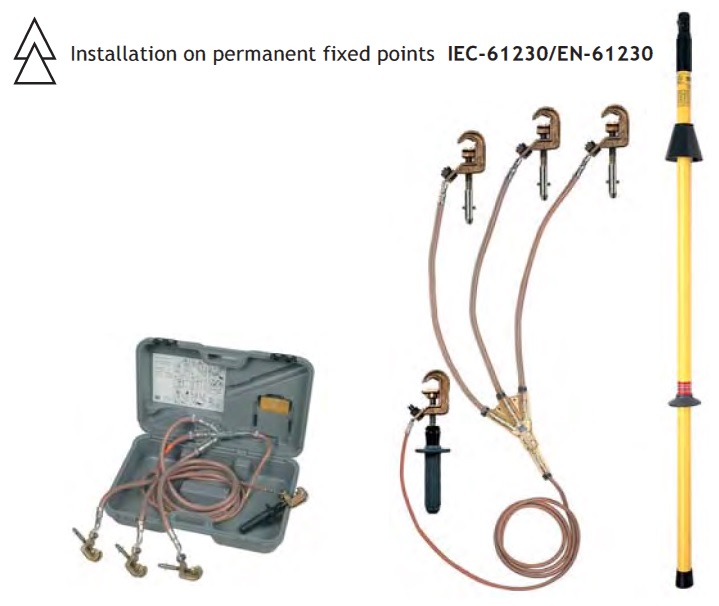

Short Circuiting & Portable Earthing Systems

| Installations on fixed permanent points | ||||

| CATU Part Reference | Rating (kA/1 s) | Installation on fixed points | Composition | Connection set |

| CATU MT-1910 | 20 | Ø 20 mm MT-2951 range | 3 clamps MT-1911-E 1 MT-1911 | 3 cables 95 mm2 1 earth cable 35 mm2 |

| CATU MT-1920 | 30 | Ø 25 mm MT-3951 range | 3 clamps MT-1921-E 1 MT-1921 | 3 cables 150 mm2 1 earth cable 50 mm2 |

Recommended stick to be ordered separately: CF-5-40-E

| Installations on bare conductors | ||||

| CATU Part Reference | Rating (kA/1 s) | Installation on fixed points | Composition | Connection set |

| CATU MT-5805 | 20 | Ø 5-35 16-40 5-40 | 3 clamps MT-815-C 1 MT-840/1 | 3 cables 95 mm2 1 earth cable 35 mm2 |

| CATU MT-8408 | 12.5 | Ø 18-33 | 3 clamps MT-814/3 1 MT-840/1 | 3 cables 70 mm2 1 earth cable 35 mm2 |

| CATU MT-9801 | 10 | Ø 5-16 0-16 Ø 5-28 | 3 clamps MT-817-C 3 clamps MT-814/2 1 MT-840/1 | 3 cables 50 mm2 1 earth cable 25 mm2 |

Recommended stick to be ordered separately: CF-4-21-C

♦ Further Reading

For more reading about Electrical Safety, read the T&D blog:

- Electrical Safety – Arc Flash Accidents & Electrocution In LV-HV Installations

- Can Arc Flash Clothing Save Cable Jointers Lives?

- Arc Flash Calculation – Selecting Clothing & PPE To Protect Lives Against Arc Hazard

- Insulating Matting – IEC 61111 Specifications & Selection For Switchboard Matting

Thorne & Derrick distribute the most extensive range of Low & High Voltage Cable Installation & Electrical Distribution Equipment to the Power Transmission & Distribution industry in the onshore and offshore wind, solar, rail, oil/gas, data centre, battery storage and utility sectors – this includes Joints, Terminations & Connectors to enable the installation of low, medium and high voltage power cables into underground trench or duct.

Key Product Categories: Connectors, Joints & Terminations MV HV | Cable Preparation & Jointing Tools | Duct Seals | Cable Transits | Cable Cleats | Cable Glands | Electrical Safety | Arc Flash Clothing & Protection | Cable Pulling | Earthing & Lightning Protection | Feeder Pillars

Main UK Stockists for: 3M Electrical, PFISTERER Connex, Nexans Power Cable Accessories (Euromold), Alroc, Ellis Patents, ABB, Roxtec, Cembre & CATU Electrical.

Repairing Damaged Cables, Cable Sheath & Jackets

May 4th, 2018

A Solution To Repairing Damaged Cables | LV MV HV 11kV 33kV | Onshore & Offshore

Cable Repair

-

Uploaded By: Chris Dodds – T&D Distributors of LV, MV & HV Cable Terminations & Cable Joints

Earlier this year the UK government unveiled a total phase-out plan for coal-fired power plants. No big gasp there – cast your mind back to April 22nd 2017.

On that monumental date forever etched into the memories of energy analysts from Black Thunder to Kamuthi, Britain went 24 hours without turning on its coal-fired power stations for the first time in more than 130 years.

The share of power from the fossil fuel fell to zero for the first time since 1882 – the UK will be 100% coal-free by 2025.

King Coal has been unthroned and the new Clean & Green monarchs of UK Power have been coronated – bucket-wheel excavators please make way for the nacelle.

So welcome to the 21st Century – we are going greener faster with low carbon energy including wind and solar power generation overtaking both fossil-fuel and nuclear in the UK electricity source mix.

Despite this the engineering challenges facing Humankind of building, operating and maintaining LV HV power system infrastructures remain.

Without power distributed by electrical cables the wind turbine blades would stand as still as the motionless mine shuttle car.

Their common enemy is withdrawal of safe and reliable power distribution and this depends upon the integrity of electrical power and the monitoring and maintenance of cable condition and ensuring service is not disrupted by cable failure – the early warning system of potential looming power problems is the Cable Sheath or Jacket.

Image: Nexans

Repairing The Cable Sheath or Jacket

The cable sheath is the first line of moisture, mechanical, flame, fire, hydrocarbon and chemical defence for any cable – whether LV (low voltage), MV (medium voltage) or HV (high voltage), onshore or offshore, underground or overground.

Cable damage to the outer sheath is commonplace for aged or newly installed cables – whether unavoidable during normal service life or accidental strike by 3rd party.

Cable strikes are generally caused by non adherence to HSG47 while excavating underground cables with digging machines such as JCB, track machine or mini excavator.

Multi-disciplined contractors failing to observe the separation between underground utilities (electrical cables, gas or water pipes) often leads to cable strike. Moling devices set in the direction of underground electricity cables (often waveform or PILC main cables) not only leads to loss of electricity supply but also serious injuries.

Failure to maintain and observe accurate cable records during utility upgrades such as installing drainage apparatus further impacts upon cable damage. In conclusion, most utility LV cable strikes could be avoided if strict adherence to HSG47 is implemented.

LV Power Cable Strike Caused By Excavator – highlights dangers of using mini excavator in close proximity to a low voltage cable. Image : Scottish Power Energy Networks (SPEN).

Cables are often damaged during the cable pulling process as cable sheathing is vulnerable to “snagging” damage from cable containment – where cables are being pulled into underground cable trenches the cable sheath can be damaged by surface abrasion from stones and rocks.

Cable Repair Solution

However damaged cable sheaths and jackets can be repaired and re-instated on site using heat shrink cable repair sleeves – watch the following video to learn the step-by-step process for reinstating insulation and protection to repair damaged cables and sheaths.

Video : HellermannTyton RMS – Cable Repairs Sleeve For Damaged Cable

Hellermann Tyton Cable Repair RMS : Features & Benefits

- Fast, moisture proof and permanent repair of cable jackets and sheath LV MV HV

- Only 6 sizes for a wide range of cable diameters from 15 mm up to 160 mm

- Available in 4 standard lengths and also available in custom lengths of heat shrink

- RMS kit is ready for use with instruction sheet, abrasive strip and cable cleaner

- Weather resistant and halogen free cable repairs

- TCP spots indicate the repair sleeve has been sufficiently heated

Hellermann Tyton RMS cable repair sleeves suit cable sheath outside diameters from 15-160mm. The wrap around sleeves are a fast, labour saving and permanent cable repair and water-tight sealing system – this includes repairing damage to the cable sheaths and jackets of LV MV HV cables.

The sleeve is simply wrapped around the cable and held in place using a rail and steel channel closure to provide a quick and inexpensive repair to in-stu damaged cables – cable repair sleeves are especially useful for repair of long and buried cables where it would be difficult or impossible to use a heat shrink tubing.

The wrap-around design (“lay-flat”) of the cable repair sleeve enables mid-span or mid-circuit repairs without resort to disconnecting the remote end of cable circuit at the cable termination point and cable gland location.

Heating by a gas torch will shrink the repair sleeve and melt the adhesive inner coating resulting in a moisture-proof, insulating and tight-fitting repair. The cable sheath repair will be permanent and waterproof.

Damage to the red cable sheaths of 11kV high voltage power cables can be made quick and fast – cable sheaths can be further degraded due to exposure to gases and emissions from diesel generator exhaust systems and this can be averted by heat shrink sleeve repair.

Wrap heat shrink sleeve around the damaged cable.Install the steel closure channel over the raised profiles of the sleeve and centre the heat shrink sleeve over the damaged area before applying heat

➡ Some Installation Tips When Repairing Damaged Cables

- to ensure excellent sealing of the heat shrink onto the cable jacket use abrasive cloth strip to roughen the cable sheath jacket

- wrap heat shrink sleeve around the cable and install the steel closure channel over the raised profiles of the heat shrink sleeve and centre the repair sleeve over the cable damage section

- use yellow flame tip of a suitable heat shrink propane torch – start heating the metal channel area first for about half a minute

- start heat shrinking the sleeve at the centre working the flame around all sides of the cable sleeve to apply uniform heat.

- keep heating flame moving consistently to avoid scorching cable – after the centre part has shrunk work the torch to one end of the heat shrink sleeve then to the opposite end

- when selecting cable repair sleeves choose the sleeve length so that the cable next to the damaged area is covered by at least 40mm of heat shrink sleeve length

Heat Shrink Cable Repair Sleeves For Damaged Cables

Cable Repair Kit: Heat shrink wrap-around sleeve, steel closure, abrasive strip, cable cleaning sachet and instruction sheet

Offshore Cable Repairs

Cable repair kits are commonly used to repair offshore cables and prevent corrosion effects to steel wire braided or wire armoured cables which can rust rapidly in humid conditions and accelerate with exposure to salt water atmosphere, splash or immersion.

Flexible and trailing cables for ROV equipment and offshore pump systems can be spliced, jointed or repaired using 3M Scotchcast submersible cable joints which are flexible, flame retardant with seawater resistant resins compatible with EPR, neoprene, hypalon, PVC and nitrile cable sheaths.

There is direct causation between the type of cable maintenance approach and unplanned downtime.

Careful monitoring of cable condition carves down unplanned downtime whether onshore or offshore – the predictive maintenance approach is better than routine or preventative maintenance and this trumps the reactive PANIC as a result of “sit back and wait”.

Offshore cables are exposed to extreme and continuous operating environments – this includes temperature extremes, mechanical stress, gassy chemicals, hydrocarbons, drilling mud and seawater atmospheres. Not to mention the Weather…..

…..and what about potentially explosive atmospheres where “hot-working” is precluded. Heat shrink cable repairs cannot be safely effected in the presence of naked flames and flammable gases.

In this instance you can benefit from reading our earlier Blog about repairing and jointing cables in hazardous areas as defined by the ATEX Directive.

Down well hole extraction systems are vital to crude oil production.

The reliability of electrical down well pump systems is directly dependent on the performance of the electrical power supply and cable integrity through to the wellhead, power cable, cable joint, termination and related equipment such as the pump and motor.

Unplanned downtime of essential assets caused by offshore power outages in the oil and gas sector as the result of maintenance oversight requires rapid intervention and power restoration at the lowest possible cost.

Financial hits to the bottom line as a result of cable outage inflicted by failure to repair damaged cables include the repair cost (calculable) as well as those consequential and often hidden costs associated with lost or deferred productions (often incalculable).

Heat shrink cable repair sleeves provide a low-cost, simple to install and use solution to damaged cable problems.

If electrical power is the lifeblood of an offshore platform then the cable must be the main artery.

If neglected overtime damaged cables lead to cable failure.

Here abrasion damage has been inflicted to the MV power cable sheath exposing the wire braid in an offshore transformer and is need of urgent cable repair or re-jointing.

Repair Or Replace Cable?

Answering the Cost Conundrum

Nose-diving global oil prices inevitably places downward pressure on operating margins and in turn operators dictate that maintenance work is conducted at the lowest possible cost.

The Big Conversation between North Sea operators, national regulators and industry experts in recent years has been consumed by a trend for declining production efficiency, lost revenues and questions over the long-term sustainability of oil and gas operations as costs continue to rise in one of the world’s most mature offshore regions.

Preventative maintenance would usually detect “wear and tear” on cable installations and depending on condition would be replaced, repaired or in worst cases scenarios jointed.

The hardening trend towards “cost-cutting” often delivers a patch-up repair in pocket areas of cable degradation and not scaled to complete circuits as part of a more holistic concept of cable care and repair.

Oil prices fell almost 50% between 2015 and 2014, averaging $52 per barrel in 2015 compared to $99 in 2014, according to the Energy Information Administration.

In 2015 US benchmark West Texas Intermediate (WTI) ended July on its biggest monthly fall since the 2008 financial crisis during July.

- West Texas Intermediate (WTI), also known as Texas light sweet, is a grade of crude oil used as a benchmark in oil pricing.

How Much Does Downtime Cost

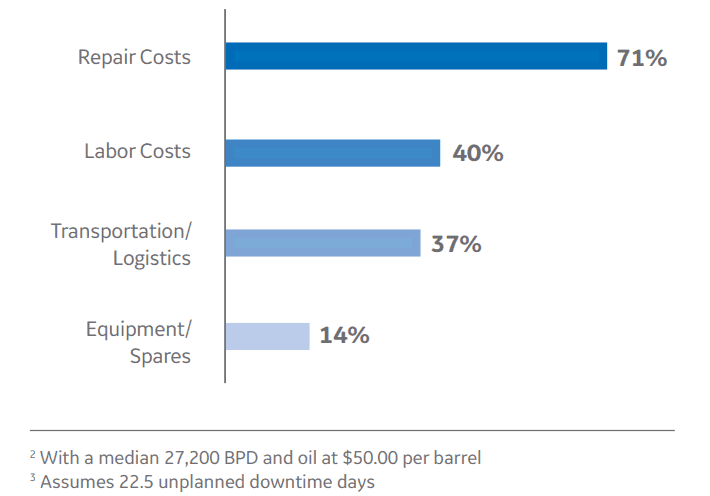

According to a recent report by GE Oil & Gas “The Impact of Digital on Unplanned Downtime” the major costs linked to unplanned downtime are shown below- the report informed “when looking at repair costs, the typical offshore oil and gas field worldwide most often incurs expenses resulting from unplanned downtime in the areas of repair costs (71%), followed by labour costs (40%) and transportation/logistics (37%).

Offshore high voltage cables (5kV ESP Cable) requiring outer sheath repair to damage caused by abrasion contact with adjacent pipe supports. The cables feed the platforms Electrical Submersible Pumps. Image : Statoil.

Damaged green cable duct and Virgin Media cables from the street cabinet feeder pillars.

Should you require any assistance with the jointing, termination or repair of power LV-HV cables please do not hesitate to contact us to discuss your application.

THORNE & DERRICK SPECIALIST ELECTRICAL DISTRIBUTOR

LV ♦ MV ♦ HV

T&D distribute the most extensive range of LV, MV & HV Cable Jointing, Terminating, Pulling & Installation Equipment – we service UK and international clients working on underground cables, overhead lines, substations and electrical construction at LV, 11kV, 33kV and EHV transmission and distribution voltages.

- Key Products: MV-HV Cable Joints & Terminations, Cable Cleats, Duct Seals, Cable Transits, Underground Cable Protection, Cable Jointing Tools, Feeder Pillars, Cable Ducting, Earthing & Lightning Protection, Electrical Safety, Cable Glands, Arc Flash Protection & Fusegear.

- Distributors for: 3M, ABB, Alroc, Band-It, Catu, Cembre, Centriforce, CMP, Elastimold, Ellis Patents, Emtelle, Furse, Lucy Zodion, Nexans Euromold, Pfisterer, Polypipe, Prysmian, Roxtec.

LV – Low Voltage Cable Joints, Glands, Cleats, Lugs & Accessories (1000 Volts)

MV HV – Medium & High Voltage Cable Joints, Terminations & Connectors (11kV 33kV EHV)

Cable Laying – Underground Cable Covers, Ducting, Seals & Cable Pulling Equipment

T&D, CATU Electrical Safety & Arc Flash Protection Specialists for SAP’s, Linesmen, Jointers & Electrical Engineers – Largest UK Stockist

Cable Abandonment For MV HV Cables Including 11kV 33kV High Voltages

May 2nd, 2018

11kV 33kV | Medium & High Voltage Cables

-

uploaded by Chris Dodds - Thorne & Derrick Sales & Marketing Manager

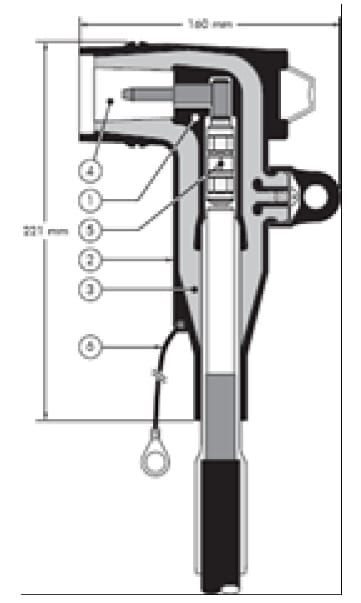

Cable abandonment kits can be supplied for medium/high voltage cables if the cables are left in the ground but aren’t energised. From the outside, they look similar to live pot end kits, but internally, the phase or phases are connected to earth so that if a voltage is applied to the cables by mistake, an immediate earth fault occurs which trips the circuit breaker.

Please Note: The following Jointing Instructions should be used by a trained competent cable jointer only – contact us to discuss the availability of Cable Jointer Training Courses.

A Jointers gas torch is preferred method for heat shrinking these materials making sure all tubes and materials are kept clean, dry and are free from dust, sand or grease.

In the following post we reproduce the Cable Abandonment Kit installation instruction – should you have any questions or queries please do not hesitate to contact us.

See also:

- Pot End Live Cable End Seal | 11kV Cables Single Core XLPE CWS

- Pot End Live Cable End Seal | 11kV Cables 3 Core XLPE EPR

MV HV Cable Abandonment

XLPE EPR Insulated Power Cables 11kV 33kV

Abandonment kits can be kitted from stock using heat shrink tubes to suit 11kV/33kV medium and high voltage cables with polyermic (XLPE EPR) or paper insulation (PILC) – single or 3 core cables accommodated with wire armour (SWA AWA), wire braid (PBSB GSWB) and lead cover sheaths.

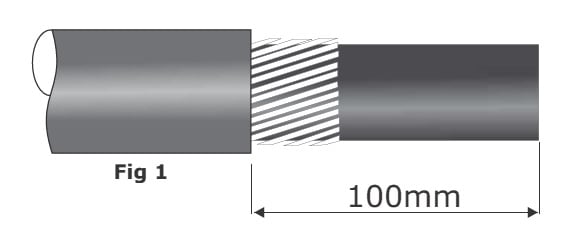

1. Remove the outer cable jacket using appropriate sheath stripping tools and expose approximately 100mm of the inner cable bedding with the cable cores beneath.

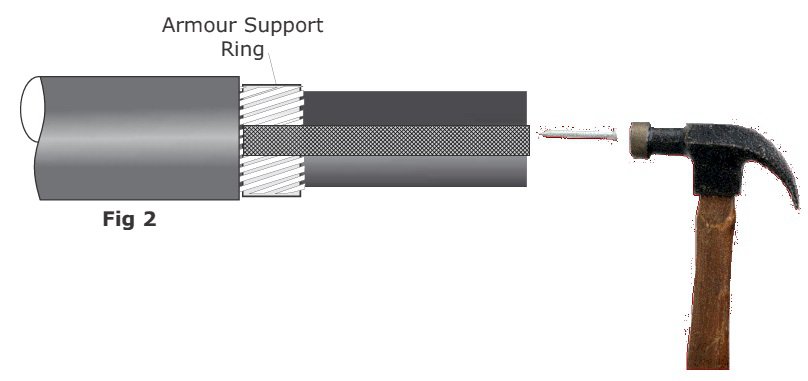

2. If cable is armoured (SWA) or has a braid screen, expose the cable armour wires or screen to the length of the armour support ring. Fit the support ring as shown in Fig 2.

3. As shown in Fig 2, position the copper earth braid upon each conductor and hammer a nail through the braid so that it is held securely in place. Do this on each core with the same copper earth braid.

Note: if solid aluminium conductor, remove some insulation on each core and use the copper mesh supplied to wrap around the MV HV cable conductors before taking this back to the armour wires.

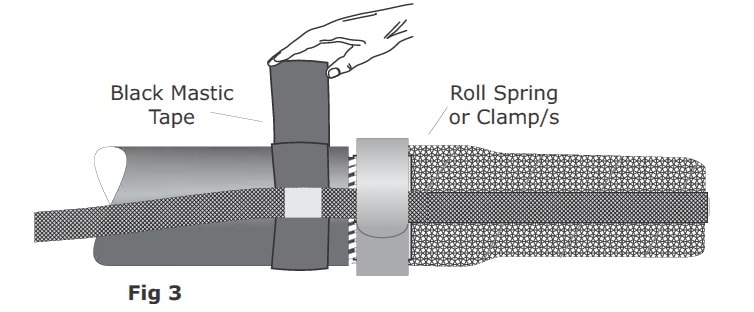

4. Wrap copper mesh all around the cable and secure along with the earth braid to the armour wires/braid screen with the worm drive clamp or constant force roll spring supplied as shown above in Fig 3. Apply black mastic tape over any sharp points.

Note: if non armoured cable and if specified, the cable abandonment kit can be supplied with a copper strap to bond to earth externally. Position the solder block on a turn of mastic tape and apply a further turn of tape as shown above in Fig 3.

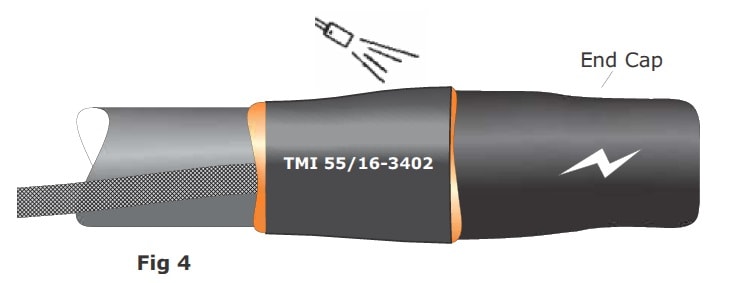

5.Position the heatshrink end cap over the cable and using a suitable heat source, heat shrink the cap into position.

If the cap does not cover the exposed earthing, position the additional heat shrink tube and shrink so that it overlaps onto the outer cable sheath and onto the cable end cap.

Note: clean and abrade the outer cable jacket before fitting.

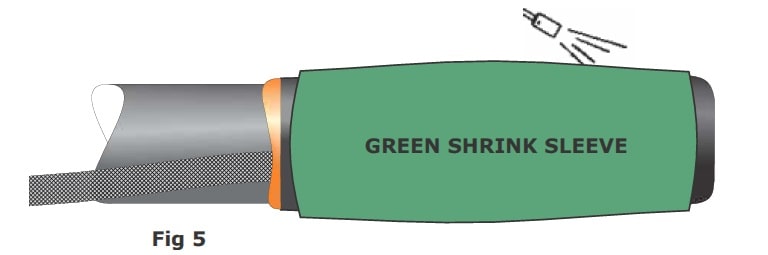

6. Additional green heatshrink sleeve can be supplied to fit onto the outside of the cable abandonment kit to comply with DNO specifications. Trim before fitting if necessary.

Low Voltage Cable Abandonment Using 3M Cold Shrink

For the abandonment of LV power and instrumentation cables located both onshore and offshore we can recommend 3M Cold Shrink cable abandonment kits.

| 3M Part Number | Power Cables 600/1000V 3.3kV | Instrumentation Cables |

| Overall Cable Diameter | Number of Pairs | |

| 3M CSCAK/1 | 12 – 18mm | Up to 5 |

| 3M CSCAK/2 | 18 – 25mm | Up to 10 |

| 3M CSCAK/3 | 25 – 42mm | Up to 20 |

| 3M CSCAK/4 | 42 – 55mm | n/a |

| 3M CSCAK/5 | 56 – 81mm | n/a |

Cable Abandonment Using Cold Shrink

Thorne & Derrick – Stockists & Suppliers of MV HV Joints, Terminations & Connectors

THORNE & DERRICK are national distributors MV & HV Cable Jointing, Substation Earthing & Cable Installations – we service UK and global businesses involved in cable installations, cable jointing, substation, overhead line and electrical construction at LV, 11kV, 33kV and EHV.

LV Cable Accessory Distributors

T&D stock and supply cable accessories to Cable Cleat, Gland, Joint & Terminate armoured/unarmoured multicore (SWA) or single core (AWA) power cables into low and high voltage substations – the LV cable installation accessories support electricity distribution to main distribution switchgear, sub-distribution boards and transformers.

➡ How To Abandon Cables Using 3M Cold Shrink Cable Abandonment Kits CSCAK

CMP Glands | 3M Joints | Cembre Lugs | Ellis Cleats | LV Cable Accessories

Since 1985, T&D have established an international reputation based on SERVICE | INTEGRITY | TRUST.

Separable Connectors For Eaton Xiria MV HV Switchgear RMU (Ring Main Unit)

May 2nd, 2018

Separable Connectors To Terminate Cables Into MV Switchgear

-

Uploaded By: Chris Dodds Thorne & Derrick Sales & Marketing Manager

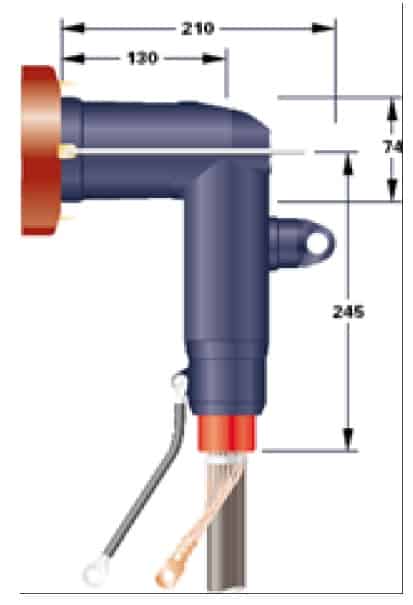

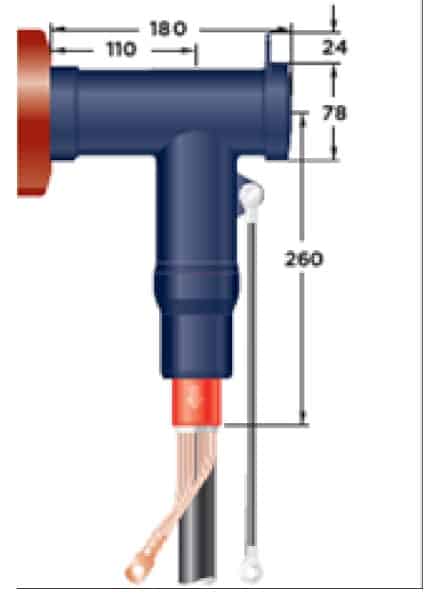

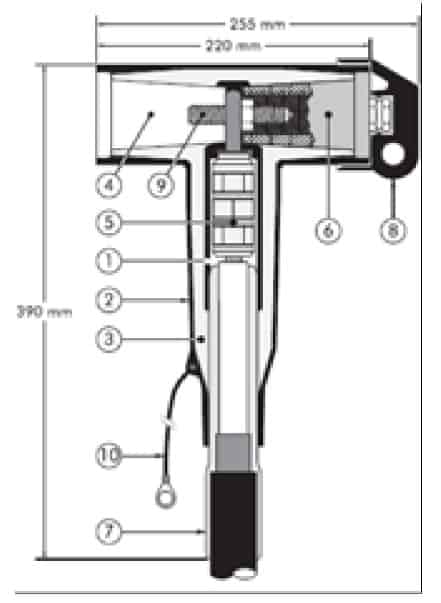

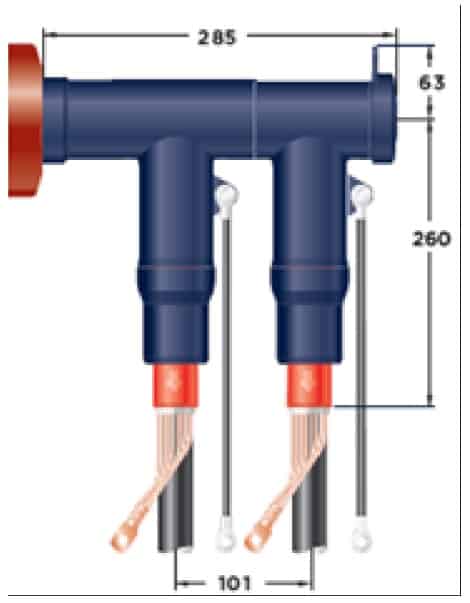

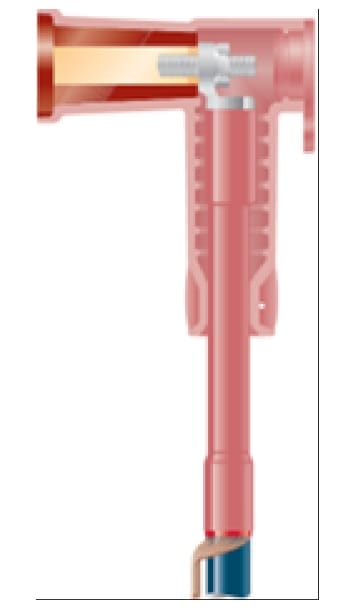

The following article confirms the current types and manufacturers brands of Separable Connectors that are approved to terminate medium/high voltage cables (11kV/12kV up to 24kV) into Ring Main Unit switchgear for application with Eaton Xiria 12kV/24kV medium voltage distribution networks.

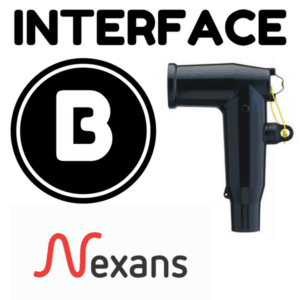

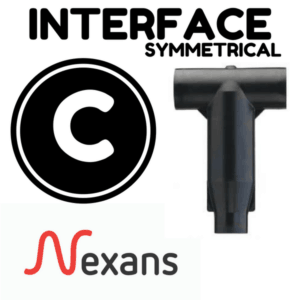

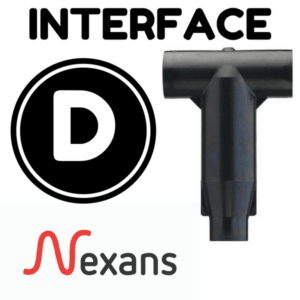

Separable connectors manufactured by Nexans Euromold are moulded from high quality EPDM rubber, fully insulated and sealed, widely installed onto medium/high voltage pad-mounted switchgear, transformers, sectionalising cabinets and used to terminate MV cables into switchgear up to 24kV.

Separable Connectors

The MV switchgear manufactured by Eaton is provided with epoxy resin cable bushings or cones according to EN 50181 – the following types of separable connectors are manufacturer approved and compatible with their switchgear.

| MV Panel Type | Switchgear Bushing Cone | I [A] | Maximum Short-Circuit Current | Cable Connector | MV Cable |

| Load Break Switch | Interface C | 630A | 17.5-24kV 16kA-1 & 3s | Bolted T-Plug | Cu/Al XLPE |

| 3.6-12kV 20kA-1 & 3s | |||||

| Circuit Breaker | Interface A | 200A | 17.5-24kV 16kA-0.6s | Elbow Type Plug | Cu/Al XLPE |

| 3.6-12kV 20kA-0.4s | |||||

| Circuit Breaker | Interface C | 500A | 17.5-24kV 16kA-1 & 3s | Bolted T-Plug | Cu/Al XLPE |

| 3.6-12kV 20kA-1 & 3s |

- Cables are Polymeric Insulated XLPE type usually with operating voltages of 11kV/12kV up to 24kV

Interface A Circuit-breaker 200A including current transformers

Interface C Circuit-breaker 500A including current transformers

Interface C Load-break switch 630A without current transformers

MV Cable connectors & Terminations

Cable connectors are not included with the switchgear and should be ordered seperately.

For 24kV connections separable connectors with an earthed layer on the outside must be used, for 12kV connections connectors without an earthed layer might be used also.

Both types of separable connectors may not exceed certain dimensions to avoid incompatibility of the MV connector with the switchgear panel.

The interface bushings or switchgear cones in the Eaton medium voltage system are according to EN 50181. They can be of the Interface A (250A design, panel rating 200A) and Interface C (630A).

For connection of MV-HV cables into air insulated equipment or cable-end boxes we can provide a complete range of heat shrink cable terminations or for working on switchgear located in potentially explosive atmospheres such as offshore oil and gas platforms where it is not possible to use heat shrink type kits a cold shrink termination can be provided.

Full supporting range of MV-HV cable connectors to enable the termination and connection of copper or aluminium conductors onto busbar are available also from stock.

As an example some possible brands are shown here including Nexans Euromold connectors:

Euromold Type K158LR Xiria Circuit Breaker Outer Cone Type Interface A 200A Bushing

Euromold Type K430TB Xiria Circuit Breaker Outer Cone Interface Type C 500A Bushing

Tyco Type RSES Xiria Circuit Breaker Outer Cone Inerface Type A 200A Bushing

Tyco Type RSTI58 Xiria Load Break Switch Outer Cone Interface Type C 630A Bushing

Euromold Type K400TB Xiria Load Break Switch Outer Cone Interface Type C 630A Bushing

Tyco RSTICC58 Xiria Circuit Breaker Outer Cone Interface Type C 500A Bushing with double cable for metering (one primary cable and one cable for a voltage transformer)

Tyco Type RICS Xiria Load Break Switch Outer Cone Interface Type C 630A Bushing

Euromold

The Euromold range of Separable Connectors are suitable for the termination of power cables onto all MV-HV bushing interfaces:

|

|

|

|

|

|

View the complete range of Nexans Terminations | Joints | Connectors

THORNE & DERRICK are national distributors LV, MV & HV Cable Installation, Jointing, Substation & Electrical Equipment – we service UK and global businesses involved in cable installations, cable jointing, substation, overhead line and electrical construction at LV, 11kV, 33kV and EHV.

Since 1985, T&D have established an international reputation based on SERVICE | INTEGRITY | TRUST.

Contact us for 3M Electrical, ABB, Alroc, AN Wallis, CATU Electrical, Cembre, Centriforce, CMP, CSD, Elastimold, Ellis Patents, Emtelle, Euromold, Filoform , Furse, Lucy Electric & Zodion, Nexans, Pfisterer, Polypipe, Prysmian, Roxtec, Sicame, WT Henley.

Invitation

Thorne & Derrick invite you to join LinkedIn’s largest LV-HV Electrical Discussion Group : Low & High Voltage Power, Cabling, Jointing & Electricals. Discussion subjects include cable installations, earthing, cable jointing, substation, overhead line and electrical construction at LV, 11kV, 33kV and EHV. Network, engage and promote your profile, company or products with over 10,000 influencers.